444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The Commercial Aircraft Aerostructures Market is a critical sector within the aviation industry that encompasses the design, manufacturing, and assembly of aircraft components and structures. Aerostructures are essential elements of an aircraft, providing structural integrity, aerodynamics, and stability during flight. These components include wings, fuselage, empennage (tail section), and nacelles, among others. The market’s growth is directly influenced by the demand for new aircraft as well as the replacement of aging fleets with more fuel-efficient and technologically advanced models.

Meaning

Commercial aircraft aerostructures refer to the structural components and assemblies that form the physical framework of an aircraft. They are engineered to withstand various aerodynamic forces and provide support to the aircraft’s body and systems. Aerostructures play a vital role in ensuring the safety, efficiency, and performance of modern commercial airplanes. Companies specializing in aerostructures are responsible for design, testing, and production, adhering to stringent industry regulations and safety standards.

Executive Summary

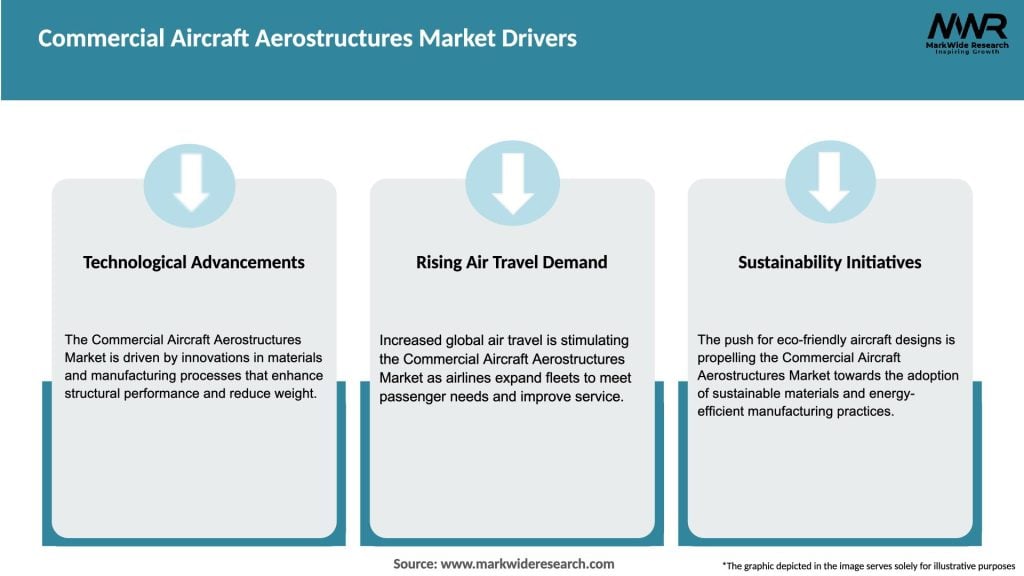

The Commercial Aircraft Aerostructures Market has experienced substantial growth in recent years due to increased air travel demands, expanding fleets, and technological advancements in aircraft design. With an emphasis on fuel efficiency, lightweight materials, and environmental sustainability, the market has witnessed notable developments to meet the growing requirements of the aviation industry. This executive summary provides a concise overview of the key market insights, drivers, restraints, opportunities, and market dynamics that will be explored in detail throughout this report.

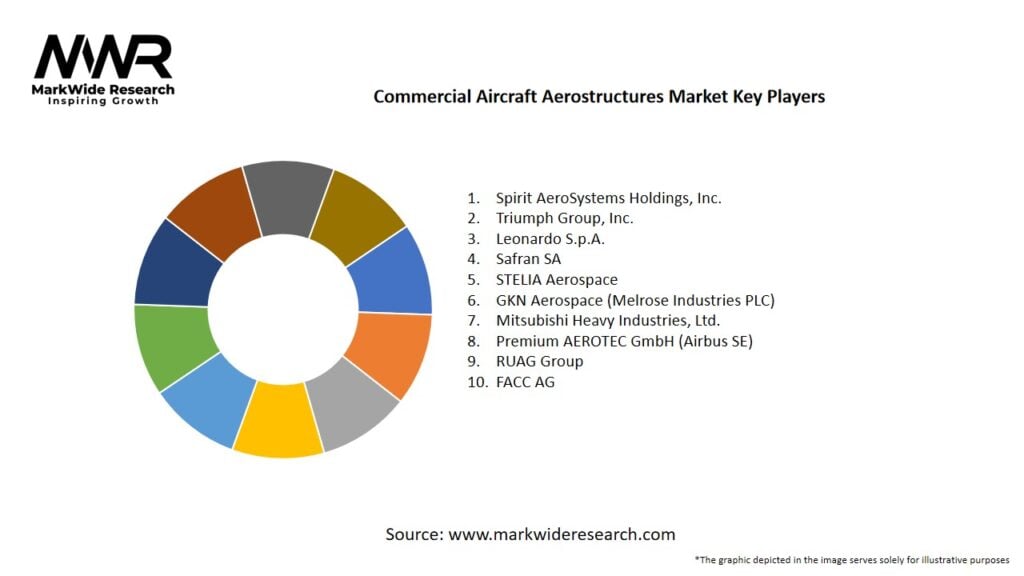

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

The Commercial Aircraft Aerostructures Market is witnessing a significant surge in demand as airlines seek to modernize their fleets and enhance fuel efficiency. Key market insights reveal that the growing adoption of advanced composite materials in aerostructure manufacturing is gaining momentum due to their lightweight and high-strength properties. Additionally, increasing investments in research and development, coupled with innovative manufacturing techniques, are fostering the market’s growth. The rising focus on eco-friendly aircraft designs and the emergence of urban air mobility are also driving factors for the aerostructures market.

Market Drivers

Several drivers fuel the expansion of the Commercial Aircraft Aerostructures Market. One of the primary drivers is the robust growth of the aviation industry worldwide. With the rising number of passengers opting for air travel, airlines are looking to expand and modernize their fleets, creating a substantial demand for new commercial aircraft and aerostructures. Furthermore, stringent regulations and emissions standards set by regulatory authorities are compelling airlines to adopt fuel-efficient aircraft, thereby boosting the demand for advanced aerostructures.

Market Restraints

Despite the optimistic outlook, the Commercial Aircraft Aerostructures Market faces some significant challenges. A key restraint is the high cost associated with the development and manufacturing of aerostructures. The complex design processes and the use of advanced materials increase production expenses, making it challenging for smaller players to enter the market. Moreover, geopolitical tensions and economic uncertainties may also hinder market growth, as they can lead to fluctuations in air travel demands and aircraft orders.

Market Opportunities

The market presents numerous opportunities for stakeholders and participants. The increasing focus on aircraft weight reduction to improve fuel efficiency opens up opportunities for the adoption of advanced lightweight materials in aerostructure manufacturing. Additionally, the growing interest in sustainable aviation and electric aircraft technologies provides avenues for companies to invest in research and development of eco-friendly aerostructures. Furthermore, the expansion of the global aerospace industry into emerging markets offers new prospects for market players to explore untapped regions and establish a strong foothold.

Market Dynamics

The Commercial Aircraft Aerostructures Market operates in a dynamic environment influenced by various factors. The interplay of market drivers, restraints, and opportunities shapes the industry’s trajectory. Additionally, market dynamics are impacted by technological advancements, customer preferences, regulatory changes, and geopolitical developments. Understanding these dynamics is crucial for stakeholders to make informed decisions and strategize effectively in a rapidly evolving market.

Regional Analysis

The Commercial Aircraft Aerostructures Market exhibits varying patterns across different regions. North America remains a dominant player due to the presence of major aerospace companies and substantial investments in research and development. Europe follows closely, boasting a well-established aerospace industry with a focus on sustainable aviation. Asia Pacific has emerged as a significant market, driven by the rising demand for air travel and the growth of budget airlines. The Middle East and Latin America also present opportunities for market expansion, driven by the expansion of airline fleets and increasing air travel connectivity.

Competitive Landscape

Leading Companies in the Commercial Aircraft Aerostructures Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

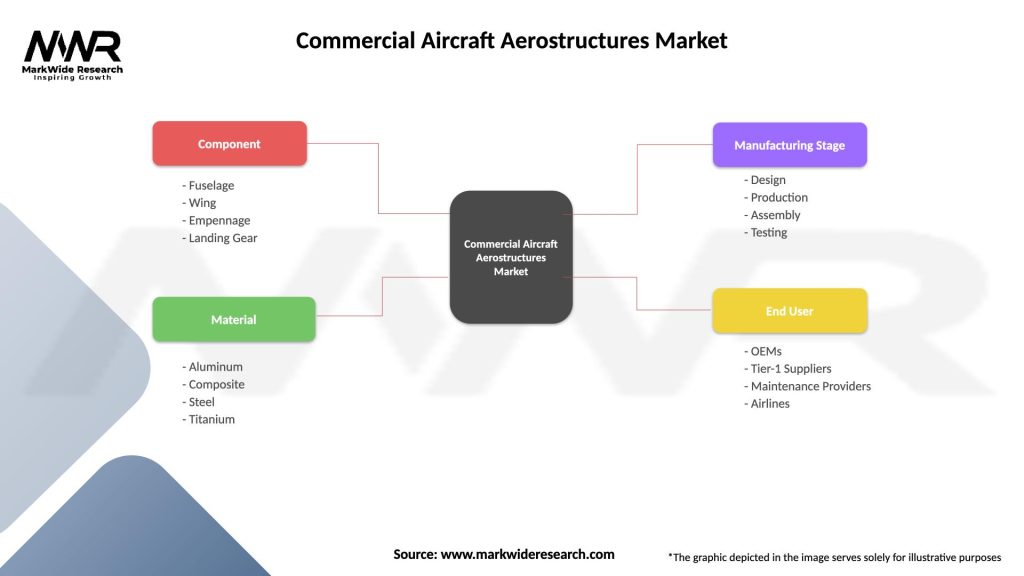

Segmentation

The Commercial Aircraft Aerostructures Market can be segmented based on various factors, including aircraft type, component, material, and end-user. Aircraft type segmentation involves categorizing aerostructures based on commercial aircraft models, such as narrow-body, wide-body, and regional jets. Component segmentation includes wings, fuselage, empennage, flight control surfaces, and nacelles, among others. The material segment comprises traditional metals and advanced composites, while end-user segmentation involves distinguishing between original equipment manufacturers (OEMs) and aftermarket services.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

The Commercial Aircraft Aerostructures Market offers various benefits to industry participants and stakeholders:

SWOT Analysis

A SWOT analysis provides an assessment of the Commercial Aircraft Aerostructures Market’s strengths, weaknesses, opportunities, and threats:

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Several key trends shape the Commercial Aircraft Aerostructures Market:

Covid-19 Impact

The Covid-19 pandemic had a significant impact on the Commercial Aircraft Aerostructures Market. The aviation industry faced a severe downturn, with travel restrictions and border closures leading to reduced air travel demand. Airlines deferred new aircraft orders and focused on fleet preservation, impacting aerostructure manufacturers. However, the pandemic also accelerated the adoption of eco-friendly and fuel-efficient aircraft, leading to increased demand for advanced aerostructures to retrofit existing fleets and cater to future aircraft orders.

Key Industry Developments

The Commercial Aircraft Aerostructures Market has witnessed several key developments:

Analyst Suggestions

Future Outlook

The future outlook for the Commercial Aircraft Aerostructures Market remains positive, driven by factors such as increasing air travel demand, advancements in aerostructure technologies, and a focus on sustainable aviation. As the aerospace industry continues to recover from the pandemic’s impact, aircraft manufacturers and aerostructure suppliers are expected to witness renewed growth. The adoption of electric aircraft and urban air mobility concepts presents exciting opportunities for aerostructure manufacturers to contribute to the next generation of aviation.

Conclusion

The Commercial Aircraft Aerostructures Market is a vital segment within the aviation industry, encompassing the design and manufacturing of essential aircraft components. With an ever-increasing demand for fuel-efficient and technologically advanced commercial aircraft, the market has experienced significant growth in recent years. While facing challenges related to high production costs and economic uncertainties, the market presents numerous opportunities for industry participants and stakeholders. Leveraging advanced materials, investing in sustainable practices, and embracing innovation will be critical for companies seeking to maintain a competitive edge in this dynamic market. As the aerospace industry continues to evolve, aerostructure manufacturers must adapt to emerging trends and technologies to shape the future of commercial aviation.

What is Commercial Aircraft Aerostructures?

Commercial Aircraft Aerostructures refer to the various structural components of an aircraft, including wings, fuselage, and tail sections, that are essential for its integrity and performance. These components are designed to withstand aerodynamic forces and ensure safety during flight.

What are the key players in the Commercial Aircraft Aerostructures Market?

Key players in the Commercial Aircraft Aerostructures Market include Boeing, Airbus, and Lockheed Martin, which are known for their extensive experience in aerospace manufacturing. Other notable companies include Spirit AeroSystems and Bombardier, among others.

What are the growth factors driving the Commercial Aircraft Aerostructures Market?

The growth of the Commercial Aircraft Aerostructures Market is driven by increasing air travel demand, advancements in lightweight materials, and the need for fuel-efficient aircraft designs. Additionally, the rise in aircraft production rates contributes to market expansion.

What challenges does the Commercial Aircraft Aerostructures Market face?

The Commercial Aircraft Aerostructures Market faces challenges such as high manufacturing costs, stringent regulatory requirements, and supply chain disruptions. These factors can impact production timelines and overall market growth.

What opportunities exist in the Commercial Aircraft Aerostructures Market?

Opportunities in the Commercial Aircraft Aerostructures Market include the development of sustainable aviation technologies and the integration of advanced manufacturing techniques like additive manufacturing. These innovations can enhance efficiency and reduce environmental impact.

What trends are shaping the Commercial Aircraft Aerostructures Market?

Trends in the Commercial Aircraft Aerostructures Market include the increasing use of composite materials for weight reduction and improved fuel efficiency. Additionally, digital transformation and automation in manufacturing processes are becoming more prevalent.

Commercial Aircraft Aerostructures Market

| Segmentation Details | Description |

|---|---|

| Component | Fuselage, Wing, Empennage, Landing Gear |

| Material | Aluminum, Composite, Steel, Titanium |

| Manufacturing Stage | Design, Production, Assembly, Testing |

| End User | OEMs, Tier-1 Suppliers, Maintenance Providers, Airlines |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Commercial Aircraft Aerostructures Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at