444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The bending press machine market refers to the industry that deals with the manufacturing, distribution, and sales of machines used for bending various materials such as metal, plastic, and wood. These machines play a crucial role in industries such as automotive, construction, aerospace, and manufacturing, where precise bending of materials is required.

Bending press machines are designed to apply force and pressure on a material, causing it to bend or shape according to the desired specifications. These machines utilize hydraulic or mechanical systems to exert the necessary force, making them efficient and reliable tools for bending operations.

Meaning

A bending press machine is a powerful tool used to bend or shape different materials such as metal, plastic, and wood. It applies force and pressure to deform the material, allowing it to take on a desired shape or form. This process is widely used in various industries to create components and parts that are integral to the production of different products.

Bending press machines are available in different sizes and capacities, ranging from small manual machines used in workshops to large automated machines used in industrial-scale production. These machines are capable of performing precise and accurate bending operations, ensuring consistency and quality in the manufactured components.

Executive Summary

The bending press machine market has witnessed significant growth in recent years, driven by the increasing demand for bent components in various industries. The market is characterized by the presence of several key players who offer a wide range of bending press machines to cater to diverse customer requirements.

Rapid industrialization, especially in emerging economies, has fueled the demand for bending press machines. The automotive and construction sectors are the major end-users of these machines, as they require bent components for the production of vehicles, infrastructure, and other products. Additionally, advancements in technology have led to the development of automated bending press machines, further driving market growth.

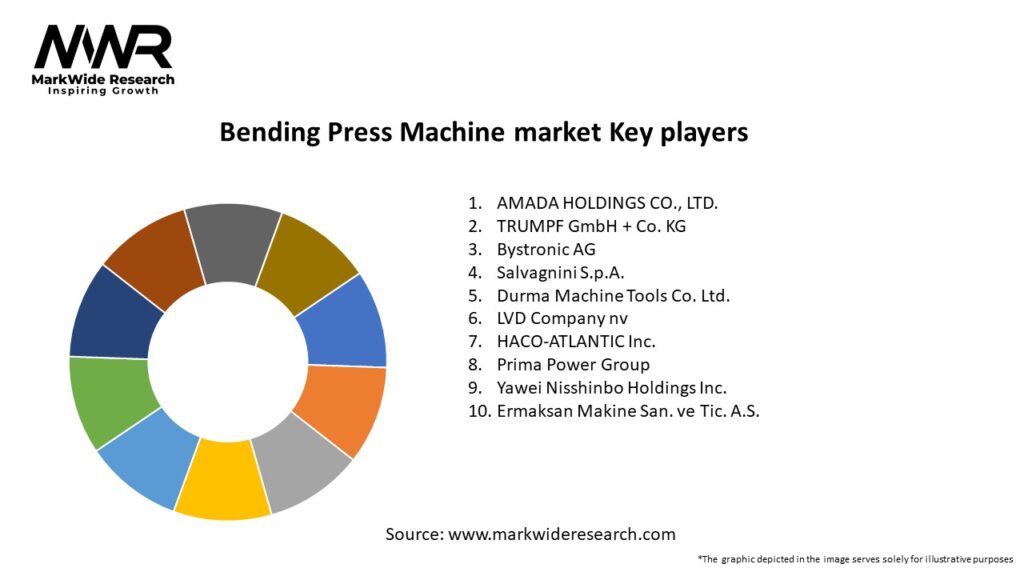

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

The bending press machine market is primarily driven by the following factors:

Market Restraints

Despite the positive growth prospects, the bending press machine market faces some challenges, including:

Market Opportunities

Market Dynamics

The bending press machine market is driven by a combination of factors, including industry trends, technological advancements, and economic factors. The dynamics of the market are influenced by the demand from end-user industries, such as automotive, construction, and manufacturing. Technological developments in bending press machines, such as automation and advanced control systems, also shape the market dynamics.

The market is characterized by intense competition, with several key players vying for market share. Manufacturers focus on product innovation, customization, and value-added services to gain a competitive advantage. They also strive to expand their geographic presence and strengthen their distribution networks to cater to a broader customer base.

The COVID-19 pandemic had a significant impact on the bending press machine market. The initial outbreak led to disruptions in the global supply chain and a slowdown in manufacturing activities. However, as the economies recover and industrial production resumes, the market is expected to regain its momentum.

Regional Analysis

The bending press machine market can be analyzed on a regional basis to understand the market dynamics and opportunities in specific geographies. The key regions in the market include:

Competitive Landscape

Leading Companies in the Bending Press Machine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The bending press machine market can be segmented based on various factors, including machine type, application, end-user industry, and geography. The segmentation helps in understanding the specific requirements and preferences of different customer segments. The key segments in the market include:

Segmenting the market allows manufacturers and suppliers to identify specific customer needs and tailor their products and services accordingly.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

The bending press machine market offers several benefits for industry participants and stakeholders, including:

SWOT Analysis

A SWOT (Strengths, Weaknesses, Opportunities, and Threats) analysis provides insights into the internal and external factors that impact the bending press machine market.

Strengths:

Weaknesses:

Opportunities:

Threats:

By analyzing these factors, companies can formulate effective strategies to capitalize on strengths, address weaknesses, exploit opportunities, and mitigate threats in the bending press machine market.

Market Key Trends

The bending press machine market is characterized by several key trends that shape the industry’s direction:

Covid-19 Impact

The COVID-19 pandemic had a significant impact on the bending press machine market. The initial outbreak led to disruptions in the global supply chain, temporary shutdowns of manufacturing facilities, and a decline in demand for bending press machines. The pandemic affected various industries, including automotive, construction, and manufacturing, which are key end-users of bending press machines.

However, as economies started recovering and industrial activities resumed, the demand for bending press machines gradually picked up. The need for automation, productivity enhancement, and operational efficiency became more crucial, leading to the resumption of investment in bending press machines.

The pandemic also highlighted the importance of resilience and adaptability in manufacturing operations. Manufacturers started prioritizing technologies that minimize human contact, increase automation, and enable remote monitoring and control. These trends have accelerated the adoption of advanced bending press machines with IoT and AI capabilities.

Overall, while the pandemic initially caused disruptions, the bending press machine market has shown resilience and adaptability, and it is expected to recover and grow in the post-pandemic period.

Key Industry Developments

Despite the challenges posed by the pandemic, the bending press machine market witnessed several key industry developments. One notable trend was the increasing adoption of automated bending press machines. Automation has gained prominence in various industries due to its ability to enhance efficiency, accuracy, and productivity. Bending press machines integrated with advanced automation technologies, such as robotics and artificial intelligence, offer improved precision and reduced production time.

Another significant development in the market was the emphasis on sustainability and eco-friendly manufacturing practices. Bending press machine manufacturers have been increasingly focused on developing energy-efficient machines and implementing green initiatives. This shift is driven by growing environmental awareness and the need to comply with stringent regulations.

Furthermore, technological advancements have played a crucial role in shaping the bending press machine market. Manufacturers have introduced innovative features and software solutions to enhance machine performance, ease of use, and safety. These developments have positively influenced the market and attracted the attention of various end-user industries.

Analyst Suggestions

Industry analysts have provided valuable suggestions to overcome the challenges posed by the Covid-19 pandemic and position the bending press machine market for future growth. Firstly, they emphasize the need for manufacturers to diversify their customer base and explore new markets. By expanding their geographical reach, companies can mitigate risks associated with regional economic downturns and leverage opportunities in emerging economies.

Additionally, analysts recommend enhancing product portfolios by introducing customized bending press machines to cater to the specific needs of different industries. This approach can help manufacturers differentiate themselves in the market and establish long-term customer relationships.

Moreover, digital transformation is a crucial aspect highlighted by analysts. Manufacturers should embrace Industry 4.0 technologies, such as Internet of Things (IoT) connectivity and data analytics, to improve machine performance, predictive maintenance, and overall operational efficiency. These digital solutions can offer valuable insights and drive informed decision-making.

Future Outlook

Looking ahead, the bending press machine market is expected to witness a gradual recovery from the impact of the Covid-19 pandemic. As economies stabilize and restrictions ease, the demand for bending press machines is anticipated to rise, driven by the resumption of construction and manufacturing activities.

The increasing adoption of automation in various industries will likely fuel the demand for advanced bending press machines. Automation not only enhances productivity but also reduces labor costs and minimizes errors, making it an attractive investment for businesses.

Furthermore, the rising emphasis on sustainable manufacturing practices will continue to influence the bending press machine market. Manufacturers that prioritize eco-friendly solutions and energy-efficient machines are likely to gain a competitive edge.

Additionally, the integration of advanced technologies, such as machine learning and artificial intelligence, will further revolutionize the bending press machine industry. These technologies can enable predictive maintenance, real-time monitoring, and optimization of machine operations, resulting in improved performance and reduced downtime.

Conclusion

As economies recover and industries regain momentum, the bending press machine market is expected to bounce back, driven by increasing demand from construction and manufacturing sectors. The market’s future looks promising, characterized by automation, sustainability, and cutting-edge technologies that will shape the industry and offer opportunities for innovation and growth.

What is Bending Press Machine?

A Bending Press Machine is a type of industrial equipment used to bend metal sheets and plates into desired shapes and angles. It is commonly utilized in manufacturing processes for various applications, including automotive, construction, and metal fabrication.

What are the key players in the Bending Press Machine market?

Key players in the Bending Press Machine market include Amada Co., Ltd., Trumpf GmbH + Co. KG, and Bystronic AG, among others. These companies are known for their innovative technologies and extensive product offerings in the bending press segment.

What are the growth factors driving the Bending Press Machine market?

The growth of the Bending Press Machine market is driven by increasing demand for precision metal fabrication, advancements in automation technology, and the expansion of the automotive and aerospace industries. Additionally, the rise in infrastructure development projects contributes to market growth.

What challenges does the Bending Press Machine market face?

The Bending Press Machine market faces challenges such as high initial investment costs and the need for skilled operators to manage complex machinery. Furthermore, fluctuations in raw material prices can impact production costs and profitability.

What opportunities exist in the Bending Press Machine market?

Opportunities in the Bending Press Machine market include the growing trend of Industry Four Point Zero, which emphasizes automation and smart manufacturing. Additionally, the increasing adoption of eco-friendly practices in manufacturing processes presents new avenues for growth.

What trends are shaping the Bending Press Machine market?

Current trends in the Bending Press Machine market include the integration of advanced technologies such as CNC controls and IoT connectivity. These innovations enhance operational efficiency and precision, catering to the evolving needs of various industries.

Bending Press Machine market

| Segmentation Details | Description |

|---|---|

| Product Type | Hydraulic, Mechanical, Pneumatic, Electric |

| End User | Aerospace, Automotive OEMs, Metal Fabrication, Construction |

| Technology | Digital Control, Manual Control, CNC, Hybrid |

| Application | Sheet Metal, Tube Bending, Forming, Stamping |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Bending Press Machine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at