444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

Composite pipes are advanced piping systems that are made from a combination of different materials such as fibers, resins, and additives. These pipes offer numerous advantages over traditional piping systems, including high strength, corrosion resistance, and lightweight properties. The composite pipes market has witnessed significant growth in recent years due to the rising demand from various end-use industries, including oil and gas, chemical, water treatment, and infrastructure.

Meaning

Composite pipes are a type of piping system that combines different materials to create a high-performance and durable pipe. These pipes are typically made by reinforcing fibers, such as carbon, glass, or aramid, with a polymer matrix, which is usually a resin. The combination of these materials results in a pipe that has excellent mechanical properties, resistance to corrosion, and can withstand high temperatures and pressures.

Executive Summary

The composite pipes market has been experiencing steady growth in recent years, driven by the increasing demand for lightweight and corrosion-resistant piping systems across various industries. The market is characterized by the presence of several key players who are continuously investing in research and development activities to enhance the performance and efficiency of composite pipes. Additionally, the growing focus on infrastructure development and the need for efficient fluid transportation systems are further fueling the demand for composite pipes globally.

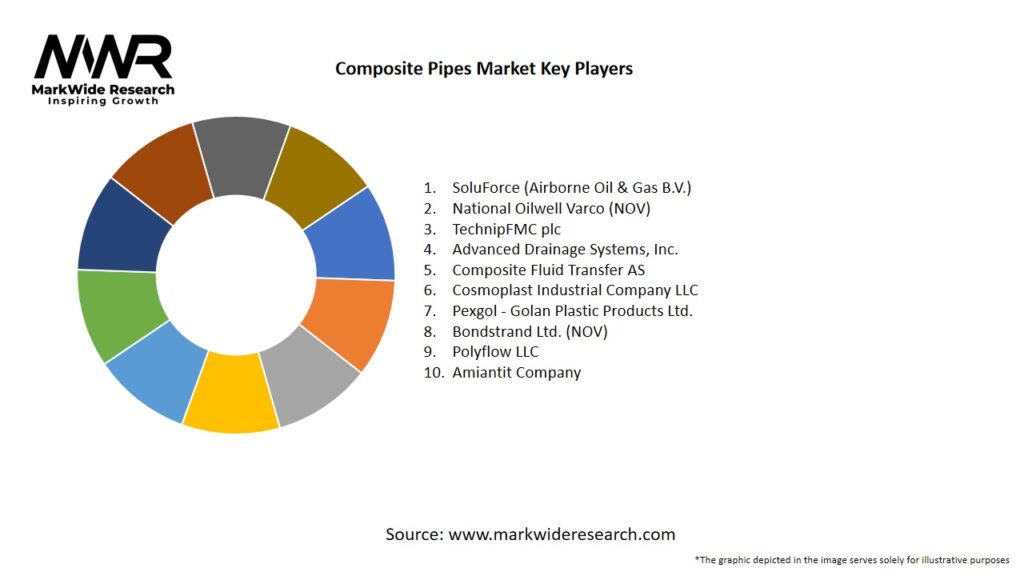

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The composite pipes market is driven by several dynamic factors that influence its growth and development. These factors include technological advancements, changing end-user requirements, market competition, government regulations, and economic conditions. The market dynamics play a crucial role in shaping the strategies of market players and determining the overall growth trajectory of the composite pipes industry.

Regional Analysis

The global composite pipes market can be segmented into several regions, including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Among these, the Asia Pacific region is expected to dominate the market due to rapid industrialization, urbanization, and infrastructure development in countries like China and India. North America and Europe are also significant markets for composite pipes, driven by the presence of well-established industries and ongoing investments in pipeline infrastructure.

Competitive Landscape

Leading Companies in the Composite Pipes Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

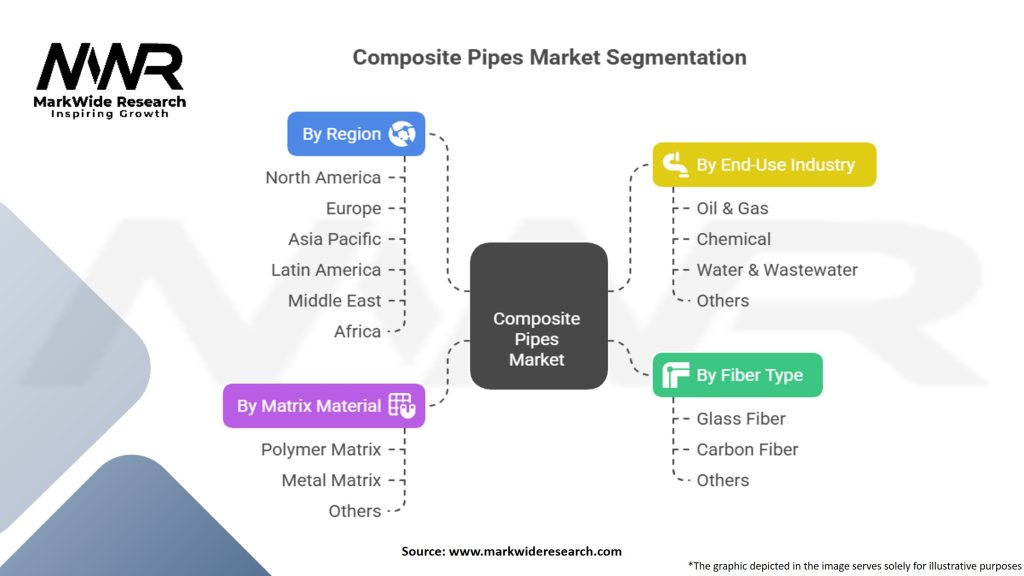

Segmentation

The composite pipes market can be segmented based on material type, manufacturing process, end-use industry, and region. Material types include carbon fiber, glass fiber, aramid fiber, and others. Manufacturing processes encompass filament winding, pultrusion, and others. End-use industries comprise oil and gas, chemical, water treatment, infrastructure, and others.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic had a significant impact on the composite pipes market. The temporary shutdown of industries, disruption in supply chains, and reduced construction activities negatively affected the demand for composite pipes. However, the market showed resilience and gradually recovered as economic activities resumed and industries adapted to the new normal. The need for efficient fluid transportation systems and infrastructure development projects played a crucial role in driving the market’s recovery.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future of the composite pipes market looks promising, with steady growth expected in the coming years. The increasing demand from end-use industries, advancements in composite materials, and rising infrastructure development projects will drive market expansion. Moreover, the growing emphasis on sustainability and the adoption of smart technologies will further enhance the market’s potential. However, market players need to address challenges related to cost, technical limitations, and regulatory compliance to fully capitalize on the opportunities in the composite pipes market.

Conclusion

The composite pipes market is witnessing robust growth, driven by the advantages offered by these pipes over traditional piping systems. With their superior corrosion resistance, lightweight properties, and durability, composite pipes find extensive applications in various industries. While challenges such as high initial costs and limited awareness exist, the market presents significant opportunities in water treatment, renewable energy, and emerging markets. Strategic initiatives, technological advancements, and sustainability-focused approaches will be crucial for industry players to thrive in this evolving market.

What is Composite Pipes?

Composite pipes are engineered pipes made from a combination of materials, typically including polymers and reinforcing fibers, designed to offer enhanced strength, durability, and resistance to corrosion. They are widely used in various applications such as oil and gas, water distribution, and chemical processing.

What are the key players in the Composite Pipes Market?

Key players in the Composite Pipes Market include companies like Future Pipe Industries, National Oilwell Varco, and Amiblu, which specialize in manufacturing composite piping solutions for various industries. These companies focus on innovation and quality to meet the growing demand for composite materials in infrastructure projects, among others.

What are the main drivers of growth in the Composite Pipes Market?

The growth of the Composite Pipes Market is driven by factors such as the increasing demand for lightweight and corrosion-resistant materials in construction and industrial applications. Additionally, the rising focus on sustainable and efficient piping solutions contributes to the market’s expansion.

What challenges does the Composite Pipes Market face?

The Composite Pipes Market faces challenges such as high manufacturing costs and the need for specialized installation techniques. Furthermore, competition from traditional materials like metal and PVC can hinder market growth.

What opportunities exist in the Composite Pipes Market?

Opportunities in the Composite Pipes Market include the growing adoption of composite materials in renewable energy projects and advancements in manufacturing technologies. Additionally, increasing investments in infrastructure development present significant growth potential for composite pipe applications.

What trends are shaping the Composite Pipes Market?

Trends in the Composite Pipes Market include the development of smart piping systems that integrate sensors for monitoring and maintenance. There is also a shift towards eco-friendly materials and processes, reflecting the industry’s commitment to sustainability and reducing environmental impact.

Composite Pipes Market

| Segmentation Details | Description |

|---|---|

| By Fiber Type | Glass Fiber, Carbon Fiber, and Others |

| By Matrix Material | Polymer Matrix, Metal Matrix, and Others |

| By End-Use Industry | Oil & Gas, Chemical, Water & Wastewater, and Others |

| By Region | North America, Europe, Asia Pacific, Latin America, Middle East, and Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Composite Pipes Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at