444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview

The China protective coatings market refers to the industry that deals with the production, distribution, and application of coatings designed to protect various surfaces from damage, corrosion, and wear. Protective coatings are essential in preserving the longevity and aesthetic appeal of surfaces, such as metals, concrete, and wood, by providing a barrier against environmental factors and chemical exposure. This market has experienced significant growth in recent years, driven by the increasing demand from various end-use sectors, including automotive, aerospace, construction, and marine industries.

Meaning

Protective coatings are specialized formulations applied to surfaces to provide a layer of protection against factors that could potentially cause damage or deterioration. These coatings act as a shield, safeguarding surfaces from corrosion, abrasion, chemical attack, and UV radiation. They offer resistance to harsh environmental conditions, extend the lifespan of surfaces, and enhance their overall performance. Protective coatings can be applied through various methods, including spraying, brushing, and dipping, and they come in different forms such as liquid coatings, powder coatings, and specialty coatings.

Executive Summary

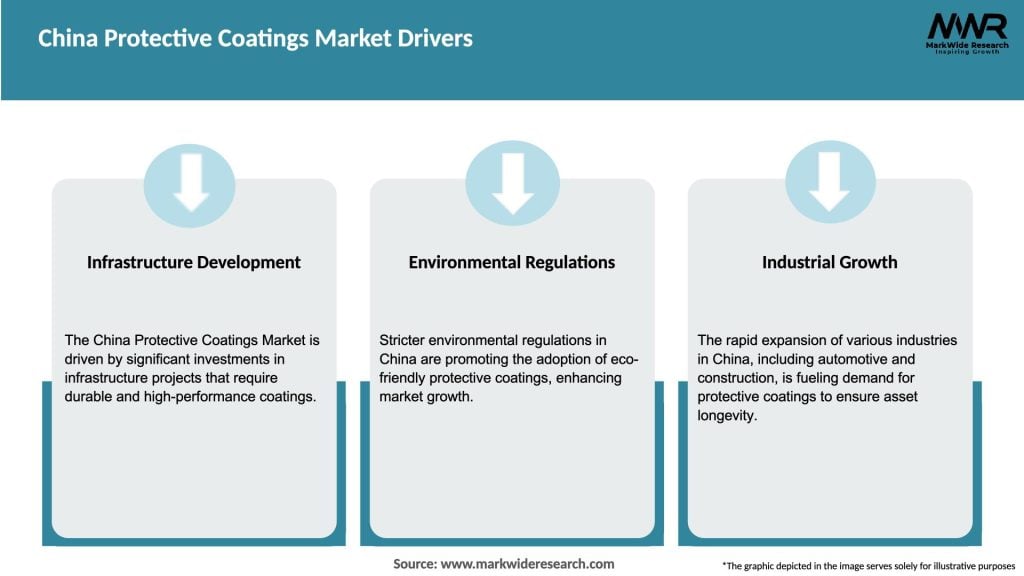

The China protective coatings market has witnessed substantial growth in recent years, driven by increasing industrialization, infrastructure development, and the need for advanced surface protection solutions. The market is characterized by a wide range of coatings, including epoxy, polyurethane, acrylic, alkyd, and silicone-based coatings, among others. These coatings find extensive applications in sectors such as automotive, oil and gas, marine, aerospace, construction, and electronics.

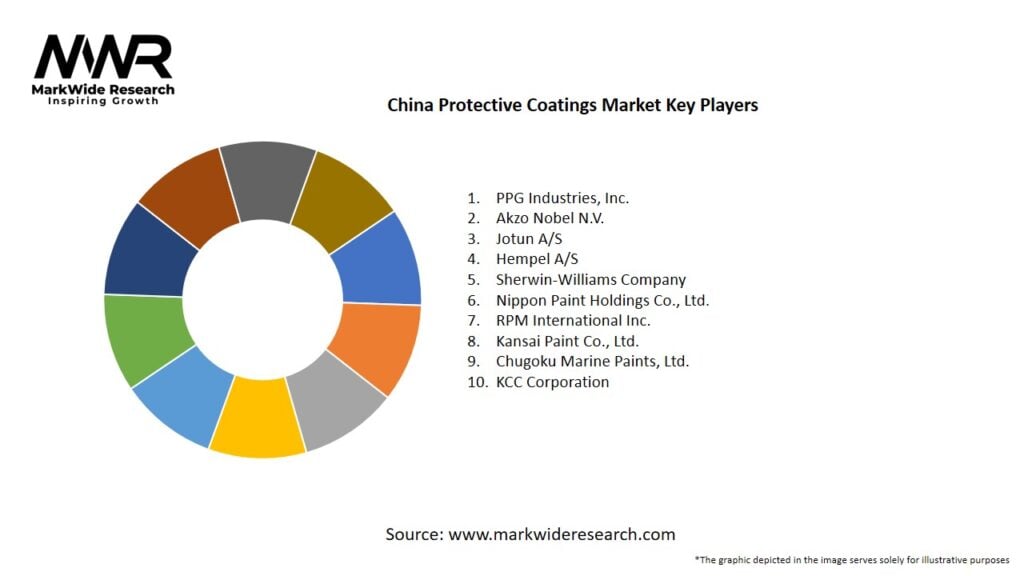

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The China protective coatings market is characterized by dynamic factors that influence its growth and competitiveness. These dynamics include market drivers, market restraints, market opportunities, and industry trends. Understanding and effectively responding to these dynamics are crucial for businesses operating in this market to remain competitive and capitalize on emerging opportunities.

Regional Analysis

China’s vast size and regional diversity contribute to variations in the demand for protective coatings across different regions. Coastal regions with heavy industrialization and marine activities often exhibit higher demand for marine coatings. Inland regions, particularly those experiencing rapid urbanization and infrastructure development, drive the demand for architectural and construction coatings. Moreover, regional variations in environmental regulations, economic conditions, and industrial activities also influence the market dynamics and demand patterns of protective coatings.

Competitive Landscape

Leading companies in the China Protective Coatings Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

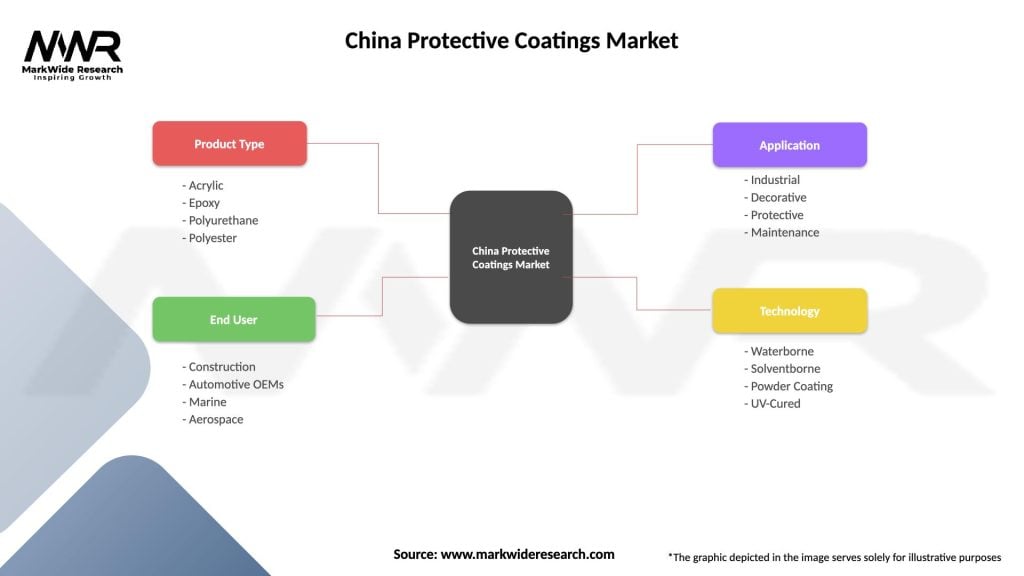

Segmentation

The China protective coatings market can be segmented based on various factors, including type of coating, end-use sector, and application method. Common segmentation categories include epoxy coatings, polyurethane coatings, acrylic coatings, alkyd coatings, powder coatings, liquid coatings, marine coatings, automotive coatings, industrial coatings, and architectural coatings.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic had a significant impact on the China protective coatings market. The initial outbreak led to disruptions in manufacturing and supply chains, causing a slowdown in production and sales. However, as the situation improved, the market witnessed a gradual recovery, driven by the resumption of industrial activities, infrastructure projects, and the rebound of the automotive sector. The pandemic also highlighted the importance of surface protection, leading to increased awareness and demand for protective coatings with antimicrobial properties.

Key Industry Developments

Analyst Suggestions

Future Outlook

The China protective coatings market is expected to continue its growth trajectory in the coming years. Factors such as rapid industrialization, infrastructure development, and increasing demand from end-use sectors will drive market expansion. Technological advancements, focus on sustainability, and emerging trends such as nanocoatings and self-healing coatings will shape the future of the market. However, challenges related to raw material prices, environmental regulations, and intense competition will require market participants to be agile, innovative, and customer-centric.

Conclusion

The China protective coatings market is a dynamic and competitive industry driven by the need to protect surfaces from damage, corrosion, and wear. With the country’s rapid industrialization, infrastructure development, and expanding automotive and marine industries, the demand for protective coatings is expected to rise. Key market players must adapt to market dynamics, invest in research and development, and focus on sustainable and innovative solutions to capitalize on the opportunities presented by this growing market. By addressing challenges and staying at the forefront of technological advancements, the China protective coatings market is poised for a promising future.

What is Protective Coatings?

Protective coatings are specialized materials applied to surfaces to protect them from corrosion, wear, and environmental damage. They are commonly used in industries such as construction, automotive, and marine.

What are the key players in the China Protective Coatings Market?

Key players in the China Protective Coatings Market include companies like PPG Industries, AkzoNobel, and Sherwin-Williams, which offer a range of protective coating solutions for various applications, among others.

What are the growth factors driving the China Protective Coatings Market?

The growth of the China Protective Coatings Market is driven by increasing industrialization, rising demand for durable and high-performance coatings, and the expansion of the construction sector.

What challenges does the China Protective Coatings Market face?

The China Protective Coatings Market faces challenges such as stringent environmental regulations, fluctuating raw material prices, and competition from alternative materials.

What opportunities exist in the China Protective Coatings Market?

Opportunities in the China Protective Coatings Market include the development of eco-friendly coatings, advancements in nanotechnology, and the growing demand for coatings in the automotive and aerospace industries.

What trends are shaping the China Protective Coatings Market?

Trends in the China Protective Coatings Market include the increasing focus on sustainability, the rise of smart coatings with self-healing properties, and the integration of digital technologies in coating applications.

China Protective Coatings Market

| Segmentation Details | Description |

|---|---|

| Product Type | Acrylic, Epoxy, Polyurethane, Polyester |

| End User | Construction, Automotive OEMs, Marine, Aerospace |

| Application | Industrial, Decorative, Protective, Maintenance |

| Technology | Waterborne, Solventborne, Powder Coating, UV-Cured |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the China Protective Coatings Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at