444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

The Canada data center cooling market represents a critical infrastructure segment experiencing unprecedented growth as digital transformation accelerates across industries. Data center cooling systems have become essential components for maintaining optimal operating temperatures in facilities housing servers, storage systems, and networking equipment. The Canadian market demonstrates robust expansion driven by increasing cloud adoption, edge computing deployment, and stringent energy efficiency regulations.

Market dynamics indicate that Canadian data centers are experiencing a 12.5% annual growth rate in cooling system installations, reflecting the nation’s commitment to sustainable technology infrastructure. Energy efficiency remains a paramount concern, with modern cooling solutions achieving 35% better performance compared to traditional systems. The market encompasses various cooling technologies including air-based systems, liquid cooling, immersion cooling, and hybrid solutions tailored to diverse operational requirements.

Regional distribution shows concentrated activity in major metropolitan areas, with Toronto, Vancouver, and Montreal accounting for 68% of total installations. The Canadian government’s emphasis on digital infrastructure development and environmental sustainability creates favorable conditions for advanced cooling technology adoption. Enterprise demand continues expanding as organizations migrate workloads to local data centers, driving consistent market growth across multiple sectors.

The Canada data center cooling market refers to the comprehensive ecosystem of thermal management solutions, technologies, and services designed to maintain optimal operating temperatures within Canadian data center facilities. This market encompasses hardware systems, software controls, maintenance services, and innovative cooling methodologies that ensure reliable performance of critical IT infrastructure while minimizing energy consumption and operational costs.

Cooling technologies within this market include precision air conditioning units, chilled water systems, direct expansion cooling, liquid cooling solutions, and emerging immersion cooling technologies. The market also covers related components such as cooling towers, pumps, heat exchangers, monitoring systems, and intelligent control platforms that optimize thermal management across diverse data center environments.

Market participants include equipment manufacturers, system integrators, maintenance service providers, and technology consultants who collectively deliver comprehensive cooling solutions. The Canadian market specifically addresses unique climatic conditions, regulatory requirements, and sustainability mandates that distinguish it from global counterparts while maintaining alignment with international best practices.

Strategic analysis reveals the Canada data center cooling market as a rapidly evolving sector characterized by technological innovation and increasing demand for energy-efficient solutions. The market benefits from Canada’s favorable climate conditions, which enable natural cooling strategies and reduce overall energy consumption. Government initiatives promoting digital infrastructure development and environmental sustainability create supportive regulatory frameworks for market expansion.

Technology adoption trends show accelerating deployment of liquid cooling systems, with 28% of new installations incorporating advanced liquid cooling technologies. Traditional air-based cooling systems continue dominating existing facilities, while newer deployments increasingly favor hybrid approaches combining multiple cooling methodologies. Edge computing growth drives demand for compact, efficient cooling solutions suitable for distributed deployment scenarios.

Market competitiveness intensifies as global technology providers establish Canadian operations while domestic companies develop specialized solutions for local market requirements. The convergence of artificial intelligence, high-performance computing, and cloud services creates new cooling challenges that drive innovation and investment in next-generation thermal management technologies.

Primary market insights demonstrate the Canada data center cooling market’s evolution toward intelligent, sustainable, and highly efficient thermal management solutions:

Digital transformation acceleration serves as the primary driver propelling Canada’s data center cooling market forward. Organizations across industries migrate workloads to cloud platforms and establish local data processing capabilities, creating sustained demand for reliable cooling infrastructure. Cloud service adoption continues expanding as businesses prioritize digital resilience and data sovereignty requirements.

Artificial intelligence and machine learning workloads generate unprecedented heat densities within data centers, necessitating advanced cooling solutions capable of managing high-performance computing environments. Edge computing deployment creates distributed cooling requirements as processing capabilities move closer to end users, driving demand for compact and efficient thermal management systems.

Regulatory compliance requirements mandate energy-efficient operations and environmental sustainability, encouraging adoption of innovative cooling technologies. Canadian environmental standards promote solutions that minimize carbon footprints while maintaining optimal performance levels. Energy cost management becomes increasingly critical as organizations seek to control operational expenses through efficient cooling system deployment.

Infrastructure modernization initiatives drive replacement of legacy cooling systems with advanced technologies offering improved efficiency and reliability. The growing emphasis on business continuity and disaster recovery capabilities requires robust cooling infrastructure supporting mission-critical operations without interruption.

High capital investment requirements present significant barriers for organizations considering advanced cooling system implementations. Initial deployment costs for sophisticated liquid cooling or immersion cooling technologies often exceed traditional air-based solutions, creating budget constraints for smaller data center operators. Return on investment calculations must account for long-term operational savings versus upfront expenditures.

Technical complexity associated with modern cooling systems requires specialized expertise for design, installation, and maintenance activities. The shortage of qualified technicians familiar with advanced cooling technologies creates implementation challenges and increases operational risks. Training requirements for existing personnel add additional costs and time delays to deployment schedules.

Integration challenges arise when implementing new cooling solutions within existing data center infrastructure. Legacy systems may require significant modifications to accommodate modern cooling technologies, creating compatibility issues and extended downtime periods. Retrofit limitations in older facilities constrain cooling system upgrade options and performance optimization opportunities.

Regulatory uncertainty regarding future environmental standards and energy efficiency requirements creates hesitation among potential investors. Organizations may delay cooling system investments pending clarification of long-term regulatory frameworks and compliance obligations.

Sustainability initiatives create substantial opportunities for innovative cooling solution providers offering environmentally responsible technologies. Canadian organizations increasingly prioritize carbon neutrality goals, driving demand for cooling systems powered by renewable energy sources and featuring minimal environmental impact. Green technology adoption accelerates as companies align operations with environmental, social, and governance objectives.

Edge computing expansion presents significant growth opportunities for compact, efficient cooling solutions suitable for distributed deployment scenarios. The proliferation of Internet of Things devices and real-time processing requirements drives demand for localized data processing capabilities requiring specialized thermal management. 5G network deployment creates additional edge computing infrastructure needs with associated cooling requirements.

Artificial intelligence workloads generate opportunities for high-performance cooling solutions capable of managing extreme heat densities. Machine learning training and inference operations require advanced thermal management technologies that traditional cooling systems cannot adequately address. Quantum computing development introduces entirely new cooling challenges requiring innovative technological approaches.

Government infrastructure investments in digital transformation and smart city initiatives create opportunities for large-scale cooling system deployments. Public sector modernization programs prioritize energy-efficient technologies that align with environmental sustainability mandates while supporting critical government operations.

Supply chain dynamics within the Canada data center cooling market reflect global technology trends while addressing local market requirements. International equipment manufacturers establish Canadian distribution networks and service capabilities to support growing demand. Local partnerships between global providers and Canadian system integrators create comprehensive solution offerings tailored to regional needs.

Competitive dynamics intensify as established cooling system providers compete with emerging technology companies offering innovative solutions. Traditional air conditioning manufacturers expand into data center-specific cooling technologies while specialized providers develop niche solutions for high-density computing environments. Technology convergence creates opportunities for companies combining cooling expertise with artificial intelligence and automation capabilities.

Customer dynamics show increasing sophistication in cooling system selection criteria, with organizations evaluating total cost of ownership, energy efficiency, reliability, and environmental impact. Procurement processes increasingly emphasize long-term partnerships with providers offering comprehensive service and support capabilities rather than simple equipment transactions.

Innovation dynamics drive continuous development of more efficient, intelligent, and sustainable cooling technologies. Research and development investments focus on breakthrough technologies such as immersion cooling, advanced heat recovery systems, and AI-powered optimization platforms that revolutionize data center thermal management approaches.

Comprehensive market analysis employs multiple research methodologies to ensure accurate and reliable insights into the Canada data center cooling market. Primary research activities include structured interviews with industry executives, technology providers, data center operators, and end-user organizations across various sectors. Survey instruments capture quantitative data regarding market trends, technology adoption patterns, and future investment intentions.

Secondary research encompasses analysis of industry reports, government publications, regulatory documents, and company financial statements to validate primary research findings. Market intelligence gathering includes monitoring of industry conferences, trade publications, and technology announcements that influence market dynamics and competitive positioning.

Data validation processes ensure information accuracy through cross-referencing multiple sources and expert review of findings. Statistical analysis techniques identify trends, correlations, and market patterns that inform strategic insights and future projections. Quality assurance protocols maintain research integrity throughout the analysis process.

Analytical frameworks incorporate both quantitative and qualitative assessment methodologies to provide comprehensive market understanding. Scenario modeling examines potential market developments under various economic and technological conditions, enabling robust strategic planning and risk assessment capabilities.

Ontario region dominates the Canadian data center cooling market, accounting for approximately 42% of total installations due to concentrated technology infrastructure in the Greater Toronto Area. The province’s robust telecommunications network, proximity to major US markets, and favorable business environment attract significant data center investments. Toronto metropolitan area serves as the primary hub for enterprise data centers and cloud service provider facilities.

British Columbia represents the second-largest regional market with 26% market share, benefiting from Vancouver’s strategic location for trans-Pacific connectivity and the province’s abundant renewable energy resources. The region’s cool climate provides natural cooling advantages that reduce operational costs and environmental impact. Submarine cable landing points in Vancouver create demand for high-capacity data center facilities with advanced cooling systems.

Quebec province demonstrates rapid growth in data center cooling deployments, capturing 18% of the national market through competitive electricity rates and government incentives for technology infrastructure development. Montreal’s bilingual workforce and established technology sector support data center operations requiring sophisticated cooling solutions. Hydroelectric power availability enables sustainable cooling system operations aligned with environmental objectives.

Alberta region emerges as a growing market for data center cooling systems, particularly in Calgary and Edmonton, where energy sector companies establish digital infrastructure supporting oil and gas operations. The province’s natural cooling climate and energy resources create favorable conditions for large-scale data center development requiring advanced thermal management capabilities.

Market leadership in the Canada data center cooling sector includes both international technology providers and specialized Canadian companies offering comprehensive thermal management solutions:

Competitive strategies focus on technology innovation, energy efficiency improvements, and comprehensive service offerings that address complete customer lifecycle requirements. Companies invest in research and development to create differentiated solutions while establishing local partnerships to enhance market reach and customer support capabilities.

Technology segmentation reveals diverse cooling approaches serving different data center requirements and operational preferences:

By Cooling Type:

By Application:

By Component:

Air-based cooling systems continue dominating the Canadian market due to established infrastructure, familiar maintenance requirements, and proven reliability in diverse operating conditions. Precision air conditioning units designed specifically for data center environments offer superior performance compared to traditional HVAC systems. Recent innovations include variable speed drives, advanced filtration, and intelligent controls that optimize energy consumption while maintaining precise temperature and humidity control.

Liquid cooling technologies gain momentum as data centers deploy high-density computing equipment generating heat loads beyond air cooling capabilities. Direct-to-chip cooling systems provide efficient thermal management for processors and graphics cards used in artificial intelligence and high-performance computing applications. MarkWide Research analysis indicates liquid cooling adoption accelerating at 22% annually among Canadian data centers implementing advanced computing infrastructure.

Immersion cooling solutions represent the cutting edge of data center thermal management, offering exceptional efficiency for specialized applications. These systems submerge IT equipment in dielectric fluids that absorb heat directly from components, eliminating traditional air circulation requirements. Energy efficiency improvements of up to 45% compared to air cooling make immersion systems attractive for organizations prioritizing sustainability and operational cost reduction.

Hybrid cooling approaches combine multiple technologies to optimize performance across varying operational conditions and equipment types. These systems automatically adjust cooling methods based on ambient conditions, equipment loads, and energy costs to maintain optimal efficiency. Intelligent control systems enable seamless transitions between cooling modes while maintaining precise environmental conditions required for reliable IT operations.

Data center operators benefit from advanced cooling systems through reduced energy consumption, improved equipment reliability, and enhanced operational efficiency. Modern cooling technologies enable higher equipment density deployments while maintaining optimal operating conditions that extend hardware lifecycles. Operational cost savings from efficient cooling systems contribute directly to improved profitability and competitive positioning.

Technology providers gain opportunities to develop innovative solutions addressing evolving market requirements while establishing long-term customer relationships through comprehensive service offerings. The growing market creates revenue opportunities across equipment sales, installation services, and ongoing maintenance contracts. Partnership opportunities with data center operators enable collaborative development of customized solutions optimized for specific operational requirements.

End-user organizations benefit from reliable data center operations supporting business-critical applications and services. Efficient cooling systems reduce total cost of ownership for IT infrastructure while supporting sustainability objectives through reduced energy consumption. Business continuity improvements from reliable cooling infrastructure minimize risks of equipment failures and service disruptions.

Environmental stakeholders benefit from reduced energy consumption and carbon emissions associated with efficient data center cooling systems. Advanced technologies enable data centers to operate with minimal environmental impact while supporting digital transformation initiatives. Renewable energy integration becomes more feasible with efficient cooling systems that reduce overall power requirements.

Strengths:

Weaknesses:

Opportunities:

Threats:

Artificial intelligence integration transforms data center cooling through predictive analytics and automated optimization systems that continuously adjust thermal management parameters. Machine learning algorithms analyze historical performance data, weather patterns, and equipment loads to optimize cooling system operations proactively. These intelligent systems reduce energy consumption while maintaining precise environmental conditions required for reliable IT operations.

Liquid cooling mainstream adoption accelerates as data centers deploy high-density computing equipment that exceeds air cooling capabilities. Direct liquid cooling systems provide efficient thermal management for processors, graphics cards, and memory modules used in artificial intelligence and high-performance computing applications. The technology evolution from specialized applications to mainstream deployment reflects growing acceptance and proven reliability.

Sustainability integration becomes paramount as organizations align data center operations with environmental, social, and governance objectives. Renewable energy integration with cooling systems enables carbon-neutral operations while reducing operational costs. Heat recovery systems capture waste heat from cooling operations for building heating or other applications, maximizing energy efficiency and environmental benefits.

Modular cooling solutions gain popularity for their flexibility and scalability advantages in dynamic data center environments. These systems enable rapid capacity adjustments as computing requirements evolve, supporting both growth and optimization initiatives. Prefabricated cooling modules reduce installation time and complexity while ensuring consistent performance across multiple deployments.

Technology partnerships between cooling system providers and data center operators drive collaborative development of customized solutions optimized for specific operational requirements. These relationships enable rapid innovation cycles and market-responsive product development that addresses evolving customer needs. Joint research initiatives focus on breakthrough technologies such as advanced heat recovery systems and AI-powered optimization platforms.

Regulatory developments in Canadian provinces establish energy efficiency standards and environmental requirements that influence cooling system selection and deployment strategies. New building codes incorporate data center-specific requirements that promote efficient cooling technologies and sustainable operational practices. Incentive programs support adoption of high-efficiency cooling systems through tax credits and utility rebates.

Infrastructure investments by major cloud service providers and telecommunications companies create substantial demand for advanced cooling systems in Canadian markets. These large-scale deployments drive technology innovation and cost optimization that benefits the broader market. Hyperscale facility development introduces new cooling requirements and performance standards that influence industry best practices.

Acquisition activities consolidate market participants as larger companies acquire specialized cooling technology providers to expand solution portfolios and market reach. These transactions accelerate technology development and market penetration while creating comprehensive service offerings for customers. Strategic partnerships between equipment manufacturers and service providers enhance customer support capabilities and market competitiveness.

Investment prioritization should focus on energy-efficient cooling technologies that align with Canadian environmental regulations and sustainability objectives. Organizations planning data center investments should evaluate total cost of ownership including energy consumption, maintenance requirements, and environmental impact over extended operational periods. MWR analysis recommends prioritizing cooling systems achieving power usage effectiveness ratios below 1.3 for optimal operational efficiency.

Technology selection requires careful evaluation of current and future computing requirements to ensure cooling systems can accommodate evolving workload characteristics. Organizations should consider hybrid cooling approaches that provide flexibility across diverse operational conditions and equipment types. Scalability planning ensures cooling infrastructure can support business growth without requiring complete system replacements.

Partnership strategies should emphasize long-term relationships with cooling system providers offering comprehensive service and support capabilities rather than focusing solely on equipment costs. Successful implementations require ongoing optimization, maintenance, and technology updates that benefit from established provider relationships. Service level agreements should address performance guarantees, response times, and continuous improvement initiatives.

Risk management strategies should address potential supply chain disruptions, technology obsolescence, and regulatory changes that may impact cooling system operations. Organizations should maintain contingency plans for cooling system failures and establish relationships with multiple service providers to ensure operational continuity. Insurance considerations should account for cooling system failures and their potential impact on IT operations and business continuity.

Market evolution toward intelligent, sustainable, and highly efficient cooling solutions will continue accelerating as Canadian data centers adopt advanced technologies supporting digital transformation initiatives. Artificial intelligence integration will become standard in cooling system operations, enabling predictive maintenance and automated optimization that reduces energy consumption while improving reliability. The convergence of cooling technology with renewable energy systems will create new opportunities for carbon-neutral data center operations.

Technology advancement will focus on breakthrough cooling solutions capable of managing extreme heat densities generated by quantum computing, advanced artificial intelligence, and high-performance computing applications. Immersion cooling adoption is projected to grow at 38% annually as organizations deploy specialized computing infrastructure requiring advanced thermal management. Liquid cooling systems will become mainstream for enterprise data centers as equipment density and performance requirements continue increasing.

Market expansion will be driven by edge computing deployment, 5G network infrastructure, and Internet of Things applications requiring distributed data processing capabilities. Regional growth will extend beyond traditional technology hubs as organizations establish data centers in secondary markets to support local processing requirements and regulatory compliance. Government digital transformation initiatives will create substantial opportunities for cooling system providers serving public sector customers.

Sustainability integration will become mandatory rather than optional as organizations face increasing pressure to achieve carbon neutrality goals and comply with environmental regulations. Circular economy principles will influence cooling system design and lifecycle management, emphasizing recyclability, energy efficiency, and minimal environmental impact throughout operational lifecycles.

The Canada data center cooling market stands at a transformative juncture where technological innovation, environmental sustainability, and business growth requirements converge to create unprecedented opportunities for advanced thermal management solutions. Market dynamics reflect the nation’s commitment to digital infrastructure development while maintaining environmental stewardship through energy-efficient technologies and sustainable operational practices.

Strategic positioning within this evolving market requires understanding of diverse customer requirements, technology trends, and regulatory frameworks that shape cooling system selection and deployment strategies. Organizations that prioritize comprehensive solutions addressing efficiency, reliability, and sustainability will achieve competitive advantages in the expanding Canadian data center ecosystem. The integration of artificial intelligence, renewable energy, and advanced cooling technologies creates new possibilities for optimized operations that support both business objectives and environmental responsibilities.

Future success in the Canada data center cooling market will depend on continuous innovation, strategic partnerships, and commitment to sustainable practices that align with national environmental goals and customer expectations. As digital transformation accelerates across industries, the demand for sophisticated cooling solutions will continue growing, creating substantial opportunities for technology providers, service companies, and end-user organizations committed to excellence in data center operations and environmental stewardship.

What is Data Center Cooling?

Data Center Cooling refers to the methods and technologies used to maintain optimal temperature and humidity levels in data centers, ensuring the efficient operation of servers and IT equipment. Effective cooling is crucial for preventing overheating and ensuring reliability in data processing environments.

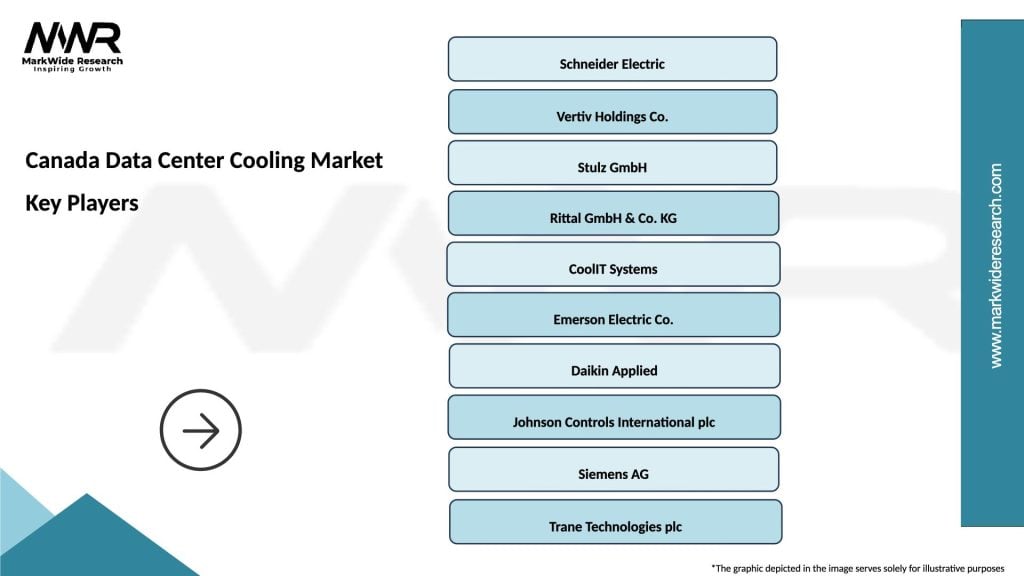

What are the key players in the Canada Data Center Cooling Market?

Key players in the Canada Data Center Cooling Market include companies like Schneider Electric, Vertiv, and Rittal, which provide innovative cooling solutions and technologies. These companies focus on energy efficiency and advanced cooling systems to meet the growing demands of data centers, among others.

What are the main drivers of the Canada Data Center Cooling Market?

The main drivers of the Canada Data Center Cooling Market include the increasing demand for data storage and processing, the rise of cloud computing, and the need for energy-efficient cooling solutions. Additionally, the growth of big data analytics and IoT applications further fuels the market.

What challenges does the Canada Data Center Cooling Market face?

The Canada Data Center Cooling Market faces challenges such as high operational costs associated with advanced cooling technologies and the environmental impact of energy consumption. Additionally, the rapid pace of technological change can make it difficult for companies to keep up with the latest cooling innovations.

What opportunities exist in the Canada Data Center Cooling Market?

Opportunities in the Canada Data Center Cooling Market include the development of sustainable cooling solutions and the integration of AI and machine learning for optimized cooling management. Furthermore, the increasing focus on green data centers presents avenues for innovation and growth.

What trends are shaping the Canada Data Center Cooling Market?

Trends shaping the Canada Data Center Cooling Market include the adoption of liquid cooling technologies, the use of modular cooling systems, and the emphasis on energy efficiency. Additionally, there is a growing interest in hybrid cooling solutions that combine traditional and innovative methods.

Canada Data Center Cooling Market

| Segmentation Details | Description |

|---|---|

| Product Type | Chillers, Cooling Towers, Air Conditioners, Heat Exchangers |

| Technology | Liquid Cooling, Air Cooling, Evaporative Cooling, Immersion Cooling |

| End User | Telecommunications, Cloud Service Providers, Enterprises, Colocation Facilities |

| Installation | On-Premises, Off-Site, Modular, Hybrid |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Canada Data Center Cooling Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at