444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The Cobalt 60 sterilization equipment market has witnessed substantial growth in recent years, driven by the increasing demand for sterilization solutions across various industries such as healthcare, food processing, and pharmaceuticals. Cobalt 60 sterilization equipment utilizes gamma radiation emitted by Cobalt-60 isotopes to effectively sterilize medical devices, pharmaceutical products, food packaging, and other sensitive materials. This comprehensive market overview aims to provide insights into various aspects of the Cobalt 60 sterilization equipment market, including its current state, key trends, competitive landscape, and future prospects.

Meaning

Cobalt 60 sterilization equipment refers to specialized devices and systems used for sterilizing medical equipment, pharmaceutical products, and food packaging using gamma radiation emitted by Cobalt-60 isotopes. Cobalt 60 sterilization is a widely recognized method for achieving high levels of sterility and ensuring product safety and efficacy. These sterilization systems are employed across various industries to eliminate microorganisms, including bacteria, viruses, and spores, from surfaces and materials without the need for heat or chemicals.

Executive Summary

The Cobalt 60 sterilization equipment market is experiencing steady growth, fueled by the increasing emphasis on product safety and quality assurance across industries, stringent regulatory requirements, and advancements in sterilization technologies. Key players in the market are focusing on product innovation, strategic partnerships, and geographic expansion to capitalize on emerging opportunities and address evolving customer needs.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Cobalt 60 sterilization equipment market is characterized by technological innovation, regulatory compliance, and industry consolidation. Manufacturers and suppliers of Cobalt 60 sterilization equipment are continuously investing in research and development to improve product performance, enhance safety features, and address regulatory requirements. Additionally, strategic partnerships, mergers, and acquisitions are shaping the competitive landscape of the market, as companies seek to expand their product portfolios, geographic presence, and market share.

Regional Analysis

Geographically, North America dominates the Cobalt 60 sterilization equipment market, owing to the presence of leading healthcare facilities, stringent regulatory frameworks, and widespread adoption of sterilization technologies. Europe follows closely, with significant investments in pharmaceutical manufacturing, medical device production, and food processing industries. The Asia Pacific region presents lucrative opportunities for market growth, driven by increasing healthcare expenditure, growing awareness about infection control measures, and expanding pharmaceutical and food industries.

Competitive Landscape

Leading Companies in the Cobalt 60 Sterilization Equipment Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

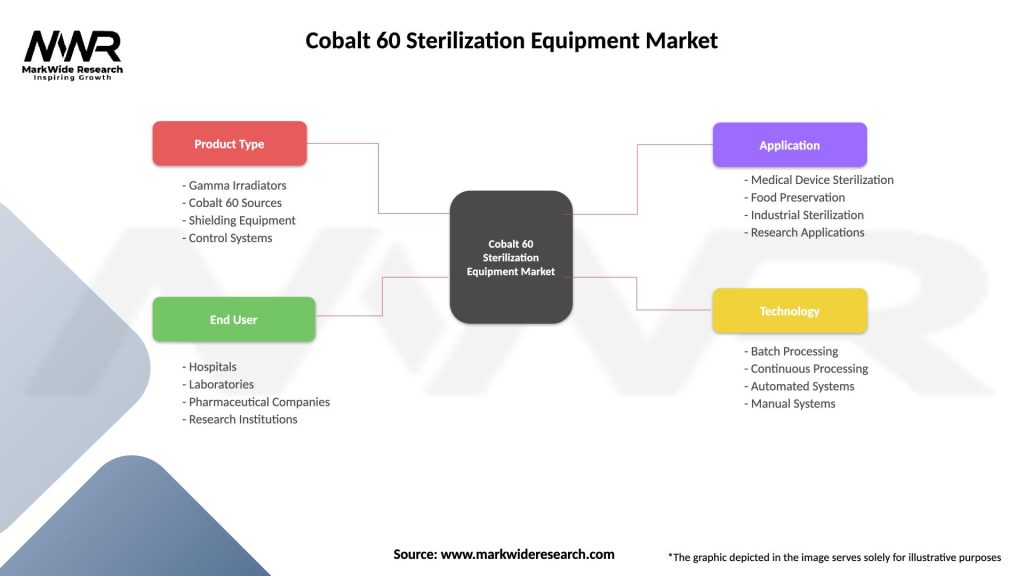

Segmentation

The Cobalt 60 sterilization equipment market can be segmented based on:

Understanding these segmentation factors enables manufacturers and suppliers to tailor their product offerings and marketing strategies to meet the specific needs of target customers and address niche market segments.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

Industry participants and stakeholders benefit from Cobalt 60 sterilization equipment in several ways, including ensuring product safety and quality, complying with regulatory requirements, and reducing the risk of contamination and product recalls. By leveraging Cobalt 60 sterilization technology, manufacturers and suppliers can enhance their competitiveness, meet customer expectations, and contribute to public health and safety.

SWOT Analysis

Strengths

• Cobalt 60 sterilization equipment is highly effective, offering superior penetration capabilities that ensure thorough sterilization of various medical and pharmaceutical products.

• The technology is well-established and widely recognized in the healthcare industry, leading to a strong trust and reliability among users and stakeholders.

• Cobalt 60 sources provide a consistent and controlled sterilization process, which is crucial for maintaining the integrity of sensitive medical devices and materials.

• The growing demand for sterilization in healthcare settings has led to advancements in Cobalt 60 technology, enhancing operational efficiency and reducing turnaround times.

Weaknesses

• The initial investment and operational costs associated with Cobalt 60 sterilization equipment can be significant, limiting accessibility for smaller facilities.

• Regulatory compliance and safety concerns surrounding the use of radioactive materials may deter some potential users from adopting this technology.

• The dependency on a consistent supply of Cobalt 60 can lead to vulnerabilities in operations if supply chains are disrupted or if there are fluctuations in availability.

• Limited awareness and understanding of the benefits of Cobalt 60 sterilization among certain segments of the healthcare market may hinder broader adoption.

Opportunities

• The increasing global emphasis on infection control and patient safety presents a significant growth opportunity for Cobalt 60 sterilization equipment in healthcare settings.

• Emerging markets are experiencing a rise in healthcare infrastructure development, creating demand for advanced sterilization solutions like Cobalt 60.

• Innovations in equipment design and automation can enhance the efficiency and effectiveness of Cobalt 60 sterilization processes, attracting new customers.

• Collaborations with research institutions and healthcare organizations can lead to advancements in sterilization techniques, further expanding the market potential.

Threats

• The emergence of alternative sterilization technologies, such as ethylene oxide and hydrogen peroxide plasma, poses competitive pressure on the Cobalt 60 market.

• Stringent regulatory frameworks governing radioactive materials may impose additional compliance burdens, impacting operational flexibility and costs.

Market Key Trends

Several key trends are shaping the Cobalt 60 sterilization equipment market, including the adoption of automation and robotics for process optimization and efficiency, the development of advanced dosimetry and monitoring systems for radiation safety, and the integration of quality management systems for regulatory compliance and product traceability. Additionally, there is a growing emphasis on sustainable practices and environmental stewardship, driving demand for eco-friendly packaging materials and sterilization methods.

Covid-19 Impact

The Covid-19 pandemic has highlighted the critical importance of sterilization technologies in ensuring public health and safety, driving demand for Cobalt 60 sterilization equipment in healthcare facilities, pharmaceutical manufacturing, and food processing industries. The pandemic has underscored the need for reliable and scalable sterilization solutions to prevent the spread of infectious diseases and ensure the safety of frontline workers and consumers. While the pandemic has presented challenges such as supply chain disruptions and regulatory complexities, it has also accelerated investments in sterilization technologies and raised awareness about infection control measures.

Key Industry Developments

Key industry developments in the Cobalt 60 sterilization equipment market include the development of advanced dosimetry systems for dose mapping and optimization, investments in facility upgrades and infrastructure expansion to meet growing demand, and collaborations between industry stakeholders and regulatory agencies to address radiation safety concerns and ensure compliance with regulatory requirements. Additionally, there is growing research and development activity focused on improving Cobalt 60 sterilization technology, enhancing process efficiency, and reducing environmental impact.

Analyst Suggestions

Analysts suggest several strategies for industry participants to navigate the evolving landscape of the Cobalt 60 sterilization equipment market, including investing in research and development to enhance product performance and safety features, strengthening regulatory compliance and quality management systems, and fostering collaboration and engagement with stakeholders to address industry challenges and opportunities. By adopting these strategies, market players can position themselves for sustained success and contribute to advancements in sterilization technology and public health.

Future Outlook

The future outlook for the Cobalt 60 sterilization equipment market is promising, with continued growth expected in the coming years. The increasing demand for sterile medical devices, pharmaceutical products, and food packaging, coupled with advancements in Cobalt 60 sterilization technology, are driving market expansion. Additionally, there is growing awareness about the importance of infection control measures and regulatory compliance in various industries, further fueling demand for Cobalt 60 sterilization equipment. Moving forward, industry players are expected to focus on innovation, collaboration, and regulatory compliance to meet the evolving needs of customers and address the challenges and opportunities in the dynamic and rapidly evolving Cobalt 60 sterilization equipment market.

Conclusion

In conclusion, the Cobalt 60 sterilization equipment market plays a critical role in ensuring product safety, quality assurance, and infection control across various industries. Cobalt 60 sterilization technology offers an effective and reliable solution for achieving high levels of sterility and preventing the spread of infectious diseases. Despite challenges such as regulatory complexities and radiation safety concerns, the market continues to witness steady growth, driven by increasing demand from healthcare, pharmaceutical, and food processing industries. By embracing innovation, regulatory compliance, and industry collaboration, market participants can capitalize on emerging opportunities and contribute to advancements in Cobalt 60 sterilization technology and public health.

What is Cobalt 60 Sterilization Equipment?

Cobalt 60 Sterilization Equipment refers to devices that utilize cobalt-60 isotopes for the sterilization of medical instruments, pharmaceuticals, and food products. This method is widely recognized for its effectiveness in eliminating bacteria, viruses, and other pathogens.

What are the key players in the Cobalt 60 Sterilization Equipment Market?

Key players in the Cobalt 60 Sterilization Equipment Market include companies like Nordion, Inc., Gamma Service, and Sterigenics, which are known for their advanced sterilization technologies and services, among others.

What are the growth factors driving the Cobalt 60 Sterilization Equipment Market?

The growth of the Cobalt 60 Sterilization Equipment Market is driven by the increasing demand for sterilized medical devices, the rise in healthcare-associated infections, and the expansion of the pharmaceutical industry requiring effective sterilization methods.

What challenges does the Cobalt 60 Sterilization Equipment Market face?

Challenges in the Cobalt 60 Sterilization Equipment Market include regulatory hurdles related to the use of radioactive materials, the high cost of equipment, and competition from alternative sterilization methods such as ethylene oxide and steam sterilization.

What opportunities exist in the Cobalt 60 Sterilization Equipment Market?

Opportunities in the Cobalt 60 Sterilization Equipment Market include advancements in radiation technology, increasing applications in the food industry for shelf-life extension, and growing awareness of the benefits of radiation sterilization in developing regions.

What trends are shaping the Cobalt 60 Sterilization Equipment Market?

Trends in the Cobalt 60 Sterilization Equipment Market include the integration of automation in sterilization processes, the development of more efficient cobalt-60 sources, and a growing focus on sustainability and environmental safety in sterilization practices.

Cobalt 60 Sterilization Equipment Market

| Segmentation Details | Description |

|---|---|

| Product Type | Gamma Irradiators, Cobalt 60 Sources, Shielding Equipment, Control Systems |

| End User | Hospitals, Laboratories, Pharmaceutical Companies, Research Institutions |

| Application | Medical Device Sterilization, Food Preservation, Industrial Sterilization, Research Applications |

| Technology | Batch Processing, Continuous Processing, Automated Systems, Manual Systems |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Cobalt 60 Sterilization Equipment Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at