444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview:

The Canada Electrostatic Discharge (ESD) Packaging Market is an essential segment within the packaging industry, specializing in the design and production of protective packaging solutions to prevent electrostatic damage to sensitive electronic components during storage, handling, and transportation. With the increasing demand for electronic devices and components, the ESD packaging market in Canada plays a crucial role in ensuring product integrity and reliability.

Meaning:

Electrostatic discharge (ESD) packaging refers to specialized packaging materials and containers designed to protect electronic devices and components from electrostatic discharge, which can cause damage or malfunction. ESD packaging utilizes materials with low static electricity generation and provides a conductive or dissipative path to safely discharge static charges, preventing costly failures and ensuring product quality.

Executive Summary:

The Canada Electrostatic Discharge (ESD) Packaging Market is experiencing significant growth driven by factors such as the expanding electronics industry, increasing adoption of ESD-sensitive components, and stringent regulatory requirements for product safety and reliability. Key players in the market are focusing on product innovation, sustainability, and customer-centric solutions to capitalize on emerging opportunities and address evolving customer needs. Despite challenges such as environmental concerns and supply chain disruptions, the market holds immense potential for growth and innovation in the coming years.

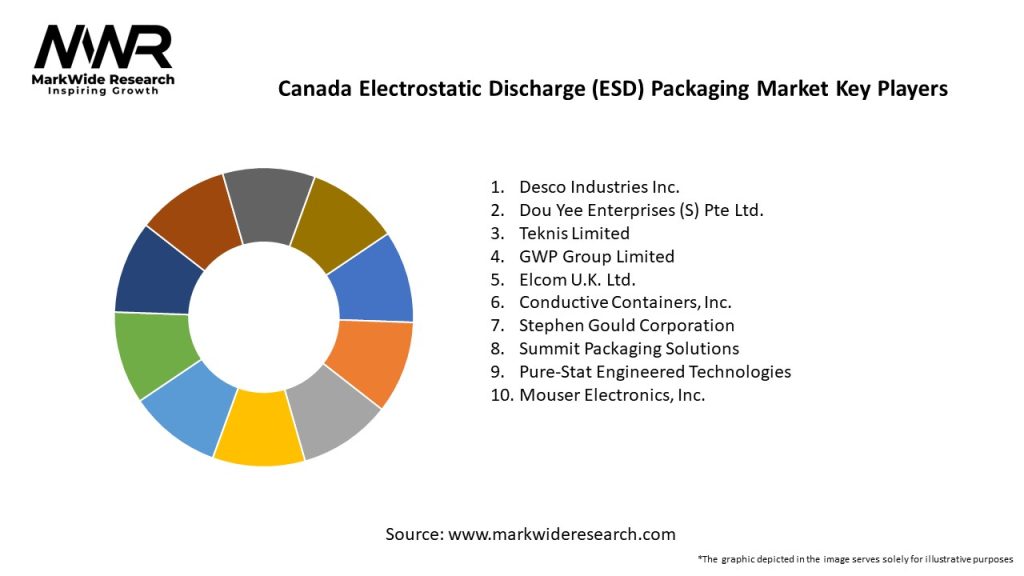

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights:

Market Drivers:

Market Restraints:

Market Opportunities:

Market Dynamics:

The Canada Electrostatic Discharge (ESD) Packaging Market operates in a dynamic environment influenced by various factors, including technological advancements, regulatory requirements, industry trends, and customer preferences. These dynamics shape market trends, product innovations, competitive landscape, and business strategies, requiring industry participants to adapt, innovate, and differentiate to maintain competitiveness and sustain growth in the long term.

Regional Analysis:

The Canada Electrostatic Discharge (ESD) Packaging Market exhibits regional variations in demand, adoption, and regulatory compliance due to differences in industry sectors, geographic locations, and customer preferences. Key regions driving market growth include Ontario, Quebec, British Columbia, Alberta, and Manitoba, with concentrations of electronics manufacturing, assembly, and distribution facilities.

Competitive Landscape:

Leading Companies in Canada Electrostatic Discharge (ESD) Packaging Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

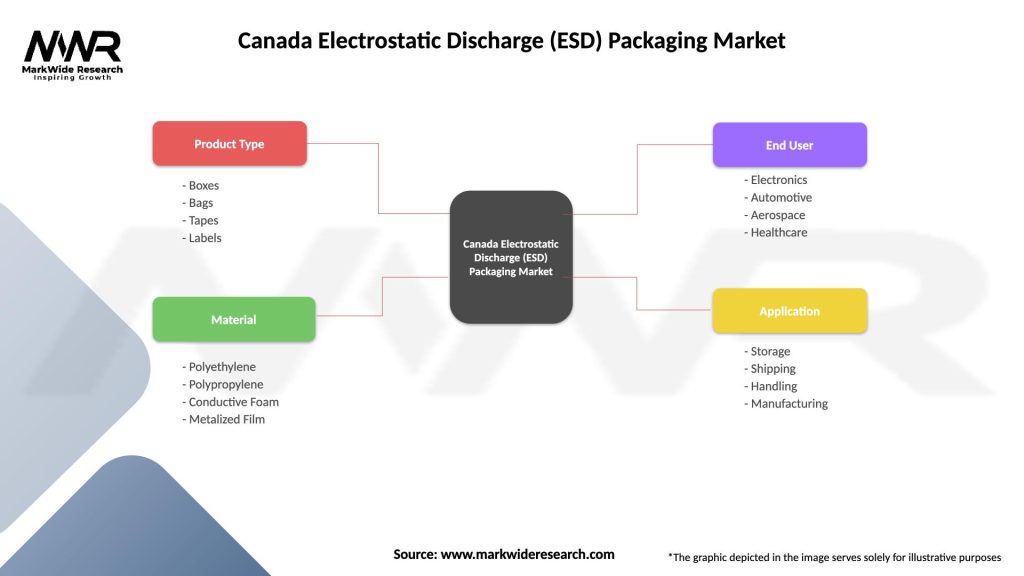

Segmentation:

The Canada Electrostatic Discharge (ESD) Packaging Market can be segmented based on various criteria, including:

Segmentation provides a structured approach to understanding market dynamics, customer needs, and product requirements, enabling packaging suppliers to develop targeted solutions, expand market reach, and enhance customer satisfaction.

Category-wise Insights:

Key Benefits for Industry Participants and Stakeholders:

SWOT Analysis:

A SWOT analysis of the Canada Electrostatic Discharge (ESD) Packaging Market provides insights into its strengths, weaknesses, opportunities, and threats:

Understanding these factors helps packaging suppliers, manufacturers, and distributors capitalize on strengths, address weaknesses, leverage opportunities, and mitigate threats to achieve sustainable growth and competitive advantage in the Canada Electrostatic Discharge (ESD) Packaging Market.

Market Key Trends:

Covid-19 Impact:

The Covid-19 pandemic has profound effects on the Canada Electrostatic Discharge (ESD) Packaging Market, influencing demand patterns, supply chain dynamics, and market trends:

Key Industry Developments:

Analyst Suggestions:

Future Outlook:

The Canada Electrostatic Discharge (ESD) Packaging Market is poised for steady growth and innovation driven by factors such as the expanding electronics industry, regulatory compliance requirements, technological advancements, and sustainability initiatives. Opportunities abound for packaging suppliers, manufacturers, and solution providers to capitalize on emerging trends, address evolving customer needs, and drive value creation through innovation, collaboration, and sustainability.

Conclusion:

The Canada Electrostatic Discharge (ESD) Packaging Market plays a critical role in safeguarding sensitive electronic components, devices, and assemblies from electrostatic damage, ensuring product integrity, reliability, and performance throughout the supply chain. Despite challenges such as environmental concerns, supply chain disruptions, and regulatory complexities, the market offers immense opportunities for innovation, collaboration, and sustainable growth. By embracing technological advancements, strengthening supply chain resilience, and prioritizing sustainability, stakeholders can navigate market dynamics, capitalize on emerging trends, and drive long-term success and competitiveness in the Canada Electrostatic Discharge (ESD) Packaging Market.

What is Electrostatic Discharge (ESD) Packaging?

Electrostatic Discharge (ESD) Packaging refers to materials and methods used to protect electronic components from electrostatic discharge, which can cause damage. This type of packaging is crucial in industries such as electronics manufacturing and semiconductor production.

What are the key players in the Canada Electrostatic Discharge (ESD) Packaging Market?

Key players in the Canada Electrostatic Discharge (ESD) Packaging Market include companies like Desco Industries, Inc., and 3M Company, which provide a range of ESD protective packaging solutions. Other notable companies include Sealed Air Corporation and DuPont, among others.

What are the growth factors driving the Canada Electrostatic Discharge (ESD) Packaging Market?

The growth of the Canada Electrostatic Discharge (ESD) Packaging Market is driven by the increasing demand for electronic devices, the rise in semiconductor manufacturing, and the need for effective protection against electrostatic discharge in sensitive components.

What challenges does the Canada Electrostatic Discharge (ESD) Packaging Market face?

Challenges in the Canada Electrostatic Discharge (ESD) Packaging Market include the high cost of advanced ESD materials and the need for compliance with stringent regulations regarding electronic waste and packaging standards.

What opportunities exist in the Canada Electrostatic Discharge (ESD) Packaging Market?

Opportunities in the Canada Electrostatic Discharge (ESD) Packaging Market include the development of innovative materials that enhance protection and sustainability, as well as the growing trend of miniaturization in electronics, which increases the need for effective ESD solutions.

What trends are shaping the Canada Electrostatic Discharge (ESD) Packaging Market?

Trends in the Canada Electrostatic Discharge (ESD) Packaging Market include the increasing adoption of biodegradable ESD packaging materials and advancements in smart packaging technologies that provide real-time monitoring of ESD protection levels.

Canada Electrostatic Discharge (ESD) Packaging Market

| Segmentation Details | Description |

|---|---|

| Product Type | Boxes, Bags, Tapes, Labels |

| Material | Polyethylene, Polypropylene, Conductive Foam, Metalized Film |

| End User | Electronics, Automotive, Aerospace, Healthcare |

| Application | Storage, Shipping, Handling, Manufacturing |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in Canada Electrostatic Discharge (ESD) Packaging Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at