444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The built-in stainless steel sink market is witnessing steady growth, driven by the increasing demand for durable, hygienic, and aesthetically pleasing kitchen fixtures. Built-in stainless steel sinks are integral components of modern kitchens, offering functionality, durability, and design versatility. With advancements in manufacturing techniques and design innovations, manufacturers are offering a wide range of built-in stainless steel sinks to cater to the diverse needs and preferences of consumers worldwide.

Meaning

A built-in stainless steel sink refers to a kitchen sink unit that is installed directly into the countertop, creating a seamless and integrated look. Stainless steel is a popular material choice for kitchen sinks due to its durability, corrosion resistance, and easy maintenance properties. Built-in sinks are available in various configurations, including single-bowl, double-bowl, and farmhouse styles, to accommodate different kitchen layouts and user requirements.

Executive Summary

The built-in stainless steel sink market is experiencing robust growth, fueled by factors such as increasing urbanization, rising disposable incomes, and changing consumer lifestyles. Consumers are prioritizing kitchen renovations and upgrades, driving demand for high-quality and aesthetically pleasing fixtures such as built-in stainless steel sinks. Key market players are focusing on product innovation, sustainability, and customer-centric strategies to gain a competitive edge in the market.

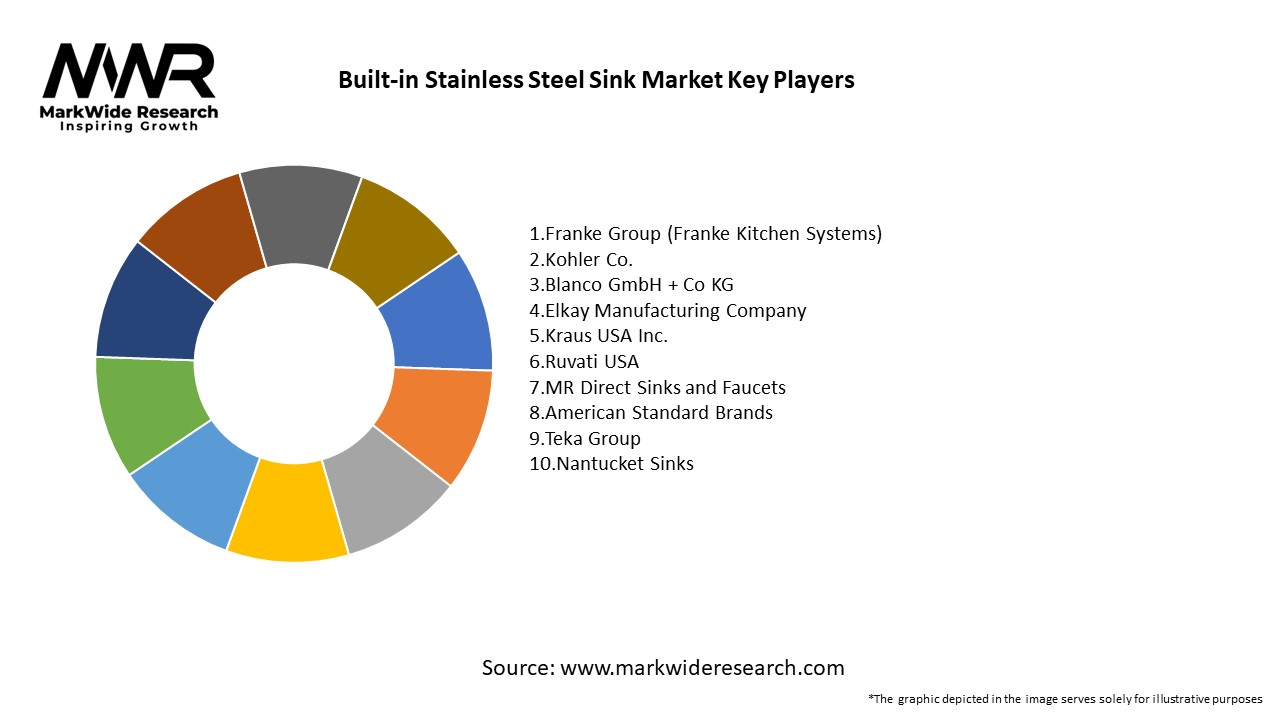

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Several factors are driving the growth of the built-in stainless steel sink market, including:

Market Restraints

Despite the positive growth outlook, the built-in stainless steel sink market faces certain challenges, including:

Market Opportunities

The built-in stainless steel sink market presents several opportunities for manufacturers and suppliers, including:

Market Dynamics

The built-in stainless steel sink market is characterized by dynamic trends and developments, including:

Regional Analysis

The global built-in stainless steel sink market is geographically segmented into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. North America and Europe are major markets for built-in stainless steel sinks, driven by high levels of consumer spending on home renovations and kitchen remodeling projects. In contrast, Asia Pacific and Latin America represent emerging markets with significant growth potential, fueled by rapid urbanization, rising disposable incomes, and increasing adoption of modern kitchen amenities.

Competitive Landscape

Leading Companies in the Built-in Stainless Steel Sink Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The built-in stainless steel sink market can be segmented based on sink type, installation method, configuration, and application. Sink types include single-bowl, double-bowl, farmhouse, bar/prep, and utility sinks, each offering different capacities and functionalities. Installation methods include undermount, drop-in/top-mount, and integrated sink/countertop designs, catering to different kitchen layouts and design preferences. Sink configurations may vary in terms of bowl size, depth, and accessories such as drainboards, cutting boards, and colanders. Applications span across residential, commercial, and industrial sectors, with residential kitchens accounting for the largest market share.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

The adoption of built-in stainless steel sinks offers several benefits for industry participants and stakeholders, including:

SWOT Analysis

Market Key Trends

Key trends shaping the built-in stainless steel sink market include:

Covid-19 Impact

The Covid-19 pandemic has had both positive and negative impacts on the built-in stainless steel sink market. On one hand, there has been increased demand for home renovation and improvement projects as people spend more time indoors and prioritize living spaces. On the other hand, supply chain disruptions, production delays, and economic uncertainties have affected manufacturing operations and consumer purchasing behavior. Overall, the long-term outlook for the built-in stainless steel sink market remains positive, with continued growth expected as consumers invest in upgrading and enhancing their kitchen spaces.

Key Industry Developments

Recent industry developments in the built-in stainless steel sink market include:

Analyst Suggestions

Industry analysts suggest the following strategies for manufacturers and suppliers in the built-in stainless steel sink market:

Future Outlook

The future outlook for the built-in stainless steel sink market is positive, with sustained growth expected in the coming years. Factors such as urbanization, rising disposable incomes, and changing consumer lifestyles will continue to drive demand for high-quality and aesthetically pleasing kitchen fixtures. Additionally, advancements in materials science, manufacturing technologies, and design innovations will fuel product developments and market competition, leading to a wider range of options for consumers worldwide.

Conclusion

In conclusion, the built-in stainless steel sink market is experiencing steady growth, driven by increasing consumer demand for durable, hygienic, and aesthetically pleasing kitchen fixtures. Manufacturers are responding to market trends and consumer preferences by offering a wide range of sink designs, materials, and features to suit diverse kitchen layouts and user requirements. Despite challenges such as price sensitivity and supply chain disruptions, the long-term outlook for the built-in stainless steel sink market remains positive, with opportunities for innovation, expansion, and market differentiation. By investing in product innovation, sustainability, and customer-centric strategies, industry players can capitalize on growing demand and maintain a competitive edge in the global market.

What is a Built-in Stainless Steel Sink?

A Built-in Stainless Steel Sink is a type of sink that is integrated into the countertop, providing a seamless look and efficient use of space. These sinks are popular in both residential and commercial kitchens due to their durability and ease of cleaning.

What are the key players in the Built-in Stainless Steel Sink Market?

Key players in the Built-in Stainless Steel Sink Market include Kohler Co., Moen Incorporated, Franke Holding AG, and Elkay Manufacturing Company, among others. These companies are known for their innovative designs and high-quality products.

What are the main drivers of the Built-in Stainless Steel Sink Market?

The main drivers of the Built-in Stainless Steel Sink Market include the growing trend of modern kitchen designs, increasing consumer preference for durable materials, and the rise in home renovation activities. Additionally, the demand for easy-to-maintain kitchen fixtures is contributing to market growth.

What challenges does the Built-in Stainless Steel Sink Market face?

The Built-in Stainless Steel Sink Market faces challenges such as competition from alternative materials like composite and ceramic sinks, as well as price sensitivity among consumers. Additionally, fluctuations in raw material costs can impact production and pricing strategies.

What opportunities exist in the Built-in Stainless Steel Sink Market?

Opportunities in the Built-in Stainless Steel Sink Market include the potential for product innovation, such as the introduction of smart sinks with integrated technology. Furthermore, expanding into emerging markets presents a significant growth opportunity for manufacturers.

What trends are shaping the Built-in Stainless Steel Sink Market?

Trends shaping the Built-in Stainless Steel Sink Market include the increasing popularity of minimalist designs, the use of eco-friendly manufacturing processes, and the integration of advanced features like soundproofing and anti-bacterial coatings. These trends reflect changing consumer preferences towards functionality and sustainability.

Built-in Stainless Steel Sink Market

| Segmentation Details | Description |

|---|---|

| Product Type | Single Bowl, Double Bowl, Triple Bowl, Farmhouse |

| Installation Type | Undermount, Topmount, Flushmount, Wall-mounted |

| End User | Residential, Commercial, Hospitality, Industrial |

| Size | Small, Medium, Large, Custom |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at