444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

Base molding, also known as baseboard molding, is a type of architectural trim used to cover the joint between the wall surface and the floor. It serves both aesthetic and functional purposes, enhancing the visual appeal of interior spaces while protecting walls from damage and concealing uneven edges. Base molding comes in a variety of materials, styles, and finishes, offering versatility and customization options to suit different design preferences and architectural styles.

Meaning

Base molding is a decorative trim installed at the base of interior walls to provide a finished look and transition between the wall and floor surfaces. It typically extends horizontally along the bottom of walls, covering the gap where the wall meets the floor and creating a smooth, cohesive transition between the two surfaces. Base molding can be made from various materials, including wood, MDF (medium-density fiberboard), PVC (polyvinyl chloride), and composite materials, and is available in different profiles and dimensions to accommodate diverse design requirements.

Executive Summary

The base molding market is driven by factors such as increasing construction and renovation activities, growing demand for interior design customization, and rising consumer awareness about the importance of architectural detailing. While the market offers significant opportunities for growth and innovation, it also faces challenges such as pricing pressures, fluctuating raw material costs, and competition from alternative products. By focusing on product differentiation, quality craftsmanship, and customer service, base molding manufacturers can capitalize on emerging trends and strengthen their market position.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The base molding market operates in a dynamic environment shaped by factors such as consumer preferences, design trends, technological advancements, and economic conditions. Market dynamics influence product development, marketing strategies, distribution channels, and competitive positioning for base molding manufacturers and suppliers. Understanding and adapting to market dynamics is essential for success in the base molding industry.

Regional Analysis

The base molding market exhibits regional variations in demand, market maturity, and product preferences due to factors such as regional architectural styles, construction activity levels, and economic development. While mature markets in North America and Europe offer stable demand for base molding products, emerging markets in Asia Pacific, Latin America, and the Middle East present opportunities for growth and expansion through infrastructure development projects and urbanization trends.

Competitive Landscape

Leading Companies in the Base Molding Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

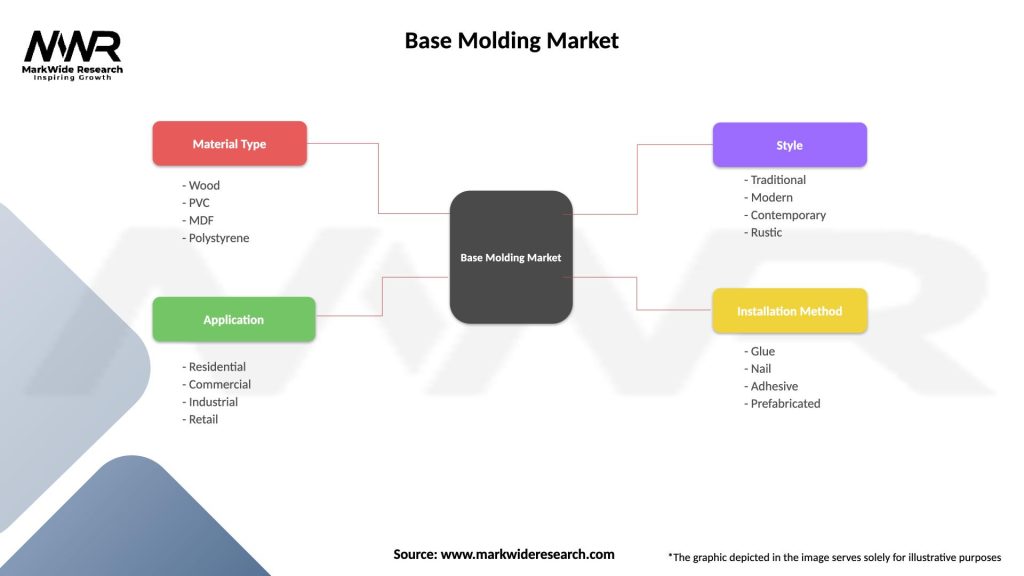

Segmentation

The base molding market can be segmented based on various factors, including material type, profile design, application, end-user industry, and geographic region. Common segments include wood base molding, MDF base molding, PVC base molding, decorative base molding, and architectural base molding. Segmentation allows manufacturers to target specific customer needs, preferences, and market segments more effectively and tailor their product offerings accordingly.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic has had mixed effects on the base molding market, with disruptions to supply chains, construction activities, and consumer spending affecting demand and sales. While lockdowns and social distancing measures initially slowed down construction projects and home remodeling activities, increased time spent at home and heightened focus on home improvement projects led to a surge in DIY renovations and online purchases of building materials, including base molding products.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future outlook for the base molding market is positive, with continued growth expected driven by factors such as urbanization, population growth, and increasing investment in residential and commercial construction projects. Technological advancements, design innovations, and sustainability initiatives will shape the market landscape, creating opportunities for base molding manufacturers to innovate, differentiate, and expand market presence in a dynamic and evolving industry environment.

Conclusion

In conclusion, the base molding market offers significant opportunities for growth and innovation, driven by factors such as construction activity levels, interior design trends, and consumer demand for customizable architectural trim solutions. While the market faces challenges such as pricing pressures, raw material costs, and competition from alternative products, strategic focus on product differentiation, customer education, and sustainability can help base molding manufacturers navigate market dynamics and capitalize on emerging trends. By staying agile, responsive, and customer-centric, base molding companies can position themselves for success and contribute to the enhancement of interior spaces worldwide.

What is Base Molding?

Base molding, also known as baseboard, is a type of trim that is installed at the junction of the wall and the floor. It serves both decorative and functional purposes, such as covering gaps and protecting walls from damage.

What are the key players in the Base Molding Market?

Key players in the Base Molding Market include companies like Metrie, Royal Building Products, and Fypon, which offer a variety of materials and styles for base molding. These companies focus on innovation and quality to meet diverse consumer needs, among others.

What are the growth factors driving the Base Molding Market?

The growth of the Base Molding Market is driven by increasing construction activities, rising demand for home renovations, and a growing preference for aesthetic interior designs. Additionally, the trend towards sustainable building materials is influencing market dynamics.

What challenges does the Base Molding Market face?

The Base Molding Market faces challenges such as fluctuating raw material prices and competition from alternative wall finishing options. Additionally, the need for skilled labor for installation can hinder market growth.

What opportunities exist in the Base Molding Market?

Opportunities in the Base Molding Market include the expansion of e-commerce platforms for easier access to products and the increasing popularity of custom designs. Furthermore, the rise in eco-friendly materials presents a chance for innovation.

What trends are shaping the Base Molding Market?

Current trends in the Base Molding Market include the use of advanced manufacturing technologies and the growing popularity of minimalist designs. Additionally, there is an increasing focus on integrating smart home features with traditional molding applications.

Base Molding Market

| Segmentation Details | Description |

|---|---|

| Material Type | Wood, PVC, MDF, Polystyrene |

| Application | Residential, Commercial, Industrial, Retail |

| Style | Traditional, Modern, Contemporary, Rustic |

| Installation Method | Glue, Nail, Adhesive, Prefabricated |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Base Molding Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at