444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The CHO (Chinese Hamster Ovary) Medium market is experiencing steady growth driven by the increasing demand for cell culture media and reagents in biopharmaceutical and biotechnology industries. CHO cells are widely used in the production of therapeutic proteins, monoclonal antibodies, vaccines, and viral vectors due to their high protein expression levels, post-translational modification capabilities, and regulatory acceptance. CHO media play a critical role in supporting cell growth, viability, and productivity during bioprocess development, scale-up, and manufacturing of biologics.

Meaning

CHO Medium refers to the specialized cell culture media formulations designed for the growth and maintenance of CHO cells in laboratory and industrial settings. These media are optimized to provide essential nutrients, vitamins, minerals, amino acids, and growth factors required for CHO cell proliferation, protein synthesis, and product quality attributes. CHO media formulations may vary based on cell line characteristics, culture conditions, and process requirements, aiming to maximize cell productivity, product yield, and bioprocess performance.

Executive Summary

The CHO Medium market is driven by the growing demand for biologics, biosimilars, and cell-based therapies, coupled with advancements in cell line engineering, bioprocess optimization, and regulatory compliance. Key players in the market are focusing on developing innovative CHO media formulations, improving manufacturing processes, and expanding market reach to meet the evolving needs of biopharmaceutical manufacturers. With the increasing complexity and diversity of biologics, CHO media are expected to play a pivotal role in enabling efficient and cost-effective bioproduction processes.

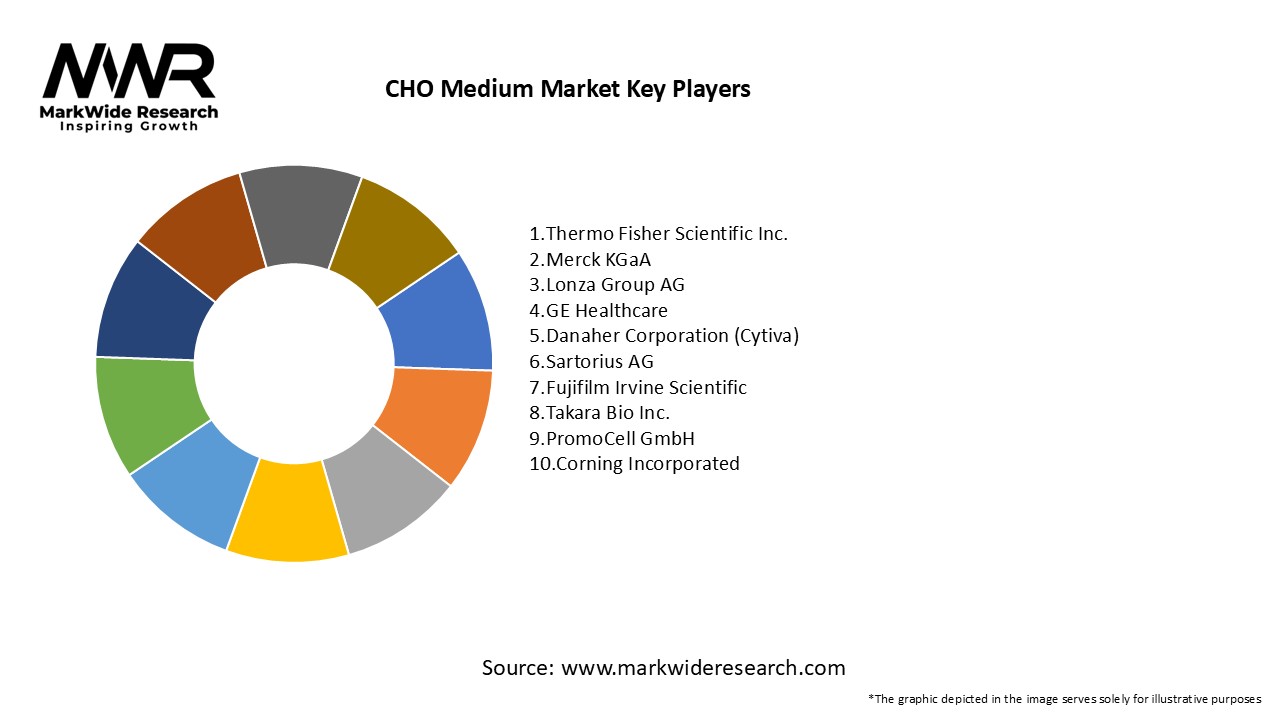

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The CHO Medium market is characterized by dynamic market dynamics, including technological advancements, regulatory developments, and changing customer preferences. Market players need to stay abreast of these dynamics by investing in research and development, regulatory compliance, and market intelligence. Moreover, strategic partnerships, acquisitions, and collaborations are essential for driving innovation, expanding market reach, and sustaining growth in the CHO Medium market.

Regional Analysis

North America dominates the global CHO Medium market, driven by the presence of leading biopharmaceutical companies, contract manufacturing organizations (CMOs), and academic research institutions. The region’s well-established biotechnology ecosystem, favorable regulatory environment, and robust healthcare infrastructure contribute to market leadership. Europe and Asia-Pacific are also significant markets for CHO media, with increasing investments in biopharmaceutical research, manufacturing, and innovation. Emerging markets in Latin America, the Middle East, and Africa offer growth opportunities due to rising healthcare expenditures, increasing access to biologics, and supportive government initiatives.

Competitive Landscape

Leading Companies in CHO Medium Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The CHO Medium market can be segmented based on product type, formulation type, application, end-user, and region. Product types include serum-containing media, serum-free media, chemically defined media, and specialized media supplements. Formulation types encompass liquid media, powdered media, and concentrated media formulations. Applications of CHO media include monoclonal antibody production, recombinant protein expression, vaccine manufacturing, and viral vector production. End-users of CHO media include biopharmaceutical companies, contract manufacturing organizations (CMOs), academic research laboratories, and regulatory agencies.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has underscored the importance of biopharmaceutical manufacturing and innovation in addressing global health challenges. While the pandemic has led to disruptions in supply chains, laboratory operations, and clinical trials, it has also accelerated the development and production of vaccines, monoclonal antibodies, and other biologics for Covid-19 prevention and treatment. Moreover, the pandemic has highlighted the resilience and adaptability of biopharmaceutical companies, contract manufacturers, and research institutions in responding to emerging infectious diseases and public health crises.

Key Industry Developments

Analyst Suggestions

Future Outlook

The CHO Medium market is poised for continued growth and innovation, driven by increasing demand for biologics, biosimilars, and cell-based therapies in healthcare, agriculture, and industrial applications. Market players should focus on product innovation, sustainability, and customer-centricity to stay competitive in the dynamic biopharmaceutical marketplace. Moreover, strategic partnerships, regulatory compliance, and market intelligence will be essential for navigating market complexities, sustaining growth, and delivering value to stakeholders in the CHO Medium market.

Conclusion

In conclusion, the CHO Medium market offers significant growth opportunities for cell culture media suppliers, biopharmaceutical manufacturers, and contract manufacturing organizations seeking to meet the increasing demand for biologics and vaccines. With the advantages of high protein expression levels, regulatory acceptance, and customizable formulations, CHO media play a critical role in supporting efficient and scalable bioproduction processes. By embracing innovation, collaboration, and sustainability, the CHO Medium market can contribute to advancing biopharmaceutical research, manufacturing, and healthcare delivery, ultimately improving patient outcomes and public health worldwide.

What is CHO Medium?

CHO Medium refers to a type of culture medium used in microbiology for the growth of specific microorganisms, particularly in laboratory settings. It is designed to support the growth of cells and is essential for various applications in research and biotechnology.

What are the key players in the CHO Medium Market?

Key players in the CHO Medium Market include companies such as Thermo Fisher Scientific, Merck KGaA, and Sartorius AG, which provide a range of products and solutions for cell culture. These companies are known for their innovations in bioprocessing and cell line development, among others.

What are the growth factors driving the CHO Medium Market?

The CHO Medium Market is driven by the increasing demand for biopharmaceuticals and the growing focus on cell-based therapies. Additionally, advancements in cell culture technologies and the rising prevalence of chronic diseases are contributing to market growth.

What challenges does the CHO Medium Market face?

The CHO Medium Market faces challenges such as the high cost of specialized media and the complexity of optimizing culture conditions for different cell lines. Additionally, regulatory hurdles in biopharmaceutical production can impact market dynamics.

What opportunities exist in the CHO Medium Market?

Opportunities in the CHO Medium Market include the development of more efficient and cost-effective culture media and the expansion of applications in regenerative medicine. The increasing investment in research and development also presents significant growth potential.

What trends are shaping the CHO Medium Market?

Trends in the CHO Medium Market include the shift towards serum-free and chemically defined media, which enhance reproducibility and reduce variability in cell culture. Additionally, the integration of automation and digital technologies in bioprocessing is gaining traction.

CHO Medium Market

| Segmentation Details | Description |

|---|---|

| Product Type | CHO, Medium, High, Low |

| Application | Food Industry, Pharmaceuticals, Cosmetics, Nutraceuticals |

| End User | Manufacturers, Retailers, Distributors, Consumers |

| Packaging Type | Bottles, Tetra Packs, Pouches, Jars |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in CHO Medium Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at