444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The derouging chemicals market is witnessing significant growth and is expected to expand at a steady pace in the coming years. Derouging chemicals are used in various industries to remove rouge, a reddish-brown scale that forms on stainless steel surfaces due to corrosion. These chemicals help maintain the integrity and cleanliness of stainless steel equipment and prevent contamination in critical applications.

Meaning

Derouging chemicals are specialized formulations designed to dissolve and remove rouge from stainless steel surfaces. Rouge is formed as a result of corrosion in stainless steel equipment, which can occur due to various factors such as exposure to harsh chemicals, high temperatures, and improper cleaning and maintenance practices. Derouging chemicals effectively eliminate rouge and restore the surface finish of stainless steel, ensuring optimal performance and longevity of equipment.

Executive Summary

The derouging chemicals market is experiencing steady growth due to the increasing demand for stainless steel equipment across various industries. These chemicals play a crucial role in maintaining the performance and cleanliness of stainless steel surfaces by removing rouge and preventing further corrosion. The market is driven by factors such as the rising adoption of stainless steel equipment in the pharmaceutical and food processing sectors, stringent cleanliness and hygiene regulations, and the need for prolonged equipment life.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Semiconductor Sector Dominance: Over half of derouging chemical demand originates from wafer fabrication facilities, where rouge removal from ultra‐pure water loops is critical to yield and equipment longevity.

Green Chemistry Shift: Increasing customer demand for low‐TOC, phosphate‐free, and biodegradable derouging formulations is driving R&D toward organic acid–only chemistries with minimal environmental impact.

Service‐Based Models: End‐users are increasingly contracting suppliers for turnkey CIP/derouging services—encompassing chemical dosing, circulation, rinse validation, and surface monitoring—to ensure consistency and alleviate in‐house labor burdens.

Automation & Monitoring Integration: Introduction of programmable logic controller (PLC)–enabled circulation skid systems with real‐time pH, ORP, and iron‐monitoring sensors optimizes derouging cycles and ensures process safety.

Regulatory & Standards Compliance: Semiconductor Equipment and Materials International (SEMI) F63–0705 and USP <1231> guidelines mandate validated derouging and passivation protocols to control particulate and metallic contamination.

Market Drivers

Fab Capacity Expansion: Global semiconductor capacity is projected to grow at 6 % annually through 2027, with new fabs requiring robust derouging regimens for multipoint ultrapure water loops.

Pharmaceutical Purity Demands: Active pharmaceutical ingredient (API) plants and biotech facilities are upgrading water‐for‐injection (WFI) and pure steam systems, necessitating periodic derouging to meet USP/EP microbial and particulate limits.

Aging Infrastructure Retrofits: Many nuclear and conventional power plants built in the 1970s–1990s require derouging of steam generators and condensate polishing loops as part of life‐extension and performance upgrade projects.

Environmental Regulations: Stricter discharge regulations (e.g., EU Water Framework Directive, U.S. Clean Water Act) drive adoption of low‐phosphate and biodegradable derouging chemistries to minimize wastewater treatment costs.

Total Cost of Ownership Focus: OEMs and end‐users recognize that proactive derouging extends equipment life, improves heat‐transfer efficiency, and reduces unplanned downtime, supporting higher capital lifetimes.

Market Restraints

Chemical Handling Hazards: Strong acids—such as citric or hydrofluoric acid blends—require specialized handling, corrosion‐resistant materials of construction, and trained personnel, raising operational costs.

Cycle Time Constraints: Derouging cycles can take 4–12 hours plus rinse steps, potentially impacting production runs if not carefully scheduled, reducing overall throughput.

Surface Compatibility: In mixed‐alloy systems (e.g., duplex stainless steels, Hastelloy), derouging formulations must be precisely tailored to avoid preferential corrosion of less‐noble alloys.

Capital Expenditure for Automation: Investment in dedicated CIP/derouging skids and sensor networks can be significant, deterring smaller facilities from full automation.

Wastewater Treatment Load: High iron and chelant carryover in effluent may necessitate enhanced wastewater treatment or chelant recovery systems, adding to process complexity.

Market Opportunities

Enzyme‐Augmented Formulations: Emerging research into oxidase and peroxidase enzyme catalysts offers potential to enhance iron oxide dissolution at milder pH and temperature.

Continuous Micro‐Derouging: Development of inline microfilter/acidic‐flush modules that perform incremental derouging without large CIP skids, reducing batch cycle times.

Digital Surface Analysis: Non‐contact optical sensors and ultrasonic thickness gauges can monitor residual oxide film in real time, enabling predictive derouging scheduling.

Green Chemistry Leadership: Suppliers that achieve fully biodegradable, phosphate‐free derouging chemistries with neutral pH operation will capture environmentally sensitive markets.

Service Consolidation: Bundling derouging with passivation and chemical management services under single‐vendor contracts simplifies procurement and compliance for end‐users.

Market Dynamics

Consolidation of Service Providers: Global chemical service companies are acquiring niche derouging specialists to expand geographically and integrate offerings into broader water treatment portfolios.

R&D Collaborations: Partnerships between universities, national labs, and chemical firms are exploring novel chelants (e.g., siderophores, polyaspartic acids) and catalytic additives to improve derouging kinetics.

Digital Twin Implementation: Creation of virtual replicas of water loops to simulate rouge formation and derouging performance, optimizing chemical usage and cycle parameters.

Regulatory Evolution: Anticipated tightening of SEMI standards around sub‐10 ppt particulate removal may force more frequent derouging or adoption of more aggressive formulations.

Regional Capacity Investments: New chemical plants specializing in derouging formulations are being established near major fab clusters in Taiwan, South Korea, and China to ensure rapid supply.

Regional Analysis

Asia Pacific: Dominant region accounting for ~55% of market volume, driven by wafer fab expansion in Taiwan (TSMC), South Korea (Samsung, SK Hynix), and China’s SMIC. Domestic chemical producers are ramping capacity to serve local fabs.

North America: Mature market with high per‐fab consumption due to stringent USP and SEMI purity requirements. Major service providers maintain fleets of derouging rigs for automotive, pharmaceutical, and power clients.

Europe: Steady demand tied to pharmaceutical clusters in Germany, Switzerland, and Ireland, and nuclear plant maintenance in France and Eastern Europe. Environmental compliance drives green‐chemistry adoption.

Latin America: Emerging demand in Brazilian pharmaceutical and food & beverage sectors; limited local production leads to higher import reliance.

Middle East & Africa: Nascent market; demand primarily from petrochemical complexes and growing medical device manufacturing in UAE and South Africa.

Competitive Landscape

Leading Companies in the Derouging Chemicals Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

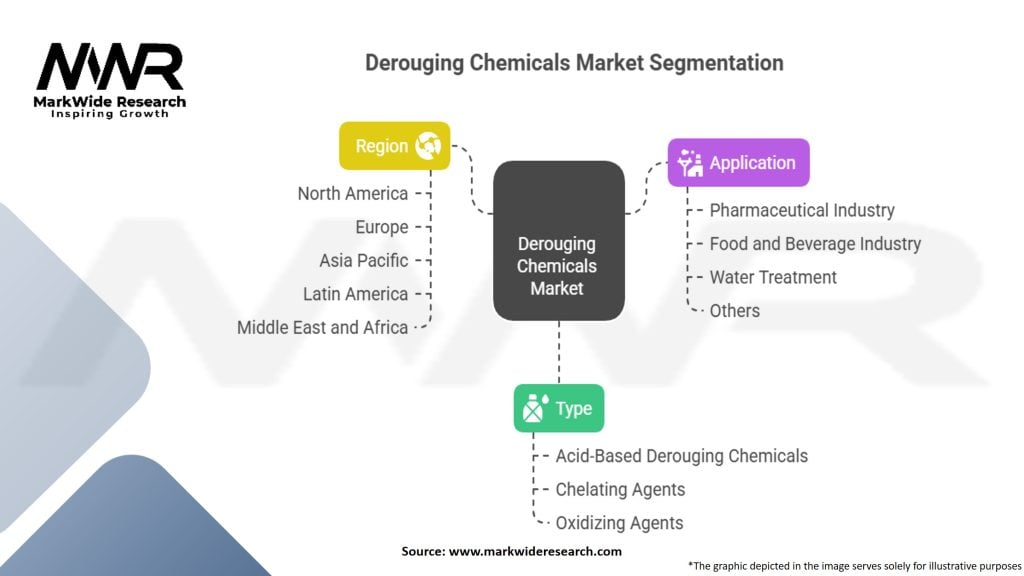

Segmentation

The derouging chemicals market can be segmented based on type, application, and end-use industry.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths

Critical, non‐substitutable function in high‐purity water systems.

Established best practices and robust validation frameworks.

Weaknesses

Specialty chemicals command premium pricing, impacting OPEX budgets.

Dependence on highly trained technicians for safe and effective application.

Opportunities

Development of catalytic or enzymatic derouging chemistries for faster, lower‐temperature cycles.

Expansion of digital surface sensors and predictive maintenance to optimize derouging schedules.

Threats

Potential emergence of non‐chemical (e.g., ultrasonic, pigging) derouging technologies.

Volatility in raw material costs (acids, chelants) affecting margin stability.

Market Key Trends

Green Derouging Chemistry: Phosphate‐free, bio‐based chelants and organic acids reduce environmental impact and wastewater treatment costs.

Real‐Time Surface Monitoring: Inline turbidity, iron, and particle sensors trigger automated derouging cycles only when thresholds are exceeded—minimizing chemical use.

Automation & Robotics: Automated CIP/derouging modules with robotic hose handling and PLC control reduce manual labor and cross‐contamination risk.

Hybrid Cleanliness Strategies: Combining derouging with periodic passivation restores stainless steel’s chromium oxide layer, extending time between cycles.

Digital Twins for Water Loops: Virtual simulations predict rouge buildup patterns based on temperature, flow, and oxygen content, guiding proactive derouging planning.

Covid-19 Impact

The derouging chemicals market experienced a temporary slowdown during the COVID-19 pandemic due to disruptions in various industries. However, as industries gradually resumed operations and implemented stringent hygiene measures, the demand for derouging chemicals rebounded. The need for maintaining cleanliness and hygiene in critical applications drove the market recovery.

Key Industry Developments

Analyst Suggestions

Future Outlook

The derouging chemicals market is poised for steady growth in the coming years, driven by the increasing adoption of stainless steel equipment and stringent cleanliness regulations. Technological advancements in derouging chemical formulations and the growing focus on sustainable solutions will shape the future of the market. Additionally, emerging economies and the expanding water treatment sector present lucrative opportunities for market players.

Conclusion

The derouging chemicals market plays a vital role in maintaining the cleanliness and performance of stainless steel equipment across various industries. The market is driven by factors such as the rising demand for stainless steel equipment, stringent cleanliness regulations, and the need for prolonged equipment life. While environmental concerns and the availability of alternative cleaning methods pose challenges, the market offers significant opportunities in emerging economies and water treatment applications. With continuous innovation and strategic partnerships, the derouging chemicals market is expected to thrive in the future.

What is Derouging Chemicals?

Derouging chemicals are specialized cleaning agents used to remove iron oxide and other contaminants from surfaces, particularly in industries such as pharmaceuticals, food processing, and water treatment. They help maintain equipment efficiency and product quality by preventing corrosion and contamination.

What are the key players in the Derouging Chemicals Market?

Key players in the Derouging Chemicals Market include companies like BASF, Ecolab, and Henkel, which provide a range of cleaning and maintenance solutions. These companies focus on developing innovative products to meet the specific needs of various industries, among others.

What are the growth factors driving the Derouging Chemicals Market?

The growth of the Derouging Chemicals Market is driven by increasing demand for high-purity water in pharmaceutical manufacturing and the need for effective cleaning solutions in food processing. Additionally, the rising awareness of equipment maintenance and safety standards contributes to market expansion.

What challenges does the Derouging Chemicals Market face?

The Derouging Chemicals Market faces challenges such as stringent regulatory requirements and the potential environmental impact of chemical waste. Additionally, the availability of alternative cleaning methods may hinder market growth.

What opportunities exist in the Derouging Chemicals Market?

Opportunities in the Derouging Chemicals Market include the development of eco-friendly cleaning agents and the expansion of applications in emerging industries such as renewable energy. The increasing focus on sustainability also opens avenues for innovative product development.

What trends are shaping the Derouging Chemicals Market?

Trends in the Derouging Chemicals Market include the growing adoption of automated cleaning systems and advancements in chemical formulations that enhance efficiency. Additionally, there is a rising emphasis on sustainability and the use of biodegradable ingredients in cleaning products.

Derouging Chemicals Market

| Segmentation | Details |

|---|---|

| Type | Acid-Based Derouging Chemicals, Chelating Agents, Oxidizing Agents |

| Application | Pharmaceutical Industry, Food and Beverage Industry, Water Treatment, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East and Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Derouging Chemicals Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at