444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The conformal coatings market is witnessing significant growth due to the increasing demand for electronic devices in various industries. Conformal coatings are protective materials that are applied to electronic components and printed circuit boards (PCBs) to protect them from moisture, dust, chemicals, and other environmental factors. These coatings provide a protective barrier that ensures the longevity and reliability of the electronic devices.

Meaning

Conformal coatings refer to a range of materials that are applied in thin layers onto electronic components and PCBs. These coatings conform to the contours of the substrate, creating a protective barrier that safeguards the components against external elements. Conformal coatings are essential in preventing corrosion, electrical short circuits, and other issues that can arise from exposure to moisture, dust, and chemicals.

Executive Summary

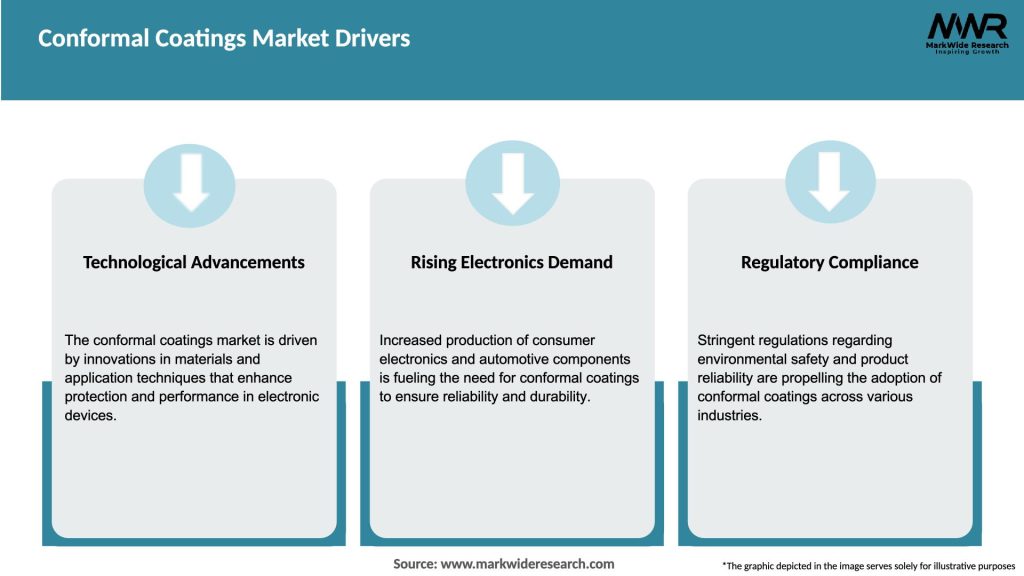

The global conformal coatings market is experiencing steady growth, driven by the increasing adoption of electronic devices across various sectors. The market is characterized by the presence of both established players and new entrants, offering a wide range of conformal coating solutions to cater to diverse industry requirements. Key factors influencing the market include technological advancements, stringent regulations for electronic product reliability, and the growing trend of miniaturization in electronics.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The conformal coatings market is influenced by various dynamic factors that shape its growth trajectory. These dynamics include market trends, customer preferences, technological advancements, competitive landscape, and regulatory environment.

Rapid technological advancements and the continuous evolution of the electronics industry play a crucial role in shaping the demand for conformal coatings. The introduction of new electronic devices, the miniaturization trend, and the increasing complexity of electronic components drive the need for advanced and reliable conformal coatings.

Changing customer preferences, particularly the growing demand for durable and reliable electronic products, contribute to the market dynamics. Consumers are increasingly aware of the importance of protection and reliability in electronic devices, which drives the adoption of conformal coatings by manufacturers.

The competitive landscape of the conformal coatings market is characterized by the presence of both established players and new entrants. Market players are focusing on product innovation, strategic collaborations, and mergers and acquisitions to gain a competitive edge. This dynamic competitive environment influences market trends and customer choices.

The regulatory environment, including standards and regulations for electronic reliability and environmental sustainability, significantly impacts the market dynamics. Compliance with these regulations is essential for manufacturers to ensure the reliability and safety of electronic devices, driving the demand for conformal coatings.

Regional Analysis

The conformal coatings market can be analyzed across various regions, including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Each region has its unique characteristics and market dynamics that influence the demand for conformal coatings.

Competitive Landscape

Leading Companies in the Conformal Coatings Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The conformal coatings market can be segmented based on various factors, including coating type, application method, end-use industry, and geography.

Segmenting the market helps in understanding specific market trends, customer preferences, and growth opportunities in each segment. It enables market players to tailor their strategies and offerings to cater to the unique requirements of different segments.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Critical Electronics Protection: Conformal coatings provide moisture, dust, and chemical resistance, essential for reliability in harsh environments.

Wide Substrate Compatibility: Available in a range of chemistries (acrylic, silicone, urethane), fitting diverse PCB applications.

Regulatory Compliance: Many formulations meet UL, IPC, and RoHS standards, facilitating adoption across industries.

Weaknesses:

Application Complexity: Uniform coating thickness and cure control require skilled operators and specialized equipment.

Inspection Challenges: Detecting coating defects (voids, bubbles) often demands costly microscopy or X‑ray analysis.

Environmental Concerns: Some solvent‑based coatings face VOC emission restrictions and disposal regulations.

Opportunities:

Miniaturization Trend: As electronics shrink, demand for thin, high‑performance coatings in wearable and IoT devices grows.

Automated Dispensing: Innovations in robotic spray and selective conformal coating systems can reduce labor costs and improve consistency.

New Chemistries: Development of UV‑cure, low‑temperature, and eco‑friendly formulations can open new market segments.

Threats:

Substitute Technologies: Emerging potting and encapsulation solutions may displace conformal coatings in some applications.

Raw Material Volatility: Fluctuating prices for polymers and specialty solvents can squeeze margins.

Stringent Environmental Laws: Tightening VOC and hazardous air pollutant regulations may increase compliance costs.

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic had a mixed impact on the conformal coatings market. While there was a temporary slowdown in demand due to disruptions in the global supply chain and manufacturing operations, the market rebounded quickly as the demand for electronic devices, particularly for remote work and communication, surged during the pandemic.

The pandemic also highlighted the importance of reliability and protection in electronic devices, driving the adoption of conformal coatings to ensure the uninterrupted performance of critical equipment in various sectors such as healthcare, telecommunications, and home electronics.

Key Industry Developments

Analyst Suggestions

Future Outlook

The conformal coatings market is expected to witness steady growth in the coming years, driven by the increasing demand for electronic devices and the need for reliable and durable protection. Technological advancements, such as the development of eco-friendly coatings, self-healing coatings, and coatings for flexible electronics, will shape the market’s future.

The Asia Pacific region is anticipated to maintain its dominance in the market, fueled by the rapid growth of the electronics industry in countries like China, India, and South Korea. The increasing adoption of conformal coatings in emerging economies and the expansion of automotive electronics will also contribute to the market’s growth.

Overall, the conformal coatings market presents lucrative opportunities for industry participants and stakeholders, provided they focus on innovation, sustainability, strategic partnerships, and geographic expansion. By addressing customer needs and complying with regulatory standards, market players can position themselves for long-term success.

Conclusion

The conformal coatings market is witnessing significant growth, driven by the increasing demand for electronic devices across various industries. These coatings play a vital role in protecting electronic components and PCBs from moisture, dust, chemicals, and other environmental factors, ensuring their reliability and longevity.

The market is influenced by factors such as the growing electronics industry, stringent regulations for electronic reliability, the trend of miniaturization, and the increasing demand for durable and reliable products. While high costs and complex application processes can pose challenges, emerging applications in emerging economies, the development of advanced coatings, collaboration with electronics manufacturers, and aftermarket services present opportunities for market participants.

A thorough understanding of market dynamics, regional analysis, competitive landscape, segmentation, and key trends is crucial for industry participants and stakeholders to make informed decisions and develop effective strategies. By focusing on customer needs, technological advancements, sustainability, and geographic expansion, market players can position themselves for future growth and success in the conformal coatings market.

What are conformal coatings?

Conformal coatings are protective chemical coatings applied to electronic circuits and components to safeguard them from environmental factors such as moisture, dust, and chemicals. They are essential in enhancing the reliability and longevity of electronic devices in various applications.

What are the key companies in the conformal coatings market?

Key companies in the conformal coatings market include Henkel, Dow Corning, and H.B. Fuller, which are known for their innovative coating solutions. Other notable players include Electrolube and PPG Industries, among others.

What are the growth factors driving the conformal coatings market?

The conformal coatings market is driven by the increasing demand for electronic devices in automotive, aerospace, and consumer electronics sectors. Additionally, the growing emphasis on miniaturization and the need for enhanced durability in electronic components contribute to market growth.

What challenges does the conformal coatings market face?

Challenges in the conformal coatings market include the complexity of application processes and the need for stringent quality control. Additionally, the availability of alternative protective solutions may hinder market growth.

What opportunities exist in the conformal coatings market?

Opportunities in the conformal coatings market include the development of eco-friendly coatings and advancements in nanotechnology. The rising trend of smart electronics also presents new avenues for growth in this sector.

What trends are shaping the conformal coatings market?

Current trends in the conformal coatings market include the increasing adoption of UV-cured coatings and the integration of advanced materials for better performance. Additionally, the focus on sustainability is driving innovations in environmentally friendly coating solutions.

Conformal Coatings Market

| Segmentation Details | Description |

|---|---|

| Type | Acrylic, Silicone, Polyurethane, Others |

| End-Use Industry | Electronics, Automotive, Aerospace & Defense, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Conformal Coatings Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at