444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The Bumping Services Market encompasses services provided to enhance and optimize semiconductor packaging, particularly focusing on improving the electrical connections between integrated circuits (ICs) and their packaging substrates. Bumping involves adding metallic bumps or balls to the contact pads of ICs, enabling efficient electrical and mechanical connections during assembly onto circuit boards or other substrates.

Meaning

Bumping services involve specialized processes to apply solder bumps, gold bumps, or other metallization techniques onto semiconductor devices. These bumps facilitate reliable electrical connections between ICs and circuit boards, ensuring efficient signal transmission and thermal management.

Executive Summary

The Bumping Services Market is witnessing growth driven by advancements in semiconductor technology, increasing demand for miniaturization, and complexity in IC designs. Key market players are focusing on developing advanced bumping techniques, materials, and processes to meet the evolving requirements of electronic devices in automotive, consumer electronics, telecommunications, and industrial applications. As semiconductor packaging requirements become more stringent, the market for bumping services is expected to expand, supported by innovations in flip-chip technology, wafer-level packaging, and heterogeneous integration.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Several factors are driving the growth of the Bumping Services Market:

Market Restraints

Despite its growth, the Bumping Services Market faces several challenges:

Market Opportunities

The Bumping Services Market presents several growth opportunities:

Market Dynamics

The Bumping Services Market is characterized by dynamic trends and technological advancements:

Regional Analysis

The Bumping Services Market exhibits regional variations and growth dynamics:

Competitive Landscape

Leading Companies in the Bumping Services Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

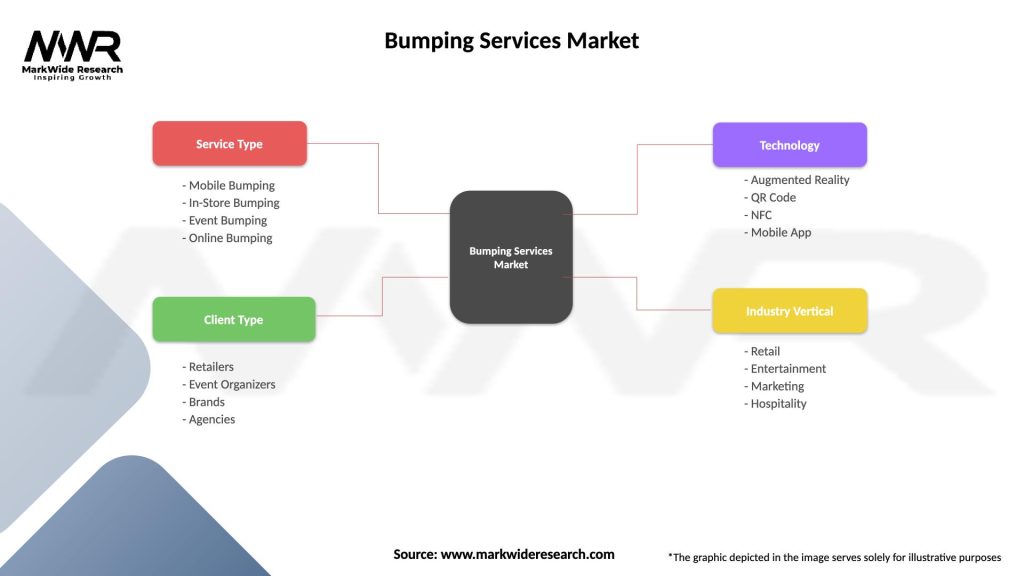

The Bumping Services Market can be segmented based on:

Category-wise Insights

Different categories of Bumping Services offer unique features and applications:

Key Benefits for Industry Participants and Stakeholders

The Bumping Services Market offers several benefits:

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Key trends shaping the Bumping Services Market include:

Covid-19 Impact

The Covid-19 pandemic has influenced the Bumping Services Market in several ways:

Key Industry Developments

Recent developments in the Bumping Services Market include:

Analyst Suggestions

To capitalize on growth opportunities in the Bumping Services Market, analysts recommend the following strategies:

Future Outlook

The future outlook for the Bumping Services Market is promising, driven by technological advancements, semiconductor industry expansion, and increasing demand for high-performance electronic devices. Key trends such as 5G network deployments, AI-driven applications, environmental sustainability, and digital transformation initiatives are expected to shape the market landscape. Industry stakeholders focusing on innovation, operational excellence, and strategic collaborations are well-positioned to capitalize on emerging opportunities and drive sustainable growth in the dynamic Bumping Services Market.

Conclusion

In conclusion, the Bumping Services Market is poised for growth, supported by advancements in semiconductor packaging technologies, evolving consumer electronics demand, and expansion into new application areas. Despite challenges related to technological complexity, supply chain disruptions, and regulatory compliance, the market offers significant opportunities for innovation, market expansion, and strategic partnerships. By focusing on technological leadership, customer-centric solutions, and operational efficiency, industry participants can navigate market dynamics, leverage emerging trends, and achieve long-term success in the competitive Bumping Services Market.

What is Bumping Services?

Bumping services refer to specialized techniques used to enhance the visibility and ranking of online content, particularly in search engines and social media platforms. These services often involve strategies like link building, content optimization, and social media engagement.

What are the key players in the Bumping Services Market?

Key players in the Bumping Services Market include companies like Boostability, WebFX, and Ignite Digital, which provide various digital marketing services aimed at improving online presence and engagement. These companies focus on different aspects of bumping services, such as SEO, social media marketing, and content creation, among others.

What are the main drivers of growth in the Bumping Services Market?

The growth of the Bumping Services Market is driven by the increasing importance of online visibility for businesses, the rise of digital marketing, and the growing competition among brands to capture consumer attention. Additionally, the shift towards e-commerce and online services has heightened the demand for effective bumping strategies.

What challenges does the Bumping Services Market face?

The Bumping Services Market faces challenges such as the constantly changing algorithms of search engines, which can affect the effectiveness of bumping strategies. Additionally, there is a risk of over-saturation in the market, leading to diminishing returns for businesses investing in these services.

What opportunities exist in the Bumping Services Market?

Opportunities in the Bumping Services Market include the potential for innovation in service offerings, such as the integration of AI and machine learning for more effective strategies. Furthermore, as more businesses recognize the value of online presence, there is an expanding customer base for bumping services.

What trends are shaping the Bumping Services Market?

Trends in the Bumping Services Market include the increasing use of video content and influencer marketing as part of bumping strategies. Additionally, there is a growing emphasis on data analytics to measure the effectiveness of these services and optimize campaigns.

Bumping Services Market

| Segmentation Details | Description |

|---|---|

| Service Type | Mobile Bumping, In-Store Bumping, Event Bumping, Online Bumping |

| Client Type | Retailers, Event Organizers, Brands, Agencies |

| Technology | Augmented Reality, QR Code, NFC, Mobile App |

| Industry Vertical | Retail, Entertainment, Marketing, Hospitality |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Bumping Services Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at