444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview

The China battery manufacturing equipment market is experiencing significant growth due to the rising demand for batteries in various sectors, including automotive, consumer electronics, and renewable energy. Battery manufacturing equipment plays a crucial role in producing high-quality batteries efficiently and cost-effectively. These equipment ensure precise and consistent manufacturing processes, resulting in batteries with enhanced performance and durability.

Meaning

Battery manufacturing equipment refers to the machinery, tools, and technologies used in the production of batteries. This equipment includes battery assembly lines, electrode coating machines, cell formation systems, testing and inspection equipment, and other related machinery. The primary objective of battery manufacturing equipment is to streamline the production process, improve productivity, and maintain quality standards.

Executive Summary

The China battery manufacturing equipment market is witnessing robust growth driven by the increasing adoption of electric vehicles, growing demand for portable electronic devices, and the rapid expansion of the renewable energy sector. Battery manufacturers are investing in advanced equipment to meet the rising demand for high-performance batteries and gain a competitive edge in the market.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

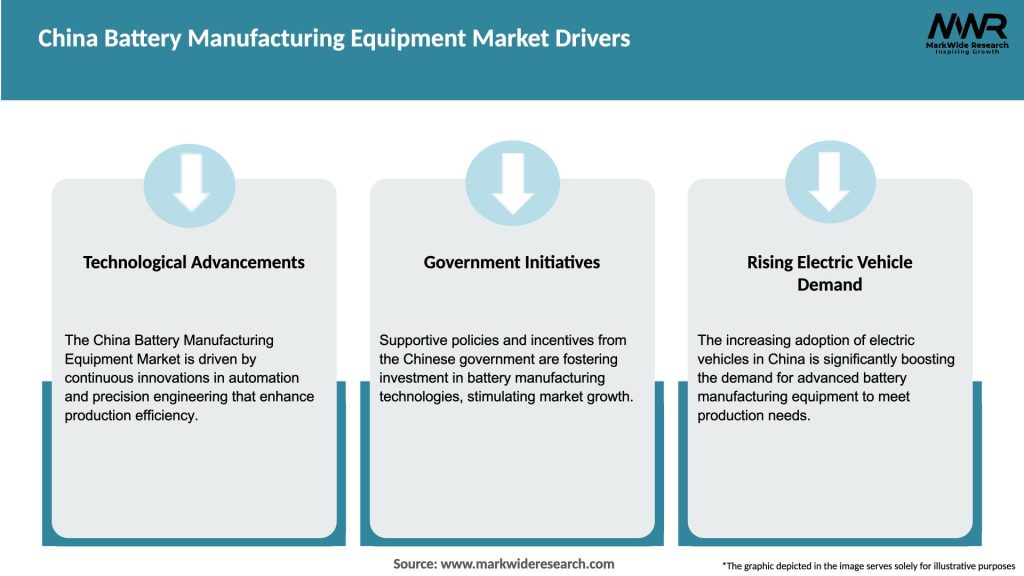

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The China battery manufacturing equipment market is driven by a combination of factors such as increasing demand for electric vehicles, growing adoption of portable electronic devices, government initiatives to promote clean energy, and expansion of the renewable energy sector. These drivers are fueling the demand for advanced manufacturing equipment that can produce high-quality batteries efficiently and cost-effectively.

The market is highly competitive, with numerous domestic and international players vying for market share. Manufacturers are focusing on product innovation, technological advancements, and strategic partnerships to gain a competitive edge. Continuous research and development in battery technology are driving the need for advanced manufacturing equipment capable of producing batteries with improved performance, energy density, and longer lifespan.

Environmental concerns and stringent regulations related to battery manufacturing pose challenges for market players. The handling and disposal of chemicals and materials used in the manufacturing process require compliance with environmental standards. Battery manufacturers need to invest in sustainable manufacturing practices and equipment that minimize environmental impacts.

The market offers significant opportunities for technological advancements, collaboration, international expansion, and a focus on sustainability. Continued investments in research and development, along with strategic partnerships, can unlock new growth avenues. Furthermore, the market is expected to witness considerable growth due to the increasing demand for batteries in various sectors and the ongoing transition towards clean energy sources.

Regional Analysis

China’s battery manufacturing equipment market is spread across various regions, including major cities such as Beijing, Shanghai, Shenzhen, and Guangzhou. These regions serve as manufacturing hubs for batteries and related equipment due to their infrastructure, skilled labor availability, and proximity to key customers.

The coastal regions, including Guangdong and Jiangsu provinces, are home to several battery manufacturers and equipment suppliers. These regions benefit from the proximity to major seaports, facilitating transportation and export of batteries and equipment.

In recent years, China’s central and western regions have also witnessed significant growth in the battery manufacturing equipment market. The government’s focus on balanced regional development and investments in infrastructure have attracted battery manufacturers to these regions.

The battery manufacturing equipment market in China is driven by both domestic demand and export opportunities. Chinese battery manufacturers have a strong presence in the global market, supplying batteries and equipment to various industries worldwide.

Competitive Landscape

Leading Companies in the China Battery Manufacturing Equipment Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

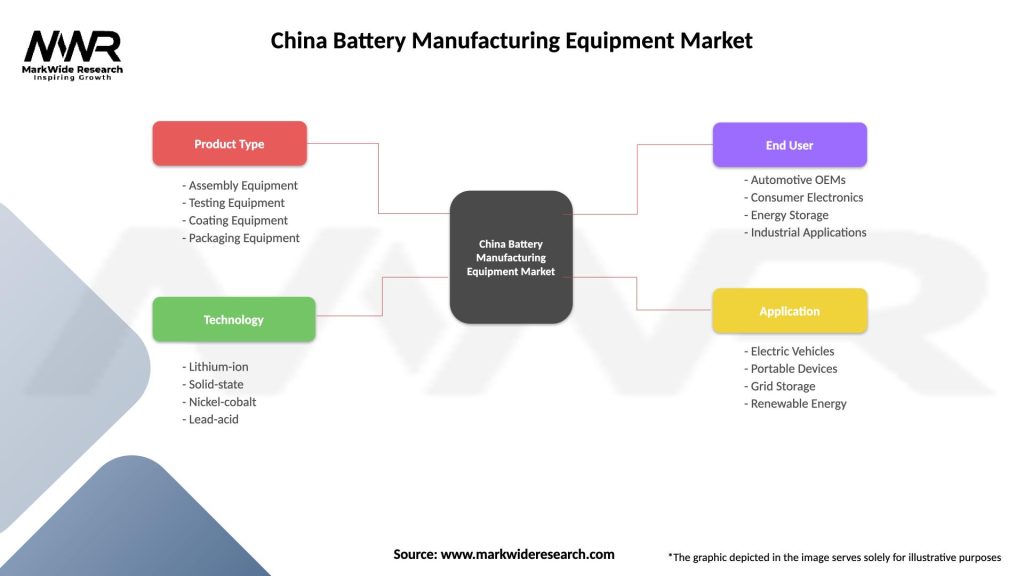

The China battery manufacturing equipment market can be segmented based on equipment type, battery type, and end-user industry.

Segmentation allows for a more detailed analysis of the market, enabling manufacturers to focus on specific equipment types, battery types, and end-user industries based on market demand and growth opportunities.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

The China battery manufacturing equipment market offers several key benefits for industry participants and stakeholders:

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

A comprehensive SWOT analysis helps industry participants and stakeholders identify internal strengths and weaknesses, external opportunities, and potential threats in the China battery manufacturing equipment market. This analysis enables businesses to develop strategies that capitalize on strengths, minimize weaknesses, and leverage opportunities while mitigating threats.

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic had a significant impact on the China battery manufacturing equipment market. During the initial stages of the pandemic, the market experienced disruptions in supply chains, temporary shutdowns, and reduced production due to lockdown measures and workforce limitations.

However, as the situation improved and economic activities resumed, the market witnessed a recovery. The demand for batteries used in medical devices, remote work equipment, and energy storage systems remained stable, providing a lifeline for battery manufacturers.

The pandemic also highlighted the importance of clean energy and the role of batteries in energy storage. This increased awareness is expected to drive the demand for battery manufacturing equipment in the long term, as governments and industries prioritize clean energy initiatives.

To adapt to the pandemic’s challenges, manufacturers implemented safety protocols, increased automation, and explored remote monitoring and maintenance options. These measures helped ensure the continuity of production and minimize disruptions.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future outlook for the China battery manufacturing equipment market is promising. The market is expected to witness substantial growth driven by factors such as the increasing adoption of electric vehicles, growing demand for portable electronic devices, and the expansion of the renewable energy sector.

The transition towards clean energy sources, supported by government initiatives and environmental regulations, will fuel the demand for battery manufacturing equipment. Technological advancements, including automation, robotics, and Industry 4.0 integration, will revolutionize the manufacturing processes and enhance overall efficiency.

Battery manufacturers will continue to invest in advanced equipment to produce high-performance batteries with improved energy density, longer lifespan, and enhanced safety features. Collaboration and partnerships among industry players will foster innovation and drive the development of customized solutions.

Conclusion

The China battery manufacturing equipment market is experiencing robust growth driven by the increasing demand for batteries in various sectors such as automotive, consumer electronics, and renewable energy. The market offers significant opportunities for manufacturers, suppliers, and service providers.

Key market drivers include the rising demand for electric vehicles, the growing popularity of portable electronic devices, government initiatives to promote clean energy, and the expansion of the renewable energy sector. These factors are fueling the need for advanced battery manufacturing equipment that can produce high-quality batteries efficiently and cost-effectively.

What is Battery Manufacturing Equipment?

Battery manufacturing equipment refers to the machinery and tools used in the production of batteries, including processes such as electrode fabrication, cell assembly, and battery testing. This equipment is essential for producing various types of batteries, including lithium-ion and lead-acid batteries.

What are the key players in the China Battery Manufacturing Equipment Market?

Key players in the China Battery Manufacturing Equipment Market include companies like CATL, BYD, and A123 Systems, which are known for their advanced battery technologies and manufacturing capabilities. These companies are significant contributors to the growth and innovation in the battery manufacturing sector, among others.

What are the growth factors driving the China Battery Manufacturing Equipment Market?

The growth of the China Battery Manufacturing Equipment Market is driven by the increasing demand for electric vehicles, the expansion of renewable energy storage solutions, and advancements in battery technology. These factors are leading to higher production capacities and innovations in manufacturing processes.

What challenges does the China Battery Manufacturing Equipment Market face?

The China Battery Manufacturing Equipment Market faces challenges such as high initial investment costs, the need for skilled labor, and stringent regulatory requirements. These factors can hinder the entry of new players and the expansion of existing manufacturers.

What opportunities exist in the China Battery Manufacturing Equipment Market?

Opportunities in the China Battery Manufacturing Equipment Market include the growing trend towards electric mobility, the rise of energy storage systems, and the increasing focus on sustainable manufacturing practices. These trends are expected to create new avenues for innovation and investment.

What trends are shaping the China Battery Manufacturing Equipment Market?

Trends shaping the China Battery Manufacturing Equipment Market include the shift towards automation in manufacturing processes, the development of more efficient battery chemistries, and the integration of smart technologies in production lines. These trends are enhancing productivity and reducing costs.

China Battery Manufacturing Equipment Market

| Segmentation Details | Description |

|---|---|

| Product Type | Assembly Equipment, Testing Equipment, Coating Equipment, Packaging Equipment |

| Technology | Lithium-ion, Solid-state, Nickel-cobalt, Lead-acid |

| End User | Automotive OEMs, Consumer Electronics, Energy Storage, Industrial Applications |

| Application | Electric Vehicles, Portable Devices, Grid Storage, Renewable Energy |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the China Battery Manufacturing Equipment Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at