Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

-

Natural vs. Precipitated: Precipitated calcium carbonate (PCC) accounts for ~35% of market share, favored for uniform particle size and high purity, while ground calcium carbonate (GCC) dominates due to lower cost and high-volume applications.

-

Particle Size Trends: Ultrafine and nano-sized products are in demand for high-performance plastics and coatings, offering improved tensile strength and barrier properties.

-

Sustainability Focus: Eco-friendly mining practices and use of industrial by-products (e.g., eggshell, oyster shell) are gaining traction to reduce environmental footprint.

-

Regional Leadership: Asia-Pacific leads both in production and consumption, driven by rapid industrialization, infrastructure development, and growth in consumer goods sectors.

-

Value-Added Products: Surface-treated and functionalized calcium carbonate (stearic, silane, polymer-coated) are escalating in specialty applications like automotive compounding and medical devices.

Market Drivers

-

Construction & Infrastructure: Rapid urbanization and government spending on roads, bridges, and buildings fuel demand for GCC as a primary raw material in cement and concrete.

-

Paper & Packaging Industry: Growth in high-grade paper production and sustainable packaging solutions drives demand for PCC as a brightness enhancer and barrier filler.

-

Plastics & Polymers: Lightweight automotive and packaging applications require fine, treated calcium carbonate to improve mechanical properties and reduce weight.

-

Paints & Coatings: Demand for high-opacity, weather-resistant paints increases consumption of nano- and micro-sized PCC for improved coverage and rheology.

-

Pharmaceuticals & Food: Rising nutraceutical consumption supports demand for pharmaceutical-grade calcium carbonate as a calcium supplement and antacid.

Market Restraints

-

Raw Material Price Volatility: Fluctuating costs of limestone and energy inputs impact profitability for miners and processors.

-

Environmental Regulations: Stringent quarrying laws and land use restrictions increase compliance costs and limit expansion in key producing regions.

-

Competition from Substitutes: Alternative fillers like talc, kaolin, and magnesium carbonate may offer specific performance advantages in certain end-use sectors.

-

Quality Variability: Inconsistent purity and particle size from GCC require additional processing or switching to more expensive PCC for high-grade applications.

-

Logistics Challenges: High bulk density and shipping volumes make transportation costly, particularly for international trade.

Market Opportunities

-

Eco-Friendly Sourcing: Utilizing biogenic calcium carbonate from eggshells, shell waste, and industrial by-products to meet sustainability goals.

-

Nano-CaCO₃ Development: Expanding production of nanometer-scale calcium carbonate for advanced coatings, adhesives, and polymer composites.

-

Functionalized Grades: Growth in surface-modified and polymer-grafted calcium carbonate for specialty applications such as anti-caking and controlled release in pharmaceuticals.

-

Emerging Economies: Infrastructure build-out and rising consumer demand in Africa, Latin America, and Southeast Asia present new market entrants.

-

Circular Economy Integration: Offering post-consumer recycled calcium carbonate from concrete rubble and paper sludge.

Market Dynamics

-

Supply Side: Technological investments in ultra-fine grinding, surface treatment lines, and PCC precipitation reactors improve yield and quality. Vertical integration by major players secures raw material supply and enhances margin control.

-

Demand Side: Shifting toward lightweight materials in automotive and packaging boosts CaCO₃ uptake. Environmental legislation favors eco-friendly fillers over petroleum-derived additives.

-

Economic Factors: Global GDP growth, trade policies, and currency fluctuations in key producing/consuming nations impact export-import dynamics. Tariffs and trade barriers can reshape regional supply chains.

Regional Analysis

-

Asia-Pacific: Dominant region, >45% global volume share. China leads production and consumption; India’s expanding paper and plastics sectors contribute rapid growth.

-

North America: Mature market with strong demand in the U.S. for high-purity PCC in pharmaceuticals and specialty plastics; Canada’s limestone reserves support GCC export.

-

Europe: Steady demand driven by automotive lightweighting, paper recycling mandates, and stringent environmental regulations favoring PCC and functionalized products.

-

Latin America: Infrastructure investments in Brazil and Mexico drive GCC use in cement and construction; niche pharmaceutical and food-grade calcium carbonate gaining prominence.

-

Middle East & Africa: Infrastructure development and petrochemical expansion in Gulf states spur demand; South Africa’s mining sector supports GCC production.

Competitive Landscape

Leading Companies in the Calcium Carbonate Market:

- Omya International AG

- Minerals Technologies Inc.

- Imerys S.A.

- Huber Engineered Materials

- Mississippi Lime Company

- Shiraishi Calcium Kaisha Ltd.

- Excalibar Minerals LLC

- Maruo Calcium Co., Ltd.

- Emirates Calcium Carbonate Factory LLC

- Zhejiang Jiande Longhua Plastic Chemical Co., Ltd.

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

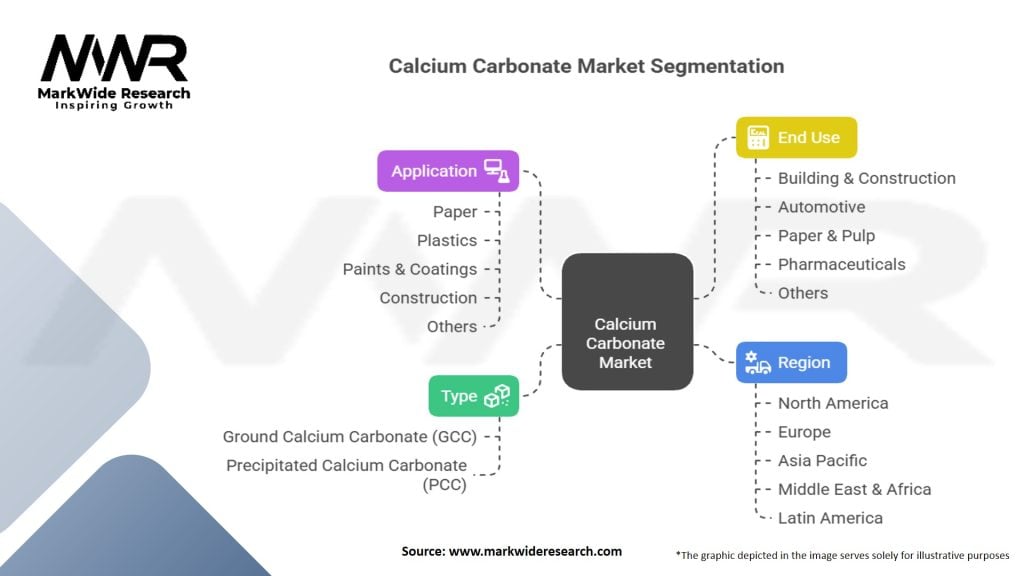

Segmentation

-

By Product Type:

-

Ground Calcium Carbonate (GCC)

-

Precipitated Calcium Carbonate (PCC)

-

-

By Purity/Grade:

-

Industrial Grade (construction, cement, agriculture)

-

Specialty Grade (paper, plastics, paints)

-

Pharmaceutical/Food Grade (dietary supplements, antacids)

-

-

By Particle Size:

-

Standard (2–5 µm)

-

Ultrafine (≤1 µm)

-

Nano-scale (<100 nm)

-

-

By Application:

-

Construction & Building Materials

-

Paper & Packaging

-

Plastics & Polymers

-

Paints, Coatings & Inks

-

Pharmaceuticals & Food

-

Others (agriculture, water treatment, adhesives)

-

-

By Region:

-

Asia-Pacific

-

North America

-

Europe

-

Latin America

-

Middle East & Africa

-

Category-wise Insights

-

GCC for Construction: Dominant segment by volume; key for cement modification, road base, and agricultural lime.

-

PCC for Paper: Largest specialty application; improves brightness, opacity, and smoothness in coated and uncoated papers.

-

PCC in Plastics: Fills and reinforces polypropylene, PVC, and polyethylene, reducing cost and improving stiffness and heat resistance.

-

Functionalized CaCO₃: Surface-treated grades tailored for specific polymer matrices (e.g., PVC stabilization, PVC window profiles).

-

Pharma & Food Grade: High-purity, low-heavy-metal calcium carbonate for tablets, antacids, and dietary calcium fortification.

Key Benefits for Industry Participants and Stakeholders

-

Cost Reduction: Lower material costs through high-fill loading in plastics and paper reduces reliance on costly polymers.

-

Performance Enhancement: Improved mechanical, optical, and thermal properties for advanced material applications.

-

Sustainability: Calcium carbonate is non-toxic, abundant, and often locally sourced, aligning with green manufacturing and circular economy principles.

-

Regulatory Compliance: Calcium carbonate meets stringent food and pharmaceutical standards, enabling formulators to comply with health & safety regulations.

-

Supply Security: Globally distributed limestone reserves ensure stable raw material availability.

SWOT Analysis

Strengths:

-

Abundant Natural Reserves: Wide geographical distribution of limestone ensures reliable supply.

-

Versatility: Broad application spectrum across multiple industries.

-

Cost-Effectiveness: Low cost relative to many specialty fillers and minerals.

Weaknesses:

-

Bulk Transport Costs: High volume-to-value ratio increases logistics expenses.

-

Environmental Impact: Quarrying activities face regulatory and community resistance.

-

Quality Variability: GCC purity and color vary by source, requiring beneficiation.

Opportunities:

-

High-Purity PCC Expansion: Rising demand in electronics, pharma, and high-performance coatings.

-

Biogenic CaCO₃ Production: Valorization of shell waste and bio-based feedstocks for sustainable niche markets.

-

Nano-CaCO₃ Innovation: New applications in drug delivery, flame retardancy, and advanced composites.

Threats:

-

Substitute Fillers: Growth of novel fillers (silica, nanoclays) offering unique functionalities.

-

Regulatory Changes: Tightening environmental regulations may restrict quarry operations.

-

Economic Downturns: Reduced construction and consumer goods demand could depress volumes.

Market Key Trends

-

Nano- and Micronization: Demand for ultra-fine calcium carbonate (<500 nm) in high-tech applications.

-

Surface Functionalization: Growth in polymer-compatible CaCO₃ through silane, fatty acid, and polymer coatings.

-

Green Sourcing: Adoption of recycled and biogenic calcium carbonate to meet sustainability mandates.

-

Digitalization & Supply Chain Transparency: Blockchain and IoT for provenance tracking and quality assurance.

-

Collaborative R&D: Partnerships between miners, chemical companies, and end-users accelerate new application development.

Covid-19 Impact

-

Supply Disruptions: Temporary mine closures and logistics slowdowns disrupted GCC and PCC supply chains.

-

Demand Fluctuations: Construction slowdown in H1 2020 reduced CaCO₃ consumption, but rebound in packaging and pharmaceuticals mitigated losses.

-

Health & Nutraceutical Growth: Increased demand for food-grade CaCO₃ as a calcium supplement during the pandemic.

-

Operational Resilience: Companies accelerated automation and remote monitoring in production facilities.

-

Sustainability Renewed Focus: Post-pandemic stimulus favored green infrastructure, supporting long-term CaCO₃ demand.

Key Industry Developments

-

Capacity Expansions: New GCC quarries in India and Africa; PCC plants in Southeast Asia to meet regional demand.

-

Next-Gen Precipitation: Continuous-flow PCC reactors reducing water usage and energy consumption.

-

Functional Grade Launches: Specialty CaCO₃ grades for flame retardant, anti-bacterial, and UV-protective applications.

-

Acquisitions & Partnerships: Vertical integration by major chemical players securing limestone reserves and enhancing downstream capabilities.

-

Digital Twins & AI: Implementation of smart mine and mill control systems via AI-driven process optimization.

Analyst Suggestions

-

Invest in Specialty Grades: Focus R&D on nano- and surface-treated CaCO₃ to capture high-margin segments in polymers, coatings, and pharma.

-

Enhance Sustainability Credentials: Develop biogenic and recycled CaCO₃ offerings, and pursue certifications (e.g., ISO 14001) to appeal to eco-conscious customers.

-

Optimize Logistics: Establish regional grinding and distribution hubs to minimize freight costs and improve service levels.

-

Collaborate Across Value Chain: Partner with end-users and academic institutions to co-develop tailored solutions and accelerate market adoption.

-

Leverage Digital Tools: Deploy IoT and predictive analytics in quarry and plant operations to boost efficiency, reduce downtime, and improve product consistency.

Future Outlook

The Calcium Carbonate Market is projected to grow steadily at a 4–5% CAGR through 2030, underpinned by:

-

Green Construction & Infrastructure: Demand for low-carbon building materials promoting GCC use in cement and concrete.

-

Lightweight Plastics & Circular Packaging: Regulatory pushes for recyclable polymers driving PCC uptake as a bio-based filler.

-

Pharma & Nutraceuticals Boom: Aging populations and health‑focused consumers boosting pharmaceutical- and food-grade CaCO₃ demand.

-

Advanced Materials: Nanotechnology and specialty functional additives opening new high‑value applications.

-

Digital & Sustainable Integration: Continued focus on digital transformation and environmental stewardship shaping production and sourcing strategies.

Conclusion

Calcium carbonate remains a cornerstone mineral across diverse industries. Its broad availability, affordability, and multifunctional properties ensure enduring relevance. To thrive in a competitive, sustainability‑driven landscape, stakeholders must innovate specialty grades, embrace green and digital technologies, and forge collaborative partnerships. By aligning production practices with evolving regulatory, environmental, and market demands, the calcium carbonate industry can secure long‑term growth and profitability while contributing to a more sustainable global economy.