444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The cut-resistant gloves market has witnessed significant growth in recent years, driven by the increasing awareness about workplace safety and the rising demand for personal protective equipment (PPE) across various industries. Cut-resistant gloves are designed to protect the hands from sharp objects, blades, and other potential hazards, making them an essential safety measure for workers in industries such as construction, manufacturing, healthcare, and food processing.

Meaning

Cut-resistant gloves refer to a type of protective handwear that is specifically designed to minimize the risk of lacerations and injuries caused by sharp objects or blades. These gloves are made using advanced materials such as high-performance fibers, including aramid fibers, glass fibers, and stainless steel fibers, which provide exceptional resistance against cuts and abrasions. They offer a crucial layer of protection for workers in industries where hand injuries are common.

Executive Summary

The cut-resistant gloves market has experienced substantial growth in recent years, primarily due to the growing emphasis on workplace safety and the need for effective hand protection. These gloves are widely adopted across industries to minimize the risk of hand injuries and improve worker safety. The market is characterized by the presence of several key players offering a diverse range of cut-resistant gloves to cater to different industry requirements.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

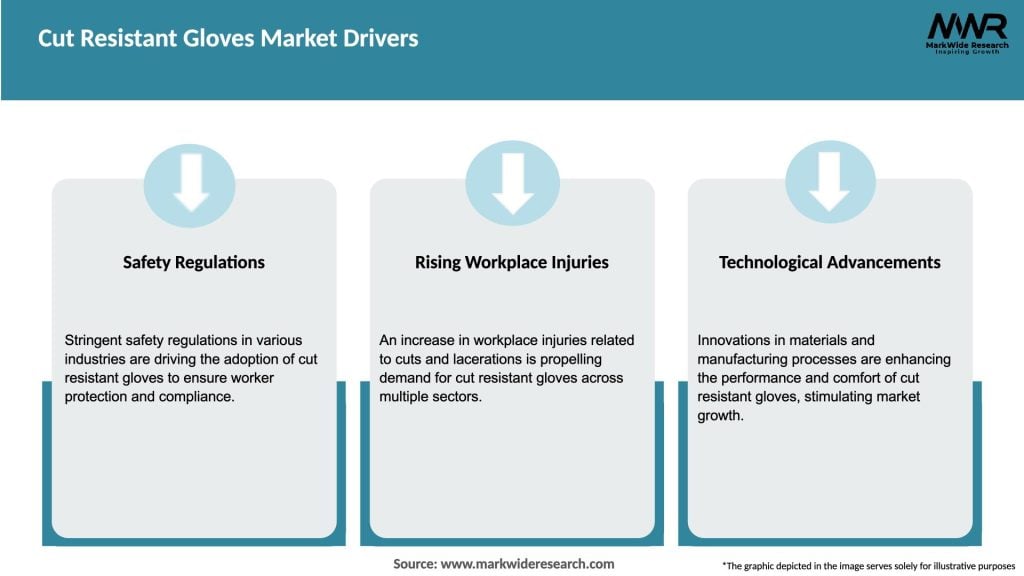

The cut-resistant gloves market is driven by a combination of factors that influence its dynamics. The increasing emphasis on workplace safety and the need for hand protection are primary drivers of market growth. Organizations across various industries are becoming more conscious of their employees’ safety, leading to the adoption of cut-resistant gloves as a preventive measure against hand injuries.

Moreover, stringent safety regulations imposed by government bodies and industry standards have further accelerated the demand for cut-resistant gloves. These regulations make it mandatory for employers to provide appropriate personal protective equipment to their workers, including cut-resistant gloves. This regulatory landscape has significantly contributed to market expansion.

The market is also driven by advancements in material technology. Manufacturers are constantly investing in research and development to create innovative materials that offer enhanced cut resistance, durability, and comfort. High-performance fibers like aramid fibers, glass fibers, and stainless steel fibers are widely used to manufacture cut-resistant gloves with superior protective properties. These advancements attract consumers who seek gloves with improved performance and longevity.

Despite the positive growth drivers, the market faces certain restraints that can impede its progress. One major challenge is the cost consideration associated with cut-resistant gloves. These gloves tend to be more expensive than traditional gloves due to their specialized materials and manufacturing processes. This cost factor can be a barrier, especially for small and medium-sized enterprises with limited budgets. However, as the market continues to mature and economies of scale are achieved, the prices of cut-resistant gloves are expected to become more affordable.

Another restraint is the lack of awareness in certain regions and industries regarding the importance of cut-resistant gloves. In such cases, there is a need for educational campaigns and training programs to raise awareness about the potential hazards in the workplace and the benefits of using cut-resistant gloves. Increasing awareness can drive market growth by encouraging wider adoption of these gloves across industries.

The presence of counterfeit and low-quality cut-resistant gloves is also a concern in the market. Counterfeit products not only compromise worker safety but also create a negative perception of the overall effectiveness of cut-resistant gloves. To address this issue, market players should focus on quality assurance, certifications, and stringent supply chain management to ensure the authenticity and reliability of their products.

Nevertheless, the cut-resistant gloves market presents several opportunities for industry participants. The rapid industrialization and infrastructure development in emerging economies create a fertile ground for market expansion. As more companies establish their operations in these regions, the demand for cut-resistant gloves is expected to rise.

Technological innovations in material science and glove manufacturing techniques provide opportunities for the development of advanced cut-resistant gloves. Manufacturers can explore new materials and design concepts to enhance the gloves’ cut resistance, dexterity, breathability, and ergonomic features. Additionally, there is an increasing focus on sustainable materials in the market. Manufacturers can capitalize on this trend by developing eco-friendly and biodegradable cut-resistant gloves, catering to the environmentally conscious consumer segment.

In conclusion, the cut-resistant gloves market is driven by the increasing emphasis on workplace safety, stringent safety regulations, advancements in material technology, and the need for hand protection across various industries. While cost considerations, lack of awareness, and counterfeit products pose challenges, there are opportunities for market players in emerging economies and the development of innovative and sustainable gloves. The market is expected to continue its growth trajectory as organizations prioritize worker safety and seek effective solutions to minimize hand injuries in the workplace.

Regional Analysis

The cut-resistant gloves market can be analyzed based on regional segmentation to gain insights into geographical trends and market dynamics. The market’s growth and opportunities vary across different regions due to factors such as industrial development, safety regulations, and the level of awareness about workplace safety.

North America

North America holds a significant share in the cut-resistant gloves market. The region’s strict safety regulations and high awareness levels regarding workplace safety contribute to the demand for cut-resistant gloves. Industries such as manufacturing, construction, and healthcare are major end-users in this region. The presence of well-established manufacturers and distributors further fuels market growth.

Europe

Europe is another prominent market for cut-resistant gloves. Stringent safety standards and regulations, particularly in countries like Germany, France, and the United Kingdom, drive the adoption of cut-resistant gloves across various industries. The market in Europe benefits from the region’s focus on worker safety, technological advancements, and the presence of key players offering innovative products.

Asia Pacific

The Asia Pacific region exhibits substantial growth potential in the cut-resistant gloves market. Rapid industrialization, infrastructure development, and increasing investments in workplace safety contribute to market expansion. Countries like China, India, Japan, and South Korea are major contributors to market growth in this region. Rising awareness about employee safety, along with the implementation of safety regulations, drives the adoption of cut-resistant gloves in diverse industries.

Latin America

Latin America represents a growing market for cut-resistant gloves. Industries such as construction, mining, and oil and gas have witnessed significant growth in this region. The focus on improving worker safety, driven by regulatory initiatives and increasing awareness, creates opportunities for the adoption of cut-resistant gloves. Brazil and Mexico are key markets in Latin America, with a rising demand for protective equipment.

Middle East and Africa

The Middle East and Africa region present a mixed market for cut-resistant gloves. While some countries have stringent safety regulations and a growing emphasis on worker safety, others are still in the early stages of developing safety standards. Industries like oil and gas, construction, and manufacturing drive the demand for cut-resistant gloves in this region. With increasing awareness about workplace safety and the implementation of safety regulations, the market is expected to witness gradual growth.

Competitive Landscape

Leading Companies in the Cut Resistant Gloves Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

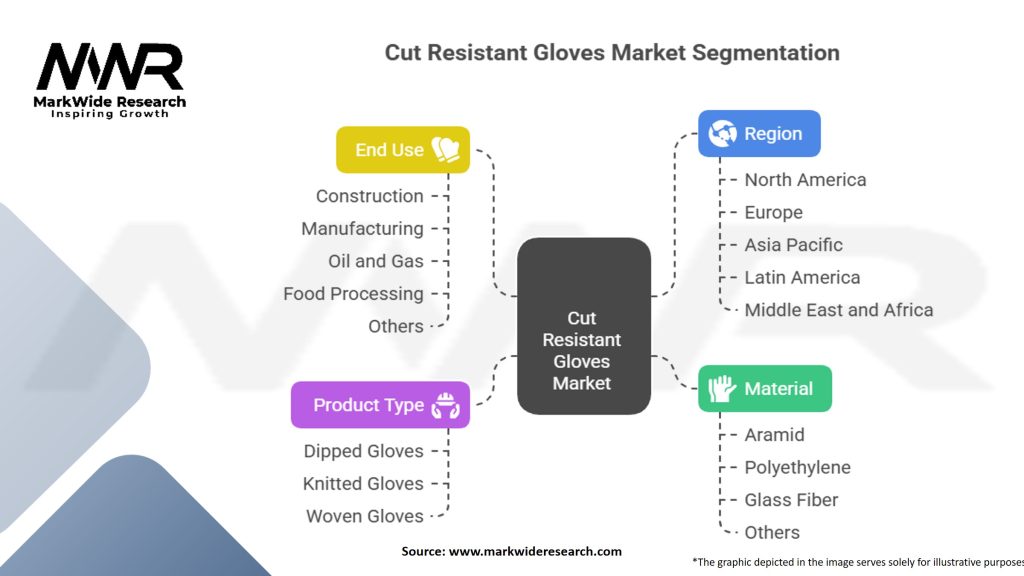

Segmentation

The cut-resistant gloves market can be segmented based on various factors such as material type, glove type, end-use industry, and application. Segmentation provides a comprehensive understanding of the market, allowing manufacturers and stakeholders to identify specific target segments and tailor their offerings accordingly.

Segmentation allows market participants to identify specific industry verticals, applications, or material preferences that offer growth opportunities. It enables targeted marketing strategies and product development tailored to the needs of each segment.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders:

SWOT Analysis

A SWOT (Strengths, Weaknesses, Opportunities, and Threats) analysis provides a comprehensive assessment of the cut-resistant gloves market, enabling stakeholders to identify internal strengths and weaknesses while leveraging external opportunities and mitigating threats.

Strengths:

Weaknesses:

Opportunities:

Threats:

Understanding the market’s strengths, weaknesses, opportunities, and threats enables industry participants to devise effective strategies, capitalize on market trends, and mitigate potential risks.

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic had a profound impact on various industries, including the cut-resistant gloves market. While the primary focus during the pandemic was on medical gloves and PPE for healthcare workers, the need for cut-resistant gloves remained prevalent in industries such as manufacturing and construction. The pandemic highlighted the importance of workplace safety and the need for proper hand protection, leading to increased awareness and demand for cut-resistant gloves in these sectors.

The pandemic also resulted in disruptions to global supply chains, impacting the availability of raw materials and manufacturing processes. Manufacturers faced challenges in meeting the increased demand for cut-resistant gloves while ensuring the safety of their workforce and adhering to social distancing measures.

Despite these challenges, the market witnessed a surge in demand for cut-resistant gloves due to the heightened emphasis on worker safety and the implementation of strict hygiene protocols. The pandemic served as a catalyst for organizations to prioritize employee protection and invest in appropriate PPE, including cut-resistant gloves.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future outlook for the cut-resistant gloves market remains optimistic. The growing awareness of workplace safety, increasing emphasis on employee well-being, and the implementation of stringent safety regulations are expected to drive market growth.

Technological advancements will continue to play a significant role in shaping the market. Manufacturers will focus on developing gloves with superior cut resistance, flexibility, breathability, and comfort. Integration of smart technologies, such as sensors and connectivity features, may become more prevalent, providing real-time insights on glove integrity and worker safety.

The market will witness further expansion into emerging economies, where industrialization and infrastructure development are on the rise. Companies will capitalize on these opportunities by establishing partnerships, expanding distribution networks, and customizing products to cater to the specific needs of these regions.

Sustainability will also become a key factor in the market. Manufacturers will increasingly adopt eco-friendly materials and manufacturing processes, aligning with the global trend towards sustainability and environmental responsibility.

In conclusion, the cut-resistant gloves market is poised for growth due to increased awareness of workplace safety, stringent regulations, technological advancements, and the need for hand protection across industries. The market will continue to evolve as manufacturers focus on product innovation, customization, sustainability, and partnerships to meet the evolving demands of end-users.

Conclusion

The cut-resistant gloves market is experiencing steady growth driven by the rising emphasis on workplace safety, strict safety regulations, and the need to protect workers from hand injuries. Cut-resistant gloves provide a crucial layer of protection against cuts, lacerations, and abrasions caused by sharp objects, making them an essential component of personal protective equipment (PPE).

Market players are leveraging advancements in material technology to develop gloves with enhanced cut resistance, durability, and comfort. High-performance fibers like aramid, glass, and stainless steel are commonly used to provide superior protection. Additionally, customization options, ergonomic designs, and the integration of smart technologies are shaping the market, catering to the evolving needs of end-users.

In conclusion, the cut-resistant gloves market is driven by the imperative need for workplace safety and the increasing demand for protective handwear across industries. As organizations continue to prioritize worker well-being and invest in PPE, the market is poised to expand, offering opportunities for manufacturers, distributors, and stakeholders to contribute to safer work environments and protect workers from hand injuries.

What is Cut Resistant Gloves?

Cut resistant gloves are specialized protective gear designed to prevent cuts and lacerations while handling sharp objects. They are commonly used in industries such as manufacturing, construction, and food processing.

What are the key players in the Cut Resistant Gloves Market?

Key players in the Cut Resistant Gloves Market include companies like Ansell, Honeywell, and MCR Safety, which are known for their innovative safety solutions and high-quality protective gear, among others.

What are the main drivers of the Cut Resistant Gloves Market?

The main drivers of the Cut Resistant Gloves Market include the increasing focus on workplace safety regulations, the rising demand from the manufacturing and construction sectors, and the growing awareness of the importance of personal protective equipment.

What challenges does the Cut Resistant Gloves Market face?

Challenges in the Cut Resistant Gloves Market include the high cost of advanced materials used in manufacturing these gloves and the need for continuous innovation to meet evolving safety standards and consumer expectations.

What opportunities exist in the Cut Resistant Gloves Market?

Opportunities in the Cut Resistant Gloves Market include the expansion of e-commerce platforms for safety gear, the development of smart gloves with integrated technology, and the increasing adoption of cut resistant gloves in emerging markets.

What trends are shaping the Cut Resistant Gloves Market?

Trends shaping the Cut Resistant Gloves Market include the growing demand for eco-friendly materials, advancements in glove technology for enhanced dexterity and comfort, and the rising popularity of customized protective solutions tailored to specific industry needs.

Cut Resistant Gloves Market

| Segmentation | Details |

|---|---|

| Material | Aramid, Polyethylene, Glass Fiber, Others |

| Product Type | Dipped Gloves, Knitted Gloves, Woven Gloves |

| End Use | Construction, Manufacturing, Oil and Gas, Food Processing, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East and Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Cut Resistant Gloves Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at