444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview

The Canada robotic fruit picker market is witnessing significant growth due to advancements in automation technology and the increasing demand for efficient harvesting solutions in the agriculture industry. Robotic fruit pickers are automated machines designed to accurately and delicately pick fruits from trees, minimizing damage and increasing productivity. These robots are equipped with advanced sensors, computer vision, and robotic arms to perform the harvesting tasks with precision.

Meaning

The robotic fruit picker market refers to the industry involved in the development, production, and distribution of automated machines specifically designed for fruit picking applications. These robots are designed to overcome the limitations of traditional manual labor in fruit harvesting, such as labor shortages, high labor costs, and time-consuming processes. By leveraging advanced technologies, robotic fruit pickers offer increased efficiency, productivity, and accuracy, thereby benefiting fruit growers and the overall agriculture sector.

Executive Summary

The Canada robotic fruit picker market is experiencing substantial growth driven by the need for enhanced harvesting techniques in the agricultural sector. With the rising demand for fresh fruits and the challenges faced by farmers in recruiting and retaining skilled labor, the adoption of robotic fruit pickers is gaining traction. These robots not only streamline the harvesting process but also contribute to improved yield and reduced operational costs. This report analyzes the market trends, drivers, restraints, opportunities, and provides insights into the competitive landscape and future outlook of the robotic fruit picker market in Canada.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

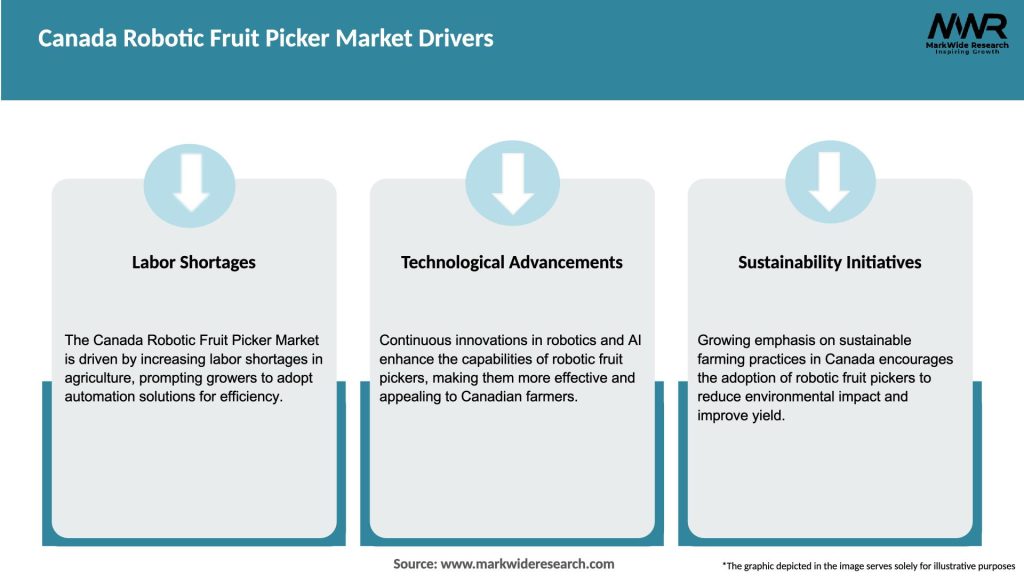

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Canada robotic fruit picker market is driven by the convergence of various factors, including labor shortages, rising labor costs, technological advancements, and the need for improved harvesting efficiency. While high initial investment and lack of awareness pose challenges, the market offers opportunities for manufacturers to innovate and collaborate. By addressing these dynamics, the market is poised for steady growth in the coming years.

Regional Analysis

The adoption of robotic fruit pickers in Canada varies across different regions due to variations in fruit cultivation patterns, orchard sizes, and labor availability. The major fruit-growing regions, such as British Columbia, Ontario, and Quebec, have shown a higher inclination towards robotic fruit pickers due to the scale of operations and the need for efficient harvesting techniques. Other regions, such as the Maritimes and the Prairie provinces, are gradually exploring the benefits of automation in fruit picking.

Competitive Landscape

Leading Companies in the Canada Robotic Fruit Picker Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

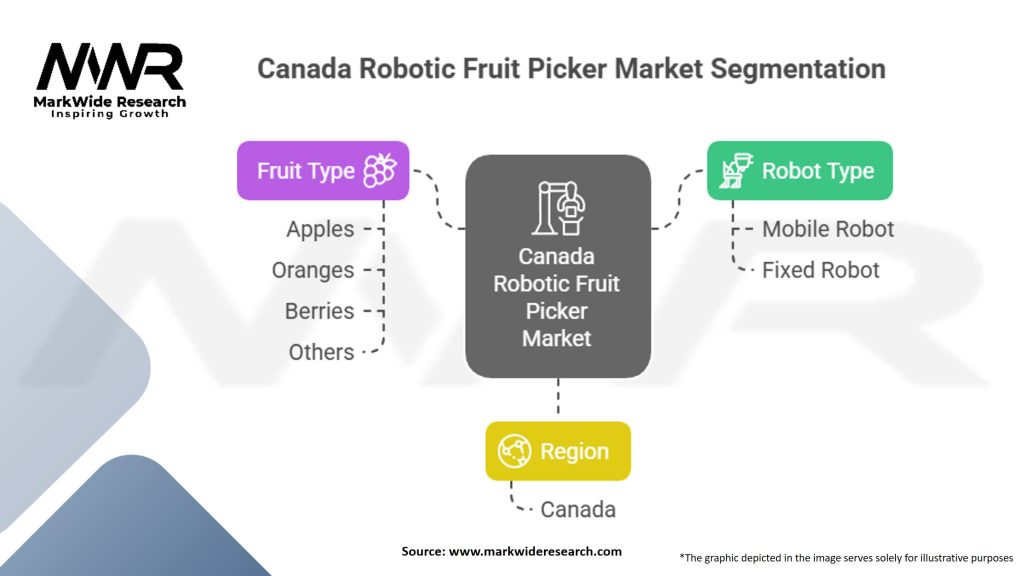

Segmentation

The Canada robotic fruit picker market can be segmented based on fruit type, robot type, and end-user.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic had a mixed impact on the Canada robotic fruit picker market. While the agriculture sector continued to operate as an essential service, the pandemic highlighted the vulnerabilities of the labor-intensive fruit harvesting process. The need for social distancing and restrictions on cross-border labor mobility resulted in labor shortages for fruit growers.

This situation prompted farmers to explore alternative solutions, including the adoption of robotic fruit pickers. The pandemic served as a catalyst for the market, accelerating the realization of the benefits of automation in fruit harvesting. Robotic fruit pickers offered a viable solution to minimize the reliance on manual labor, ensuring uninterrupted harvesting operations while maintaining social distancing protocols.

Key Industry Developments

Analyst Suggestions

Future Outlook

The Canada robotic fruit picker market is poised for significant growth in the coming years. The increasing need for efficient harvesting techniques, labor shortages, and rising labor costs are expected to drive the adoption of robotic fruit pickers among fruit growers. Technological advancements, such as AI, computer vision, and automation, will continue to fuel innovation in this market. Government support and industry collaborations will play a crucial role in expanding the market and addressing the challenges associated with adoption. The future outlook for the Canada robotic fruit picker market is promising, with opportunities for manufacturers to revolutionize fruit harvesting practices and contribute to the growth of the agriculture sector.

Conclusion

The Canada robotic fruit picker market is witnessing rapid growth due to the increasing demand for efficient harvesting solutions in the agriculture industry. Robotic fruit pickers offer benefits such as increased productivity, cost savings, improved fruit quality, and enhanced work safety. While the market faces challenges such as high initial investment and lack of awareness, opportunities lie in technological advancements, collaborations, and sustainable farming practices. The future of the market looks promising, with the potential to revolutionize fruit harvesting and contribute to the growth of the agriculture sector in Canada.

What is the Canada Robotic Fruit Picker?

The Canada Robotic Fruit Picker refers to automated machines designed to harvest fruits efficiently and effectively, reducing labor costs and increasing productivity in the agricultural sector.

Who are the key players in the Canada Robotic Fruit Picker Market?

Key players in the Canada Robotic Fruit Picker Market include companies like Agrobot, Harvest CROO Robotics, and Octinion, among others.

What are the main drivers of growth in the Canada Robotic Fruit Picker Market?

The main drivers of growth in the Canada Robotic Fruit Picker Market include the increasing demand for labor-saving technologies, the need for efficient harvesting solutions, and advancements in robotics and AI technologies.

What challenges does the Canada Robotic Fruit Picker Market face?

Challenges in the Canada Robotic Fruit Picker Market include high initial investment costs, the complexity of fruit picking tasks, and the need for ongoing maintenance and technical support.

What opportunities exist in the Canada Robotic Fruit Picker Market?

Opportunities in the Canada Robotic Fruit Picker Market include the potential for innovation in machine learning algorithms, expansion into new fruit varieties, and increasing adoption among small to medium-sized farms.

What trends are shaping the Canada Robotic Fruit Picker Market?

Trends shaping the Canada Robotic Fruit Picker Market include the integration of AI for improved decision-making, the development of more versatile robotic systems, and a growing focus on sustainable agricultural practices.

Canada Robotic Fruit Picker Market

| Segmentation | Details |

|---|---|

| Robot Type | Mobile Robot, Fixed Robot |

| Fruit Type | Apples, Oranges, Berries, Others |

| Region | Canada |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Canada Robotic Fruit Picker Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at