444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

The China electric vehicle battery manufacturing market represents one of the most dynamic and rapidly evolving sectors in the global automotive industry. China’s dominance in electric vehicle battery production has established the country as a global leader, controlling approximately 75% of global battery manufacturing capacity. The market encompasses lithium-ion battery production, battery management systems, and advanced energy storage solutions specifically designed for electric vehicles.

Market dynamics in China’s electric vehicle battery sector are driven by aggressive government policies, substantial investments in research and development, and the presence of world-leading manufacturers such as CATL, BYD, and CALB. The industry has experienced remarkable growth, with production capacity expanding at a compound annual growth rate of 28.5% over recent years, reflecting the country’s commitment to electric mobility and energy transition.

Technological advancement remains at the forefront of China’s battery manufacturing capabilities, with companies investing heavily in next-generation battery technologies including solid-state batteries, silicon nanowire anodes, and advanced lithium iron phosphate formulations. The market benefits from integrated supply chains, government subsidies, and strategic partnerships between battery manufacturers and automotive companies, creating a comprehensive ecosystem that supports sustainable growth and innovation in the electric vehicle sector.

The China electric vehicle battery manufacturing market refers to the comprehensive industrial ecosystem encompassing the design, production, and distribution of rechargeable battery systems specifically engineered for electric vehicles within China’s borders. This market includes lithium-ion battery cells, battery packs, battery management systems, thermal management solutions, and associated manufacturing equipment and technologies.

Manufacturing scope extends beyond basic battery production to include advanced research and development facilities, raw material processing, component manufacturing, and quality control systems. The market encompasses both domestic consumption for China’s rapidly growing electric vehicle market and export production serving global automotive manufacturers seeking high-quality, cost-effective battery solutions.

Strategic importance of this market lies in its role as the foundation of China’s electric vehicle industry and its contribution to global decarbonization efforts. The sector represents a critical component of China’s industrial strategy, combining advanced manufacturing capabilities with sustainable energy technologies to create competitive advantages in the global transition toward electric mobility.

China’s electric vehicle battery manufacturing market has emerged as a global powerhouse, establishing the country as the undisputed leader in battery production technology and capacity. The market benefits from comprehensive government support, advanced manufacturing infrastructure, and strategic positioning within global supply chains, creating unprecedented opportunities for growth and innovation.

Key market characteristics include rapid technological advancement, aggressive capacity expansion, and increasing focus on sustainability and recycling. Chinese manufacturers have achieved significant cost reductions while improving battery performance, with energy density improvements of 12% annually and cost reductions enabling broader electric vehicle adoption across multiple market segments.

Competitive landscape features several world-leading companies that have established dominant positions through strategic investments, technological innovation, and vertical integration. The market continues to attract substantial foreign investment and partnerships, reflecting international recognition of China’s manufacturing capabilities and market potential in the electric vehicle battery sector.

Strategic insights reveal several critical factors driving market development and competitive positioning:

Government policy support serves as the primary driver for China’s electric vehicle battery manufacturing market, with comprehensive incentives, subsidies, and regulatory frameworks promoting industry development. The Chinese government has implemented strategic initiatives including the New Energy Vehicle mandate, battery recycling regulations, and substantial funding for research and development programs.

Domestic demand growth from China’s rapidly expanding electric vehicle market creates substantial opportunities for battery manufacturers. With electric vehicle sales growing at 35% annually, domestic demand provides a stable foundation for manufacturing capacity expansion and technological advancement, enabling companies to achieve scale economies and invest in innovation.

Technological advancement drives continuous improvement in battery performance, safety, and cost-effectiveness. Chinese manufacturers invest heavily in research and development, focusing on energy density improvements, charging speed optimization, and battery life extension. These technological capabilities create competitive advantages in both domestic and international markets.

Supply chain advantages including access to raw materials, component manufacturing, and logistics infrastructure support market growth. China’s integrated approach to battery manufacturing, from lithium processing to finished battery systems, creates cost advantages and supply chain resilience that benefit the entire industry ecosystem.

Raw material dependency presents significant challenges for China’s battery manufacturing industry, particularly regarding lithium, cobalt, and nickel supplies. Price volatility and supply chain disruptions in critical materials can impact production costs and manufacturing schedules, requiring strategic inventory management and alternative sourcing strategies.

Environmental concerns related to battery manufacturing processes and waste management create regulatory and operational challenges. Increasing scrutiny of environmental impact requires substantial investments in clean manufacturing technologies, waste treatment systems, and recycling infrastructure, potentially affecting profitability and operational efficiency.

International trade tensions and geopolitical factors may limit market access and create uncertainty for Chinese battery manufacturers seeking to expand globally. Trade restrictions, tariffs, and technology transfer limitations can impact export opportunities and international partnerships, requiring strategic adaptation and market diversification.

Technology transition risks associated with rapid advancement in battery technologies may render existing manufacturing investments obsolete. The shift toward solid-state batteries and other next-generation technologies requires continuous capital investment and technological adaptation, creating financial and operational challenges for manufacturers.

Global expansion opportunities present significant growth potential for Chinese battery manufacturers as international demand for electric vehicle batteries continues to accelerate. European and North American markets offer substantial opportunities for partnerships, joint ventures, and direct investment, enabling Chinese companies to establish global manufacturing presence and market share.

Technology diversification into energy storage systems, grid-scale batteries, and specialized applications creates new revenue streams beyond automotive markets. The growing demand for renewable energy storage and grid stabilization solutions provides opportunities for battery manufacturers to leverage their technological capabilities in expanding market segments.

Recycling and circular economy initiatives offer opportunities to develop sustainable business models while addressing environmental concerns. Battery recycling technologies and closed-loop manufacturing processes can create competitive advantages while meeting increasing regulatory requirements and consumer expectations for environmental responsibility.

Strategic partnerships with international automotive manufacturers, technology companies, and research institutions can accelerate market expansion and technological development. Collaborative approaches to battery development, manufacturing optimization, and market entry strategies can create mutual benefits and competitive advantages in the global electric vehicle market.

Supply and demand dynamics in China’s electric vehicle battery market reflect the rapid growth of electric vehicle adoption and the corresponding expansion of manufacturing capacity. MarkWide Research analysis indicates that demand growth consistently outpaces supply expansion, creating opportunities for new entrants and capacity investments while maintaining favorable pricing conditions for manufacturers.

Competitive dynamics feature intense competition among leading manufacturers, driving continuous innovation and cost reduction. Market leaders such as CATL and BYD compete through technological differentiation, manufacturing efficiency, and strategic partnerships, while emerging companies focus on specialized applications and next-generation technologies.

Price dynamics reflect the balance between raw material costs, manufacturing efficiency, and market demand. Battery prices have declined by 18% annually over recent years due to scale economies and technological improvements, making electric vehicles more affordable and accessible to broader consumer segments.

Innovation dynamics drive rapid technological advancement and product development cycles. Companies invest substantially in research and development, with innovation cycles accelerating and new technologies reaching commercial viability more quickly, creating both opportunities and challenges for market participants.

Primary research methodology encompasses comprehensive interviews with industry executives, manufacturing specialists, and technology experts across China’s electric vehicle battery manufacturing sector. Data collection includes structured surveys, in-depth interviews, and expert consultations to gather insights on market trends, technological developments, and competitive dynamics.

Secondary research approach involves extensive analysis of industry reports, government publications, patent filings, and financial disclosures from leading battery manufacturers. This methodology ensures comprehensive coverage of market developments, regulatory changes, and technological advancement across all segments of the battery manufacturing industry.

Data validation processes include cross-referencing multiple sources, expert review panels, and statistical analysis to ensure accuracy and reliability of market insights. Quantitative data undergoes rigorous verification through industry databases, government statistics, and company financial reports to maintain research integrity and credibility.

Analytical framework combines quantitative modeling with qualitative assessment to provide comprehensive market understanding. The methodology incorporates trend analysis, competitive benchmarking, and scenario planning to deliver actionable insights for industry stakeholders and strategic decision-making.

Eastern China region dominates battery manufacturing with approximately 55% of national production capacity, centered around major industrial hubs including Shanghai, Jiangsu, and Zhejiang provinces. This region benefits from advanced manufacturing infrastructure, skilled workforce, and proximity to automotive manufacturing centers, creating integrated supply chains and operational efficiencies.

Southern China region accounts for 25% of manufacturing capacity, with significant concentrations in Guangdong and Shenzhen areas. The region specializes in advanced battery technologies and export-oriented production, leveraging proximity to international shipping routes and established electronics manufacturing ecosystems.

Central and Western regions represent emerging manufacturing centers with 20% of production capacity, supported by government incentives for industrial development and access to raw materials. These regions offer cost advantages and strategic positioning for domestic market supply, particularly for the growing electric vehicle markets in inland cities.

Regional specialization reflects different competitive advantages and market focus areas. Eastern regions emphasize high-technology applications and premium battery systems, while central regions focus on cost-effective production for mass-market applications, creating a diversified and complementary manufacturing landscape across China.

Market leadership is concentrated among several key players who have established dominant positions through technological innovation, manufacturing scale, and strategic partnerships:

Competitive strategies include vertical integration, technological differentiation, and strategic partnerships with automotive manufacturers. Leading companies invest heavily in research and development while expanding manufacturing capacity to meet growing domestic and international demand.

By Battery Type:

By Application:

Lithium Iron Phosphate segment demonstrates exceptional growth with 42% market share due to cost advantages and safety benefits. This category particularly appeals to commercial vehicle manufacturers and energy storage applications where cost-effectiveness and reliability are prioritized over maximum energy density.

Nickel Cobalt Manganese batteries maintain strong position in premium passenger vehicle applications, offering optimal balance between energy density, cost, and performance. This segment benefits from continuous technological advancement and increasing adoption in mid-range and luxury electric vehicles.

Manufacturing automation category shows rapid advancement with companies investing in intelligent manufacturing systems, quality control automation, and production efficiency optimization. These investments improve product consistency while reducing manufacturing costs and production cycle times.

Battery management systems represent a critical technology category with sophisticated software and hardware integration ensuring optimal battery performance, safety, and longevity. This segment demonstrates strong growth as battery systems become more complex and performance requirements increase.

Manufacturing companies benefit from China’s comprehensive industrial ecosystem, including access to skilled workforce, advanced manufacturing equipment, and integrated supply chains. The market offers opportunities for scale economies, cost optimization, and technological advancement through collaboration and competition.

Automotive manufacturers gain access to high-quality, cost-effective battery solutions with reliable supply chains and continuous technological improvement. Chinese battery manufacturers provide flexible partnership models, customization capabilities, and responsive customer support for diverse automotive applications.

Technology investors find substantial opportunities in China’s battery manufacturing sector through direct investment, joint ventures, and strategic partnerships. The market offers exposure to rapidly growing electric vehicle adoption and advancing battery technologies with strong return potential.

Government stakeholders benefit from job creation, industrial development, and environmental improvement through the growth of clean energy manufacturing. The battery industry supports China’s strategic objectives for energy independence, technological leadership, and sustainable economic development.

Strengths:

Weaknesses:

Opportunities:

Threats:

Solid-state battery development represents the most significant technological trend, with Chinese manufacturers investing heavily in next-generation battery technologies offering enhanced safety, energy density, and charging capabilities. This trend promises to revolutionize electric vehicle performance and market adoption.

Manufacturing automation advancement continues accelerating with implementation of artificial intelligence, robotics, and quality control systems improving production efficiency and product consistency. Automation reduces labor costs while enhancing manufacturing precision and scalability.

Sustainability integration becomes increasingly important with companies developing closed-loop manufacturing processes, renewable energy utilization, and comprehensive recycling programs. This trend addresses environmental concerns while creating operational efficiencies and cost advantages.

International expansion strategies focus on establishing global manufacturing presence through partnerships, joint ventures, and direct investment. Chinese companies seek to diversify market exposure while accessing international technology and expertise.

Technology partnerships between Chinese battery manufacturers and international automotive companies have accelerated, creating collaborative development programs for next-generation battery systems. These partnerships combine Chinese manufacturing capabilities with international market access and technology expertise.

Capacity expansion projects continue across China with major manufacturers announcing substantial investments in new production facilities and technology upgrades. Recent developments include gigafactory construction and advanced manufacturing line installations supporting growing domestic and international demand.

Regulatory developments include new safety standards, environmental regulations, and quality certification requirements affecting manufacturing processes and product specifications. These developments drive industry standardization while ensuring product safety and environmental compliance.

Research breakthroughs in battery chemistry, manufacturing processes, and recycling technologies continue advancing industry capabilities. Recent developments include improvements in energy density, charging speed, and battery life extending electric vehicle performance and market appeal.

Strategic recommendations for market participants include focusing on technological differentiation, international market expansion, and sustainable manufacturing practices. MWR analysis suggests that companies should prioritize research and development investment while building strategic partnerships for global market access.

Investment priorities should emphasize next-generation battery technologies, manufacturing automation, and supply chain diversification. Companies should balance capacity expansion with technological advancement to maintain competitive positioning in rapidly evolving markets.

Risk management strategies should address raw material supply chain vulnerabilities, regulatory compliance requirements, and international trade uncertainties. Diversification of supply sources, markets, and technologies can mitigate potential disruptions and maintain operational stability.

Market positioning recommendations include developing specialized capabilities, building brand recognition, and establishing quality reputation in international markets. Companies should focus on customer relationships, technical support, and product reliability to differentiate from competitors.

Long-term growth prospects for China’s electric vehicle battery manufacturing market remain exceptionally strong, driven by accelerating global electric vehicle adoption and China’s technological leadership position. The market is projected to maintain robust growth rates exceeding 25% annually through the next decade.

Technology evolution will continue driving market transformation with solid-state batteries, advanced manufacturing processes, and integrated energy management systems becoming commercially viable. These technological advances will enhance product performance while reducing costs and environmental impact.

Global market integration will accelerate as Chinese manufacturers establish international presence through partnerships, acquisitions, and direct investment. This expansion will create opportunities for market share growth while requiring adaptation to diverse regulatory and competitive environments.

Sustainability focus will become increasingly critical with circular economy principles, renewable energy utilization, and environmental responsibility becoming competitive differentiators. Companies that successfully integrate sustainability into their operations will achieve long-term competitive advantages and market leadership positions.

China’s electric vehicle battery manufacturing market represents a transformative force in the global automotive industry, combining technological innovation, manufacturing excellence, and strategic market positioning to create unprecedented opportunities for growth and development. The market’s comprehensive ecosystem, from raw material processing to advanced battery systems, provides competitive advantages that extend beyond cost considerations to include technological capability and supply chain reliability.

Strategic importance of this market extends beyond China’s borders, influencing global electric vehicle adoption, energy storage development, and sustainable transportation solutions. The industry’s continued investment in research and development, manufacturing capacity, and international expansion positions China as the dominant force in the global transition toward electric mobility.

Future success will depend on continued technological advancement, sustainable manufacturing practices, and successful international market penetration. Companies that effectively balance innovation, cost competitiveness, and environmental responsibility will capture the greatest opportunities in this dynamic and rapidly expanding market, contributing to global decarbonization efforts while achieving sustainable business growth and market leadership.

What is Electric Vehicle Battery Manufacturing?

Electric Vehicle Battery Manufacturing refers to the production processes involved in creating batteries specifically designed for electric vehicles, including lithium-ion and solid-state batteries. This sector plays a crucial role in the automotive industry as it supports the transition to sustainable transportation.

What are the key players in the China Electric Vehicle Battery Manufacturing Market?

Key players in the China Electric Vehicle Battery Manufacturing Market include CATL, BYD, and LG Chem, which are known for their advanced battery technologies and significant production capacities. These companies are pivotal in meeting the growing demand for electric vehicle batteries in China, among others.

What are the growth factors driving the China Electric Vehicle Battery Manufacturing Market?

The growth of the China Electric Vehicle Battery Manufacturing Market is driven by increasing government support for electric vehicles, rising consumer demand for sustainable transportation, and advancements in battery technology. Additionally, the expansion of charging infrastructure is enhancing market growth.

What challenges does the China Electric Vehicle Battery Manufacturing Market face?

The China Electric Vehicle Battery Manufacturing Market faces challenges such as supply chain disruptions, high raw material costs, and environmental concerns related to battery disposal. These factors can hinder production efficiency and sustainability efforts.

What opportunities exist in the China Electric Vehicle Battery Manufacturing Market?

Opportunities in the China Electric Vehicle Battery Manufacturing Market include the development of next-generation battery technologies, such as solid-state batteries, and the potential for international collaborations. Additionally, the increasing focus on renewable energy integration presents new avenues for growth.

What trends are shaping the China Electric Vehicle Battery Manufacturing Market?

Trends shaping the China Electric Vehicle Battery Manufacturing Market include the shift towards higher energy density batteries, the rise of battery recycling initiatives, and the integration of artificial intelligence in manufacturing processes. These trends are crucial for enhancing efficiency and sustainability in battery production.

China Electric Vehicle Battery Manufacturing Market

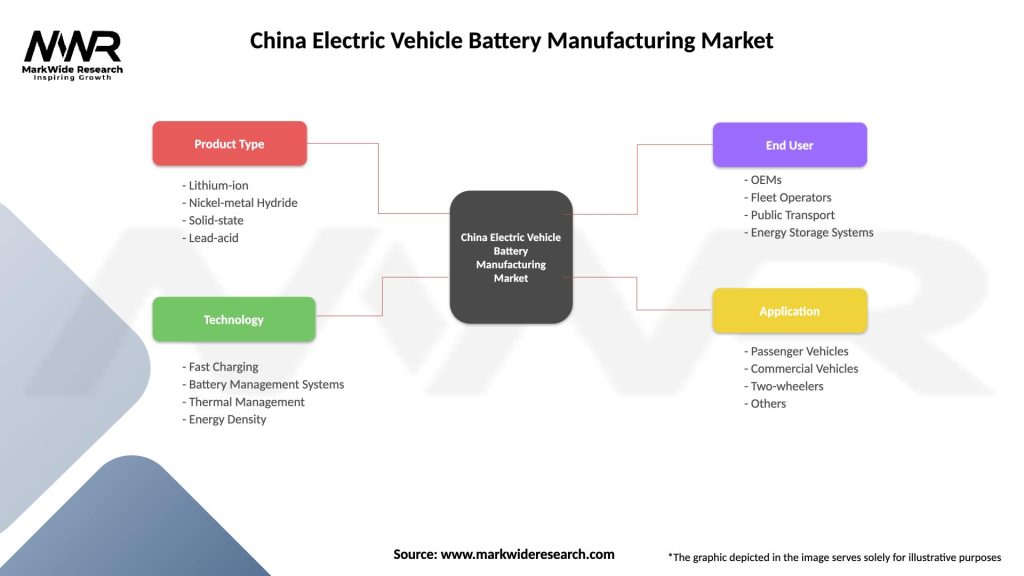

| Segmentation Details | Description |

|---|---|

| Product Type | Lithium-ion, Nickel-metal Hydride, Solid-state, Lead-acid |

| Technology | Fast Charging, Battery Management Systems, Thermal Management, Energy Density |

| End User | OEMs, Fleet Operators, Public Transport, Energy Storage Systems |

| Application | Passenger Vehicles, Commercial Vehicles, Two-wheelers, Others |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the China Electric Vehicle Battery Manufacturing Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at