444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The brewery equipment market has witnessed substantial growth in recent years, owing to the rising popularity of craft beer, expanding microbrewery culture, and increasing consumer preference for unique flavors and experiences. Brewery equipment refers to the machinery, tanks, vessels, and other tools used in the brewing process, including brewing systems, fermentation tanks, cooling systems, and cleaning equipment. These equipment play a pivotal role in ensuring the quality, consistency, and efficiency of beer production.

Meaning

Brewery equipment encompasses a wide range of specialized machinery and tools designed specifically for brewing beer. From large-scale commercial breweries to small craft breweries, the equipment used varies based on production capacity, brewing style, and technological requirements. The equipment is carefully engineered to meet the unique needs of brewers, facilitating the entire brewing process from malt milling to wort production, fermentation, maturation, and packaging.

Executive Summary

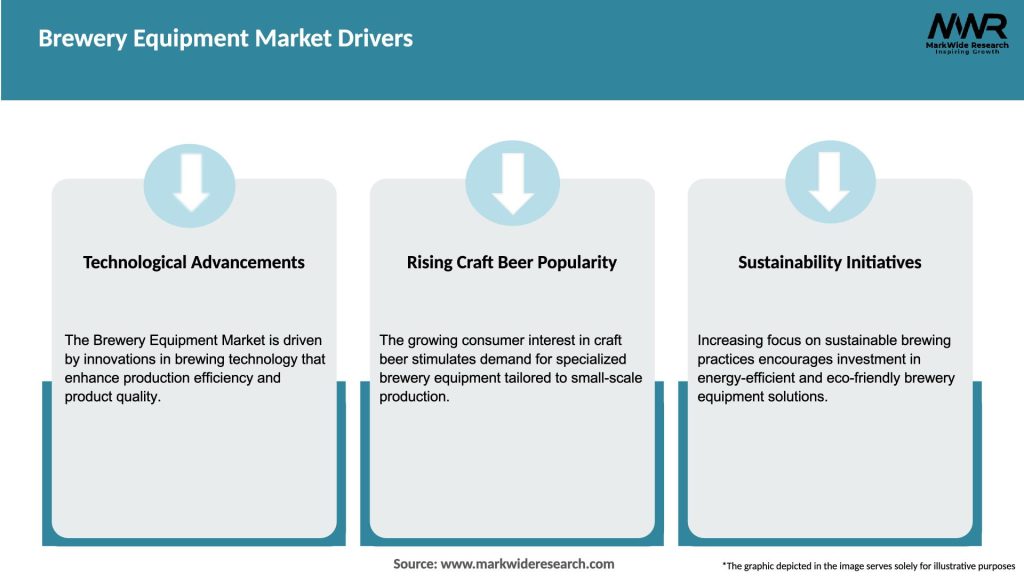

The global brewery equipment market has been experiencing significant growth, driven by the rising demand for craft beer, the emergence of microbreweries, and technological advancements in brewing processes. The market has witnessed a surge in investments and expansions, reflecting the increasing consumer demand for innovative and high-quality beers. Additionally, the growing trend of experiential brewing and the shift toward sustainable brewing practices have also contributed to market growth.

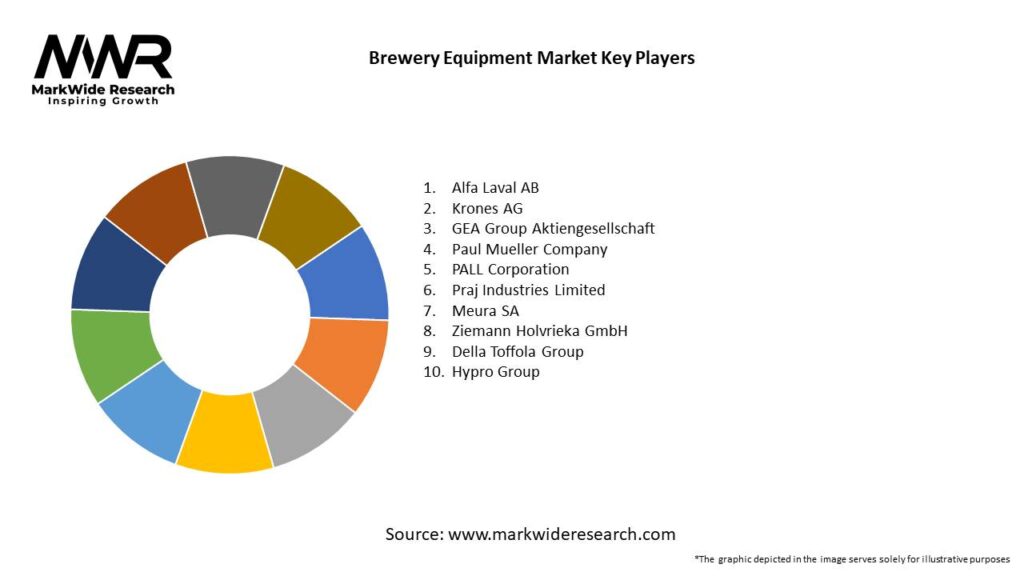

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The brewery equipment market is characterized by intense competition, continuous innovation, and strategic partnerships among manufacturers, suppliers, and breweries. The market dynamics are influenced by factors such as changing consumer preferences, regulatory frameworks, technological advancements, and regional market trends. Collaboration between breweries and equipment manufacturers, customization of equipment to suit specific brewing requirements, and focus on sustainability are key industry dynamics.

Competitive Landscape

Leading companies in the Brewery Equipment Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

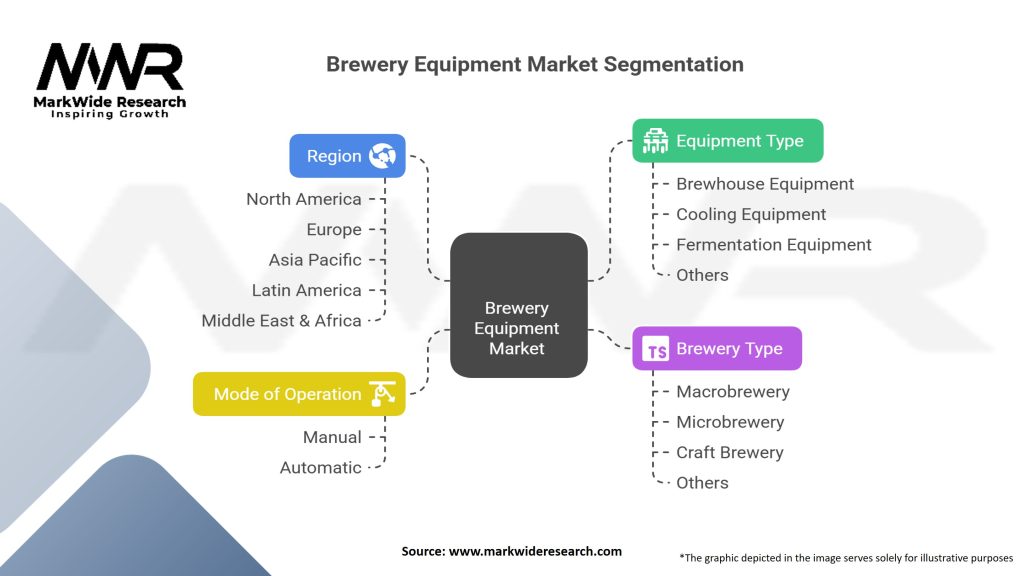

The brewery equipment market can be segmented based on various factors, including equipment type, brewery type, and region. Segmentation enables a detailed analysis of each segment’s growth, market size, and potential opportunities. The major segments in the brewery equipment market include:

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic has had a significant impact on the brewery equipment market. The implementation of lockdown measures, restrictions on social gatherings, and closure of bars and restaurants have resulted in reduced beer consumption and disrupted the supply chain. Breweries faced challenges such as reduced production, declining sales, and the need to adapt to changing consumer behaviors.

However, the pandemic also presented opportunities for breweries to explore direct-to-consumer sales, online platforms, and takeaway options. Breweries that swiftly adapted their business models, implemented safety measures, and focused on e-commerce and home delivery were able to mitigate the impact to some extent.

The market witnessed a shift in consumer preferences, with increased demand for packaged beer and craft beer sold through retail channels. This trend led to the need for canning and bottling equipment to meet the changing consumption patterns. The pandemic also emphasized the importance of hygiene and safety measures in the brewing process, leading to increased investments in cleaning equipment and sanitation protocols.

While the short-term impact was challenging, the brewery equipment market is expected to recover gradually as economies reopen, vaccination programs progress, and the hospitality industry regains momentum.

Key Industry Developments

Analyst Suggestions

Future Outlook

The brewery equipment market is poised for steady growth in the coming years. The rising popularity of craft beer, expanding microbrewery culture, and increasing consumer demand for unique flavors and experiences will drive market growth. Technological advancements, such as automation, IoT integration, and sustainability-focused solutions, will further propel the market.

The Asia Pacific region is expected to witness significant growth, driven by the emergence of craft beer culture, changing consumer preferences, and urbanization. Manufacturers will continue to invest in R&D to introduce advanced brewing technologies, improve equipment efficiency, and meet the evolving needs of breweries worldwide.

Conclusion

The brewery equipment market is experiencing a dynamic and transformative phase, fueled by the growing demand for craft beer, technological advancements, and sustainable brewing practices. Breweries that adapt to changing consumer preferences, invest in advanced equipment, prioritize quality control and sustainability, and forge strategic partnerships will be well-positioned for success in this competitive market. As the brewing industry continues to evolve, the brewery equipment market will play a crucial role in shaping the future of beer production and consumption.

What is brewery equipment?

Brewery equipment refers to the machinery and tools used in the brewing process, including fermentation tanks, kettles, and bottling lines. This equipment is essential for producing beer and other fermented beverages in various scales, from craft breweries to large-scale operations.

Who are the key players in the Brewery Equipment Market?

Key players in the Brewery Equipment Market include companies like GEA Group, Krones AG, and Alfa Laval, which provide a range of brewing solutions. These companies are known for their innovative technologies and comprehensive service offerings, among others.

What are the main drivers of growth in the Brewery Equipment Market?

The growth of the Brewery Equipment Market is driven by the increasing demand for craft beer, advancements in brewing technology, and the rising popularity of home brewing. Additionally, the expansion of microbreweries and the trend towards sustainable brewing practices contribute to market growth.

What challenges does the Brewery Equipment Market face?

The Brewery Equipment Market faces challenges such as high initial investment costs and the need for skilled labor to operate complex machinery. Additionally, regulatory compliance and the impact of supply chain disruptions can pose significant hurdles for manufacturers.

What opportunities exist in the Brewery Equipment Market?

Opportunities in the Brewery Equipment Market include the growing trend of automation in brewing processes and the increasing focus on sustainability. Innovations in energy-efficient equipment and the development of modular brewing systems are also paving the way for new market entrants.

What trends are shaping the Brewery Equipment Market?

Trends in the Brewery Equipment Market include the rise of smart brewing technologies, which utilize IoT and data analytics for improved efficiency. Additionally, there is a growing emphasis on eco-friendly equipment and practices, as breweries seek to reduce their environmental impact.

Brewery Equipment Market

| Segmentation | Details |

|---|---|

| Equipment Type | Brewhouse Equipment, Cooling Equipment, Fermentation Equipment, Others |

| Brewery Type | Macrobrewery, Microbrewery, Craft Brewery, Others |

| Mode of Operation | Manual, Automatic |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Brewery Equipment Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at