444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Conveyor systems are an essential component of numerous industries, including manufacturing, food and beverage, pharmaceuticals, and logistics, to name a few. These systems allow for the efficient and automated movement of materials, goods, and products throughout a production or distribution facility. Conveyor systems are commonly used in industries that require the movement of heavy or bulky items, as they can move these items quickly and efficiently, reducing the need for manual labor.

The conveyor systems market is expected to experience significant growth in the coming years, driven by factors such as increasing automation in industries, rising demand for e-commerce logistics, and the need for improved efficiency and productivity in manufacturing processes.

A conveyor system is a mechanical handling equipment that transports materials, products, or goods from one place to another. Conveyor systems are designed to move materials horizontally, vertically, or at an incline, and can be used to transport a wide variety of materials, including raw materials, finished products, and packaging materials. Conveyor systems can be powered by electricity, gravity, or manually operated.

Executive Summary

The global conveyor systems market was valued at USD 7.4 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 4.6% from 2021 to 2028. The increasing demand for automation in industries and the need for improved efficiency and productivity in manufacturing processes are some of the key factors driving the growth of the conveyor systems market. Additionally, the rising demand for e-commerce logistics is expected to fuel the growth of the market further.

Based on type, the belt conveyor segment accounted for the largest market share in 2020, owing to its high load-carrying capacity and ability to transport materials over long distances. Based on end-use industry, the manufacturing segment held the largest market share in 2020, due to the widespread use of conveyor systems in the manufacturing industry to transport raw materials and finished products.

Geographically, Asia Pacific dominated the global conveyor systems market in 2020, owing to the presence of a large manufacturing sector and rising demand for automation in industries in the region.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

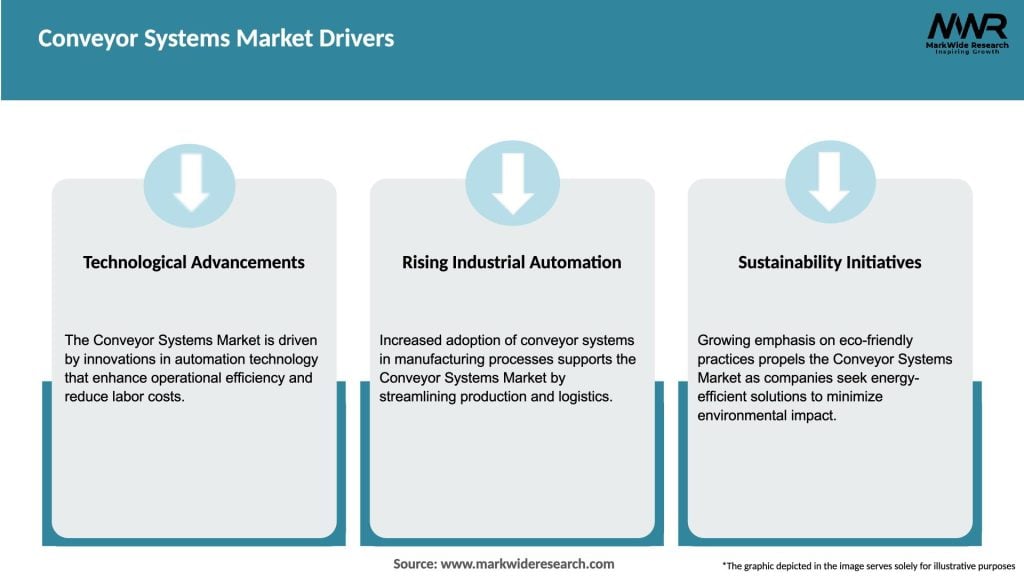

Market Drivers

The increasing demand for automation in industries is one of the key factors driving the growth of the conveyor systems market. Automation allows for the efficient and reliable movement of materials, goods, and products throughout a production or distribution facility, reducing the need for manual labor and increasing productivity.

The rising demand for e-commerce logistics is expected to fuel the growth of the conveyor systems market further. The growth of e-commerce has led to an increase in the volume of packages and parcels that need to be transported, and conveyor systems are an efficient way to transport these items.

The need for improved efficiency and productivity in manufacturing processes is another key driver of the conveyor systems market. Conveyor systems allow for the rapid movement of materials and products, reducing the time required for manufacturing processes and increasing productivity.

Market Restraints

The high initial investment required for the installation of conveyor systems is a major restraint on the growth of the market. Conveyor systems require a significant investment in infrastructure, equipment, and maintenance, which can be a barrier to entry for small and medium-sized enterprises.

Conveyor systems are designed for specific applications and may not be suitable for all types of materials or products. This can limit the flexibility of the system and make it difficult to adapt to changing production needs.

Conveyor systems require regular maintenance and repair, which can be costly for businesses. Failure to maintain the system properly can lead to downtime and reduced productivity, which can have a significant impact on the bottom line.

Market Opportunities

The growing adoption of Industry 4.0 technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), presents a significant opportunity for the conveyor systems market. These technologies can be used to improve the efficiency and reliability of conveyor systems, reduce maintenance costs, and enhance overall productivity.

Emerging markets, such as India and China, present a significant growth opportunity for the conveyor systems market. These countries have a large manufacturing sector and are rapidly adopting automation technologies, which is expected to drive the demand for conveyor systems in these regions.

The expansion of e-commerce is expected to continue driving demand for conveyor systems, as the volume of packages and parcels that need to be transported continues to grow. The need for fast and efficient delivery is expected to drive the adoption of conveyor systems in the e-commerce sector.

Market Dynamics

The conveyor systems market is highly competitive, with numerous players operating in the market. The market is characterized by intense competition, with players competing on factors such as price, quality, and innovation. The market is also highly fragmented, with numerous small and medium-sized enterprises operating in the market.

The market is expected to experience significant growth in the coming years, driven by factors such as increasing automation in industries, rising demand for e-commerce logistics, and the need for improved efficiency and productivity in manufacturing processes. However, the market is also expected to face challenges, such as the high initial investment required for the installation of conveyor systems and the limited flexibility of these systems.

Regional Analysis

The global conveyor systems market is segmented into North America, Europe, Asia Pacific, and the Rest of the World. Asia Pacific dominated the global market in 2020, accounting for the largest market share. The region is expected to continue dominating the market during the forecast period, driven by the presence of a large manufacturing sector and rising demand for automation in industries in the region.

Europe and North America are also expected to experience significant growth in the coming years, driven by factors such as the growing adoption of Industry 4.0 technologies and the need for improved efficiency and productivity in manufacturing processes.

Competitive Landscape

Leading Companies in the Conveyor Systems Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

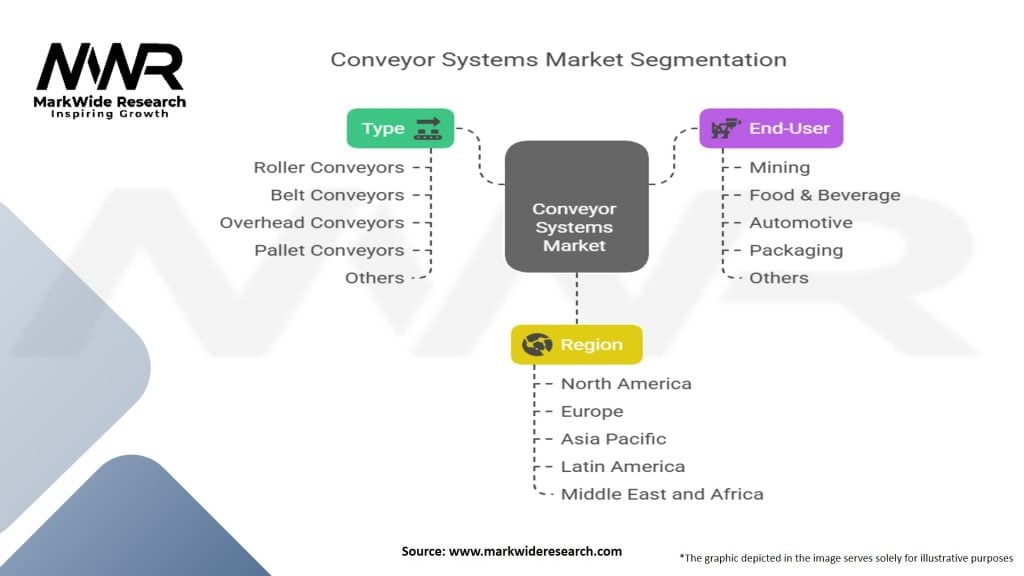

The conveyor systems market is segmented based on type, end-use industry, and geography.

By Type:

By End-Use Industry:

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

The use of conveyor systems can help improve the efficiency and productivity of manufacturing processes, reducing the time required to transport materials and products and increasing overall productivity.

The use of conveyor systems can help reduce the need for manual labor, reducing labor costs and improving the bottom line.

Conveyor systems can help improve workplace safety by reducing the risk of injury associated with manual handling of heavy or bulky items.

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has had a significant impact on the conveyor systems market. The pandemic has led to disruptions in supply chains and manufacturing processes, which has affected the demand for conveyor systems. However, the pandemic has also led to an increased focus on automation and the need for improved efficiency and productivity in manufacturing processes, which is expected to drive the demand for conveyor systems in the post-pandemic period.

Key Industry Developments

Analyst Suggestions

Future Outlook

The conveyor systems market is expected to experience significant growth in the coming years, driven by factors such as increasing automation in industries, rising demand for e-commerce logistics, and the need for improved efficiency and productivity in manufacturing processes. The market is also expected to face challenges, such as the high initial investment required for the installation of conveyor systems and the limited flexibility of these systems.

Conclusion

In conclusion, the conveyor systems market is expected to experience significant growth in the coming years, driven by factors such as increasing automation in industries, rising demand for e-commerce logistics, and the need for improved efficiency and productivity in manufacturing processes. The market is highly competitive, with numerous players operating in the market. Companies should focus on developing innovative and cost-effective conveyor systems and expanding their presence in emerging markets to gain a competitive edge. The expansion of e-commerce and the growing adoption of Industry 4.0 technologies also present significant opportunities for the market.

While the market is expected to face challenges such as the high initial investment required for the installation of conveyor systems and the limited flexibility of these systems, the overall outlook for the market is positive. The use of conveyor systems can help improve the efficiency and productivity of manufacturing processes, reduce labor costs, and improve workplace safety, making them an essential component of numerous industries.

What are conveyor systems?

Conveyor systems are mechanical devices used to transport materials or products from one location to another within a facility. They are commonly used in manufacturing, warehousing, and distribution applications to enhance efficiency and reduce manual labor.

Who are the key players in the Conveyor Systems Market?

Key players in the Conveyor Systems Market include companies such as Daifuku Co., Ltd., Siemens AG, Honeywell Intelligrated, and Dematic, among others.

What are the main drivers of growth in the Conveyor Systems Market?

The growth of the Conveyor Systems Market is driven by increasing automation in manufacturing processes, the rise of e-commerce requiring efficient logistics, and the need for improved material handling solutions across various industries.

What challenges does the Conveyor Systems Market face?

Challenges in the Conveyor Systems Market include high initial investment costs, maintenance requirements, and the need for skilled labor to operate and manage these systems effectively.

What opportunities exist in the Conveyor Systems Market?

Opportunities in the Conveyor Systems Market include advancements in technology such as smart conveyor systems, the integration of IoT for real-time monitoring, and the growing demand for sustainable and energy-efficient solutions.

What trends are shaping the Conveyor Systems Market?

Trends in the Conveyor Systems Market include the increasing adoption of automation and robotics, the development of modular conveyor systems for flexibility, and a focus on sustainability through eco-friendly materials and energy-efficient designs.

Conveyor Systems Market

| Segmentation | Details |

|---|---|

| Type | Roller Conveyors, Belt Conveyors, Overhead Conveyors, Pallet Conveyors, Others |

| End-User | Mining, Food & Beverage, Automotive, Packaging, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East and Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Conveyor Systems Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at