Market Overview

The beta and gamma thickness gauge market is integral to industries requiring precise measurement solutions for materials thickness. Leveraging beta and gamma radiation, these gauges offer non-destructive testing capabilities crucial in quality control processes across sectors like manufacturing, construction, and healthcare. The market’s significance lies in its ability to ensure material integrity and adherence to specifications, driving efficiency and safety in various applications.

Meaning

Beta and gamma thickness gauges utilize radiation-based technology to measure the thickness of materials without causing damage. These instruments are invaluable in industries where accuracy and non-destructive testing are paramount. From ensuring consistent coating thickness in manufacturing to monitoring pipeline integrity in oil and gas, beta and gamma thickness gauges play a crucial role in maintaining quality standards.

Executive Summary

The beta and gamma thickness gauge market have witnessed steady growth owing to increasing industrialization and stringent quality standards. These gauges offer unparalleled precision and efficiency, addressing the demand for non-destructive testing solutions across diverse industries. Key insights into market trends, technological advancements, and application areas are essential for stakeholders to capitalize on emerging opportunities and stay competitive.

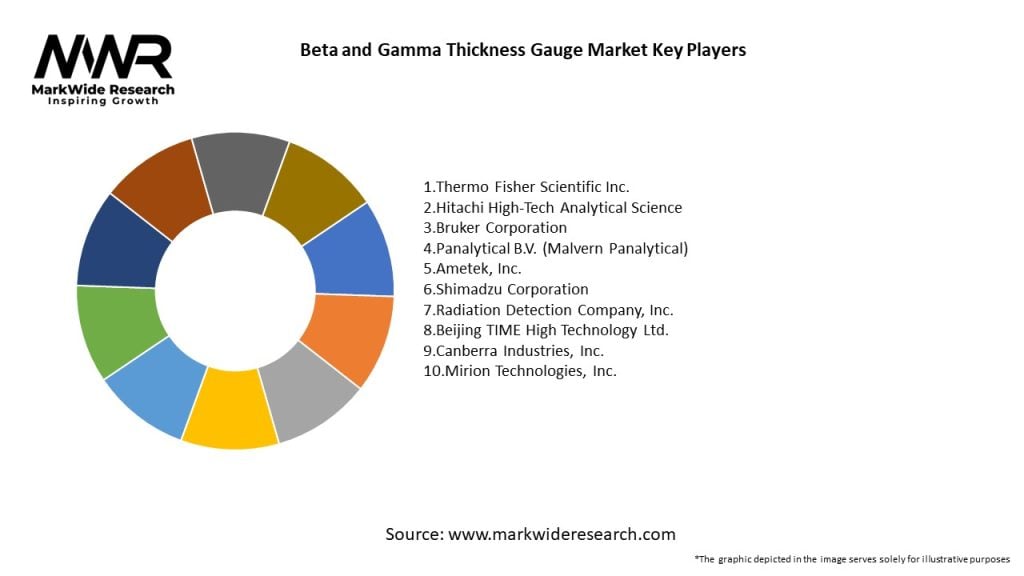

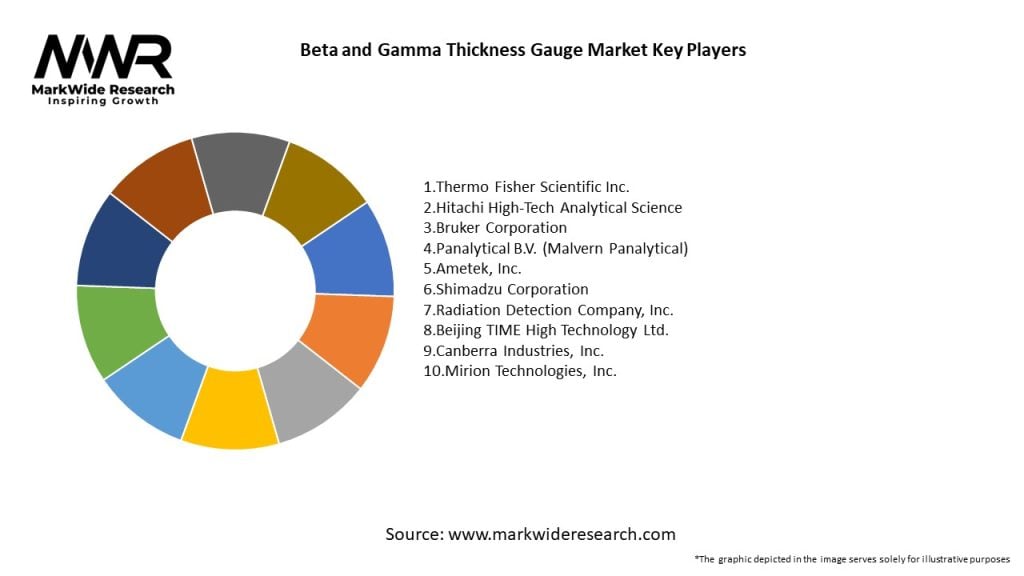

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

- Diverse Applications: Beta and gamma thickness gauges find applications in multiple industries, including automotive, aerospace, electronics, and pharmaceuticals, where precise material thickness is critical for product quality and performance.

- Technological Advancements: Ongoing technological advancements, such as digital signal processing and wireless connectivity, are enhancing the accuracy, reliability, and user-friendliness of beta and gamma thickness gauges, driving market growth.

- Regulatory Compliance: Stringent regulations mandating quality control and safety standards across industries propel the adoption of beta and gamma thickness gauges, particularly in sectors like healthcare and nuclear power, where radiation safety is paramount.

- Automation Integration: Integration with automation systems and Industry 4.0 initiatives is expanding the scope of beta and gamma thickness gauges, enabling real-time monitoring, data analytics, and predictive maintenance in manufacturing environments.

Market Drivers

- Quality Assurance Requirements: Increasing emphasis on product quality and safety drives the demand for beta and gamma thickness gauges, as they enable non-destructive testing and ensure compliance with stringent industry standards.

- Industrial Automation Trends: The trend towards automation in manufacturing and process industries necessitates advanced measurement solutions like beta and gamma thickness gauges to optimize production processes, reduce waste, and enhance productivity.

- Infrastructure Development: Infrastructure development projects, such as construction, pipeline installations, and automotive manufacturing, require precise material thickness measurements for structural integrity and longevity, spurring market growth.

- Rising Healthcare Expenditure: The healthcare sector’s burgeoning demand for medical devices and equipment necessitates accurate thickness measurements during manufacturing, contributing to the market expansion of beta and gamma thickness gauges.

Market Restraints

- Safety Concerns: Despite their non-destructive nature, beta and gamma thickness gauges utilize radiation sources, raising concerns regarding operator safety, regulatory compliance, and environmental impact, which may impede market growth.

- High Initial Costs: The initial investment required for acquiring and calibrating beta and gamma thickness gauges can be substantial, deterring small and medium-sized enterprises (SMEs) from adopting these technologies, thereby limiting market penetration.

- Complexity of Use: The complexity of operating and interpreting data from beta and gamma thickness gauges necessitates specialized training and expertise, posing a barrier to adoption for industries lacking skilled personnel.

- Alternative Technologies: The availability of alternative measurement technologies, such as ultrasonic and laser-based thickness gauges, presents competitive challenges to the beta and gamma thickness gauge market, particularly in price-sensitive industries.

Market Opportunities

- Emerging Markets: Untapped opportunities exist in emerging markets, where increasing industrialization, infrastructure development, and regulatory compliance drive the adoption of beta and gamma thickness gauges across diverse sectors.

- Customization and Integration: Offering customized solutions and integrating beta and gamma thickness gauges with existing process automation systems present avenues for market differentiation and value creation, catering to specific industry requirements.

- Technological Innovation: Continued research and development efforts aimed at enhancing gauge accuracy, reliability, and portability, as well as integrating advanced features like IoT connectivity and cloud-based analytics, unlock new growth opportunities.

- Collaborative Partnerships: Collaborating with industry stakeholders, regulatory bodies, and research institutions facilitates technology transfer, knowledge exchange, and market expansion, fostering innovation and market penetration.

Market Dynamics

The beta and gamma thickness gauge market operate in a dynamic landscape shaped by technological advancements, regulatory frameworks, industry trends, and competitive dynamics. Adapting to changing market dynamics and customer needs is imperative for stakeholders to capitalize on emerging opportunities and sustain growth in the long term.

Regional Analysis

The beta and gamma thickness gauge market exhibit regional variations influenced by factors such as industrialization, infrastructure development, regulatory environment, and technological adoption. Key regions include:

- North America: With a robust manufacturing base and stringent quality standards, North America represents a significant market for beta and gamma thickness gauges, particularly in automotive, aerospace, and healthcare industries.

- Europe: Europe’s emphasis on industrial automation, regulatory compliance, and safety standards fosters market demand for beta and gamma thickness gauges, with applications in automotive manufacturing, nuclear power, and construction.

- Asia Pacific: Rapid industrialization, infrastructure investments, and expanding manufacturing sectors in countries like China, India, and Japan drive market growth for beta and gamma thickness gauges, catering to diverse industry needs.

- Latin America and Middle East: Emerging economies in Latin America and the Middle East present opportunities for market expansion, fueled by infrastructure projects, oil and gas exploration, and automotive manufacturing activities.

Competitive Landscape

The beta and gamma thickness gauge market are characterized by intense competition among global and regional players vying for market share. Key market players include:

Key players in the Beta and Gamma Thickness Gauge market include global manufacturers such as Hitachi High-Tech, Panametrics, Olympus Corporation, Kett Electric Laboratory, and GE Measurement & Control. Competitive strategies focus on product innovation, technological differentiation, strategic alliances, and market expansion initiatives to strengthen market presence and cater to evolving customer needs.

These companies compete based on factors such as product innovation, technology differentiation, pricing strategies, distribution networks, and after-sales support, driving continuous advancements and market growth.

Segmentation

The beta and gamma thickness gauge market can be segmented based on various parameters, including:

- Industry Vertical: Automotive, aerospace, electronics, healthcare, manufacturing, construction, and others.

- Measurement Range: Thin films, coatings, pipes, tanks, sheets, and others.

- End-User: OEMs, contractors, fabricators, inspection agencies, and service providers.

- Geography: North America, Europe, Asia Pacific, Latin America, and Middle East & Africa.

Segmentation enables targeted marketing strategies, product customization, and market positioning to cater to diverse customer needs and preferences.

Category-wise Insights

- Manufacturing: In manufacturing industries, beta and gamma thickness gauges are utilized for quality control, ensuring uniformity and adherence to specifications in processes such as coating application, sheet metal forming, and welding.

- Construction: In construction, beta and gamma thickness gauges play a crucial role in monitoring structural integrity, assessing material thickness in pipelines, tanks, and structural components, and ensuring compliance with building codes and standards.

- Healthcare: The healthcare sector utilizes beta and gamma thickness gauges for medical device manufacturing, ensuring precise material thickness in products like catheters, stents, and implants, to meet regulatory requirements and ensure patient safety.

- Oil and Gas: In the oil and gas industry, beta and gamma thickness gauges are deployed for pipeline inspection, corrosion monitoring, and material thickness measurement in storage tanks and pressure vessels, enhancing safety and operational efficiency.

Key Benefits for Industry Participants and Stakeholders

The beta and gamma thickness gauge market offer several benefits for industry participants and stakeholders, including:

- Non-destructive Testing: Enables non-destructive testing of material thickness, ensuring product quality and integrity without damaging the material.

- Precision and Accuracy: Offers high precision and accuracy in thickness measurement, crucial for meeting quality standards and regulatory requirements.

- Cost Savings: Helps optimize material usage, minimize waste, and reduce production costs by ensuring uniform thickness and minimizing over-coating or under-coating.

- Operational Efficiency: Enhances operational efficiency by enabling real-time thickness monitoring, reducing downtime, and facilitating predictive maintenance.

- Compliance Assurance: Ensures compliance with industry standards, regulatory requirements, and safety norms, mitigating risks and liabilities associated with non-compliance.

SWOT Analysis

A SWOT analysis of the beta and gamma thickness gauge market provides insights into its strengths, weaknesses, opportunities, and threats:

- Strengths:

- High accuracy and precision

- Non-destructive testing capabilities

- Wide-ranging applications across industries

- Regulatory compliance and safety standards

- Weaknesses:

- High initial investment costs

- Operator training and expertise requirements

- Safety concerns associated with radiation exposure

- Competition from alternative measurement technologies

- Opportunities:

- Emerging applications in new industries

- Technological advancements and product innovation

- Market expansion in emerging economies

- Integration with automation and Industry 4.0 initiatives

- Threats:

- Regulatory constraints and compliance challenges

- Competition from alternative measurement technologies

- Economic downturns and market volatility

- Security risks associated with data breaches and cyber threats

Understanding these factors enables stakeholders to leverage strengths, address weaknesses, capitalize on opportunities, and mitigate threats in the beta and gamma thickness gauge market.

Market Key Trends

- Digitalization and Connectivity: Increasing integration of digital features and wireless connectivity enhances gauge functionality, enabling remote monitoring, data analysis, and predictive maintenance.

- Miniaturization and Portability: Advancements in miniaturization technologies result in compact and portable beta and gamma thickness gauges, facilitating on-site measurements and field inspections in diverse environments.

- Smart Sensors and IoT: Integration of smart sensors and IoT capabilities enables real-time data collection, analysis, and sharing, empowering stakeholders with actionable insights and decision-making support.

- Cloud-based Analytics: Cloud-based analytics platforms facilitate centralized data management, storage, and analysis, offering scalability, accessibility, and collaboration for stakeholders across the value chain.

Covid-19 Impact

The Covid-19 pandemic has both positive and negative implications for the beta and gamma thickness gauge market:

- Supply Chain Disruptions: Disruptions in the global supply chain due to lockdowns and restrictions affect the availability of raw materials, components, and finished products, impacting market growth.

- Remote Monitoring Solutions: The need for remote monitoring solutions drives demand for beta and gamma thickness gauges with IoT connectivity, enabling off-site measurements and data analysis to ensure business continuity.

- Focus on Safety and Compliance: Heightened emphasis on safety and compliance in industries such as healthcare, pharmaceuticals, and manufacturing drives the adoption of beta and gamma thickness gauges for quality assurance and regulatory compliance.

- Delayed Investments: Economic uncertainty and budget constraints lead to delayed investments in capital equipment, including beta and gamma thickness gauges, affecting market expansion and revenue growth.

Key Industry Developments

- Advanced Materials Testing: Research and development efforts focus on enhancing gauge capabilities for testing advanced materials such as composites, ceramics, and alloys used in aerospace, automotive, and defense applications.

- Integration with Automation: Increased integration with automation systems and robotics enhances gauge functionality, enabling seamless integration into manufacturing processes for real-time quality control and optimization.

- Focus on User Experience: Manufacturers prioritize user-friendly design, intuitive interfaces, and ergonomic features in beta and gamma thickness gauges to enhance user experience, minimize operator errors, and improve productivity.

- Environmental Sustainability: Sustainability initiatives drive innovation in radiation sources, materials, and manufacturing processes, promoting eco-friendly and energy-efficient beta and gamma thickness gauge solutions.

Analyst Suggestions

- Invest in R&D: Continued investment in research and development is essential to drive technological innovation, enhance gauge performance, and address emerging market needs for precision, reliability, and efficiency.

- Expand Market Reach: Explore opportunities in emerging markets and niche applications by tailoring products and services to meet specific customer requirements, leveraging partnerships, and fostering collaborative relationships.

- Enhance Training and Support: Provide comprehensive training programs and technical support to end-users to enhance gauge utilization, improve operator proficiency, and ensure optimal performance and safety.

- Embrace Sustainability: Emphasize sustainability in product design, manufacturing processes, and corporate practices to meet environmental regulations, reduce carbon footprint, and enhance brand reputation.

Future Outlook

The beta and gamma thickness gauge market are poised for significant growth and innovation driven by technological advancements, industrial automation, and increasing demand for quality control solutions across industries. However, addressing challenges related to safety, regulatory compliance, and market competition requires strategic planning and collaboration among stakeholders.

Conclusion

The beta and gamma thickness gauge market plays a pivotal role in ensuring material quality, safety, and regulatory compliance across diverse industries. With technological advancements, emerging applications, and evolving market trends, stakeholders must stay agile, innovate, and collaborate to capitalize on growth opportunities and address challenges. By prioritizing R&D, expanding market reach, enhancing training and support, and embracing sustainability, the beta and gamma thickness gauge market can navigate uncertainties and foster sustainable growth in the long term.

Beta and Gamma Thickness Gauge Market

| Segmentation Details |

Description |

| Product Type |

Beta Gauges, Gamma Gauges, Dual Energy Gauges, Portable Gauges |

| Application |

Manufacturing, Quality Control, Research, Construction |

| End User |

Industrial, Aerospace, Automotive, Energy |

| Technology |

Radiation Detection, Non-Destructive Testing, Thickness Measurement, Calibration |

Leading Companies in the Beta and Gamma Thickness Gauge Market:

- Thermo Fisher Scientific Inc.

- Hitachi High-Tech Analytical Science

- Bruker Corporation

- Panalytical B.V. (Malvern Panalytical)

- Ametek, Inc.

- Shimadzu Corporation

- Radiation Detection Company, Inc.

- Beijing TIME High Technology Ltd.

- Canberra Industries, Inc.

- Mirion Technologies, Inc.

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA