444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview:

The Confocal Displacement Sensor market is a rapidly growing sector within the global sensor industry. These sensors are crucial for measuring distances with exceptional precision and accuracy, making them indispensable in various industries, including manufacturing, automotive, aerospace, and electronics. Confocal displacement sensors employ a unique optical technique, offering numerous advantages over traditional sensors in terms of accuracy, speed, and non-contact measurement capabilities.

Meaning:

Confocal displacement sensors utilize the principle of confocal microscopy to measure distances between the sensor and the target object. The sensor emits light onto the surface of the object, and the reflected light is then captured by a confocal aperture. This aperture allows only the light reflected from the focal plane to pass through, filtering out other stray light. The focused light is then converted into an electrical signal, which is used to determine the precise distance between the sensor and the object surface.

Executive Summary:

The Confocal Displacement Sensor market is witnessing remarkable growth, driven by the increasing demand for high-precision measurement and inspection in manufacturing and quality control processes. These sensors offer superior accuracy, reliability, and repeatability, making them ideal for applications that require utmost precision. Moreover, the rising automation in industries and the need for non-contact measurement solutions are further fueling the adoption of confocal displacement sensors.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights:

Market Drivers:

Market Restraints:

Market Opportunities:

Market Dynamics:

The Confocal Displacement Sensor market is characterized by dynamic factors that influence its growth and development. The interplay of market drivers, restraints, and opportunities, along with technological advancements and changing industry demands, shape the overall market dynamics.

Regional Analysis:

The Confocal Displacement Sensor market exhibits a global presence, with key regions contributing to its growth. Some regions serve as manufacturing hubs, while others act as major consumers of confocal displacement sensors.

Competitive Landscape:

Leading Companies in the Confocal Displacement Sensor Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

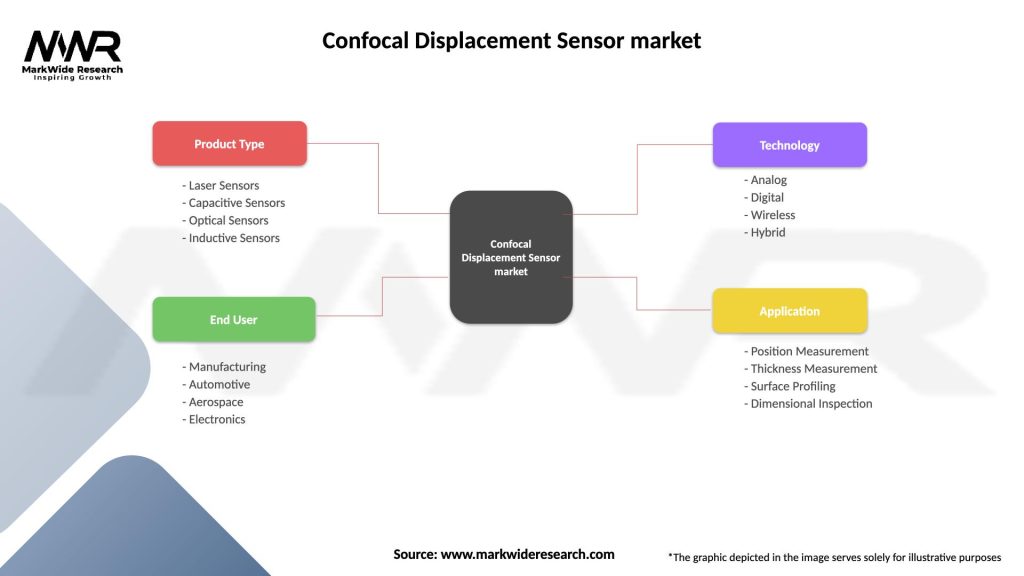

Segmentation:

The Confocal Displacement Sensor market can be segmented based on various criteria, including technology, application, industry, and geography.

Category-wise Insights:

Key Benefits for Industry Participants and Stakeholders:

SWOT Analysis:

Market Key Trends:

Covid-19 Impact:

The Covid-19 pandemic had significant repercussions on global economies and industries, including the Confocal Displacement Sensor market. The outbreak disrupted supply chains, halted manufacturing activities, and caused a decline in demand for certain products. However, the pandemic also underscored the importance of automation and contactless technologies, creating opportunities for sensor adoption in healthcare and remote monitoring applications.

Key Industry Developments:

Analyst Suggestions:

Future Outlook:

The future of the Confocal Displacement Sensor market looks promising, with rapid technological advancements and increasing demand for automation and precision measurements. The integration of sensors with Industry 4.0 technologies and IoT platforms will further propel the market’s growth. As more industries recognize the benefits of non-contact measurement solutions, the adoption of confocal displacement sensors is expected to rise steadily.

Conclusion:

The Confocal Displacement Sensor market is witnessing substantial growth driven by the increasing demand for high-precision and non-contact measurement solutions. With their exceptional accuracy and versatility, these sensors find applications in various industries, from manufacturing and automotive to electronics and healthcare. Despite challenges such as high initial investment and integration complexities, the market offers promising opportunities in emerging economies and industries like robotics and biotechnology. To capitalize on these opportunities, companies should focus on technological advancements, market diversification, and strategic collaborations to deliver innovative and tailored solutions that address industry-specific needs. As automation and quality control continue to gain importance, the demand for confocal displacement sensors is poised to expand, making them a key component in the future of industrial measurement and inspection processes.

What is Confocal Displacement Sensor?

A Confocal Displacement Sensor is a precision measurement device that uses confocal microscopy principles to measure the distance to a surface with high accuracy. These sensors are commonly used in applications such as material testing, surface profiling, and industrial automation.

What are the key companies in the Confocal Displacement Sensor market?

Key companies in the Confocal Displacement Sensor market include Keyence Corporation, Micro-Epsilon, and Renishaw, among others. These companies are known for their innovative sensor technologies and solutions tailored for various industrial applications.

What are the growth factors driving the Confocal Displacement Sensor market?

The growth of the Confocal Displacement Sensor market is driven by the increasing demand for high-precision measurement in industries such as automotive, aerospace, and electronics. Additionally, advancements in sensor technology and automation are contributing to market expansion.

What challenges does the Confocal Displacement Sensor market face?

The Confocal Displacement Sensor market faces challenges such as high costs associated with advanced sensor technologies and competition from alternative measurement methods. Additionally, the need for skilled personnel to operate and maintain these sensors can be a barrier to adoption.

What opportunities exist in the Confocal Displacement Sensor market?

Opportunities in the Confocal Displacement Sensor market include the growing trend of automation in manufacturing processes and the increasing use of sensors in quality control applications. Furthermore, the expansion of the semiconductor industry presents new avenues for growth.

What trends are shaping the Confocal Displacement Sensor market?

Trends in the Confocal Displacement Sensor market include the integration of IoT technology for real-time data monitoring and the development of miniaturized sensors for compact applications. Additionally, there is a rising focus on enhancing sensor accuracy and speed in measurement processes.

Confocal Displacement Sensor market

| Segmentation Details | Description |

|---|---|

| Product Type | Laser Sensors, Capacitive Sensors, Optical Sensors, Inductive Sensors |

| End User | Manufacturing, Automotive, Aerospace, Electronics |

| Technology | Analog, Digital, Wireless, Hybrid |

| Application | Position Measurement, Thickness Measurement, Surface Profiling, Dimensional Inspection |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Confocal Displacement Sensor Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at