444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The beer bottling kit market refers to the industry that produces and supplies equipment and accessories necessary for bottling beer. These kits are designed to provide breweries, microbreweries, and homebrewers with the tools they need to efficiently and effectively bottle their beer. The market for beer bottling kits has witnessed significant growth in recent years, driven by the increasing popularity of craft beer and the rising number of breweries worldwide.

Meaning

A beer bottling kit is a collection of equipment and components that enable the bottling process for beer. It typically includes items such as bottle fillers, cappers, labelers, sanitizing agents, and other accessories. These kits are essential for breweries and homebrewers as they provide a convenient and professional solution for packaging their beer in bottles.

Executive Summary

The beer bottling kit market is experiencing robust growth due to the surging demand for craft beer and the expansion of the brewery industry. These kits offer a cost-effective and efficient way to package beer, ensuring its quality and shelf-life. With the rise in the number of microbreweries and homebrewers, the demand for beer bottling kits is expected to continue increasing in the coming years.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The beer bottling kit market is driven by the increasing demand for craft beer and the expansion of the brewery industry. The convenience and cost-effectiveness of these kits, coupled with technological advancements, have further propelled market growth. However, high initial investments, maintenance costs, and competition from alternative packaging methods pose challenges to the market. Nonetheless, emerging markets, customization opportunities, and online retailing present promising avenues for growth in the beer bottling kit market.

Regional Analysis

The beer bottling kit market exhibits a global presence, with significant regional variations. North America and Europe are leading markets due to the strong presence of craft breweries and a mature beer industry. Asia Pacific is witnessing rapid growth, driven by the increasing adoption of craft beer in countries like China and India. Latin America and the Middle East and Africa are also emerging markets, presenting opportunities for beer bottling kit manufacturers as the craft beer industry expands in these regions.

Competitive Landscape

Leading Companies in the Beer Bottling Kit Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

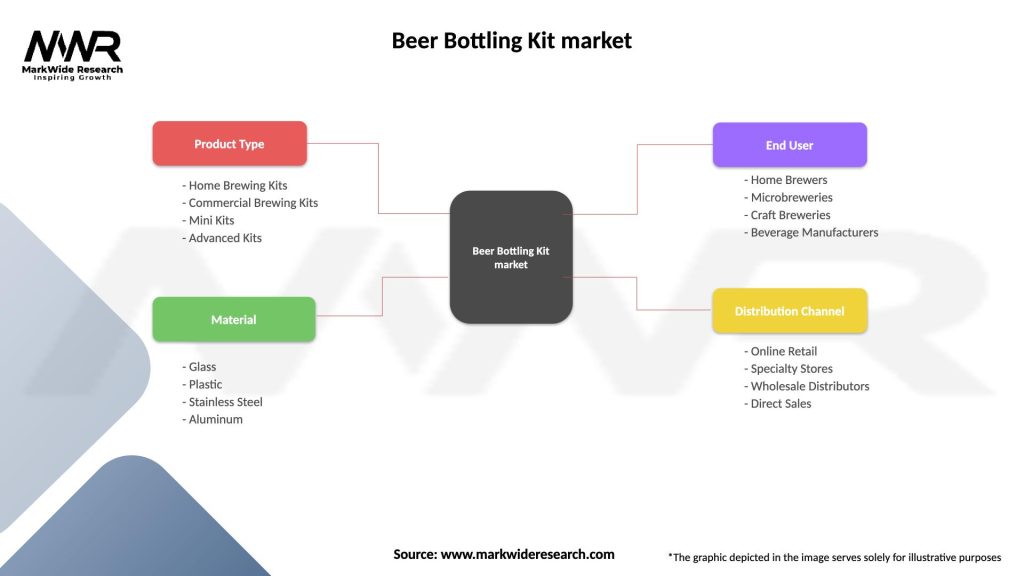

Segmentation

The beer bottling kit market can be segmented based on the type of kit and end-user.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The beer bottling kit market, like many other industries, experienced the impact of the Covid-19 pandemic. The temporary closure of bars, restaurants, and breweries, along with disruptions in the supply chain, led to a decline in demand for beer bottling kits. However, the market quickly adapted as breweries shifted their focus to packaged beer for retail sales and home consumption. The rise in homebrewing during lockdowns also contributed to the demand for beer bottling kits. As restrictions eased and the hospitality sector reopened, the market witnessed a gradual recovery with increased demand from both commercial and homebrewing segments.

Key Industry Developments

Analyst Suggestions

Future Outlook

The beer bottling kit market is expected to witness steady growth in the coming years. The increasing popularity of craft beer, the expansion of the brewery industry, and the demand for efficient packaging solutions will drive market growth. Technological advancements, customization options, and online retailing will further contribute to market expansion. However, manufacturers should remain agile and adaptable to changing consumer preferences and emerging trends to maintain a competitive edge in this dynamic market.

Conclusion

The beer bottling kit market plays a crucial role in the efficient and cost-effective packaging of beer for breweries and homebrewers. The market is driven by the growing demand for craft beer, the expansion of the brewery industry, and the convenience offered by these kits. While there are challenges such as high initial investments and competition from alternative packaging methods, emerging markets, customization opportunities, and online retailing provide avenues for growth. Manufacturers should focus on product quality, invest in research and development, expand into emerging markets, and provide comprehensive after-sales support to thrive in this competitive market. With the increasing popularity of craft beer and the evolving needs of the industry, the future outlook for the beer bottling kit market appears promising.

What is Beer Bottling Kit?

A Beer Bottling Kit is a collection of tools and equipment designed for homebrewers to package their beer into bottles. These kits typically include items such as bottles, caps, a capper, and a bottling wand, facilitating the bottling process and ensuring the beer is properly sealed and preserved.

What are the key players in the Beer Bottling Kit market?

Key players in the Beer Bottling Kit market include companies like Northern Brewer, MoreBeer!, and Brewcraft USA, which offer a variety of bottling kits and accessories for homebrewers. These companies focus on providing quality products that cater to both novice and experienced brewers, among others.

What are the growth factors driving the Beer Bottling Kit market?

The growth of the Beer Bottling Kit market is driven by the increasing popularity of homebrewing among consumers, the rise in craft beer culture, and the growing interest in DIY projects. Additionally, the availability of diverse brewing equipment and resources has made homebrewing more accessible.

What challenges does the Beer Bottling Kit market face?

Challenges in the Beer Bottling Kit market include competition from commercial breweries, which may deter homebrewers, and the potential for regulatory hurdles related to homebrewing laws. Additionally, maintaining product quality and ensuring consumer safety are ongoing concerns.

What opportunities exist in the Beer Bottling Kit market?

Opportunities in the Beer Bottling Kit market include expanding product lines to include eco-friendly materials and innovative bottling technologies. There is also potential for growth in online sales channels and educational resources to support new homebrewers.

What trends are shaping the Beer Bottling Kit market?

Trends in the Beer Bottling Kit market include a shift towards sustainable packaging solutions and the incorporation of smart technology in brewing equipment. Additionally, the rise of social media has fostered communities of homebrewers sharing tips and experiences, influencing product development.

Beer Bottling Kit market

| Segmentation Details | Description |

|---|---|

| Product Type | Home Brewing Kits, Commercial Brewing Kits, Mini Kits, Advanced Kits |

| Material | Glass, Plastic, Stainless Steel, Aluminum |

| End User | Home Brewers, Microbreweries, Craft Breweries, Beverage Manufacturers |

| Distribution Channel | Online Retail, Specialty Stores, Wholesale Distributors, Direct Sales |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Beer Bottling Kit Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at