444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The die-sinking electrical discharge machining (EDM) market is a vital segment within the manufacturing industry, providing advanced machining solutions for precision tool and die production. Die-sinking EDM, also known as ram EDM or plunge EDM, utilizes electrical discharges to shape conductive materials such as steel, titanium, and carbide into intricate and complex shapes with high accuracy and surface finish. With its ability to produce complex geometries and tight tolerances, die-sinking EDM is widely used in aerospace, automotive, mold and die, and medical device industries. The market is driven by increasing demand for customized and high-precision components, technological advancements, and growing adoption of automation in manufacturing processes.

Meaning

Die-sinking electrical discharge machining (EDM) is a non-traditional machining process used to produce complex shapes and contours in conductive materials by removing material through a series of electrical discharges between the workpiece and an electrode. The process involves submerging the workpiece and electrode in a dielectric fluid, typically deionized water, and applying controlled electrical pulses to erode the workpiece material. Die-sinking EDM is widely used for manufacturing molds, dies, punches, and other precision components requiring high accuracy, fine surface finish, and intricate details.

Executive Summary

The die-sinking EDM market is experiencing steady growth driven by factors such as increasing demand for customized and high-precision components, advancements in machine technology, and growing adoption of automation in manufacturing. Market players are focusing on product innovation, process optimization, and strategic partnerships to address evolving customer needs and gain a competitive edge in the market.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The die-sinking EDM market operates in a dynamic environment influenced by factors such as technological advancements, market trends, regulatory changes, and competitive dynamics. Understanding market dynamics is essential for stakeholders to identify opportunities, mitigate risks, and make informed decisions in the rapidly evolving landscape of manufacturing and engineering.

Regional Analysis

Regional variations in industrial activity, technological adoption, economic conditions, and regulatory frameworks impact the demand for die-sinking EDM equipment and services. Key regions such as North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa exhibit distinct market characteristics and growth trajectories.

Competitive Landscape

Leading Companies in Die-sinking Electrical Discharge Machining Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

By Type: CNC Die-Sinking EDM, Manual Die-Sinking EDM, Hybrid EDM Systems.

By Electrode Material: Graphite, Copper, Copper-Tungsten, Composite Materials.

By Application: Molds and Dies, Aerospace Components, Medical Devices, Tool and Die Manufacturing, Others.

By End User: Automotive, Aerospace & Defense, Electronics, Healthcare, Energy.

CNC-controlled systems currently account for over 65% of installations due to superior accuracy and automation compatibility.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

Enables machining of ultra-hard materials with minimal distortion.

Reduces setup times through automation and CNC integration.

Expands toolmaking and die repair capabilities for high-value components.

Enhances surface finish and tolerance consistency.

Supports production of intricate parts for aerospace, medical, and EV applications.

SWOT Analysis

Market Key Trends

AI-driven spark gap monitoring for improved consistency.

Eco-friendly dielectric oils and recycling systems reducing waste.

Integration of robotic automation for electrode handling.

Growth of multi-axis CNC die-sinking systems.

Demand for compact EDM machines for micro-tooling and prototyping.

Key Industry Developments

Launch of energy-efficient dielectric circulation systems reducing fluid consumption by 12%.

Introduction of hybrid EDM systems combining additive and subtractive manufacturing.

Partnerships between EDM OEMs and aerospace firms for precision turbine component manufacturing.

Expansion of regional service centers for after-sales and technical training.

MarkWide Research notes increasing integration of smart sensors and cloud-based diagnostics for predictive maintenance.

Analyst Suggestions

Invest in smart EDM machines with integrated automation and monitoring tools.

Expand service networks and operator training programs to reduce downtime.

Explore hybrid systems that combine EDM with laser or milling for efficiency.

Adopt sustainable dielectric solutions to meet environmental standards.

Strengthen R&D collaborations with aerospace and medical industries for next-generation applications.

Future Outlook

The future outlook for the die-sinking EDM market is positive, driven by increasing demand for high-precision components, advancements in machine technology, and growing adoption of automation in manufacturing processes. Strategic investments in technology, innovation, and market expansion will be key to sustaining growth and competitiveness in the evolving landscape of die-sinking EDM technology.

Conclusion

As a critical technology for precision manufacturing and toolmaking industries, die-sinking electrical discharge machining (EDM) plays a vital role in producing complex shapes and contours with high accuracy and surface finish. Despite challenges such as initial investment costs, skilled labor shortage, and environmental concerns, the die-sinking EDM market offers significant opportunities for innovation, growth, and market expansion. By leveraging advancements in technology, collaboration, and strategic partnerships, stakeholders can navigate market dynamics and achieve long-term success in the dynamic and evolving landscape of die-sinking EDM technology.

What is Die-sinking Electrical Discharge Machining?

Die-sinking Electrical Discharge Machining (EDM) is a manufacturing process that uses electrical discharges to remove material from a workpiece. It is commonly used for creating complex shapes and precise features in hard metals and is essential in industries such as aerospace, automotive, and mold making.

What are the key players in the Die-sinking Electrical Discharge Machining Market?

Key players in the Die-sinking Electrical Discharge Machining Market include Mitsubishi Electric Corporation, Makino Milling Machine Co., Ltd., and Sodick Co., Ltd. These companies are known for their advanced EDM technologies and solutions, among others.

What are the drivers of growth in the Die-sinking Electrical Discharge Machining Market?

The growth of the Die-sinking Electrical Discharge Machining Market is driven by the increasing demand for precision machining in various industries, advancements in EDM technology, and the rising need for complex component manufacturing in sectors like aerospace and medical devices.

What challenges does the Die-sinking Electrical Discharge Machining Market face?

The Die-sinking Electrical Discharge Machining Market faces challenges such as high operational costs, the need for skilled operators, and competition from alternative machining technologies. These factors can hinder market growth and adoption.

What opportunities exist in the Die-sinking Electrical Discharge Machining Market?

Opportunities in the Die-sinking Electrical Discharge Machining Market include the expansion of the automotive and aerospace industries, the development of hybrid machining processes, and the increasing adoption of automation and smart manufacturing technologies.

What trends are shaping the Die-sinking Electrical Discharge Machining Market?

Trends in the Die-sinking Electrical Discharge Machining Market include the integration of Industry four point zero technologies, advancements in machine tool design, and the growing focus on sustainability and energy efficiency in manufacturing processes.

Die-sinking Electrical Discharge Machining Market

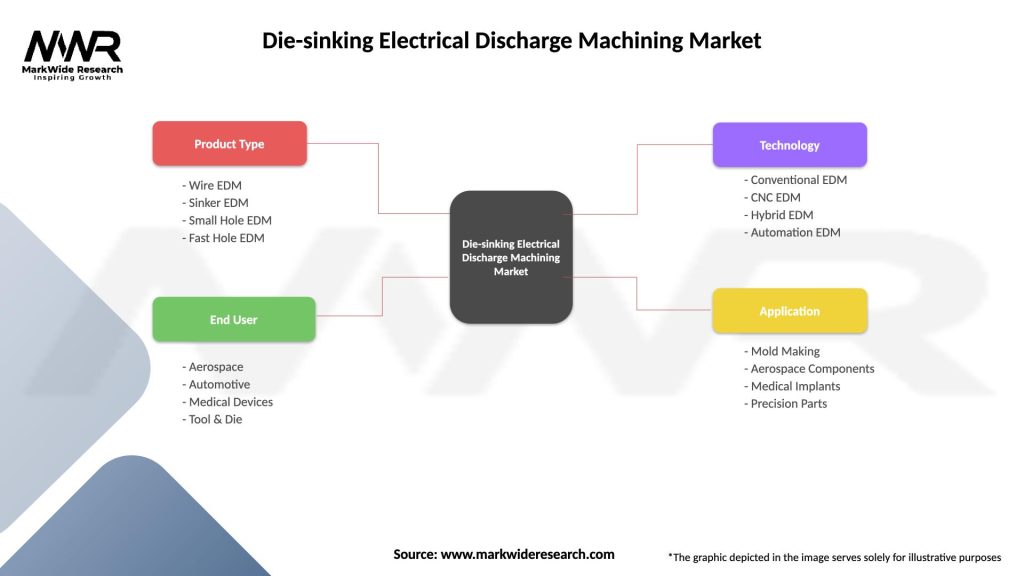

| Segmentation Details | Description |

|---|---|

| Product Type | Wire EDM, Sinker EDM, Small Hole EDM, Fast Hole EDM |

| End User | Aerospace, Automotive, Medical Devices, Tool & Die |

| Technology | Conventional EDM, CNC EDM, Hybrid EDM, Automation EDM |

| Application | Mold Making, Aerospace Components, Medical Implants, Precision Parts |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in Die-sinking Electrical Discharge Machining Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at