444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The composite pipe system market represents a pivotal segment within the broader industrial landscape, encapsulating the utilization of composite materials for constructing pipes used in various applications. Composite pipes, crafted from a blend of polymers, fibers, and resins, offer superior durability, corrosion resistance, and structural integrity compared to conventional metallic counterparts. This market burgeons with opportunities, propelled by escalating demand across diverse sectors such as oil and gas, chemical processing, and water treatment.

Meaning

Composite pipe systems entail the utilization of composite materials, including fiberglass, carbon fiber, and epoxy resins, for fabricating pipes engineered to withstand demanding operational environments. These pipes exhibit remarkable corrosion resistance, high strength-to-weight ratios, and exceptional longevity, rendering them indispensable across an array of industrial applications. Composite pipe systems epitomize innovation in material science, offering a compelling alternative to conventional metallic piping solutions.

Executive Summary

The composite pipe system market witnesses robust growth trajectories, underpinned by burgeoning demand across key end-user verticals. Composite pipes, renowned for their durability, corrosion resistance, and lightweight characteristics, assume precedence over traditional metallic counterparts, fueling market expansion. Despite market buoyancy, industry stakeholders confront challenges pertaining to material costs, regulatory compliance, and technological barriers, necessitating adept strategizing to sustain competitiveness.

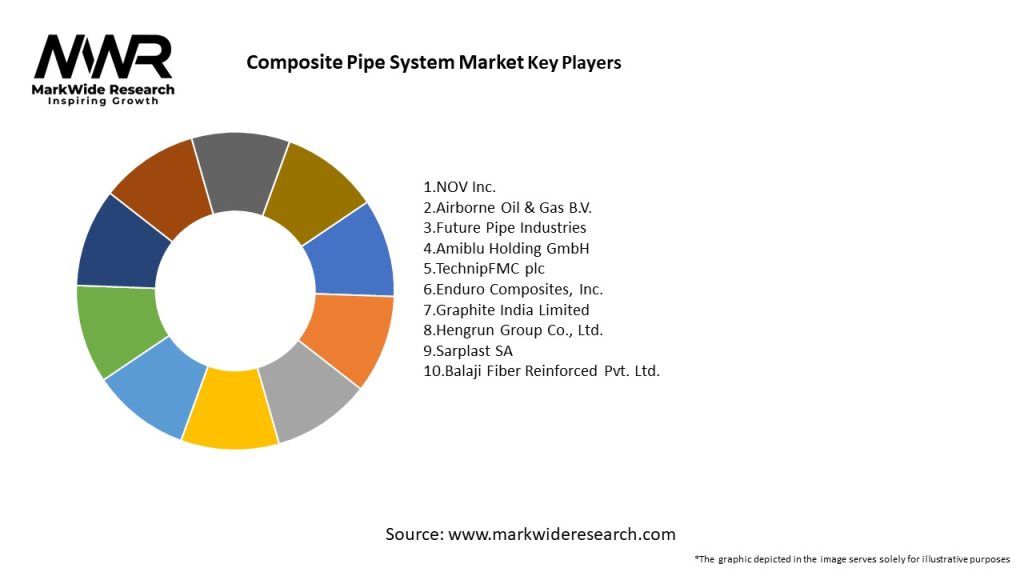

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The composite pipe system market operates within a dynamic milieu characterized by evolving end-user preferences, technological advancements, regulatory imperatives, and competitive pressures. These dynamic forces shape market trajectories, necessitating adept strategizing, agile business models, and proactive market positioning to navigate market complexities and sustain competitive advantages.

Regional Analysis

The composite pipe system market exhibits regional variations influenced by factors such as industrialization levels, infrastructure development, regulatory frameworks, and end-user demand dynamics. A nuanced regional analysis elucidates distinctive market dynamics, fostering informed decision-making and targeted market strategies.

Competitive Landscape

Leading Companies in the Composite Pipe System Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

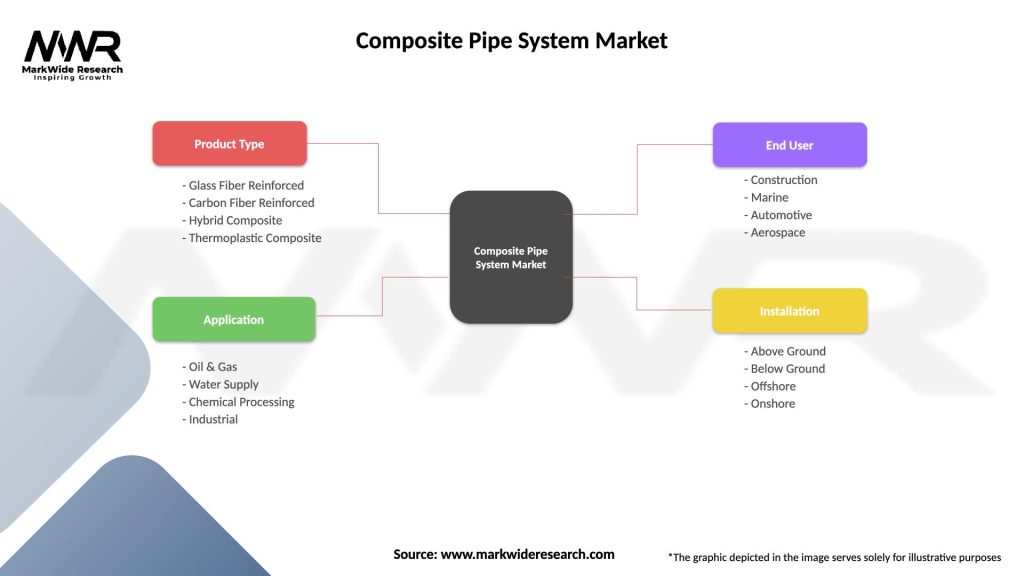

Segmentation

Segmentation serves as a strategic imperative for delineating market dynamics, targeting niche customer segments, and tailoring product offerings to align with diverse end-user requirements. Key segmentation parameters encompass material type, end-user industry, application, and geographic region, facilitating nuanced market analysis and strategic decision-making.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic exerts profound ramifications on the composite pipe system market, characterized by disruptions to global supply chains, project delays, and demand contractions across key end-user sectors. However, the sector exhibits resilience, adapting to dynamic market exigencies through operational optimization, digital transformation, and strategic diversification endeavors.

Key Industry Developments

Analyst Suggestions

Future Outlook

The composite pipe system market is poised for sustained growth and innovation, underpinned by escalating demand across diverse end-user sectors, technological advancements, and sustainability imperatives. However, industry stakeholders must navigate challenges pertaining to cost sensitivities, regulatory compliance, and technological barriers to capitalize on emergent growth opportunities and sustain market competitiveness in the dynamic industrial landscape.

Conclusion

The composite pipe system market represents a pivotal segment within the broader industrial milieu, characterized by robust growth trajectories, technological advancements, and sustainability imperatives. Despite challenges posed by cost sensitivities, regulatory compliance, and technological barriers, the market exhibits resilience and innovation, fueled by burgeoning demand across key end-user sectors and transformative advancements in material science and digital technologies. By prioritizing investments in research and development, fostering strategic partnerships, embracing digital transformation, and integrating sustainability imperatives, industry stakeholders can navigate market complexities, capitalize on emergent growth opportunities, and sustain competitive advantages in the dynamic composite pipe system market.

What is Composite Pipe System?

Composite Pipe System refers to a type of piping made from a combination of materials, typically including a polymer matrix reinforced with fibers. These systems are known for their lightweight, corrosion resistance, and high strength, making them suitable for various applications in industries such as oil and gas, water treatment, and construction.

What are the key players in the Composite Pipe System Market?

Key players in the Composite Pipe System Market include companies like Owens Corning, Solvay, and Aegion Corporation, which are known for their innovative composite materials and solutions. These companies focus on enhancing the performance and durability of composite pipes for various applications, among others.

What are the main drivers of growth in the Composite Pipe System Market?

The growth of the Composite Pipe System Market is driven by increasing demand for lightweight and corrosion-resistant materials in industries such as oil and gas, water management, and construction. Additionally, advancements in manufacturing technologies and the push for sustainable solutions are contributing to market expansion.

What challenges does the Composite Pipe System Market face?

The Composite Pipe System Market faces challenges such as high initial costs and the need for specialized installation techniques. Additionally, competition from traditional materials like metal and PVC can hinder market penetration in certain applications.

What opportunities exist in the Composite Pipe System Market?

Opportunities in the Composite Pipe System Market include the growing adoption of composite materials in emerging economies and the development of new applications in renewable energy sectors. Furthermore, increasing environmental regulations are pushing industries to seek more sustainable piping solutions.

What trends are shaping the Composite Pipe System Market?

Trends in the Composite Pipe System Market include the integration of smart technologies for monitoring and maintenance, as well as the development of bio-based composites. Additionally, there is a rising focus on enhancing the recyclability of composite materials to meet sustainability goals.

Composite Pipe System Market

| Segmentation Details | Description |

|---|---|

| Product Type | Glass Fiber Reinforced, Carbon Fiber Reinforced, Hybrid Composite, Thermoplastic Composite |

| Application | Oil & Gas, Water Supply, Chemical Processing, Industrial |

| End User | Construction, Marine, Automotive, Aerospace |

| Installation | Above Ground, Below Ground, Offshore, Onshore |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Composite Pipe System Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at