444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The Carbonated Beverage Processing Equipment market refers to the industry involved in the manufacturing and production of equipment used in the processing and production of carbonated beverages. Carbonated beverages, also known as fizzy drinks or soft drinks, are widely consumed around the world and include popular products like sodas, sparkling water, and energy drinks.

The market for carbonated beverage processing equipment is driven by the growing demand for carbonated beverages globally. These beverages are popular among consumers of all age groups and are consumed on various occasions. The market offers a wide range of processing equipment, including carbonation machines, mixing tanks, filling machines, and bottle washers, among others.

Meaning

The carbonated beverage processing equipment market encompasses the design, production, and distribution of equipment specifically used in the manufacturing process of carbonated beverages. This equipment plays a crucial role in ensuring the quality, consistency, and efficiency of the production process. It includes various machinery and systems involved in the carbonation, mixing, filtration, filling, and packaging of carbonated beverages.

Executive Summary

The carbonated beverage processing equipment market has witnessed significant growth in recent years, driven by the rising consumption of carbonated beverages and the expansion of the beverage industry. The market is highly competitive, with several key players offering a wide range of equipment and solutions to meet the diverse needs of beverage manufacturers. The industry is characterized by technological advancements aimed at enhancing production efficiency, ensuring product quality, and improving sustainability.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The carbonated beverage processing equipment market is driven by a combination of factors, including consumer demand, technological advancements, regulatory requirements, and market competition. These dynamics shape the industry and influence the strategies of equipment manufacturers and beverage producers. The market is characterized by intense competition, with several key players vying for market share. To gain a competitive edge, manufacturers focus on product innovation, technological advancements, and offering comprehensive solutions that meet the evolving needs of beverage producers. Technological advancements, such as automation, integration of IoT technology, and data analytics, have played a significant role in improving efficiency, reducing operational costs, and ensuring product quality.

Changing consumer preferences and the shift towards healthier alternatives have influenced the demand for specialized equipment capable of processing low-sugar or sugar-free carbonated beverages. Manufacturers are investing in R&D efforts to develop equipment that meets these requirements while maintaining productivity and efficiency. The market dynamics are also influenced by regulatory requirements related to product safety, labeling, and packaging. Compliance with these regulations is essential for manufacturers to ensure consumer safety and maintain market credibility. Equipment manufacturers must stay updated with the evolving regulatory landscape to design and develop equipment that meets these requirements.

Regional Analysis

The carbonated beverage processing equipment market exhibits a global presence, with significant market opportunities in various regions. The regional analysis provides insights into the market dynamics, demand trends, and growth potential in different geographical areas.

Competitive Landscape

Leading Companies in the Carbonated Beverage Processing Equipment Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The carbonated beverage processing equipment market can be segmented based on various factors, including equipment type, beverage type, and end-user.

By Equipment Type:

By Beverage Type:

By End-User:

Category-wise Insights

Carbonation Machines: Carbonation machines play a crucial role in the carbonated beverage production process. These machines are designed to infuse carbon dioxide into the beverage, creating the desired level of carbonation. They are available in various capacities and can accommodate different bottle sizes.

Mixers: Mixers are used to blend the ingredients and flavors in carbonated beverages. They ensure uniform distribution of ingredients, creating a consistent and well-mixed product. Mixers can handle multiple flavors and offer flexibility in adjusting the intensity of flavors.

Fillers: Fillers are used to fill carbonated beverages into bottles or cans. They ensure accurate and efficient filling, minimizing wastage and maintaining product quality. Fillers can handle different bottle sizes and offer options for carbonated beverages with or without preservatives.

Labeling Machines: Labeling machines apply labels to bottles or cans, providing product information, branding, and regulatory compliance. They offer various labeling options, such as wrap-around labels, pressure-sensitive labels, or shrink sleeves, catering to different packaging requirements.

Packaging Equipment: Packaging equipment includes machines for packaging carbonated beverages into cartons, trays, or multipacks. These machines ensure proper packaging and sealing, maintaining product freshness and integrity. Packaging equipment can handle different packaging formats, sizes, and materials.

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic had a significant impact on the carbonated beverage processing equipment market. The pandemic led to disruptions in the global supply chain, temporary shutdowns of manufacturing facilities, and changes in consumer behavior. During the initial phases of the pandemic, the beverage industry experienced a decline in demand as lockdown measures and restrictions limited social gatherings and on-premise consumption. This resulted in a temporary slowdown in the market, with some equipment manufacturers facing challenges due to reduced orders and delayed projects.

However, the market gradually recovered as restrictions eased and consumer demand started to rebound. The pandemic highlighted the importance of hygiene and safety measures in beverage production, leading to an increased focus on equipment that ensures product safety and cleanliness. Additionally, the pandemic accelerated certain market trends, such as the shift towards e-commerce and online ordering of beverages. This created opportunities for equipment manufacturers to develop solutions that cater to the changing distribution channels and packaging requirements.

Key Industry Developments

Analyst Suggestions

Future Outlook

The carbonated beverage processing equipment market is expected to witness steady growth in the coming years. Factors such as the increasing demand for carbonated beverages, technological advancements, and the emphasis on sustainability will drive market growth. The market is likely to witness further automation, integration of smart technologies, and the development of equipment with enhanced efficiency and productivity. Equipment manufacturers will focus on offering customizable solutions, incorporating sustainability measures, and catering to the growing demand for healthier alternatives.

The expansion of the beverage industry in emerging markets, along with the increasing disposable incomes and changing consumer lifestyles, presents significant growth opportunities. Manufacturers who can establish a strong presence in these regions and cater to the evolving demands of consumers will likely thrive in the market.

Conclusion

The carbonated beverage processing equipment market plays a critical role in meeting the global demand for carbonated beverages. Technological advancements, changing consumer preferences, and sustainability initiatives are driving the market’s growth. Equipment manufacturers must stay at the forefront of technological advancements, offer customizable solutions, and prioritize sustainability to meet the evolving needs of beverage producers. Strategic partnerships, customer support, and agility in adapting to market changes are key factors for success in this competitive market.

With the beverage industry poised for continued growth, the carbonated beverage processing equipment market offers substantial opportunities for manufacturers to innovate, expand their market presence, and contribute to the production of high-quality carbonated beverages worldwide.

What is Carbonated Beverage Processing Equipment?

Carbonated Beverage Processing Equipment refers to the machinery and technology used in the production, packaging, and distribution of carbonated drinks. This includes equipment for carbonation, mixing, bottling, and quality control, essential for ensuring the consistency and quality of beverages.

What are the key players in the Carbonated Beverage Processing Equipment market?

Key players in the Carbonated Beverage Processing Equipment market include Krones AG, Tetra Pak, and GEA Group, which provide a range of solutions for beverage production and processing. These companies are known for their innovative technologies and extensive product offerings, among others.

What are the main drivers of the Carbonated Beverage Processing Equipment market?

The main drivers of the Carbonated Beverage Processing Equipment market include the increasing demand for carbonated beverages, advancements in processing technology, and the growing trend of health-conscious consumers seeking low-calorie options. Additionally, the rise in craft beverage production is contributing to market growth.

What challenges does the Carbonated Beverage Processing Equipment market face?

The Carbonated Beverage Processing Equipment market faces challenges such as stringent regulations regarding food safety and quality, high initial investment costs, and competition from non-carbonated beverage alternatives. These factors can impact the growth and profitability of companies in this sector.

What opportunities exist in the Carbonated Beverage Processing Equipment market?

Opportunities in the Carbonated Beverage Processing Equipment market include the expansion of the beverage industry in emerging markets, the development of eco-friendly packaging solutions, and the integration of automation and smart technologies in processing equipment. These trends can enhance efficiency and sustainability.

What are the current trends in the Carbonated Beverage Processing Equipment market?

Current trends in the Carbonated Beverage Processing Equipment market include the increasing use of sustainable materials, the rise of personalized beverage options, and advancements in digital technology for monitoring and controlling production processes. These trends are shaping the future of beverage processing.

Carbonated Beverage Processing Equipment market

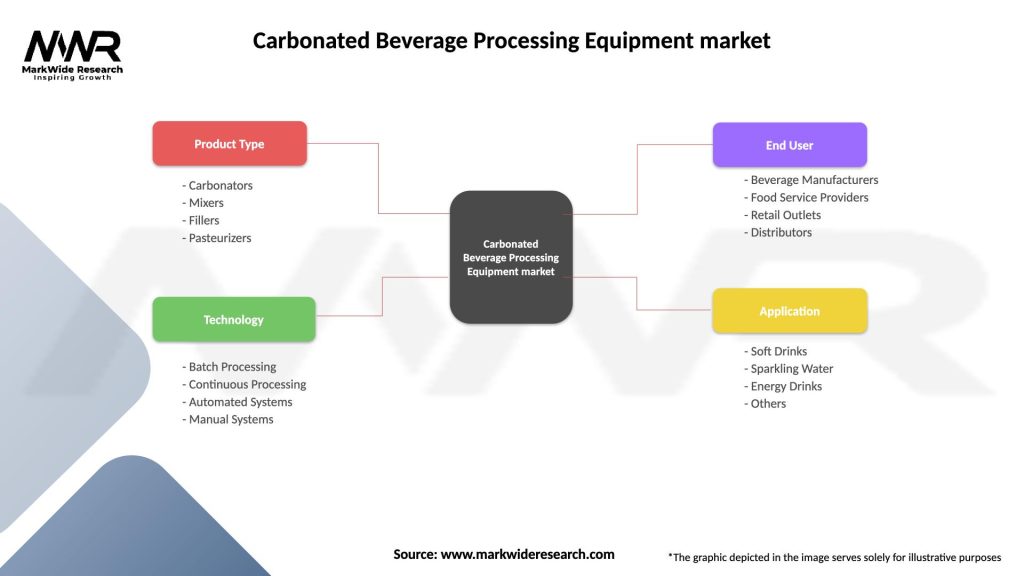

| Segmentation Details | Description |

|---|---|

| Product Type | Carbonators, Mixers, Fillers, Pasteurizers |

| Technology | Batch Processing, Continuous Processing, Automated Systems, Manual Systems |

| End User | Beverage Manufacturers, Food Service Providers, Retail Outlets, Distributors |

| Application | Soft Drinks, Sparkling Water, Energy Drinks, Others |

Leading Companies in the Carbonated Beverage Processing Equipment Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at