444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The chafing gear market encompasses a range of protective coverings and materials designed to prevent abrasion and wear damage on surfaces exposed to friction or rubbing. These products are crucial in various industries, including maritime, aerospace, automotive, and industrial applications, where protection against wear and tear is essential to prolong equipment lifespan and ensure operational safety.

Meaning

Chafing gear refers to protective coverings, often made from durable materials like synthetic fibers, rubber, or specialized fabrics, applied to vulnerable surfaces to minimize friction-induced damage. It is commonly used in marine environments to shield ropes, cables, and hulls from abrasion caused by contact with docks, rigging, or other equipment.

Executive Summary

The chafing gear market is driven by increasing awareness of equipment maintenance, safety regulations, and the need to extend operational lifespans. Key players emphasize innovative materials and designs to cater to diverse industry needs, offering solutions that enhance durability, reduce maintenance costs, and improve operational efficiency across different sectors.

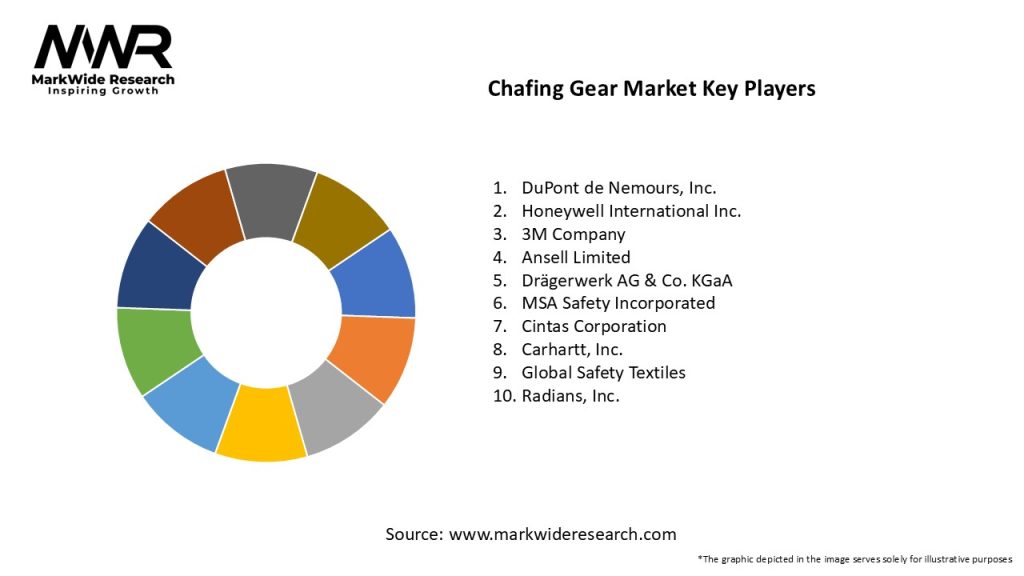

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Several factors are propelling the growth of the chafing gear market:

Market Restraints

Challenges facing the chafing gear market include:

Market Opportunities

Opportunities for growth in the chafing gear market include:

Market Dynamics

The chafing gear market dynamics are shaped by technological advancements, regulatory frameworks, industry trends, and competitive pressures. Companies must navigate these dynamics by focusing on innovation, quality assurance, and customer-centric strategies to capitalize on growth opportunities and maintain competitive advantage.

Regional Analysis

The chafing gear market exhibits regional variations:

Competitive Landscape

Leading Companies in the Chafing Gear Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

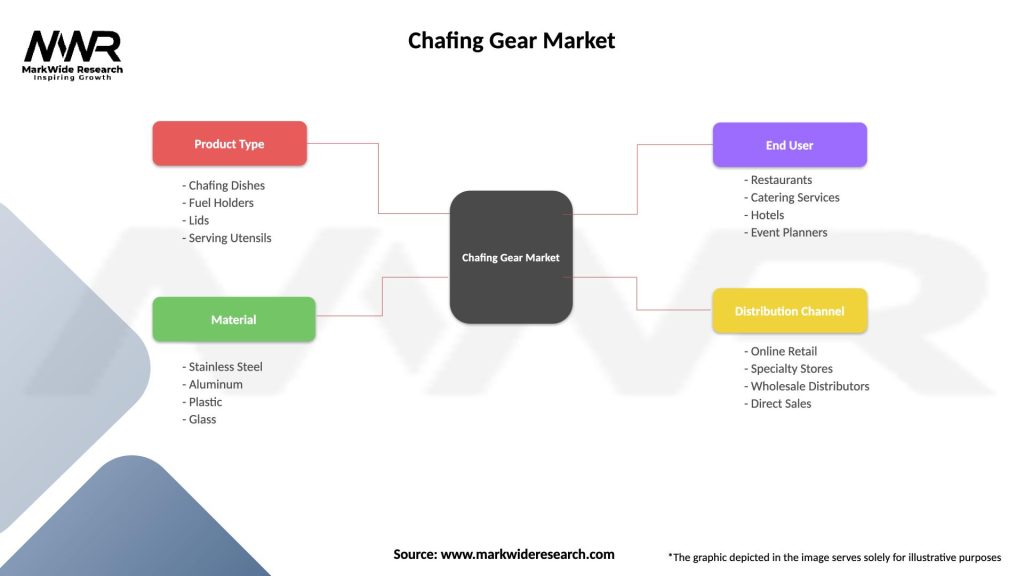

Segmentation

The chafing gear market can be segmented by:

Category-wise Insights

Different categories of chafing gear offer unique benefits:

Key Benefits for Industry Participants and Stakeholders

Benefits of chafing gear include:

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Current trends in the chafing gear market include:

Covid-19 Impact

The Covid-19 pandemic has influenced the chafing gear market:

Key Industry Developments

Recent developments in the chafing gear market include:

Analyst Suggestions

Based on market trends and developments, analysts suggest the following strategies for industry participants:

Future Outlook

The future outlook for the chafing gear market is positive, with sustained growth anticipated across industrial sectors driven by technological advancements, regulatory compliance, and increasing demand for reliable equipment protection solutions. Industry stakeholders poised to capitalize on emerging opportunities in smart materials, customization, and sustainability initiatives are well-positioned to achieve long-term success and leadership in the global chafing gear market.

Conclusion

In conclusion, the chafing gear market plays a critical role in safeguarding equipment integrity, enhancing operational efficiency, and ensuring safety across diverse industrial applications. Despite challenges such as cost constraints and competitive pressures, ongoing innovations in materials science, technological advancements, and strategic market expansion efforts will fuel market growth and innovation in the years ahead, positioning industry participants for sustainable growth and competitive advantage.

What is Chafing Gear?

Chafing gear refers to specialized equipment designed to prevent skin irritation and discomfort caused by friction during physical activities. This gear is commonly used in sports, outdoor activities, and by individuals who experience chafing due to prolonged movement.

What are the key players in the Chafing Gear Market?

Key players in the Chafing Gear Market include companies like Under Armour, Nike, and 2XU, which offer a range of products designed to minimize chafing. These companies focus on innovative materials and designs to enhance comfort and performance, among others.

What are the main drivers of growth in the Chafing Gear Market?

The growth of the Chafing Gear Market is driven by increasing participation in sports and outdoor activities, rising awareness of skin health, and advancements in fabric technology. Additionally, the demand for high-performance athletic wear contributes to market expansion.

What challenges does the Chafing Gear Market face?

The Chafing Gear Market faces challenges such as competition from alternative products, varying consumer preferences, and the need for continuous innovation. Additionally, price sensitivity among consumers can impact market growth.

What opportunities exist in the Chafing Gear Market?

Opportunities in the Chafing Gear Market include the development of eco-friendly materials, expansion into emerging markets, and the potential for customization in product offerings. Brands can also explore partnerships with fitness influencers to reach a broader audience.

What trends are shaping the Chafing Gear Market?

Trends in the Chafing Gear Market include the increasing popularity of athleisure wear, the integration of smart textiles, and a focus on sustainability. Consumers are also seeking products that offer both functionality and style, influencing design choices.

Chafing Gear Market

| Segmentation Details | Description |

|---|---|

| Product Type | Chafing Dishes, Fuel Holders, Lids, Serving Utensils |

| Material | Stainless Steel, Aluminum, Plastic, Glass |

| End User | Restaurants, Catering Services, Hotels, Event Planners |

| Distribution Channel | Online Retail, Specialty Stores, Wholesale Distributors, Direct Sales |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Chafing Gear Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at