444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The Composite Cans Machine Market comprises machinery and equipment designed to produce cylindrical composite cans—containers made from layers of paperboard, plastic, and sometimes aluminum—used for packaging dry foods, powders, confectionery, coffee, chemicals, and other goods. These machines perform operations such as tube forming, end‐cup hemming, labeling, sleeving, and sealing, offering high throughput, precision, and flexibility for varying diameters and lengths. Growth in single‐serve food packaging, sustainability concerns favoring paper‐based materials, and demand for tamper‐evident, reclosable packaging are driving market expansion. Technological advances in automation, quick‐changeover tooling, and integrated quality inspection further enhance production efficiency.

Meaning

Composite can machines automate the multi‐step process of transforming flat webs of paperboard (often pre‐laminated with thin polymer or foil layers) into finished, filled, and sealed cylindrical containers. Key stages include:

Striping & Laminating: Applying barrier films to paperboard for moisture and oxygen protection.

Tube Forming & Gluing: Wrapping and bonding the board into a seamless tube.

End‐Cup Hemming: Attaching and hemming metal/plastic ends to both tube ends.

Filling & Sealing: Precisely dispensing product and sealing with heat or ultrasonic methods.

Sleeving & Labeling: Applying shrink sleeves or wraparound labels for branding and information.

These machines vary from semi‐automatic bench‐top units to fully automated, inline production lines capable of several thousand cans per hour.

Executive Summary

The Composite Cans Machine Market was valued at approximately USD 420 million in 2023 and is projected to grow at a CAGR of 6.2% from 2024 to 2030, reaching around USD 620 million by 2030. Rising demand for sustainable, lightweight packaging solutions and increasing adoption in food & beverage, personal care, and specialty chemical segments are key drivers. Leading equipment manufacturers are focusing on modular platforms that support rapid format changes, predictive maintenance through IoT connectivity, and integrated vision systems for defect detection. Constraints include high capital investment and complexity of multi‐layer lamination processes. Opportunities lie in emerging markets where packaged food consumption is rising and in greenfield capacity expansions following sustainability regulations.

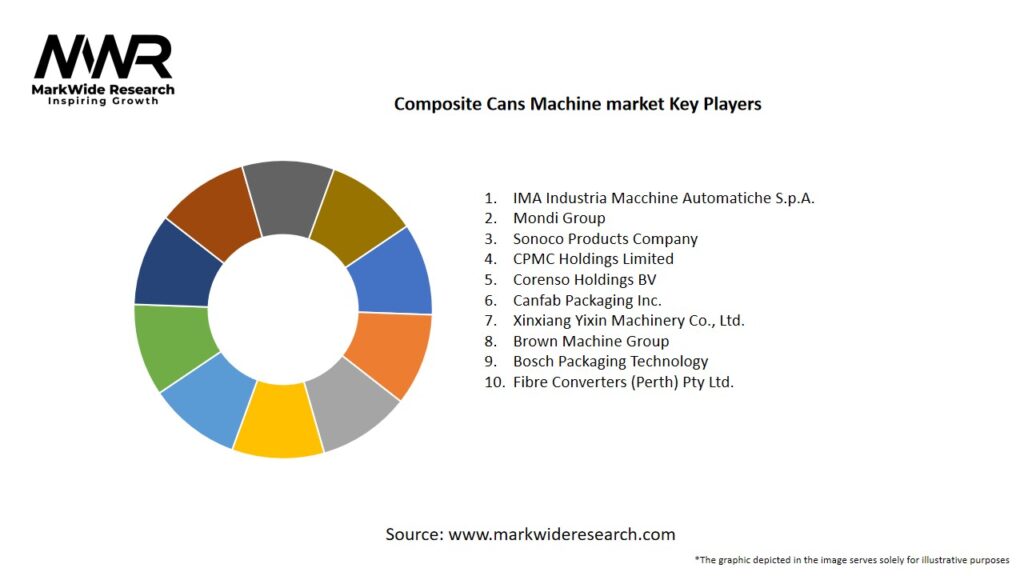

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Throughput Range: Mid‐range machines (200–1,000 cans/min) account for over 40% of installations, balancing speed with versatility.

Automation Uptake: Fully inline, automated lines represent 35% of new orders, with growing interest in semi‐inline solutions among small to medium producers.

Sustainability Push: Demand for machines capable of handling recyclable, mono‐material composite boards is rising, with 28% of new machine sales marketed as “green” solutions.

Regional Leaders: Europe (Germany, Italy) and North America lead in turnkey line deployment, while Asia–Pacific exhibits fastest growth due to expanding food processing sectors.

Service & Upgrades: Retrofit kits and IoT‐enabled monitoring subscriptions are emerging revenue streams, representing 15% of overall market value.

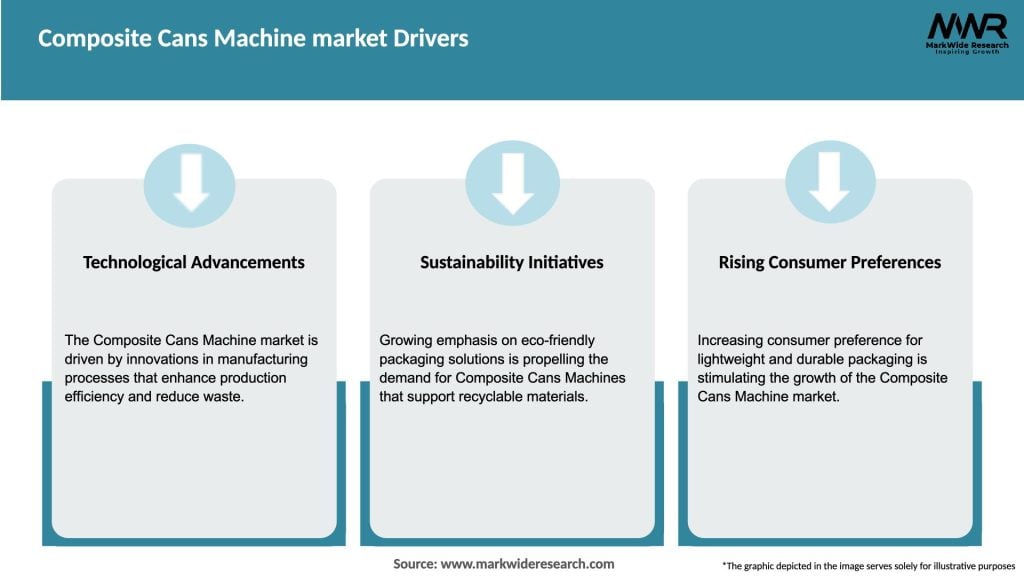

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

Supply Side Factors: Key OEMs are establishing global partnerships for subassembly sourcing and local service networks. Strategic acquisitions of vision‐system and robotics firms bolster feature sets.

Demand Side Factors: Processors seek end‐to‐end solutions—from film lamination to final pack—for single‐source accountability and faster project timelines.

Economic Factors: Capital investment decisions align with projected packaged food market growth rates; economic slowdowns can delay large line purchases but boost demand for upgrades to existing equipment.

Regional Analysis

The demand for composite cans and the machines to produce them varies by region, influenced by factors such as industry demands, consumer preferences, and economic conditions:

Competitive Landscape

Leading Companies in the Composite Cans Machine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

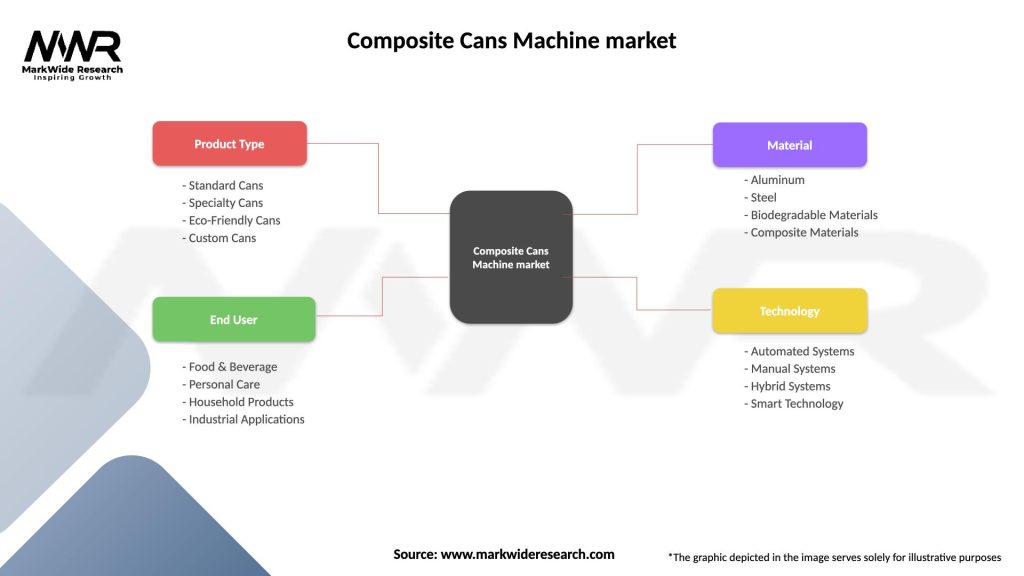

Segmentation

The Composite Cans Machine Market can be segmented based on various factors, including:

Category-wise Insights

Understanding different categories within the Composite Cans Machine Market provides deeper insights into specific market dynamics:

Key Benefits for Industry Participants and Stakeholders

Stakeholders in the Composite Cans Machine Market, including manufacturers, suppliers, and packaging companies, can enjoy several benefits:

SWOT Analysis

A SWOT analysis highlights the strengths, weaknesses, opportunities, and threats in the Composite Cans Machine Market:

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Key trends shaping the Composite Cans Machine Market include:

Covid-19 Impact

The Covid-19 pandemic had several impacts on the Composite Cans Machine Market:

Key Industry Developments

KHS Smart Line Concept: Launch of digital dashboard providing real‑time OEE, throughput, and predictive alerts across composite can lines.

Pester Pac’s Mono‑Material Tubes: Debut of machines handling 100% recyclable paperboard tubes without plastic lamination.

Grief Packaging’s Ultrasonic Sealer: Introduction of non‑heat sealing technology for sensitive applications, reducing cycle time and energy use.

Cama’s Compact Lines: New plug‑and‑play composite can machines designed for craft food producers with minimal footprint.

R.A Jones Sustainability Grant: Collaboration with material suppliers to certify composite can lines under emerging European recyclability standards.

Analyst Suggestions

Based on current market trends and dynamics, analysts suggest the following strategies for industry participants:

Future Outlook

The future of the Composite Cans Machine Market is characterized by customization, sustainability, automation, and market expansion. Despite challenges such as high initial investment costs and maintenance requirements, the market is poised for growth as the demand for innovative and sustainable packaging solutions continues to rise.

Conclusion

In conclusion, the Composite Cans Machine Market is an integral part of the packaging industry, enabling the efficient production of composite cans for various applications. Despite challenges like high initial costs and maintenance requirements, the market benefits from the increasing demand for sustainable and versatile packaging solutions. With a focus on customization, sustainability, automation, and market expansion, the Composite Cans Machine Market is set for continued growth, catering to evolving packaging needs across industries.

What is Composite Cans Machine?

Composite Cans Machine refers to equipment used in the production of composite cans, which are cylindrical containers made from layers of paperboard and other materials. These machines are essential in various industries for packaging products such as food, beverages, and consumer goods.

What are the key players in the Composite Cans Machine market?

Key players in the Composite Cans Machine market include companies like Sonoco Products Company, WestRock Company, and Smurfit Kappa Group, among others. These companies are known for their innovative packaging solutions and advanced manufacturing technologies.

What are the growth factors driving the Composite Cans Machine market?

The growth of the Composite Cans Machine market is driven by increasing demand for sustainable packaging solutions, the rise in consumer preference for eco-friendly products, and the expansion of the food and beverage industry. Additionally, innovations in packaging technology are enhancing production efficiency.

What challenges does the Composite Cans Machine market face?

The Composite Cans Machine market faces challenges such as high initial investment costs and competition from alternative packaging materials. Additionally, fluctuations in raw material prices can impact production costs and profitability.

What opportunities exist in the Composite Cans Machine market?

Opportunities in the Composite Cans Machine market include the growing trend towards sustainable packaging and the potential for expansion into emerging markets. Furthermore, advancements in automation and smart manufacturing technologies present new avenues for growth.

What trends are shaping the Composite Cans Machine market?

Trends shaping the Composite Cans Machine market include the increasing adoption of recyclable materials, the integration of digital printing technologies, and a focus on reducing carbon footprints in manufacturing processes. These trends are influencing how companies design and produce composite cans.

Composite Cans Machine market

| Segmentation Details | Description |

|---|---|

| Product Type | Standard Cans, Specialty Cans, Eco-Friendly Cans, Custom Cans |

| End User | Food & Beverage, Personal Care, Household Products, Industrial Applications |

| Material | Aluminum, Steel, Biodegradable Materials, Composite Materials |

| Technology | Automated Systems, Manual Systems, Hybrid Systems, Smart Technology |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Composite Cans Machine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at