444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The Collaborative Robotic Systems Market refers to the rapidly growing industry that focuses on the development and deployment of robots that can safely collaborate and work alongside humans. Collaborative robots, also known as cobots, are designed to interact and cooperate with humans in shared workspaces, rather than being confined to separate, isolated areas. These robots are equipped with advanced sensors, safety features, and intuitive programming interfaces that enable them to perform a wide range of tasks while ensuring the safety of human workers.

Meaning

Collaborative robotic systems are revolutionizing various industries by enhancing productivity, efficiency, and flexibility in manufacturing processes. Unlike traditional industrial robots that require dedicated workspaces and extensive safety measures, cobots offer a new paradigm of automation. They are specifically designed to work alongside humans, facilitating close collaboration and interaction. Cobots can be easily programmed and reprogrammed to perform different tasks, making them highly versatile and adaptable to changing production needs.

Executive Summary

The collaborative robotic systems market has witnessed significant growth in recent years, driven by the increasing demand for automation across various industries. The market is characterized by the presence of several key players, technological advancements, and a growing emphasis on human-robot collaboration. Collaborative robots are being increasingly adopted in industries such as manufacturing, healthcare, logistics, and agriculture, among others. These robots offer benefits such as increased productivity, improved safety, and enhanced operational efficiency.

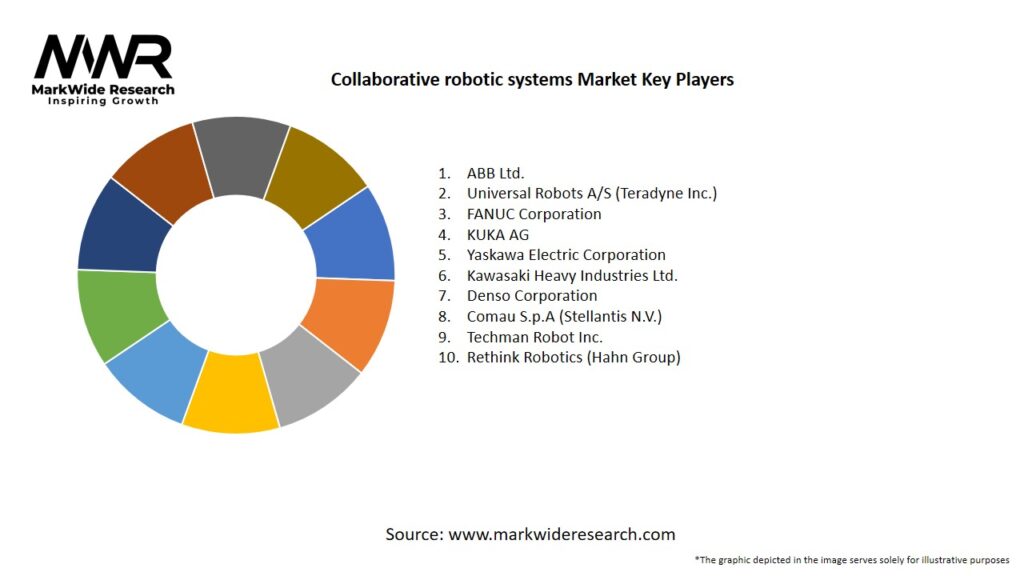

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The collaborative robotic systems market is driven by a combination of technological advancements, industry demands for automation, and evolving safety regulations. As organizations increasingly recognize the benefits of human-robot collaboration, the demand for collaborative robotic systems is expected to continue growing. Additionally, the market is characterized by intense competition, with key players focusing on innovation, partnerships, and acquisitions to gain a competitive edge. The market dynamics are influenced by factors such as customer preferences, economic conditions, and technological disruptions.

Regional Analysis

The collaborative robotic systems market exhibits a global presence, with significant growth observed across various regions. North America and Europe have traditionally been at the forefront of technological advancements and adoption of automation solutions. These regions have a high concentration of manufacturers and are early adopters of collaborative robots. Asia Pacific is witnessing rapid growth due to the presence of manufacturing hubs, such as China, Japan, and South Korea, along with increasing investments in automation technologies. Emerging markets in Latin America, the Middle East, and Africa are also expected to offer substantial growth opportunities.

Competitive Landscape

Leading Companies in the Collaborative Robotic Systems Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

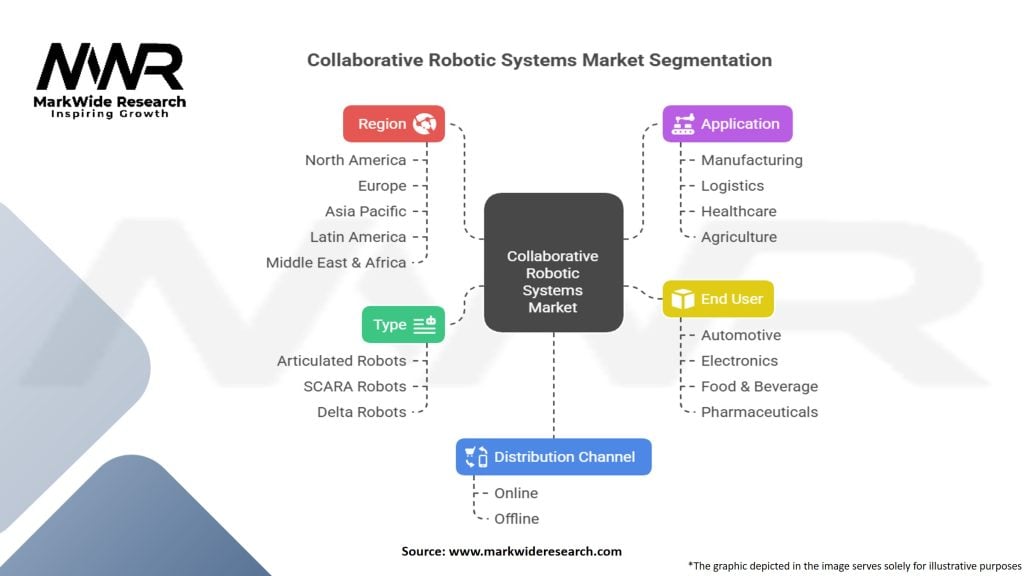

Segmentation

The collaborative robotic systems market can be segmented based on various factors, including application, payload capacity, industry vertical, and geography. By application, the market can be divided into material handling, assembly, welding, inspection, and packaging, among others. Based on payload capacity, cobots can be classified as up to 5 kg, 5-10 kg, and above 10 kg. Industry verticals that extensively utilize collaborative robotic systems include automotive, electronics, healthcare, logistics, and aerospace, among others.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

A SWOT analysis of the collaborative robotic systems market provides an assessment of its strengths, weaknesses, opportunities, and threats.

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has had both positive and negative impacts on the collaborative robotic systems market. On the positive side, the pandemic has highlighted the importance of automation and the need for resilient and adaptable manufacturing processes. As companies strive to maintain operations amid social distancing measures and workforce limitations, the demand for collaborative robots has surged.

Collaborative robots have been deployed in various industries to ensure social distancing, enable remote operations, and enhance safety measures. They have played a critical role in supporting essential sectors, such as healthcare and logistics, during the pandemic. Additionally, the pandemic has accelerated the adoption of digitalization and Industry 4.0 technologies, further driving the demand for collaborative robotic systems.

However, the pandemic has also posed challenges for the market. Supply chain disruptions, economic uncertainties, and reduced capital expenditure have impacted the implementation of collaborative robotic systems in some industries. The initial investment required for cobots may have been deprioritized by companies facing financial constraints. Furthermore, travel restrictions and lockdown measures have affected the installation, maintenance, and servicing of collaborative robotic systems.

Despite the challenges, the long-term outlook for the collaborative robotic systems market remains positive. The pandemic has underscored the value of automation and the importance of resilient and adaptable manufacturing processes, which are expected to drive the demand for collaborative robots in the post-pandemic era.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future of the collaborative robotic systems market looks promising, driven by ongoing advancements in technology, increasing demand for automation, and the need for safe and flexible manufacturing processes. Collaborative robots are expected to play a crucial role in Industry 4.0 transformation, enabling intelligent and connected manufacturing ecosystems.

As the market matures, collaborative robotic systems will become more affordable, user-friendly, and capable of handling complex tasks. Integration with emerging technologies, such as artificial intelligence, cloud computing, and IoT, will further enhance the capabilities of cobots and expand their application areas.

Moreover, the ongoing digital transformation and the adoption of automation across various industries will drive the demand for collaborative robots. The market will witness increased competition and strategic partnerships among key players, resulting in innovative solutions and improved value propositions for customers.

Conclusion

In conclusion, collaborative robotic systems are revolutionizing industries by enabling human-robot collaboration and transforming manufacturing processes. The market is poised for growth, driven by factors such as increasing automation demand, advancements in technology, and a focus on safety and efficiency. With continued innovation and widespread adoption, collaborative robotic systems are set to shape the future of manufacturing and beyond.

What is Collaborative robotic systems?

Collaborative robotic systems refer to robots designed to work alongside humans in a shared workspace. These systems enhance productivity and safety in various applications, including manufacturing, logistics, and healthcare.

What are the key players in the Collaborative robotic systems Market?

Key players in the Collaborative robotic systems Market include Universal Robots, KUKA, ABB, and FANUC, among others. These companies are known for their innovative solutions and contributions to the development of collaborative robots.

What are the main drivers of growth in the Collaborative robotic systems Market?

The main drivers of growth in the Collaborative robotic systems Market include the increasing demand for automation in manufacturing, the need for enhanced workplace safety, and the rising adoption of Industry Four-point-oh technologies.

What challenges does the Collaborative robotic systems Market face?

The Collaborative robotic systems Market faces challenges such as high initial investment costs, integration complexities with existing systems, and concerns regarding job displacement among workers.

What opportunities exist in the Collaborative robotic systems Market?

Opportunities in the Collaborative robotic systems Market include advancements in artificial intelligence and machine learning, which can enhance robot capabilities, and the growing trend of automation in small and medium-sized enterprises.

What trends are shaping the Collaborative robotic systems Market?

Trends shaping the Collaborative robotic systems Market include the increasing use of lightweight materials in robot design, the development of more intuitive user interfaces, and the expansion of collaborative robots into new sectors such as agriculture and healthcare.

Collaborative Robotic Systems Market Segmentations

| Segment | Details |

|---|---|

| Type | Articulated Robots, SCARA Robots, Delta Robots |

| Application | Manufacturing, Logistics, Healthcare, Agriculture |

| End User | Automotive, Electronics, Food & Beverage, Pharmaceuticals |

| Distribution Channel | Online, Offline (Robotics Suppliers, Distributors) |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Collaborative Robotic Systems Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at