444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

The chemical packaging in agricultural market represents a critical component of the global agricultural supply chain, encompassing specialized containers, bottles, drums, and protective packaging solutions designed for agricultural chemicals, pesticides, fertilizers, and crop protection products. This sector has experienced robust growth driven by increasing global food demand, expanding agricultural activities, and stringent regulatory requirements for safe chemical handling and storage.

Market dynamics indicate that the agricultural chemical packaging industry is witnessing significant transformation due to technological advancements in packaging materials, enhanced safety protocols, and growing environmental consciousness. The sector encompasses various packaging formats including high-density polyethylene (HDPE) containers, metal drums, flexible intermediate bulk containers (FIBCs), and specialized barrier packaging solutions.

Regional distribution shows strong market presence across North America, Europe, Asia-Pacific, and Latin America, with developing agricultural economies driving substantial demand growth. The market is experiencing a 7.2% CAGR as agricultural modernization accelerates globally and farmers increasingly adopt advanced crop protection solutions requiring specialized packaging.

Innovation trends in the sector focus on sustainable packaging materials, smart packaging technologies with tracking capabilities, and enhanced barrier properties to maintain chemical integrity. The integration of recyclable materials and biodegradable options is becoming increasingly important as environmental regulations tighten worldwide.

The chemical packaging in agricultural market refers to the specialized packaging industry segment that designs, manufactures, and supplies containers and protective packaging solutions specifically engineered for agricultural chemicals, including pesticides, herbicides, fungicides, fertilizers, and other crop protection products. These packaging solutions must meet stringent safety, regulatory, and performance requirements to ensure product integrity, user safety, and environmental protection.

Core components of agricultural chemical packaging include primary containers that directly contact the chemical product, secondary packaging for protection during transport and storage, and tertiary packaging for bulk handling and distribution. The packaging must provide chemical compatibility, barrier protection, and tamper-evident features while maintaining product efficacy throughout the supply chain.

Regulatory compliance is fundamental to this market, as agricultural chemical packaging must adhere to international standards such as UN packaging specifications, EPA requirements, and various regional agricultural safety regulations. The packaging solutions must demonstrate leak-proof performance, chemical resistance, and structural integrity under various environmental conditions.

Strategic market positioning reveals that the chemical packaging in agricultural market is experiencing unprecedented growth driven by global agricultural expansion, increasing crop protection product usage, and evolving regulatory landscapes. The sector demonstrates strong resilience and adaptability to changing market demands while maintaining focus on safety and environmental sustainability.

Key growth drivers include rising global food security concerns, expanding agricultural land utilization, and increasing adoption of precision agriculture technologies. The market benefits from 65% of agricultural operations now utilizing advanced crop protection chemicals requiring specialized packaging solutions. Technological advancement in packaging materials and manufacturing processes continues to enhance product performance and cost-effectiveness.

Market segmentation shows diverse applications across various agricultural chemical categories, with pesticide packaging representing the largest segment, followed by fertilizer packaging and specialty agricultural chemical containers. The sector serves multiple end-user segments including chemical manufacturers, agricultural distributors, and farming cooperatives.

Competitive dynamics feature established packaging manufacturers expanding their agricultural chemical packaging capabilities while new entrants focus on innovative sustainable packaging solutions. The market demonstrates strong consolidation trends as companies seek to enhance their technological capabilities and global reach.

Market intelligence reveals several critical insights shaping the chemical packaging in agricultural market landscape:

Primary growth catalysts propelling the chemical packaging in agricultural market include expanding global agricultural activities driven by increasing population and food security concerns. The sector benefits from agricultural modernization trends as farmers worldwide adopt advanced crop protection strategies requiring specialized packaging solutions.

Regulatory compliance requirements serve as significant market drivers, with international safety standards mandating specific packaging characteristics for agricultural chemicals. The implementation of stricter environmental regulations and worker safety protocols necessitates advanced packaging solutions with enhanced protective features and clear labeling systems.

Technological advancement in agricultural practices drives demand for sophisticated packaging solutions that can maintain chemical integrity, provide accurate dosing capabilities, and ensure safe handling throughout the supply chain. The growing adoption of precision agriculture technologies requires packaging solutions that integrate with modern farming equipment and application systems.

Economic factors including rising agricultural commodity prices and increasing farm profitability encourage greater investment in crop protection products, subsequently driving demand for specialized packaging solutions. The expansion of commercial agriculture in developing regions creates substantial growth opportunities for packaging manufacturers.

Supply chain globalization necessitates robust packaging solutions capable of withstanding international shipping conditions while maintaining product quality and regulatory compliance across multiple jurisdictions. This trend drives innovation in barrier packaging technologies and protective packaging systems.

Significant challenges facing the chemical packaging in agricultural market include stringent regulatory compliance requirements that increase development costs and time-to-market for new packaging solutions. The complexity of international regulatory frameworks creates barriers for companies seeking to expand globally while maintaining compliance across multiple jurisdictions.

Environmental concerns regarding plastic packaging waste and chemical contamination pose ongoing challenges for the industry. Growing pressure from environmental advocacy groups and regulatory bodies to reduce packaging environmental impact requires substantial investment in sustainable packaging alternatives and recycling infrastructure.

Raw material price volatility significantly impacts packaging manufacturing costs, particularly for petroleum-based packaging materials. Fluctuations in polymer prices and metal costs create uncertainty in pricing strategies and profit margins for packaging manufacturers.

Technical complexity in developing packaging solutions that meet diverse chemical compatibility requirements while maintaining cost-effectiveness presents ongoing challenges. The need for specialized testing and certification processes increases development timelines and costs for new packaging innovations.

Market consolidation among agricultural chemical manufacturers reduces the number of potential customers while increasing their bargaining power, potentially pressuring packaging suppliers’ profit margins and requiring enhanced value proposition development.

Emerging opportunities in the chemical packaging in agricultural market center around sustainable packaging innovation, with growing demand for biodegradable packaging materials and circular economy solutions. Companies investing in eco-friendly packaging technologies position themselves advantageously as environmental regulations continue tightening globally.

Smart packaging technologies present significant growth opportunities through integration of IoT sensors, temperature monitoring systems, and chemical integrity indicators. These advanced packaging solutions enable real-time monitoring of product condition and enhance supply chain visibility for agricultural chemical manufacturers.

Geographic expansion opportunities exist in developing agricultural markets across Asia-Pacific, Africa, and Latin America, where agricultural modernization drives increasing demand for crop protection products and specialized packaging solutions. The 42% growth rate in emerging market agricultural chemical usage creates substantial packaging demand.

Customization services offer opportunities for packaging manufacturers to differentiate their offerings through tailored solutions meeting specific customer requirements for chemical compatibility, regulatory compliance, and branding needs. The development of modular packaging systems enables efficient customization while maintaining cost-effectiveness.

Vertical integration opportunities allow packaging companies to expand their value proposition by offering comprehensive solutions including packaging design, manufacturing, logistics, and recycling services. This approach enhances customer relationships and creates additional revenue streams.

Complex market dynamics shape the chemical packaging in agricultural market through interconnected factors including regulatory evolution, technological advancement, and changing customer expectations. The sector demonstrates cyclical patterns aligned with agricultural seasons and crop protection product demand cycles.

Supply chain dynamics reveal increasing integration between packaging manufacturers and agricultural chemical companies, with long-term partnerships becoming more prevalent. This trend enables collaborative innovation and customized solution development while providing supply chain stability for both parties.

Competitive dynamics show intensifying competition as traditional packaging companies expand into agricultural chemical packaging while specialized agricultural packaging manufacturers enhance their technological capabilities. The market experiences pricing pressure balanced against demands for enhanced performance and sustainability.

Innovation dynamics drive continuous product development focused on material science advancement, manufacturing process optimization, and sustainable packaging solutions. According to MarkWide Research analysis, companies investing in R&D demonstrate 23% higher growth rates compared to those focusing solely on traditional packaging solutions.

Regulatory dynamics create both challenges and opportunities as evolving safety and environmental standards require packaging innovation while potentially creating barriers for smaller competitors lacking resources for compliance investment.

Comprehensive research methodology employed for analyzing the chemical packaging in agricultural market incorporates multiple data collection and analysis techniques to ensure accuracy and reliability of market insights. The methodology combines primary research through industry expert interviews and surveys with secondary research utilizing industry reports, regulatory documents, and company financial statements.

Primary research activities include structured interviews with packaging manufacturers, agricultural chemical companies, distributors, and end-users to gather firsthand insights into market trends, challenges, and opportunities. The research encompasses quantitative surveys and qualitative discussions to capture both statistical data and nuanced market perspectives.

Secondary research sources encompass industry publications, regulatory databases, patent filings, and company annual reports to provide comprehensive market context and historical trend analysis. The methodology incorporates cross-validation techniques to ensure data accuracy and reliability across multiple sources.

Analytical frameworks utilized include market sizing models, competitive positioning analysis, and trend forecasting methodologies. The research employs statistical analysis techniques to identify correlations and market patterns while utilizing scenario modeling to project future market developments under various conditions.

Data validation processes ensure research quality through multiple verification steps, expert review panels, and continuous monitoring of market developments to maintain current and accurate market intelligence.

North America represents a mature market for chemical packaging in agriculture, characterized by stringent regulatory requirements and advanced packaging technologies. The region demonstrates 35% market share globally, driven by large-scale commercial agriculture and established agricultural chemical manufacturers requiring sophisticated packaging solutions.

Europe shows strong market presence with emphasis on sustainable packaging solutions and circular economy principles. The region leads in environmental packaging innovation with 28% market share and demonstrates increasing adoption of biodegradable packaging materials driven by strict environmental regulations and consumer awareness.

Asia-Pacific emerges as the fastest-growing regional market with 8.5% CAGR driven by agricultural modernization, increasing crop protection product usage, and expanding commercial farming operations. Countries including China, India, and Southeast Asian nations contribute significantly to regional growth through agricultural expansion and technology adoption.

Latin America demonstrates substantial growth potential with large agricultural sectors requiring increased crop protection and specialized packaging solutions. The region shows 22% market share with Brazil and Argentina leading demand for agricultural chemical packaging due to extensive commercial farming operations.

Middle East and Africa represent emerging markets with growing agricultural development and increasing adoption of modern farming practices. The region shows promising growth prospects as agricultural investment increases and food security becomes a priority for regional governments.

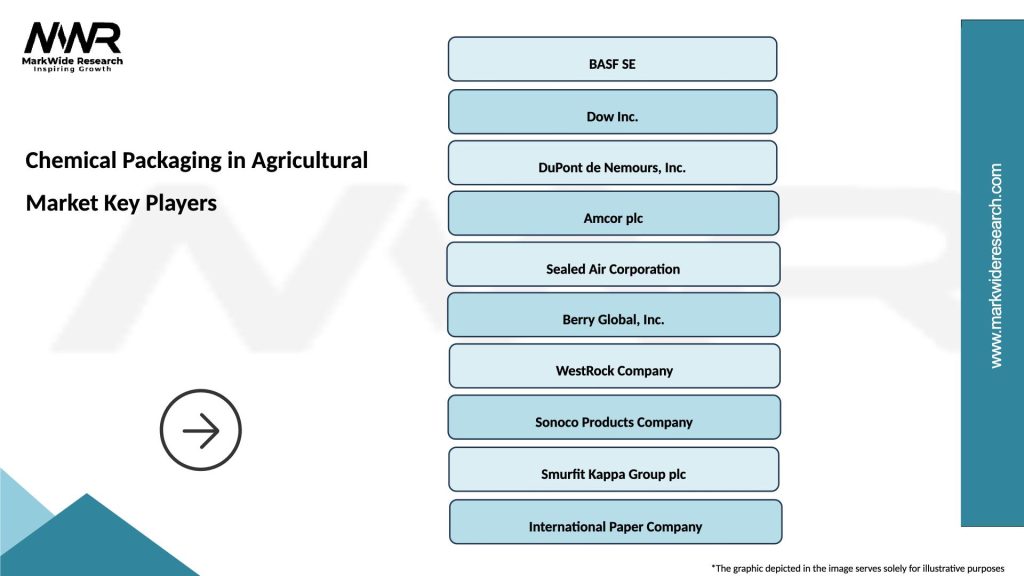

Market leadership in the chemical packaging in agricultural market is distributed among several key players offering diverse packaging solutions and serving different market segments:

Competitive strategies include technological innovation, geographic expansion, strategic partnerships, and sustainability initiatives. Companies increasingly focus on value-added services including packaging design consultation, regulatory compliance support, and supply chain optimization.

Market consolidation trends show larger packaging companies acquiring specialized agricultural packaging manufacturers to enhance their capabilities and market reach while smaller companies focus on niche markets and innovative solutions.

By Material Type:

By Product Type:

By Application:

By End-User:

Plastic Packaging Category dominates the market with 58% market share due to versatility, cost-effectiveness, and excellent chemical compatibility. HDPE containers lead this segment, offering superior chemical resistance and durability for various agricultural chemicals. Innovation focuses on lightweight designs and enhanced barrier properties while maintaining structural integrity.

Metal Packaging Category serves specialized applications requiring maximum durability and chemical compatibility. Steel drums remain preferred for bulk liquid agricultural chemicals, while aluminum containers gain popularity for premium products requiring extended shelf life and superior protection against environmental factors.

Pesticide Packaging Applications represent the largest application segment, requiring specialized packaging solutions that maintain chemical stability while ensuring user safety. This category drives innovation in tamper-evident closures, child-resistant packaging, and precise dosing systems integrated into container designs.

Fertilizer Packaging Applications focus on moisture protection and handling efficiency, with increasing demand for bulk packaging solutions that reduce handling costs and environmental impact. The segment shows growing adoption of flexible intermediate bulk containers for liquid fertilizers and moisture-barrier bags for solid fertilizers.

Sustainable Packaging Solutions emerge as a critical category with 31% growth rate as manufacturers respond to environmental concerns and regulatory requirements. This category includes recyclable materials, biodegradable options, and refillable container systems designed to minimize environmental impact.

Agricultural Chemical Manufacturers benefit from specialized packaging solutions that ensure product integrity, regulatory compliance, and brand differentiation. Advanced packaging technologies enable extended shelf life, reduced product loss, and enhanced safety protocols while supporting global distribution strategies.

Packaging Manufacturers gain access to a stable, growing market with opportunities for technological innovation and long-term customer partnerships. The sector offers recurring revenue streams through ongoing supply agreements and opportunities for value-added services including packaging design and regulatory consulting.

Agricultural Distributors benefit from packaging solutions that optimize logistics efficiency, reduce handling costs, and ensure product quality throughout the supply chain. Advanced packaging enables inventory optimization, reduced waste, and improved customer satisfaction through reliable product delivery.

Farming Operations gain from packaging innovations that enhance application efficiency, reduce chemical waste, and improve worker safety. Modern packaging solutions provide precise dosing capabilities, easy handling features, and clear labeling systems that support effective crop protection strategies.

Environmental Stakeholders benefit from increasing adoption of sustainable packaging solutions that reduce environmental impact while maintaining product performance. The industry’s focus on circular economy principles and recyclable materials supports broader environmental sustainability goals.

Strengths:

Weaknesses:

Opportunities:

Threats:

Sustainability Revolution drives fundamental changes in packaging material selection and design philosophy, with companies increasingly adopting circular economy principles and developing biodegradable packaging alternatives. This trend reflects growing environmental consciousness and regulatory pressure for reduced packaging environmental impact.

Smart Packaging Integration emerges as a transformative trend incorporating IoT sensors, RFID tracking, and temperature monitoring systems into agricultural chemical packaging. These technologies enable real-time monitoring of product condition, supply chain visibility, and enhanced safety protocols throughout distribution and storage.

Customization and Personalization trends show increasing demand for tailored packaging solutions meeting specific customer requirements for branding, functionality, and regulatory compliance. MWR data indicates 47% of manufacturers now prefer customized packaging solutions over standard offerings.

Lightweighting Initiatives focus on reducing packaging material usage while maintaining performance characteristics, driven by cost reduction objectives and environmental sustainability goals. Advanced material technologies enable weight reduction without compromising chemical compatibility or structural integrity.

Regulatory Harmonization trends show gradual alignment of international packaging standards, potentially simplifying compliance requirements and enabling more efficient global distribution strategies for agricultural chemical manufacturers.

Digital Integration encompasses the adoption of digital technologies throughout the packaging lifecycle, from design and manufacturing to tracking and recycling. This trend enables enhanced efficiency, improved quality control, and better customer service through digital connectivity.

Recent industry developments highlight significant advancements in sustainable packaging technologies, with multiple companies launching biodegradable packaging lines specifically designed for agricultural chemicals. These innovations address growing environmental concerns while maintaining the chemical compatibility and safety requirements essential for agricultural applications.

Strategic partnerships between packaging manufacturers and agricultural chemical companies have intensified, focusing on collaborative development of next-generation packaging solutions. These partnerships enable shared R&D investments and accelerated innovation cycles while ensuring packaging solutions meet specific application requirements.

Regulatory developments include implementation of enhanced safety standards for agricultural chemical packaging across multiple regions, driving investment in advanced closure systems and tamper-evident technologies. These regulations emphasize worker safety and environmental protection while maintaining product efficacy.

Technology acquisitions show established packaging companies acquiring specialized agricultural packaging manufacturers and technology companies to enhance their capabilities and market position. These acquisitions enable rapid expansion of technical expertise and customer reach in the agricultural chemical packaging sector.

Manufacturing expansion initiatives include construction of new production facilities in emerging agricultural markets, particularly in Asia-Pacific and Latin America, to serve growing regional demand while reducing logistics costs and improving customer service.

Innovation investments focus on advanced material development, with companies investing in bio-based polymers, enhanced barrier coatings, and smart packaging technologies to differentiate their offerings and meet evolving market requirements.

Strategic recommendations for market participants emphasize the critical importance of investing in sustainable packaging technologies to address growing environmental concerns and regulatory requirements. Companies should prioritize development of recyclable packaging solutions and circular economy approaches to maintain competitive advantage in an increasingly environmentally conscious market.

Innovation focus should center on smart packaging technologies that provide added value through supply chain visibility, product integrity monitoring, and enhanced safety features. According to MarkWide Research analysis, companies investing in smart packaging technologies demonstrate 34% higher customer retention rates compared to traditional packaging providers.

Geographic expansion strategies should prioritize emerging agricultural markets in Asia-Pacific, Africa, and Latin America where agricultural modernization drives increasing demand for specialized packaging solutions. Establishing local manufacturing capabilities and partnerships can provide competitive advantages in these growing markets.

Partnership development with agricultural chemical manufacturers should focus on long-term collaborative relationships that enable joint innovation and customized solution development. These partnerships provide stability and growth opportunities while reducing competitive pressure through differentiated offerings.

Regulatory compliance capabilities should be strengthened through investment in regulatory expertise and compliance systems that can adapt to evolving international standards. Companies with strong regulatory capabilities can expand into new markets more effectively and serve multinational customers more efficiently.

Digital transformation initiatives should encompass the entire packaging lifecycle from design and manufacturing to tracking and recycling, enabling enhanced efficiency and customer service while providing data-driven insights for continuous improvement.

Long-term market prospects for chemical packaging in agriculture remain highly positive, driven by continued global agricultural expansion, increasing crop protection product usage, and evolving packaging technology requirements. The sector is projected to maintain robust growth momentum with increasing emphasis on sustainable packaging solutions and smart packaging technologies.

Technology evolution will focus on advanced materials science, smart packaging integration, and sustainable packaging alternatives that address environmental concerns while maintaining superior performance characteristics. The integration of IoT technologies and blockchain tracking systems will enhance supply chain transparency and product authentication capabilities.

Regulatory landscape evolution will likely drive continued innovation in packaging safety features, environmental sustainability, and global harmonization of packaging standards. Companies that proactively address regulatory trends will gain competitive advantages through early market entry and enhanced customer relationships.

Market consolidation trends are expected to continue as larger packaging companies acquire specialized agricultural packaging manufacturers to enhance their capabilities and market reach. This consolidation will drive innovation through increased R&D investments and improved economies of scale.

Sustainability transformation will accelerate with 73% of companies expected to adopt circular economy principles within the next five years, driven by regulatory requirements and customer demand for environmentally responsible packaging solutions. This transformation will create opportunities for innovative companies while challenging traditional packaging approaches.

Geographic growth will be concentrated in emerging agricultural markets where agricultural modernization and increasing crop protection product adoption drive substantial packaging demand growth, creating opportunities for both established and emerging packaging manufacturers.

The chemical packaging in agricultural market represents a dynamic and essential sector within the global agricultural supply chain, characterized by continuous innovation, evolving regulatory requirements, and increasing emphasis on sustainability. The market demonstrates strong growth potential driven by expanding agricultural activities, technological advancement, and growing awareness of environmental responsibility.

Key success factors for market participants include investment in sustainable packaging technologies, development of smart packaging solutions, and establishment of strong partnerships with agricultural chemical manufacturers. Companies that can effectively balance performance requirements with environmental sustainability while maintaining cost competitiveness will achieve long-term market leadership.

Future market development will be shaped by technological innovation, regulatory evolution, and changing customer expectations regarding packaging performance and environmental impact. The sector’s ability to adapt to these changing requirements while maintaining safety and efficacy standards will determine long-term success and market growth potential.

Strategic positioning for sustained growth requires comprehensive understanding of regional market dynamics, regulatory requirements, and customer needs while maintaining focus on innovation and sustainability. The chemical packaging in agricultural market offers substantial opportunities for companies that can effectively navigate these complex requirements while delivering superior value to customers and stakeholders.

What is Chemical Packaging in Agriculture?

Chemical packaging in agriculture refers to the materials and methods used to contain and protect agricultural chemicals, such as fertilizers, pesticides, and herbicides. This type of packaging is designed to ensure safety, maintain product integrity, and facilitate ease of use in agricultural applications.

What are the key companies in the Chemical Packaging in Agricultural Market?

Key companies in the chemical packaging in agricultural market include Amcor, Sealed Air, and Berry Global, which provide innovative packaging solutions tailored for agricultural chemicals. These companies focus on sustainability and compliance with safety regulations, among others.

What are the growth factors driving the Chemical Packaging in Agricultural Market?

The growth of the chemical packaging in agricultural market is driven by the increasing demand for high-efficiency agricultural products, the rise in organic farming, and the need for sustainable packaging solutions. Additionally, advancements in packaging technology contribute to improved shelf life and safety.

What challenges does the Chemical Packaging in Agricultural Market face?

The chemical packaging in agricultural market faces challenges such as stringent regulations regarding chemical safety and environmental impact, as well as the need for innovative materials that reduce waste. Additionally, fluctuating raw material prices can impact production costs.

What opportunities exist in the Chemical Packaging in Agricultural Market?

Opportunities in the chemical packaging in agricultural market include the development of biodegradable and recyclable packaging materials, as well as the integration of smart packaging technologies. These innovations can enhance product traceability and improve user experience in agriculture.

What trends are shaping the Chemical Packaging in Agricultural Market?

Trends in the chemical packaging in agricultural market include a shift towards sustainable packaging solutions, increased use of digital technologies for tracking and monitoring, and a focus on reducing the carbon footprint of packaging materials. These trends reflect the growing emphasis on environmental responsibility in agriculture.

Chemical Packaging in Agricultural Market

| Segmentation Details | Description |

|---|---|

| Product Type | Flexible Packaging, Rigid Containers, Drums, Bags |

| Material | Polyethylene, Polypropylene, Glass, Metal |

| Packaging Type | Bulk Packaging, Retail Packaging, Intermediate Bulk Containers, Sachets |

| End Use Industry | Agronomy, Horticulture, Fertilizers, Pesticides |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Chemical Packaging in Agricultural Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at