444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The digital servo press market is experiencing significant growth and is expected to continue expanding in the coming years. Servo presses are advanced machines that utilize servo motors to provide precise and accurate control over the press operation. These presses offer several advantages over traditional mechanical or hydraulic presses, including improved efficiency, higher productivity, and enhanced flexibility.

Meaning

A digital servo press is a type of press machine that incorporates servo motor technology to control the pressing operation. These presses use feedback sensors to continuously monitor and adjust the position, force, and speed of the ram, resulting in precise and repeatable pressing actions. The integration of digital control systems enables operators to program various parameters and settings, allowing for a wide range of applications and customization options.

Executive Summary

The digital servo press market is witnessing rapid growth due to the increasing demand for precision manufacturing in industries such as automotive, electronics, aerospace, and medical devices. These industries require high-quality, complex components that can be efficiently produced using servo presses. Additionally, the adoption of automation and Industry 4.0 technologies further drives the market growth as digital servo presses can seamlessly integrate with advanced manufacturing systems.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Energy Efficiency: Digital servo presses reduce peak power draw by modulating motor output to process requirements, cutting energy use by 30–50% compared to hydraulics.

Precision & Repeatability: Closed-loop force and position control yield ±0.01 mm repeatability and force accuracy within ±1%, critical for micro-forming and fineblanking.

Industry 4.0 Integration: Real-time connectivity via OPC UA and MTConnect enables seamless data exchange with MES/ERP systems for predictive maintenance and quality traceability.

Flexible Production: Recipe-based setup allows quick shifts between part geometries, supporting high-mix, low-volume production without mechanical die changes.

Global Expansion: Asia-Pacific commands the largest volume share, driven by automotive and electronics manufacturing; North America leads in per-unit investment and aftermarket services.

Market Drivers

Lightweight Materials Adoption: Rising use of aluminum, magnesium, and high-strength steels in automotive and aerospace demands precise servo forming to avoid part cracking and achieve tight tolerances.

Quality & Consistency Requirements: Sectors like medical devices and electronics require ultra-clean, burr-free edges and consistent joint strengths, favoring servo-controlled dwell and force profiling.

Energy & Emissions Regulations: Stricter energy consumption and carbon footprint targets incentivize manufacturers to replace inefficient hydraulic presses with electric servo systems.

Smart Manufacturing Initiatives: Government and corporate Industry 4.0 programs promote digitalization of production, with servo presses central to process monitoring and data capture.

Total Cost of Ownership (TCO): While capital costs are higher, lower energy bills, reduced hydraulic oil handling, fewer consumables, and minimal maintenance deliver attractive TCO over 5–7 years.

Market Restraints

High Initial Investment: Digital servo presses can cost 1.5–2× more than equivalent tonnage hydraulic presses, deterring small and medium-sized enterprises.

Technical Skill Requirements: Advanced control software and integration demand specialized training and skilled engineers, creating a learning curve for operators and maintenance teams.

Limited Stroke & Tonnage Range: Some servo presses have shorter strokes and lower maximum force than large-frame hydraulics, limiting their use for very heavy or deep-draw applications.

Retrofitting Challenges: Upgrading existing hydraulic press lines to servo systems may require significant infrastructure modifications, including power supply and floor reinforcement.

Market Awareness: In certain regions, limited exposure to servo technology slows adoption compared to well-established hydraulic press equipment.

Market Opportunities

Aftermarket Upgrades: Offering retrofit kits that replace hydraulic drives with servo motors and controllers can open a large replacement market segment.

Hybrid Servo-Hydraulic Systems: Combining the force capacity of hydraulics with servo precision offers a mid-point solution for heavy forming with high accuracy.

Emerging Markets: Growing manufacturing bases in Southeast Asia, Latin America, and Eastern Europe present new sales channels, especially for mid-range tonnage presses.

Customized Application Software: Developing industry-specific control modules (e.g., for battery tab welding, lens embossing, micro-stamping) can differentiate offerings.

Service & IoT Platforms: Cloud-based performance analytics, remote diagnostics, and subscription-based predictive maintenance services can generate recurring revenue streams.

Market Dynamics

OEM Partnerships: Collaborations between servo motor suppliers, press frame manufacturers, and software developers accelerate turnkey digital press solutions.

Competitive Pricing Pressure: As more players enter the servo press space, pricing becomes more aggressive, driving innovation in cost-effective designs and modular architectures.

Technology Evolution: Advances in high-torque, low-inertia servomotors and drivetrain components enable higher force-to-size ratios and faster response times.

Standardization Efforts: Industry bodies are working on standardizing servo press interfaces and data protocols to simplify integration and reduce total engineering effort.

Sustainability Focus: End-users increasingly prefer equipment with eco-labels and certifications for energy efficiency and clean manufacturing, influencing procurement.

Regional Analysis

Asia-Pacific: Largest by volume, led by China, Japan, and South Korea. Rapid automotive electrification and electronics production drive demand for mid-range servo presses (50–500 ton).

North America: High investment per unit, focus on heavy tonnage and large-frame servo presses for aerospace and defense. Strong aftermarket services and retrofit business.

Europe: Emphasis on high precision and SME adoption in Germany and Italy, with generous energy-efficiency subsidies under EU programs fueling upgrades.

Latin America: Emerging adoption in automotive component and consumer appliances manufacturing centers in Mexico and Brazil; price sensitivity remains a factor.

Middle East & Africa: Slowly growing, led by petrochemical and heavy industry players exploring digital conversion; infrastructure constraints can delay large-scale deployment.

Competitive Landscape

Leading Companies in the Digital Servo Press Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

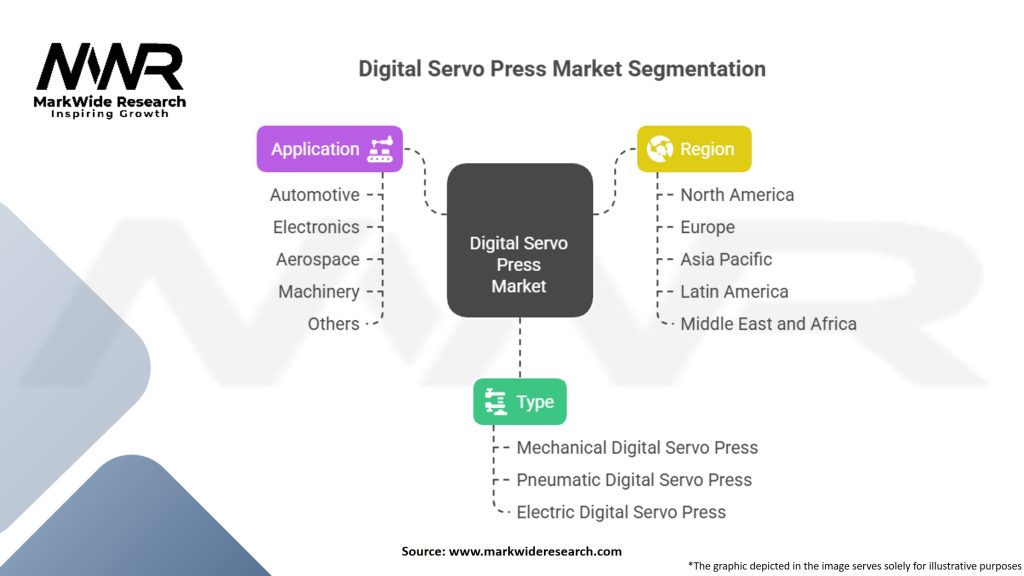

Segmentation

The digital servo press market can be segmented based on type, application, and end-use industry.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic had a mixed impact on the digital servo press market. While the initial phase of the pandemic led to disruptions in supply chains and manufacturing operations, the later stages witnessed a recovery as industries resumed their activities. The pandemic also accelerated the adoption of automation and advanced manufacturing technologies, including digital servo presses, as companies sought to enhance productivity and minimize human contact in production processes.

Key Industry Developments

Analyst Suggestions

Future Outlook

The digital servo press market is poised for significant growth in the coming years. Factors such as the increasing demand for precision manufacturing, growing automation, and emphasis on energy efficiency are expected to drive the market. The integration of IoT, cloud-based solutions, and advancements in control systems will further enhance the capabilities and functionalities of digital servo presses, opening new opportunities for market players.

Conclusion

The digital servo press market is witnessing remarkable growth due to the demand for precision manufacturing and automation in various industries. These presses offer precise control, improved productivity, and energy efficiency, making them ideal for applications in automotive, electronics, aerospace, and medical device manufacturing. The market presents opportunities in emerging economies, customization and modularity, and integration with IoT and data analytics. Continued technological advancements, collaboration, and regulatory compliance will shape the future of the digital servo press market, driving its expansion and adoption across industries.

What is Digital Servo Press?

Digital Servo Press refers to a type of press that utilizes digital servo technology to control the motion and force applied during manufacturing processes. This technology enhances precision, efficiency, and adaptability in applications such as metal forming, assembly, and packaging.

What are the key players in the Digital Servo Press Market?

Key players in the Digital Servo Press Market include companies like Schuler AG, AIDA Engineering, and Komatsu Industries, which are known for their innovative solutions and advanced manufacturing technologies. These companies focus on enhancing productivity and precision in various industrial applications, among others.

What are the growth factors driving the Digital Servo Press Market?

The Digital Servo Press Market is driven by factors such as the increasing demand for automation in manufacturing, the need for higher precision in production processes, and the growing adoption of Industry Four Point Zero technologies. Additionally, the shift towards sustainable manufacturing practices is also contributing to market growth.

What challenges does the Digital Servo Press Market face?

Challenges in the Digital Servo Press Market include high initial investment costs and the need for skilled labor to operate advanced machinery. Furthermore, the rapid pace of technological advancements can lead to obsolescence, making it difficult for companies to keep up.

What opportunities exist in the Digital Servo Press Market?

Opportunities in the Digital Servo Press Market include the expansion of electric vehicle manufacturing, which requires precise metal forming processes, and the increasing demand for lightweight materials in various industries. Additionally, advancements in AI and IoT integration present new avenues for innovation.

What trends are shaping the Digital Servo Press Market?

Trends in the Digital Servo Press Market include the growing emphasis on energy efficiency and sustainability, as manufacturers seek to reduce their carbon footprint. Moreover, the integration of smart technologies and data analytics is transforming operational efficiencies and product quality.

Digital Servo Press Market

| Segmentation | Details |

|---|---|

| Type | Mechanical Digital Servo Press, Pneumatic Digital Servo Press, Electric Digital Servo Press |

| Application | Automotive, Electronics, Aerospace, Machinery, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East and Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Digital Servo Press Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at