444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The construction industry has witnessed a significant transformation over the years, and one of the key factors driving this change is the adoption of composite materials. Construction composites are engineered materials made from two or more constituent materials, combining their unique properties to create a product that outperforms traditional materials. These materials have gained immense popularity in various construction applications due to their exceptional strength-to-weight ratio, corrosion resistance, durability, and design flexibility. The global construction composite market has been experiencing steady growth and is expected to continue its upward trajectory in the coming years.

Meaning

Construction composites are materials formed by combining two or more different substances to create a new, superior material that possesses enhanced properties. These composites can be made using a wide range of constituent materials, such as fiberglass, carbon fiber, aramid fiber, polymers, ceramics, and others. By carefully selecting and blending these materials, engineers can tailor the composites to meet specific project requirements, resulting in improved performance and longevity in various construction applications.

Executive Summary

The construction composite market has witnessed substantial growth in recent years, driven by the increasing demand for sustainable, cost-effective, and durable construction materials. The executive summary provides an overview of the market’s key highlights, including its current state, major growth drivers, challenges, and promising opportunities. It also outlines the market’s regional distribution, competitive landscape, and key industry trends.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

FRP Rebar Dominance: Glass fiber–reinforced polymer (GFRP) rebars account for over 35% of composite sales, replacing steel in reinforcement and rehabilitation applications.

Infrastructure Rehabilitation: Retrofit of aging bridges and marine structures using FRP wrap composites represents a high-growth segment.

Prefabrication Trend: Off-site manufacturing of composite panels and modules accelerates project timelines and ensures quality control.

Sustainability Drivers: LEED and BREEAM certifications increasingly recognize composites for reducing embodied carbon.

Emerging 3D Printing: Additive manufacturing of composite materials for complex façade elements and bespoke architectural components gains traction.

Market Drivers

Aging Infrastructure: Governments prioritizing maintenance of bridges, tunnels, and marine piles drive demand for corrosion-resistant composites.

Environmental Regulations: Stringent CO₂ emission targets motivate the use of lightweight, low-carbon composite materials over traditional steel and concrete.

Urbanization & High-Rise Construction: Architects and developers seek high-strength yet lightweight materials for skyscraper panels and façade systems.

Labor Shortages: Prefabricated composite modules reduce on-site labor requirements and accelerate construction schedules.

Innovations in Resin Chemistry: Development of bio-based and fire-retardant resins expands composite applicability.

Market Restraints

High Initial Costs: Premium pricing of composite materials compared to conventional alternatives limits adoption in cost-sensitive markets.

Technical Expertise Required: Specialized design, handling, and installation practices demand training and skilled labor.

Long-Term Durability Data: Limited decades-long performance data in some climates creates hesitation among conservative engineers.

Supply-Chain Constraints: Dependency on fiber and resin suppliers, with occasional material shortages or price volatility.

Regulatory Acceptance: Longer certification processes for new composite applications can delay market entry.

Market Opportunities

Modular Construction: Expansion of fully composite modular homes and commercial pods for rapid-deploy housing and offices.

3D-Printed Components: On-site additive manufacturing of composite structural elements tailored to complex geometries.

Smart Composites: Integration of sensors within composite laminates for structural health monitoring and predictive maintenance.

Green Resins: Rising research into recyclable and bio-based resin systems to enhance circular economy credentials.

Emerging Economies: Infrastructure booms in Africa and Southeast Asia offer untapped markets for composite rehabilitation and new-build projects.

Market Dynamics

Supply Side Factors: Continued investment in fiber production capacity (especially carbon and basalt fibers) and resin technology drives material innovation.

Demand Side Factors: Collaboration between composite manufacturers and EPC contractors accelerates specification in large infrastructure tenders.

Economic Factors: Infrastructure spending as a percentage of GDP—particularly in stimulus packages—directly correlates with composite uptake.

Regional Analysis

North America: Leading in FRP reinforcement and bridge strengthening, supported by DOT programs and strong composite standards.

Europe: Rapid adoption in façade panels, balcony refurbishment, and modular façade systems, driven by energy-efficiency mandates.

Asia-Pacific: Fastest growth region, propelled by China’s Belt and Road projects and India’s Smart Cities mission applying composite modular solutions.

Latin America: Emerging demand for marine infrastructure rehabilitation and lightweight roofing in coastal regions.

Middle East & Africa: Select high-profile developments and oil & gas facility upgrades using composites for corrosion resistance and weight reduction.

Competitive Landscape

Leading Companies in the Construction Composite Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

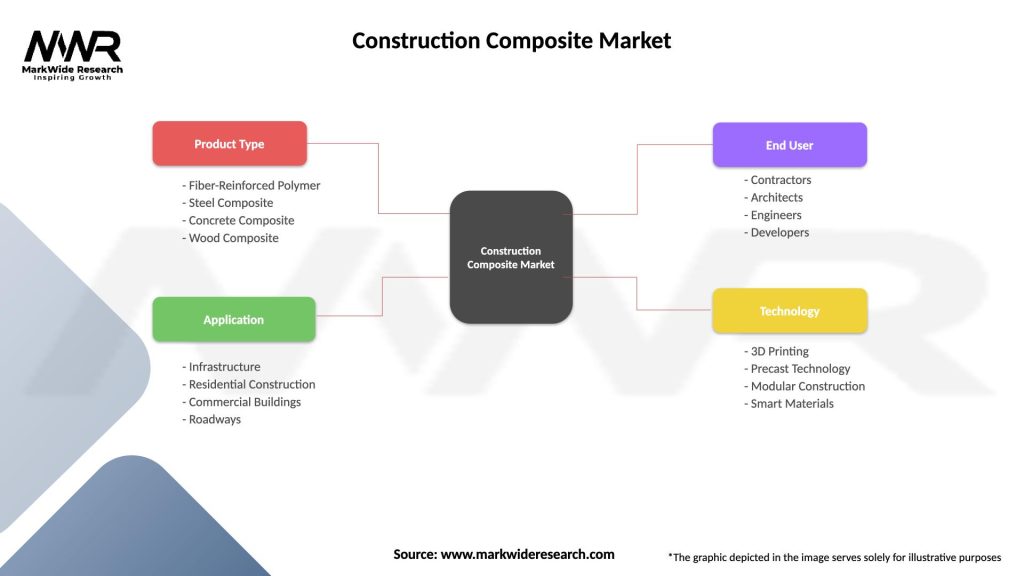

Segmentation

The construction composite market can be segmented based on the type of composites and their applications. Major types of composites include fiberglass composites, carbon fiber composites, natural fiber composites, and others. These composites find applications in various sectors, including residential construction, commercial construction, infrastructure development, and industrial applications.

Category-wise Insights

In residential construction, construction composites find extensive use in roofing, siding, and window frames. The lightweight nature and high strength of composites make them an ideal choice for constructing durable and energy-efficient homes.

Composites are widely used in the commercial sector for cladding, façade systems, and structural elements. The aesthetic appeal and design flexibility of composites enable architects and designers to create visually appealing commercial spaces.

In infrastructure projects such as bridges, highways, and tunnels, composites offer high durability, corrosion resistance, and reduced maintenance costs, making them an attractive choice for sustainable infrastructure development.

Construction composites are extensively used in industrial settings for manufacturing chemical storage tanks, pipes, and platforms due to their chemical resistance and ability to withstand harsh environments.

Key Benefits for Industry Participants and Stakeholders

The construction composite market offers numerous benefits to industry participants and stakeholders:

SWOT Analysis

Market Key Trends

The trend towards green Building practices and the rise in green building certifications, such as LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method), are driving the demand for sustainable construction composites.

Nanotechnology is being increasingly integrated into composite materials to enhance their properties further. The incorporation of nanoparticles improves mechanical strength and adds multifunctional capabilities to construction composites.

The adoption of prefabrication and modular construction methods is on the rise, and composite materials play a vital role in these processes due to their lightweight nature and ease of assembly.

Covid-19 Impact

The COVID-19 pandemic had a profound impact on the construction industry, including the composite market. Lockdowns, supply chain disruptions, and economic uncertainties led to project delays and a temporary slowdown in construction activities. However, the pandemic also underscored the importance of sustainable and resilient construction materials, driving further interest in construction composites as a long-term solution.

Key Industry Developments

Manufacturers are investing in research to develop advanced manufacturing techniques, such as automated fiber placement and resin infusion, to improve the efficiency and scalability of composite production.

In response to safety concerns, the industry has focused on creating fire-resistant composites suitable for high-rise buildings and critical infrastructure.

Analyst Suggestions

Companies should allocate resources to research and development to create new composite materials with enhanced properties and reduced production costs.

Raising awareness and providing training programs about composite materials’ benefits and applications can accelerate market growth in regions with limited knowledge about these materials.

Emphasizing the eco-friendly aspects of construction composites and their contribution to green building practices can attract environmentally-conscious customers.

Future Outlook

The future of the construction composite market looks promising, with a steady growth trajectory expected in the coming years. Advancements in manufacturing techniques, growing demand for sustainable construction, and increasing applications in various sectors will drive the market’s expansion.

Conclusion

The construction composite market has emerged as a game-changer in the building industry, offering an array of benefits that traditional materials cannot match. The market’s growth is fueled by the construction sector’s increasing focus on sustainability, durability, and cost-effectiveness. While challenges exist, such as initial cost and limited awareness, the market’s potential for innovation and expanding applications will shape the future of construction, transforming the industry with the power of advanced materials.

What is Construction Composite?

Construction composites are materials made from two or more constituent materials that provide enhanced properties, such as strength, durability, and lightweight characteristics. They are commonly used in construction applications like bridges, buildings, and infrastructure projects.

What are the key players in the Construction Composite Market?

Key players in the Construction Composite Market include companies like BASF SE, Owens Corning, and Hexcel Corporation, which are known for their innovative composite materials and solutions for construction applications, among others.

What are the main drivers of the Construction Composite Market?

The main drivers of the Construction Composite Market include the increasing demand for lightweight and high-strength materials, the growth of infrastructure projects, and the need for sustainable building solutions. These factors contribute to the rising adoption of composites in various construction applications.

What challenges does the Construction Composite Market face?

The Construction Composite Market faces challenges such as high production costs, limited awareness of composite materials among traditional builders, and regulatory hurdles related to material standards. These factors can hinder the widespread adoption of composites in construction.

What opportunities exist in the Construction Composite Market?

Opportunities in the Construction Composite Market include the development of new composite materials with enhanced properties, the expansion of applications in green building projects, and the increasing focus on infrastructure modernization. These trends are likely to drive growth in the sector.

What are the current trends in the Construction Composite Market?

Current trends in the Construction Composite Market include the integration of smart technologies in composite materials, the rise of bio-based composites, and the increasing use of composites in prefabricated construction. These innovations are shaping the future of construction materials.

Construction Composite Market

| Segmentation Details | Description |

|---|---|

| Product Type | Fiber-Reinforced Polymer, Steel Composite, Concrete Composite, Wood Composite |

| Application | Infrastructure, Residential Construction, Commercial Buildings, Roadways |

| End User | Contractors, Architects, Engineers, Developers |

| Technology | 3D Printing, Precast Technology, Modular Construction, Smart Materials |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Construction Composite Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at