444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Carbon mold market analysis provides an in-depth understanding of the market dynamics, trends, opportunities, and challenges related to the production and use of carbon molds. Carbon molds, also known as carbon fiber molds, are extensively utilized in various industries such as automotive, aerospace, electronics, and sports equipment manufacturing. This analysis aims to shed light on the current state of the market, key market insights, competitive landscape, segmentation, regional analysis, and future outlook of the carbon mold market.

Carbon molds refer to molds that are made using carbon fiber materials. Carbon fiber composites are renowned for their exceptional strength, lightweight properties, and high resistance to temperature, making them an ideal choice for creating molds. These molds are primarily used in manufacturing processes that involve the production of complex shapes and structures. The carbon mold market encompasses the suppliers, manufacturers, and end-users involved in the production and utilization of carbon molds across different industries.

Executive Summary

The executive summary of the carbon mold market analysis provides a concise overview of the key findings, market trends, and significant insights derived from the comprehensive research conducted. It highlights the growth potential, major market drivers, challenges, and opportunities that shape the carbon mold industry. This summary serves as a quick reference for industry participants and stakeholders to grasp the essential aspects of the market analysis.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Rising Demand for Lightweight Components: The growing demand for lightweight and durable components, especially in the automotive and aerospace industries, is driving the market for carbon molds.

Advancements in Carbon Composite Materials: The development of new carbon composite materials, including carbon fiber-reinforced plastics, is improving the performance and efficiency of carbon molds, expanding their use in a variety of industries.

Aerospace and Automotive Applications: Carbon molds are gaining significant traction in the aerospace and automotive sectors, where high-performance parts are required for complex components such as turbine blades and engine parts.

Growing Use in Prototyping: The use of carbon molds in rapid prototyping and 3D printing technologies is creating new opportunities for manufacturers to create customized solutions for various applications.

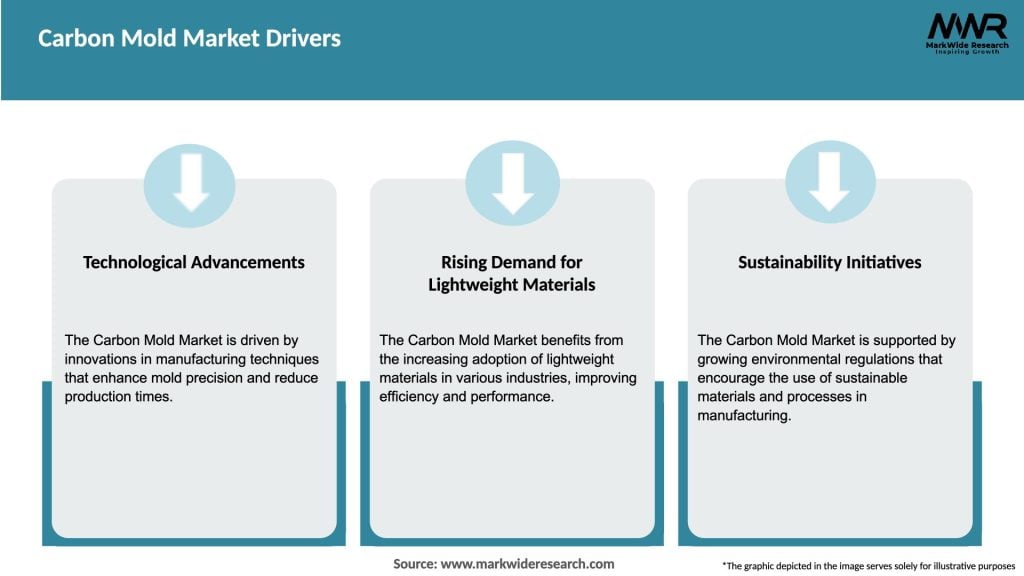

Market Drivers

Several factors are driving the growth of the Carbon Mold Market:

Rising Demand for Lightweight and High-Performance Materials: The shift towards lightweight, durable, and high-performance materials in industries like aerospace, automotive, and electronics is driving the adoption of carbon molds.

Technological Advancements in Carbon Materials: The development of new and improved carbon composite materials, including carbon fiber and carbon-based polymers, is expanding the capabilities of carbon molds, making them more versatile and cost-effective.

Increased Adoption of Additive Manufacturing: The rise of 3D printing and additive manufacturing technologies, which require specialized molds for precise components, is boosting the demand for carbon molds as they provide the necessary strength, precision, and heat resistance.

Growing Need for Rapid Prototyping: Industries such as automotive and aerospace are increasingly adopting rapid prototyping techniques to shorten product development cycles, driving the demand for carbon molds that are capable of creating complex and precise prototypes quickly.

Environmental Benefits: Carbon molds are often more sustainable compared to traditional metal molds, as they are lighter, more durable, and require fewer resources for manufacturing, contributing to the growing focus on environmentally friendly manufacturing solutions.

Market Restraints

Despite its growth potential, the Carbon Mold Market faces several challenges:

High Cost of Carbon Molds: Carbon molds, especially those made with advanced carbon composite materials, tend to be more expensive than traditional metal molds, which may limit their adoption in cost-sensitive industries.

Limited Awareness and Adoption: While carbon molds are gaining popularity, some industries still lack awareness of their benefits and may be hesitant to transition from traditional mold materials to carbon-based solutions.

Complex Manufacturing Process: The production of carbon molds involves complex processes, such as carbon fiber molding and resin infusion, which can increase lead times and the overall cost of manufacturing.

Supply Chain Limitations: The availability of high-quality carbon composite materials and the complexity of the supply chain for carbon mold production could impact the overall market growth, particularly in regions with less developed supply chains.

Market Opportunities

The Carbon Mold Market presents several opportunities for growth:

Expansion in Aerospace and Automotive Industries: The aerospace and automotive industries are key drivers of demand for carbon molds, with applications in high-performance components such as turbine blades, engine parts, and structural elements.

Integration with 3D Printing Technologies: The increasing use of carbon molds in additive manufacturing and 3D printing offers significant opportunities, as these technologies enable rapid prototyping and customized mold production.

Development of New Carbon Composites: Ongoing research into new carbon composite materials, including lighter and stronger fibers, presents opportunities for the development of advanced carbon molds with enhanced performance and reduced costs.

Customization for Niche Applications: Carbon molds can be customized to meet the specific needs of niche industries, such as medical device manufacturing, electronics, and high-tech components, providing growth opportunities for specialized mold manufacturers.

Market Dynamics

The Carbon Mold Market is influenced by several dynamic factors:

Technological Advancements: Innovations in carbon composite materials, including improved strength, heat resistance, and lightweight properties, are expanding the range of applications for carbon molds in various industries.

Sustainability Trends: The increasing focus on environmental sustainability is pushing industries to adopt materials that offer better durability, reduced waste, and improved energy efficiency, all of which contribute to the growing demand for carbon molds.

Customization and Flexibility: The ability to customize carbon molds for specific applications in sectors like aerospace, automotive, and medical devices is enabling manufacturers to cater to niche markets and meet unique customer needs.

Globalization of Manufacturing: The growing globalization of manufacturing, particularly in emerging markets, is driving demand for advanced mold materials, including carbon-based solutions, which are used for high-precision and high-performance applications.

Regional Analysis

The Carbon Mold Market shows varying trends across regions:

North America: North America, particularly the United States, is a dominant market for carbon molds due to the strong presence of aerospace, automotive, and high-tech industries. The region also benefits from significant investments in research and development for carbon composite materials.

Europe: Europe is seeing steady growth in the carbon mold market, driven by the aerospace and automotive industries in countries like Germany, France, and the UK, where demand for high-performance components is increasing.

Asia-Pacific: The Asia-Pacific region, led by China, Japan, and South Korea, is experiencing rapid growth in the carbon mold market due to the expansion of automotive, electronics, and manufacturing industries, coupled with increasing investments in advanced technologies.

Latin America: Latin America is gradually adopting carbon mold solutions, particularly in the automotive and manufacturing sectors, as industries in Brazil and Mexico continue to expand and modernize.

Middle East & Africa: The Middle East & Africa region is expected to witness moderate growth, with increasing demand for carbon molds in industries such as aerospace, automotive, and oil & gas.

Competitive Landscape

Leading Companies in the Carbon Mold Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The Carbon Mold Market can be segmented based on various factors:

Material Type: Carbon Fiber, Carbon Composites, Other Carbon Materials.

End-User Industry: Aerospace, Automotive, Electronics, Medical Devices, Industrial Manufacturing, Others.

Application: High-Performance Components, Prototyping, Mold Fabrication, Other Applications.

Category-wise Insights

Each category of carbon molds offers unique benefits and applications:

Carbon Fiber Molds: Carbon fiber molds are known for their exceptional strength-to-weight ratio and are commonly used in aerospace and automotive applications, where lightweight yet durable materials are required.

Carbon Composite Molds: These molds offer excellent heat resistance and durability, making them suitable for high-temperature applications such as engine parts and turbine blades.

Prototyping Molds: Carbon molds are widely used in rapid prototyping for industries like electronics and automotive, allowing manufacturers to create complex, customized components quickly.

Key Benefits for Industry Participants and Stakeholders

The Carbon Mold Market offers key benefits for stakeholders:

Enhanced Durability and Performance: Carbon molds provide superior performance, particularly in high-temperature, high-stress environments like aerospace and automotive manufacturing.

Cost-Effectiveness: Although the initial cost of carbon molds may be higher, their long lifespan and reduced need for maintenance make them cost-effective in the long run.

Customization: The ability to create highly customized molds for specific applications offers a competitive edge to manufacturers serving niche markets.

SWOT Analysis

Strengths:

High strength-to-weight ratio of carbon-based materials.

Versatility across multiple industries.

Weaknesses:

High cost compared to traditional metal molds.

Complexity in the manufacturing process.

Opportunities:

Increasing demand in the aerospace, automotive, and medical sectors.

Advancements in carbon composite technology.

Threats:

Competition from alternative mold materials.

Supply chain and raw material cost fluctuations.

Market Key Trends

Key trends shaping the Carbon Mold Market include:

Integration with Additive Manufacturing: The use of carbon molds in 3D printing and additive manufacturing is growing, enabling faster and more precise mold production.

Sustainability Focus: The demand for more sustainable and recyclable mold solutions is driving the development of eco-friendly carbon molds.

Covid-19 Impact

The Covid-19 pandemic has significantly impacted various industries, including the carbon mold market. The analysis examines the effects of the pandemic on the market, such as disruptions in the supply chain, temporary shutdown of manufacturing facilities, reduced demand from end-users, and the emergence of new market opportunities in sectors like healthcare and personal protective equipment (PPE). It provides insights into the short-term and long-term implications of the pandemic and suggests strategies to navigate the challenges posed by the crisis.

Key Industry Developments

The carbon mold market has witnessed several key industry developments in recent years. These developments include technological advancements, product innovations, mergers and acquisitions, collaborations, and partnerships among industry players. The analysis highlights these developments and their impact on the market dynamics, competitive landscape, and future growth potential. It helps industry participants stay updated with the latest industry trends and make informed decisions.

Analyst Suggestions

Based on the comprehensive analysis of the carbon mold market, industry analysts provide suggestions and recommendations for industry participants and stakeholders. These suggestions may include strategies to enhance production efficiency, expand market presence, optimize supply chain management, adopt sustainable practices, leverage emerging technologies, and develop innovative products and services. The analyst suggestions aim to guide industry participants in making informed decisions and maximizing their business potential.

Future Outlook

The future outlook of the carbon mold market presents a forward-looking perspective on themarket’s growth potential, emerging trends, and opportunities. It forecasts the market’s trajectory in terms of market size, revenue, and demand. The analysis takes into consideration factors such as technological advancements, regulatory policies, market dynamics, and industry developments to provide a comprehensive outlook for the coming years. The future outlook assists industry participants in making strategic decisions, identifying growth prospects, and aligning their business plans with the evolving market landscape.

Conclusion

In conclusion, the carbon mold market analysis provides valuable insights into the market’s current state, key market insights, market drivers, restraints, opportunities, and dynamics. It encompasses a comprehensive assessment of the market’s regional analysis, competitive landscape, segmentation, category-wise insights, and future outlook. The analysis equips industry participants and stakeholders with the necessary information to make informed decisions, develop effective strategies, and tap into the growing opportunities in the carbon mold market. By understanding the market trends and dynamics, industry participants can position themselves for success in this rapidly evolving industry.

What is a carbon mold?

A carbon mold is a type of mold made from carbon-based materials, often used in manufacturing processes for creating precise shapes and components. These molds are valued for their strength, durability, and ability to withstand high temperatures, making them suitable for various applications in industries such as aerospace, automotive, and electronics.

What are the key companies in the Carbon Mold Market?

Key companies in the Carbon Mold Market include Hexcel Corporation, SGL Carbon, and Mitsubishi Chemical Corporation, among others. These companies are known for their innovative approaches and extensive product offerings in carbon mold technology.

What are the growth factors driving the Carbon Mold Market?

The growth of the Carbon Mold Market is driven by the increasing demand for lightweight materials in the aerospace and automotive sectors, as well as advancements in manufacturing technologies. Additionally, the rising focus on energy efficiency and sustainability in production processes contributes to market expansion.

What challenges does the Carbon Mold Market face?

The Carbon Mold Market faces challenges such as high production costs and the complexity of manufacturing carbon molds. Additionally, competition from alternative materials and technologies can hinder market growth.

What opportunities exist in the Carbon Mold Market?

Opportunities in the Carbon Mold Market include the development of new applications in emerging industries such as renewable energy and medical devices. Furthermore, increasing investments in research and development can lead to innovative carbon mold solutions.

What trends are shaping the Carbon Mold Market?

Trends in the Carbon Mold Market include the growing adoption of automation and digital technologies in manufacturing processes. Additionally, there is a rising interest in sustainable materials and practices, which is influencing the design and production of carbon molds.

Carbon Mold Market

| Segmentation | Details |

|---|---|

| Material | Carbon Fiber, Graphite |

| Application | Aerospace & Defense, Automotive, Wind Energy, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Carbon Mold Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at