444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The Chemical Enhanced Oil Recovery (EOR) market is witnessing significant growth and is expected to continue its upward trajectory in the coming years. EOR refers to the process of using various chemicals to enhance the recovery of oil from reservoirs that have already undergone primary and secondary recovery methods. This technique plays a vital role in extracting oil from mature fields, where conventional methods have limited effectiveness. Chemical EOR involves the injection of chemicals into the reservoir to alter the properties of oil and improve its mobility, thereby increasing the overall production.

Meaning

Chemical Enhanced Oil Recovery, also known as tertiary oil recovery, is a technique used to extract additional oil from reservoirs that have reached their limit with primary and secondary recovery methods. It involves injecting chemicals, such as surfactants, polymers, alkaline agents, and gases, into the reservoir to change the characteristics of the oil and enhance its flow towards the production wells. The chemical agents used in EOR alter the interfacial tension between oil and water, increase the viscosity of the oil, or reduce the capillary forces that trap the oil in the reservoir rock.

Executive Summary

The Chemical Enhanced Oil Recovery market has been experiencing substantial growth due to the increasing demand for oil and the need to maximize production from existing oilfields. The market is driven by advancements in chemical formulations, improved understanding of reservoir dynamics, and the continuous search for alternative energy sources. The global Chemical EOR market is expected to witness significant expansion in the forecast period, with key players investing in research and development activities to develop advanced chemical agents and technologies. The market is also influenced by factors such as government initiatives, favorable regulations, and the rising adoption of EOR techniques by oil and gas companies.

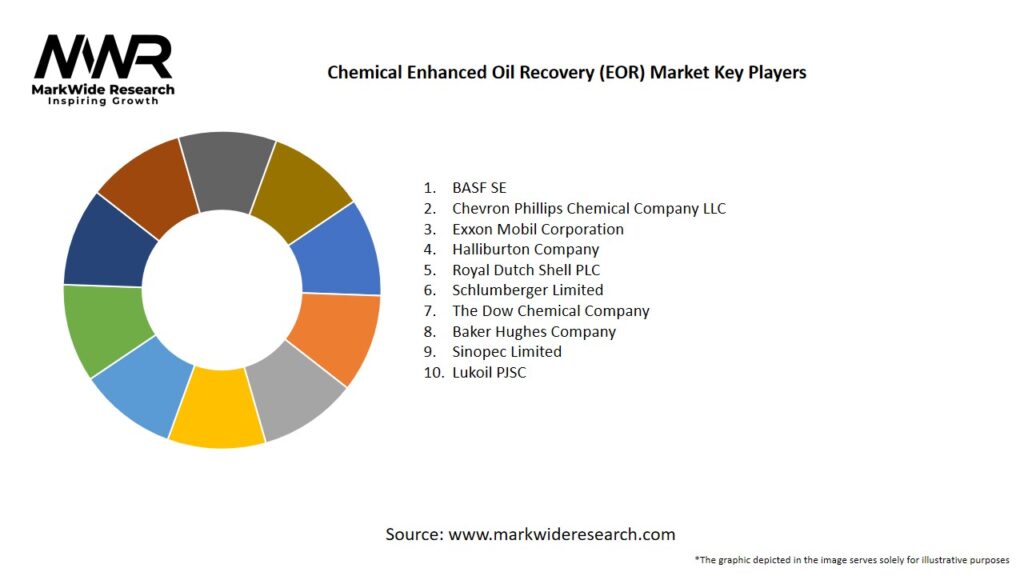

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Chemical Enhanced Oil Recovery market is driven by several dynamic factors, including technological advancements, regulatory frameworks, industry collaborations, and evolving market demands. The market dynamics are influenced by the interplay of these factors, shaping the growth and expansion of the Chemical EOR industry. Key dynamics include the availability of advanced chemicals, the exploration of new oilfields, changing market trends, fluctuating oil prices, environmental concerns, and government policies. Understanding and adapting to these dynamics are crucial for industry participants to thrive in the competitive market landscape.

Regional Analysis

The Chemical Enhanced Oil Recovery market is segmented into several regions, including North America, Europe, Asia Pacific, Middle East & Africa, and Latin America. Among these, North America holds the largest market share, driven by the presence of extensive oil reserves, well-established oil and gas infrastructure, and favorable government policies. The Middle East is another significant market for Chemical EOR, owing to its vast oil reserves and a strong focus on maximizing oil production. Asia Pacific is expected to witness substantial growth due to increasing energy demands and the exploration of unconventional oil resources. Europe, Latin America, and Africa also offer significant growth potential, driven by ongoing exploration activities and the need to enhance oil recovery from existing fields.

Competitive Landscape

Leading Companies in the Chemical Enhanced Oil Recovery (EOR) Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

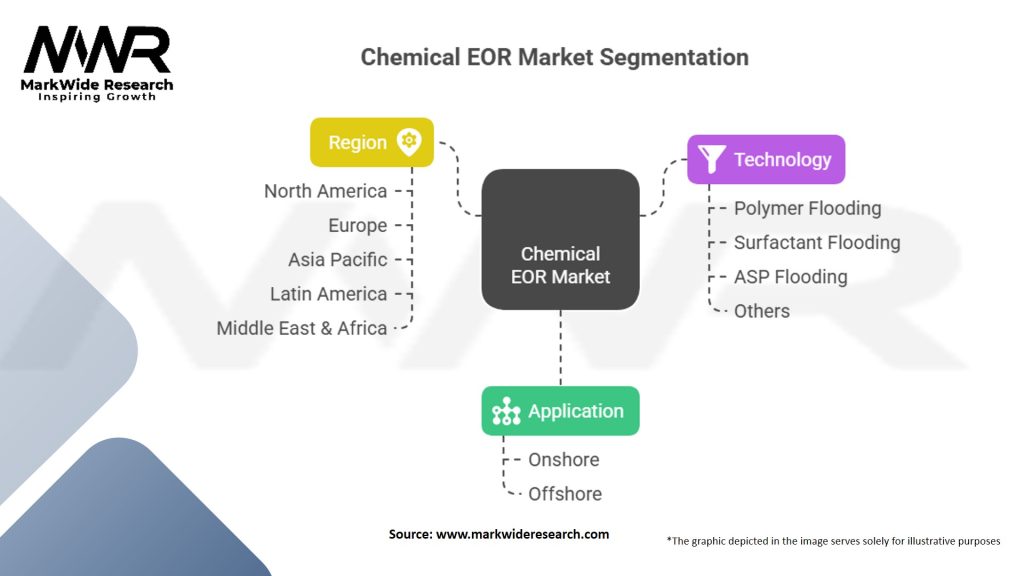

Segmentation

The Chemical Enhanced Oil Recovery market can be segmented based on the type of chemicals used, including surfactants, polymers, alkaline agents, and gases. Surfactants are extensively used to reduce interfacial tension and improve the mobility of oil in the reservoir. Polymers increase the viscosity of the injected fluid, thereby improving sweep efficiency. Alkaline agents help in reducing the acidity of oil and neutralize reservoir rock, enhancing oil recovery. Gases, such as carbon dioxide and nitrogen, are utilized to maintain reservoir pressure and improve oil displacement.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

A SWOT (Strengths, Weaknesses, Opportunities, and Threats) analysis provides valuable insights into the internal and external factors affecting the Chemical Enhanced Oil Recovery market:

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic had a significant impact on the global oil and gas industry, including the Chemical Enhanced Oil Recovery market. The restrictions imposed to curb the spread of the virus resulted in a decline in oil demand and a sharp drop in oil prices. This led to a decrease in investment and exploration activities, affecting the implementation of EOR projects. However, the long-term outlook for the Chemical EOR market remains positive as oil demand is expected to recover gradually with the easing of restrictions and the resumption of economic activities.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future outlook for the Chemical Enhanced Oil Recovery market is positive, driven by the increasing demand for oil, the need to maximize production from existing fields, and the continuous advancements in chemical formulations and technologies. The market is expected to witness substantial growth as oil companies strive to extract additional oil from mature reservoirs and explore unconventional resources. The integration of digital technologies, sustainable practices, and collaborative research efforts will shape the future of Chemical EOR, allowing for improved oil recovery rates, optimized field performance, and a more environmentally friendly approach to oil extraction.

Conclusion

The Chemical Enhanced Oil Recovery market offers significant opportunities for oil and gas companies to maximize production from existing fields and meet the growing global energy demand. The use of advanced chemical formulations, innovative technologies, and integrated solutions enables better oil recovery, extended reservoir life, and improved operational efficiency. Despite challenges such as high implementation costs, complex reservoir conditions, and environmental concerns, the market is expected to witness substantial growth with increasing investments in research and development, international expansion, and the adoption of sustainable EOR practices. By embracing technological advancements, collaborating with industry stakeholders, and prioritizing environmental sustainability, companies can thrive in the competitive Chemical EOR market and contribute to the long-term growth of the oil and gas industry.

What is Chemical Enhanced Oil Recovery (EOR)?

Chemical Enhanced Oil Recovery (EOR) refers to techniques that use chemical agents to improve the extraction of oil from reservoirs. This process often involves the use of surfactants, polymers, and alkaline substances to increase oil mobility and reduce surface tension.

What are the key players in the Chemical Enhanced Oil Recovery (EOR) Market?

Key players in the Chemical Enhanced Oil Recovery (EOR) Market include companies like Halliburton, Schlumberger, and Baker Hughes, which provide various EOR solutions and technologies. These companies focus on enhancing oil recovery through innovative chemical formulations and techniques, among others.

What are the main drivers of the Chemical Enhanced Oil Recovery (EOR) Market?

The main drivers of the Chemical Enhanced Oil Recovery (EOR) Market include the increasing demand for oil and gas, the need to maximize recovery from existing fields, and advancements in chemical technologies. Additionally, the rising focus on energy security and sustainability is pushing the adoption of EOR methods.

What challenges does the Chemical Enhanced Oil Recovery (EOR) Market face?

The Chemical Enhanced Oil Recovery (EOR) Market faces challenges such as high operational costs, environmental concerns related to chemical usage, and the technical complexity of implementing EOR techniques. These factors can hinder the widespread adoption of EOR methods in various regions.

What opportunities exist in the Chemical Enhanced Oil Recovery (EOR) Market?

Opportunities in the Chemical Enhanced Oil Recovery (EOR) Market include the development of more efficient and environmentally friendly chemical agents, as well as the potential for EOR in unconventional oil reservoirs. Additionally, increasing investments in oil recovery technologies present significant growth prospects.

What trends are shaping the Chemical Enhanced Oil Recovery (EOR) Market?

Trends shaping the Chemical Enhanced Oil Recovery (EOR) Market include the integration of digital technologies for monitoring and optimization, the use of bio-based chemicals for enhanced recovery, and a growing emphasis on sustainability practices. These trends are influencing how EOR techniques are developed and implemented.

Chemical Enhanced Oil Recovery (EOR) Market

| Segmentation Details | Details |

|---|---|

| Application | Onshore, Offshore |

| Technology | Polymer Flooding, Surfactant Flooding, Alkaline/Surfactant/Polymer (ASP) Flooding, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Chemical Enhanced Oil Recovery (EOR) Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at