444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The concrete polishing and grinding machines market is a thriving sector within the construction industry. These machines play a crucial role in achieving smooth, glossy surfaces for concrete floors. They are extensively used in commercial, industrial, and residential settings to enhance the aesthetics and durability of concrete surfaces. Concrete polishing and grinding machines offer efficient and effective solutions for preparing, polishing, and maintaining concrete floors. With the rising demand for sustainable and cost-effective flooring options, the market for these machines is experiencing significant growth.

Meaning

Concrete polishing and grinding machines are specialized equipment designed to mechanically grind, polish, and refine the surface of concrete floors. They utilize various tools, such as diamond-embedded discs or pads, to remove imperfections, level the surface, and impart a high-gloss finish. These machines employ a multi-step process involving grinding, honing, and polishing to transform rough concrete into a smooth, lustrous surface. The use of concrete polishing and grinding machines eliminates the need for coatings, resulting in long-lasting and low-maintenance floors.

Executive Summary

The concrete polishing and grinding machines market has witnessed substantial growth in recent years. The demand for visually appealing and durable concrete floors has driven the adoption of these machines across different sectors. The market is characterized by the presence of both established players and new entrants, each striving to offer innovative products with advanced features. Rising investments in construction and renovation projects, along with the increasing awareness of sustainable flooring options, are fueling the growth of this market.

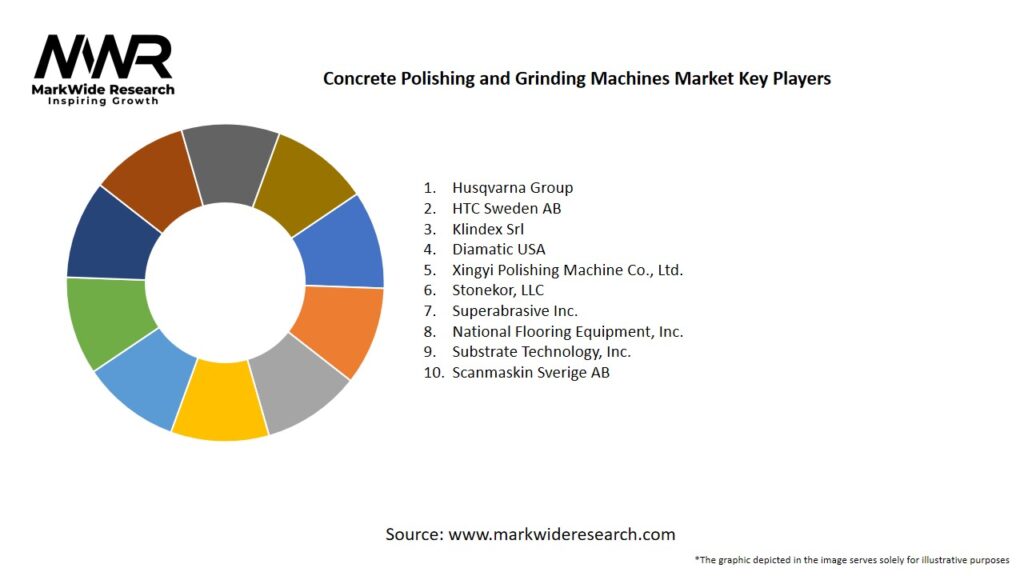

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

The concrete polishing and grinding machines market is driven by several factors that are contributing to its growth. Firstly, the increasing demand for polished concrete floors in residential, commercial, and industrial sectors is a major driver. Polished concrete offers a sleek and modern look while being highly durable and easy to maintain. This aesthetic appeal, coupled with its long-term cost-effectiveness, has fueled the demand for concrete polishing and grinding machines.

Secondly, advancements in technology have revolutionized the concrete polishing and grinding industry. The development of automated and robotic machines has significantly improved the efficiency and precision of the polishing process. These machines can cover larger areas in less time, resulting in increased productivity and cost savings for contractors. The integration of smart features and remote monitoring capabilities has further enhanced their performance.

Thirdly, there is a growing emphasis on sustainable construction practices and eco-friendly flooring solutions. Polished concrete floors eliminate the need for coatings, adhesives, and additional materials, making them an environmentally friendly option. Concrete polishing and grinding machines play a vital role in achieving sustainable flooring by reducing waste, energy consumption, and the use of harmful chemicals.

Market Restraints

Despite the positive growth prospects, the concrete polishing and grinding machines market faces certain challenges that may impede its progress. One of the key restraints is the high initial cost associated with these machines. The advanced technology and precision engineering involved in manufacturing them contribute to their relatively higher price compared to traditional floor preparation methods. This cost factor can deter some potential buyers, especially small-scale contractors or businesses with limited budgets.

Another challenge is the lack of skilled operators proficient in operating and maintaining these machines. Concrete polishing and grinding machines require proper training and expertise to ensure optimal performance and avoid damage to the floors. The shortage of skilled labor can pose a barrier to market growth, as contractors may hesitate to invest in these machines without qualified personnel to operate them effectively.

Market Opportunities

The concrete polishing and grinding machines market presents several opportunities that can be leveraged for further growth and expansion. One such opportunity lies in the untapped potential of emerging markets. As urbanization and infrastructure development continue to accelerate in countries like India, China, and Brazil, there is a growing demand for modern flooring solutions. The adoption of polished concrete floors in these regions is still relatively low, presenting a vast market potential.

Furthermore, the introduction of eco-friendly and sustainable flooring certifications and regulations provides an opportunity for the market players to position their products as compliant with environmental standards. By highlighting the energy efficiency, low maintenance, and durability of polished concrete floors achieved through the use of these machines, manufacturers can target environmentally conscious customers and gain a competitive advantage.

Moreover, the integration of advanced technologies, such as Internet of Things (IoT) and artificial intelligence, into concrete polishing and grinding machines opens doors to new possibilities. IoT-enabled machines can offer real-time monitoring, predictive maintenance, and remote control capabilities, improving operational efficiency and reducing downtime. These technological advancements can attract customers looking for smart and automated solutions.

Market Dynamics

The concrete polishing and grinding machines market is characterized by dynamic trends and factors that shape its growth trajectory. The increasing focus on sustainability, coupled with the demand for visually appealing and durable flooring solutions, has been the primary driving force behind the market’s expansion. Technological advancements have revolutionized the industry, providing more efficient and automated solutions.

The market is highly competitive, with key players investing in research and development activities to introduce innovative products with advanced features. Collaborations and partnerships between manufacturers, distributors, and contractors have become common to strengthen market presence and expand the customer base.

Geographically, the Asia Pacific region is witnessing significant growth due to rapid urbanization, infrastructure development, and the increasing adoption of modern flooring solutions. North America and Europe also hold substantial market shares, driven by the emphasis on sustainable construction practices and the renovation of existing buildings.

Overall, the concrete polishing and grinding machines market is poised for continued growth, driven by factors such as the demand for sustainable flooring, technological advancements, and expanding construction activities.

Regional Analysis

The concrete polishing and grinding machines market can be analyzed based on regional segmentation, considering factors such as market size, growth rate, and key players in each region.

It is important to note that the market dynamics and growth rates may vary within each region based on local economic factors, construction trends, and government initiatives.

Competitive Landscape

Leading Companies in the Concrete Polishing and Grinding Machines Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

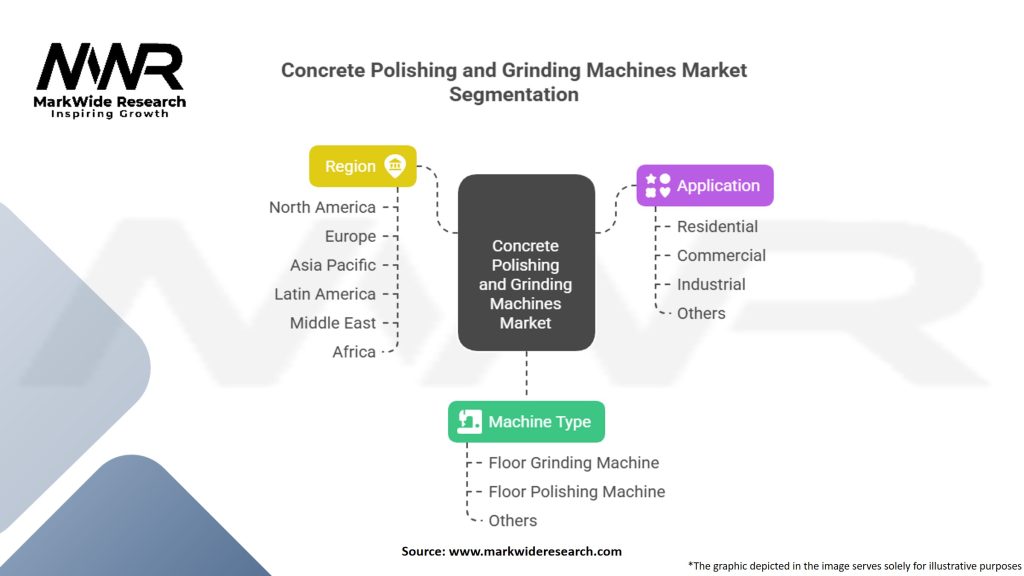

Segmentation

The concrete polishing and grinding machines market can be segmented based on various factors such as machine type, application, and end-user.

Segmentation provides a deeper understanding of market trends and helps stakeholders identify specific opportunities within each segment.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

The concrete polishing and grinding machines market offers several benefits for industry participants and stakeholders:

Overall, industry participants and stakeholders can benefit from increased efficiency, high-quality finishes, reduced maintenance costs, and sustainable flooring solutions by utilizing concrete polishing and grinding machines.

SWOT Analysis

A SWOT (Strengths, Weaknesses, Opportunities, and Threats) analysis provides insights into the internal and external factors that can impact the concrete polishing and grinding machines market:

A thorough understanding of these factors can help market participants strategize effectively, capitalize on opportunities, and mitigate potential threats.

Market Key Trends

The concrete polishing and grinding machines market are influenced by several key trends that shape its growth and direction:

Covid-19 Impact

The COVID-19 pandemic has had a significant impact on the construction industry, including the concrete polishing and grinding machines market. The initial phase of the pandemic led to a slowdown in construction activities due to lockdowns, travel restrictions, and supply chain disruptions. Many construction projects were put on hold or delayed, affecting the demand for concrete polishing and grinding machines.

However, as the pandemic progressed, the construction industry adapted to new safety protocols, and projects gradually resumed. The demand for polished concrete floors remained strong, particularly in commercial and industrial sectors, as businesses sought to create clean and hygienic environments. The focus on sustainable and low-maintenance flooring solutions further contributed to the market’s resilience during the pandemic.

Manufacturers faced challenges in terms of production and supply chain disruptions, but they quickly adapted to meet the changing market needs. The pandemic also accelerated the adoption of digital technologies, remote monitoring, and virtual demonstrations, enabling manufacturers to continue engaging with customers and providing support.

Overall, while the COVID-19 pandemic posed challenges, the concrete polishing and grinding machines market showcased resilience and adaptability, driven by the continued demand for high-quality flooring solutions.

Key Industry Developments

The concrete polishing and grinding machines market has witnessed several key industry developments that have shaped its growth and competitive landscape:

Analyst Suggestions

Based on the market analysis and trends, analysts suggest the following strategies for industry participants and stakeholders in the concrete polishing and grinding machines market:

Future Outlook

The future outlook for the concrete polishing and grinding machines market is positive, driven by various factors:

Conclusion

In conclusion, the concrete polishing and grinding machines market is poised for growth, driven by the increasing demand for visually appealing, durable, and sustainable flooring solutions. Technological advancements, focus on training and skill development, and expansion into emerging markets will shape the future landscape of this industry.

What is Concrete Polishing and Grinding Machines?

Concrete Polishing and Grinding Machines are specialized equipment used to grind, polish, and finish concrete surfaces. They are commonly utilized in construction and renovation projects to achieve a smooth, durable, and aesthetically pleasing concrete floor.

What are the key players in the Concrete Polishing and Grinding Machines Market?

Key players in the Concrete Polishing and Grinding Machines Market include Husqvarna, Makita, and Bosch, among others. These companies are known for their innovative products and technologies that enhance the efficiency and effectiveness of concrete surface preparation.

What are the main drivers of the Concrete Polishing and Grinding Machines Market?

The main drivers of the Concrete Polishing and Grinding Machines Market include the increasing demand for durable flooring solutions in commercial and residential sectors, the growth of the construction industry, and advancements in grinding technology that improve efficiency and reduce labor costs.

What challenges does the Concrete Polishing and Grinding Machines Market face?

Challenges in the Concrete Polishing and Grinding Machines Market include the high initial investment costs for advanced machinery and the need for skilled operators to effectively use the equipment. Additionally, competition from alternative flooring solutions can impact market growth.

What opportunities exist in the Concrete Polishing and Grinding Machines Market?

Opportunities in the Concrete Polishing and Grinding Machines Market include the rising trend of sustainable construction practices and the increasing popularity of polished concrete in residential and commercial spaces. Innovations in machine design and technology also present avenues for growth.

What trends are shaping the Concrete Polishing and Grinding Machines Market?

Trends shaping the Concrete Polishing and Grinding Machines Market include the growing adoption of eco-friendly grinding solutions, the integration of automation and smart technology in machinery, and the increasing focus on aesthetic finishes in concrete applications.

Concrete Polishing and Grinding Machines Market

| Segmentation Details | Description |

|---|---|

| By Machine Type | Floor Grinding Machine, Floor Polishing Machine, and Others |

| By Application | Residential, Commercial, Industrial, and Others |

| By Region | North America, Europe, Asia Pacific, Latin America, Middle East, and Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Concrete Polishing and Grinding Machines Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at