444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

The China insecticide market represents one of the most dynamic and rapidly evolving agricultural chemical sectors in the Asia-Pacific region. As the world’s largest agricultural producer and consumer of crop protection chemicals, China’s insecticide industry plays a crucial role in ensuring food security for over 1.4 billion people while supporting agricultural productivity across diverse farming systems. The market encompasses a comprehensive range of chemical and biological insecticides designed to control various pest species that threaten crop yields and quality.

Market growth in China’s insecticide sector is driven by increasing agricultural mechanization, rising demand for high-quality food products, and the need to maximize crop yields from limited arable land. The industry has experienced significant transformation in recent years, with growing emphasis on sustainable pest management practices and environmentally friendly formulations. Current market dynamics indicate robust expansion at a CAGR of 6.2%, reflecting strong domestic demand and export opportunities.

Technological advancement continues to reshape the Chinese insecticide landscape, with manufacturers investing heavily in research and development of novel active ingredients and innovative delivery systems. The market benefits from China’s position as both a major producer and consumer of agricultural chemicals, creating unique opportunities for domestic companies to serve local needs while competing in global markets. Regulatory evolution toward stricter environmental standards is driving innovation in safer, more targeted insecticide formulations.

The China insecticide market refers to the comprehensive ecosystem of chemical and biological products designed to control insect pests that damage agricultural crops, stored grains, and other economically important plants within Chinese territory. This market encompasses the research, development, manufacturing, distribution, and application of various insecticidal formulations including organophosphates, pyrethroids, neonicotinoids, and emerging biopesticide solutions.

Market scope extends beyond traditional chemical pesticides to include integrated pest management solutions, precision application technologies, and sustainable agricultural practices. The sector serves diverse agricultural segments including field crops, vegetables, fruits, and specialty crops, while also addressing pest control needs in forestry, urban environments, and public health applications. Value chain participants include multinational chemical companies, domestic manufacturers, distributors, retailers, and end-users ranging from large commercial farms to smallholder agricultural operations.

China’s insecticide market stands as a cornerstone of the nation’s agricultural chemical industry, characterized by strong domestic demand, significant manufacturing capacity, and increasing focus on sustainable pest management solutions. The market demonstrates remarkable resilience and growth potential, supported by China’s vast agricultural sector and ongoing modernization efforts across farming communities.

Key market drivers include rising food security concerns, increasing pest resistance challenges, and growing adoption of precision agriculture technologies. The sector benefits from substantial government support for agricultural modernization and food production enhancement initiatives. Market transformation is evident in the shift toward more selective, environmentally compatible insecticide formulations and integrated pest management approaches.

Competitive dynamics feature a mix of international corporations and strong domestic players, with Chinese companies gaining significant market share through cost-effective production and localized product development. The market shows particular strength in pyrethroid and organophosphate segments, while experiencing rapid growth in biological and novel chemistry categories. Export potential remains substantial, with Chinese manufacturers serving global markets while meeting domestic agricultural needs.

Strategic market insights reveal several critical trends shaping China’s insecticide industry landscape. The market demonstrates strong correlation between agricultural productivity goals and insecticide demand patterns, with seasonal variations reflecting crop cycles and pest pressure dynamics across different regions.

Primary market drivers propelling China’s insecticide industry growth stem from fundamental agricultural and economic factors that create sustained demand for effective pest control solutions. The nation’s commitment to food security and agricultural self-sufficiency generates consistent market expansion opportunities across diverse crop production systems.

Agricultural intensification represents a major growth driver, as farmers seek to maximize yields from limited arable land through improved pest management practices. Rising crop values and quality standards create economic incentives for effective insecticide use, while increasing pest pressure from climate change and evolving pest populations drives demand for advanced control solutions. Government support for agricultural modernization includes subsidies and technical assistance programs that facilitate insecticide adoption among farming communities.

Technological advancement in crop protection creates new market opportunities through development of more effective, selective, and environmentally compatible insecticide formulations. The growing adoption of precision agriculture technologies enables more targeted and efficient pesticide applications, driving demand for specialized products. Export market expansion provides additional growth momentum as Chinese manufacturers leverage cost advantages and technical capabilities to serve international customers.

Consumer demand for high-quality agricultural products drives farmers to invest in comprehensive pest management programs that ensure crop quality and marketability. Urban population growth and rising incomes create sustained demand for diverse food products, supporting agricultural expansion and associated insecticide needs. Climate variability and changing pest dynamics require adaptive pest management strategies that rely on effective insecticide tools.

Regulatory constraints pose significant challenges to China’s insecticide market, as increasingly strict environmental and safety standards require substantial investments in product reformulation and registration processes. The phase-out of certain active ingredients due to environmental or health concerns creates market disruptions and forces manufacturers to develop alternative solutions at considerable cost.

Resistance development in target pest populations reduces the effectiveness of existing insecticide products, requiring continuous investment in new active ingredients and resistance management strategies. This biological challenge creates ongoing pressure on manufacturers to innovate while potentially reducing the commercial lifespan of successful products. Environmental concerns among consumers and policymakers drive demand for reduced pesticide use, potentially limiting market growth in certain segments.

Cost pressures from raw material price volatility and increasing regulatory compliance requirements impact profit margins across the industry. Small and medium-scale farmers may face affordability challenges with premium insecticide products, limiting market penetration in certain agricultural segments. International trade restrictions and quality standards in export markets create barriers for Chinese manufacturers seeking global expansion.

Technical complexity in modern insecticide development requires substantial research and development investments that may be challenging for smaller companies. The need for extensive field testing and registration data creates lengthy product development cycles that delay market entry for new innovations. Competition intensity from both domestic and international players creates pricing pressure that may limit profitability and investment capacity.

Emerging opportunities in China’s insecticide market center around technological innovation, sustainable agriculture trends, and expanding application areas beyond traditional crop protection. The growing emphasis on integrated pest management creates demand for specialized products and services that complement chemical control methods.

Biological insecticides represent a rapidly expanding market segment, driven by environmental regulations and consumer preferences for sustainable agricultural practices. This category offers significant growth potential as manufacturers develop more effective biological control agents and improve formulation stability. Precision agriculture adoption creates opportunities for smart application technologies and data-driven pest management solutions that optimize insecticide use efficiency.

Export market expansion provides substantial growth opportunities for Chinese manufacturers who can meet international quality standards and regulatory requirements. Developing countries with expanding agricultural sectors represent particularly attractive markets for cost-effective insecticide solutions. Specialty crop protection in high-value crops like fruits, vegetables, and ornamentals offers premium pricing opportunities for targeted insecticide products.

Digital agriculture integration creates new business models combining insecticide products with monitoring, advisory, and application services. The development of resistance-breaking formulations and novel modes of action addresses critical market needs while commanding premium pricing. Urban pest control and public health applications provide diversification opportunities beyond agricultural markets, particularly in China’s rapidly urbanizing environment.

Market dynamics in China’s insecticide sector reflect complex interactions between agricultural needs, regulatory requirements, technological capabilities, and competitive pressures. The industry operates within a framework of seasonal demand patterns, regional variations, and evolving pest management practices that create both challenges and opportunities for market participants.

Supply chain dynamics demonstrate increasing integration from raw material production through final product distribution, with many companies pursuing vertical integration strategies to control costs and quality. Manufacturing capacity utilization varies seasonally, reflecting agricultural application patterns and inventory management practices. Pricing dynamics show sensitivity to raw material costs, competitive pressures, and regulatory changes that affect product availability and market positioning.

Innovation cycles in the insecticide market typically span 8-12 years from initial research to commercial launch, requiring sustained investment and strategic planning. Market leaders maintain competitive advantages through continuous product development and strong distribution networks. Customer relationships increasingly emphasize technical support and integrated solutions rather than simple product transactions, reflecting the growing sophistication of agricultural practices.

Regulatory dynamics create both constraints and opportunities, as stricter standards drive innovation while potentially limiting product options. The market shows increasing differentiation between commodity products and specialized solutions, with premium segments growing faster than traditional categories. International market integration affects domestic pricing and product development priorities as Chinese manufacturers compete globally.

Comprehensive research methodology employed in analyzing China’s insecticide market combines quantitative data analysis with qualitative insights from industry stakeholders, regulatory bodies, and market participants. The research approach integrates multiple data sources to provide accurate and actionable market intelligence for strategic decision-making.

Primary research components include structured interviews with key industry executives, agricultural extension specialists, farmer representatives, and regulatory officials. Survey methodologies capture market trends, purchasing behaviors, and technology adoption patterns across different agricultural regions and crop types. Field research activities involve on-site visits to manufacturing facilities, distribution centers, and farming operations to understand operational dynamics and market conditions.

Secondary research analysis incorporates government statistics, industry association reports, academic publications, and company financial disclosures to establish market baselines and trend analysis. Data validation processes ensure accuracy and reliability of market estimates and projections. Expert consultation with agricultural scientists, pest management specialists, and industry analysts provides technical insights and market context for research findings.

Analytical frameworks employ statistical modeling, trend analysis, and scenario planning to develop market forecasts and identify growth opportunities. Cross-referencing multiple data sources ensures comprehensive coverage of market dynamics and competitive landscapes. Continuous monitoring of regulatory changes, technological developments, and market events maintains research currency and relevance for strategic planning purposes.

Regional market analysis reveals significant variations in insecticide demand patterns, product preferences, and growth opportunities across China’s diverse agricultural regions. Each major agricultural zone demonstrates distinct characteristics based on climate conditions, crop types, pest pressures, and farming practices that influence market dynamics.

Eastern China represents the largest regional market segment, accounting for approximately 35% of national insecticide consumption. This region benefits from intensive agriculture, high-value crop production, and advanced farming practices that support premium insecticide adoption. Major provinces including Jiangsu, Shandong, and Zhejiang demonstrate strong demand for specialized formulations and integrated pest management solutions. Market sophistication in eastern regions drives innovation and technology adoption across the industry.

Central China contributes approximately 28% of market demand, characterized by large-scale grain production and traditional farming systems. Provinces such as Henan, Hubei, and Hunan focus primarily on rice, wheat, and corn production, creating demand for broad-spectrum insecticides and cost-effective solutions. Agricultural modernization initiatives in central regions are driving gradual adoption of advanced pest management technologies and sustainable practices.

Western China accounts for roughly 22% of insecticide consumption, with unique challenges related to diverse topography, climate extremes, and specialty crop production. Cotton production in Xinjiang and fruit cultivation in other western provinces create specific market niches for targeted insecticide products. Infrastructure development and government support programs are improving market access and technology adoption in western agricultural areas.

Northeastern China represents approximately 15% of market share, focusing primarily on soybean, corn, and rice production in large-scale farming operations. The region demonstrates growing adoption of precision agriculture technologies and integrated pest management practices. Seasonal concentration of agricultural activities creates distinct demand patterns and supply chain requirements for insecticide distribution and application.

Competitive landscape analysis reveals a dynamic market structure featuring both multinational corporations and strong domestic players competing across various product segments and geographic regions. The industry demonstrates ongoing consolidation trends while maintaining opportunities for specialized and innovative companies to establish market positions.

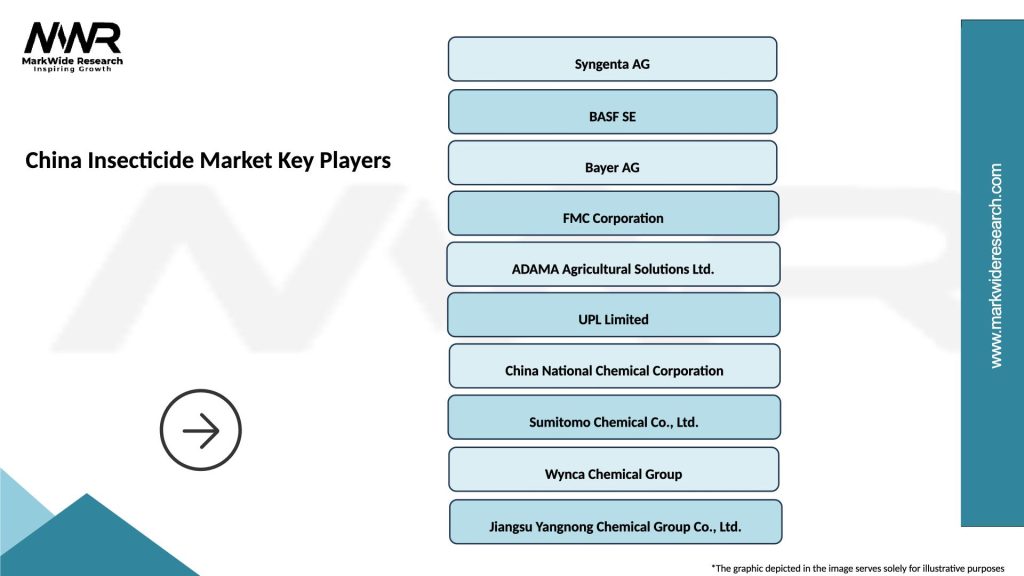

Market leaders include a combination of international and domestic companies that have established strong positions through product innovation, distribution networks, and customer relationships:

Competitive strategies emphasize product differentiation, cost optimization, and market expansion through both organic growth and strategic acquisitions. Companies invest heavily in research and development to maintain technological advantages and address evolving pest management challenges. Distribution networks and customer service capabilities increasingly differentiate market leaders from smaller competitors.

Market segmentation analysis provides detailed insights into various product categories, application methods, and end-user segments that comprise China’s insecticide market. Understanding these segments enables stakeholders to identify growth opportunities and develop targeted strategies for market participation.

By Product Type:

By Application Method:

By Crop Type:

Category-wise analysis reveals distinct market dynamics, growth patterns, and competitive landscapes across different insecticide product segments. Each category demonstrates unique characteristics related to efficacy, environmental impact, regulatory status, and market acceptance that influence adoption patterns and growth potential.

Pyrethroid insecticides maintain the largest market category, benefiting from broad-spectrum efficacy, favorable environmental profiles, and established farmer acceptance. This segment shows steady growth driven by continued agricultural expansion and integrated pest management adoption. Innovation focus in pyrethroids centers on resistance management formulations and improved selectivity for beneficial insects.

Biological insecticides represent the fastest-growing category, expanding at approximately 12% annual growth rate as farmers and regulators embrace sustainable pest management approaches. This segment benefits from increasing environmental awareness and regulatory support for reduced chemical pesticide use. Market challenges include higher costs, storage requirements, and efficacy consistency compared to synthetic alternatives.

Organophosphate insecticides face declining market share due to regulatory restrictions and safety concerns, but maintain importance in specific applications where alternatives are limited. The segment demonstrates resilience in grain crop protection and export market applications. Market transition toward safer alternatives creates opportunities for companies developing replacement technologies.

Neonicotinoid insecticides experience regulatory pressure in certain applications while maintaining market presence in approved uses. This category shows innovation in application methods and formulation technologies to address environmental concerns while preserving efficacy benefits. Research focus emphasizes targeted delivery systems and reduced environmental exposure potential.

Industry participants in China’s insecticide market benefit from multiple value creation opportunities stemming from market growth, technological advancement, and evolving agricultural practices. These benefits extend across the value chain from manufacturers to end-users, creating sustainable competitive advantages and market development potential.

Manufacturers benefit from strong domestic demand growth, export market opportunities, and technological innovation potential that support long-term business development. Access to China’s large agricultural market provides scale advantages for production efficiency and cost optimization. Research and development capabilities in China enable companies to develop products tailored to local pest pressures and farming practices while building expertise for global applications.

Distributors and retailers benefit from expanding market reach through digital platforms and modern agricultural supply chains. Growing farmer sophistication creates demand for technical services and integrated solutions that enhance value-added opportunities. Market consolidation trends provide partnership opportunities with manufacturers seeking efficient distribution networks and local market expertise.

Farmers benefit from improved pest control efficacy, reduced crop losses, and enhanced product quality through access to advanced insecticide technologies. Integrated pest management approaches supported by modern insecticides enable sustainable production practices and reduced environmental impact. Economic benefits include higher yields, improved crop quality, and reduced labor requirements for pest management activities.

Research institutions benefit from collaboration opportunities with industry partners, access to field testing facilities, and funding for agricultural innovation projects. The dynamic market environment creates demand for technical expertise and scientific research support. Technology transfer opportunities enable academic institutions to commercialize research findings and contribute to industry advancement.

Strengths:

Weaknesses:

Opportunities:

Threats:

Transformational trends shaping China’s insecticide market reflect broader changes in agricultural practices, environmental awareness, and technological capabilities. These trends create both challenges and opportunities for market participants while driving innovation and strategic adaptation across the industry.

Sustainable agriculture adoption represents the most significant trend, with farmers increasingly seeking environmentally compatible pest management solutions that minimize ecological impact while maintaining crop protection efficacy. This trend drives demand for biological insecticides, reduced-risk formulations, and integrated pest management approaches. Consumer awareness of food safety and environmental issues supports market transition toward sustainable pest control practices.

Digital agriculture integration transforms pest management through precision application technologies, monitoring systems, and data-driven decision support tools. Smart farming platforms enable optimized insecticide use based on real-time pest pressure assessment and weather conditions. Technology convergence creates opportunities for companies offering integrated solutions combining products, services, and digital tools.

Regulatory evolution toward stricter environmental and safety standards drives innovation in safer active ingredients and application technologies. The trend toward evidence-based regulation requires extensive data generation and scientific support for product registration and market access. International harmonization of regulatory standards creates opportunities for companies meeting global quality requirements.

Market consolidation continues as companies seek scale advantages, technological capabilities, and market access through mergers, acquisitions, and strategic partnerships. This trend creates opportunities for specialized companies while challenging smaller players to find competitive niches. Value chain integration enables companies to control quality, costs, and customer relationships more effectively.

Recent industry developments demonstrate the dynamic nature of China’s insecticide market, with significant investments in research and development, regulatory changes, and strategic business initiatives shaping competitive landscapes and growth opportunities. These developments reflect industry adaptation to evolving market conditions and stakeholder requirements.

Regulatory developments include implementation of stricter environmental standards and safety requirements for insecticide registration and use. Recent policy changes emphasize sustainable agriculture practices and reduced chemical pesticide dependence through integrated pest management promotion. Government initiatives supporting agricultural modernization include subsidies for environmentally friendly pest control technologies and farmer education programs.

Technology innovations focus on novel active ingredients, improved formulation technologies, and precision application systems that enhance efficacy while reducing environmental impact. Major companies have announced significant research investments in biological pest control agents and resistance management solutions. Digital integration initiatives combine insecticide products with monitoring technologies and advisory services for comprehensive pest management solutions.

Strategic partnerships between international and domestic companies facilitate technology transfer, market access, and product development capabilities. Recent joint ventures focus on biological insecticide development and sustainable agriculture solutions. Investment activities include facility expansions, research center establishments, and acquisition of specialized technology companies to enhance competitive capabilities.

Market access developments include improved distribution networks, digital sales platforms, and farmer education programs that enhance product accessibility and adoption. Export market expansion initiatives target developing countries with growing agricultural sectors and demand for cost-effective pest control solutions. Quality improvements in Chinese products support international market penetration and brand development efforts.

Strategic recommendations for China’s insecticide market participants emphasize the importance of balancing growth opportunities with sustainability requirements and regulatory compliance. MarkWide Research analysis indicates that successful companies will need to invest in innovation, market diversification, and stakeholder engagement to maintain competitive advantages in evolving market conditions.

Product development priorities should focus on environmentally compatible formulations, biological alternatives, and resistance management solutions that address critical market needs while meeting regulatory requirements. Companies should invest in research capabilities and strategic partnerships to access cutting-edge technologies and accelerate innovation cycles. Market positioning strategies should emphasize sustainability credentials, technical support capabilities, and integrated solution offerings.

Geographic expansion opportunities exist in both domestic regional markets and international export destinations, particularly in developing countries with expanding agricultural sectors. Companies should develop market-specific products and distribution strategies that address local pest pressures and farmer needs. Digital transformation initiatives should integrate product offerings with monitoring, advisory, and application technologies to create comprehensive value propositions.

Regulatory compliance strategies must anticipate future environmental and safety requirements while maintaining product efficacy and commercial viability. Companies should engage proactively with regulatory authorities and industry associations to influence policy development and ensure market access. Sustainability initiatives should encompass product stewardship, environmental impact reduction, and stakeholder engagement programs that build long-term market acceptance.

Investment priorities should balance capacity expansion with technology development and market access initiatives. Companies should consider strategic partnerships and acquisitions to acquire specialized capabilities and accelerate market entry in high-growth segments. Risk management strategies should address regulatory changes, competitive pressures, and market volatility through diversification and operational flexibility.

Future market prospects for China’s insecticide industry remain positive, supported by sustained agricultural demand, technological innovation, and expanding global market opportunities. The sector is expected to continue evolving toward more sustainable and technologically advanced pest management solutions while maintaining strong growth momentum across key market segments.

Growth projections indicate continued market expansion at a CAGR of 6.2% over the next five years, driven by agricultural modernization, crop protection needs, and export market development. Biological insecticides are expected to achieve the highest growth rates at approximately 12% annually, reflecting increasing environmental awareness and regulatory support for sustainable pest management practices. Technology integration will accelerate as digital agriculture adoption creates demand for smart pest management solutions.

Market transformation will continue toward more selective, environmentally compatible products that address specific pest challenges while minimizing ecological impact. Innovation focus will emphasize novel modes of action, resistance management, and precision application technologies that optimize pest control efficacy. Regulatory evolution will drive product development priorities and market access strategies for both domestic and international applications.

Competitive landscape changes will reflect ongoing consolidation trends, technology partnerships, and market expansion initiatives by leading companies. Chinese manufacturers are expected to strengthen their positions in global markets through quality improvements, cost advantages, and specialized product development. Export growth will provide significant opportunities for companies meeting international quality standards and regulatory requirements.

Sustainability trends will reshape market dynamics as stakeholders increasingly prioritize environmental compatibility and integrated pest management approaches. The industry will need to balance pest control efficacy with environmental stewardship and social responsibility considerations. Long-term success will depend on companies’ ability to innovate, adapt to regulatory changes, and meet evolving customer needs in dynamic market conditions.

China’s insecticide market represents a dynamic and rapidly evolving sector that plays a crucial role in supporting the nation’s agricultural productivity and food security objectives. The market demonstrates strong fundamentals with sustained growth potential driven by agricultural modernization, technological innovation, and expanding global opportunities. Market participants benefit from China’s position as both a major agricultural producer and manufacturing hub, creating unique advantages for serving domestic and international customers.

Strategic success in this market requires balancing traditional pest control needs with evolving sustainability requirements and regulatory standards. Companies that invest in innovation, environmental compatibility, and integrated solutions will be best positioned to capitalize on growth opportunities while managing competitive pressures and regulatory challenges. MWR analysis indicates that the most successful market participants will be those who can adapt quickly to changing market conditions while maintaining strong technical capabilities and customer relationships.

Future market development will be characterized by continued growth in sustainable pest management solutions, digital agriculture integration, and international market expansion. The industry’s ability to address environmental concerns while maintaining agricultural productivity will determine long-term success and stakeholder acceptance. China’s insecticide market is well-positioned to continue its growth trajectory while contributing to global food security and sustainable agricultural development objectives through innovation and responsible market practices.

What is Insecticide?

Insecticide refers to substances used to kill or manage insect populations that can harm crops, livestock, and human health. They are essential in agriculture for protecting plants from pests and ensuring food security.

What are the key players in the China Insecticide Market?

Key players in the China Insecticide Market include companies like Syngenta, BASF, and Bayer, which are known for their extensive product lines and innovations in pest control solutions, among others.

What are the growth factors driving the China Insecticide Market?

The growth of the China Insecticide Market is driven by increasing agricultural production, the rising need for pest management solutions, and advancements in formulation technologies that enhance efficacy and safety.

What challenges does the China Insecticide Market face?

The China Insecticide Market faces challenges such as stringent regulatory requirements, environmental concerns regarding pesticide use, and the development of pest resistance, which complicates pest management strategies.

What opportunities exist in the China Insecticide Market?

Opportunities in the China Insecticide Market include the development of biopesticides, increasing demand for organic farming solutions, and innovations in precision agriculture that optimize pesticide application.

What trends are shaping the China Insecticide Market?

Trends in the China Insecticide Market include a shift towards integrated pest management practices, the use of digital technologies for pest monitoring, and a growing emphasis on sustainable and eco-friendly insecticide formulations.

China Insecticide Market

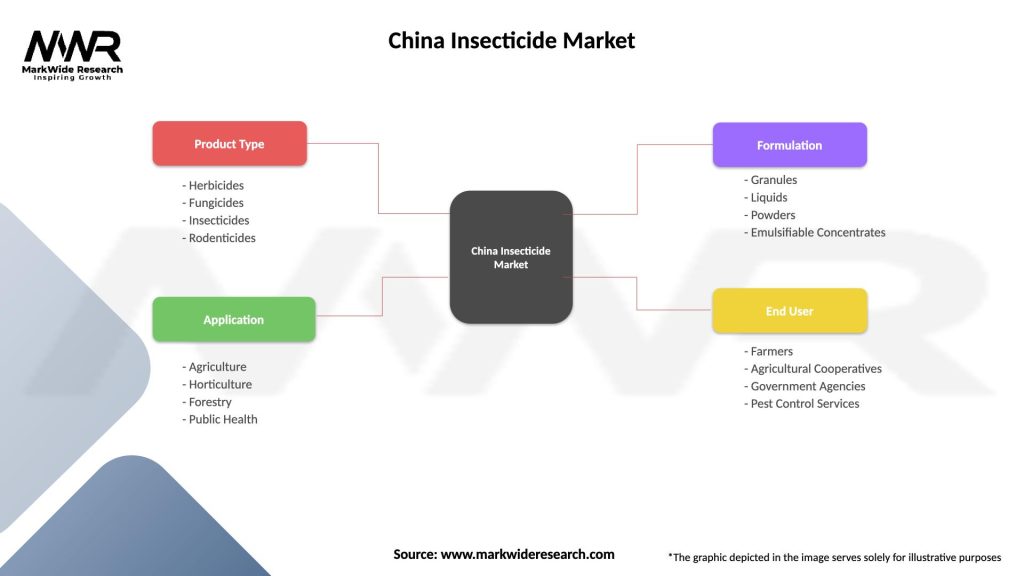

| Segmentation Details | Description |

|---|---|

| Product Type | Herbicides, Fungicides, Insecticides, Rodenticides |

| Application | Agriculture, Horticulture, Forestry, Public Health |

| Formulation | Granules, Liquids, Powders, Emulsifiable Concentrates |

| End User | Farmers, Agricultural Cooperatives, Government Agencies, Pest Control Services |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the China Insecticide Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at