Executive Summary

The global ball bearing market has witnessed significant growth in recent years, driven by the expanding industrial sector and the rising demand for efficient and reliable machinery. Manufacturers are continually focusing on product innovation and advanced technologies to enhance the performance and durability of ball bearings. The market is highly competitive, with key players adopting strategies such as mergers, acquisitions, and collaborations to gain a competitive edge.

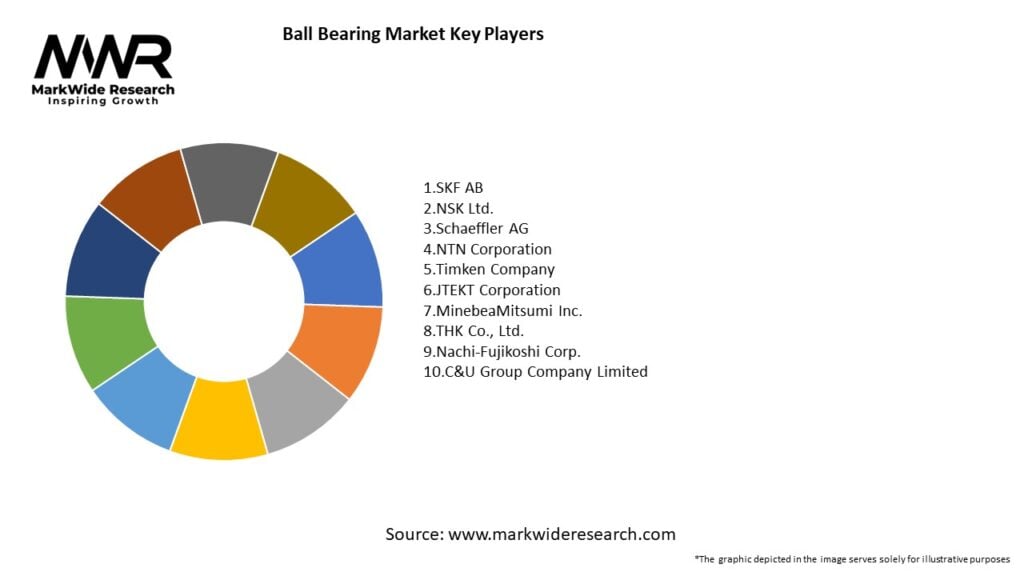

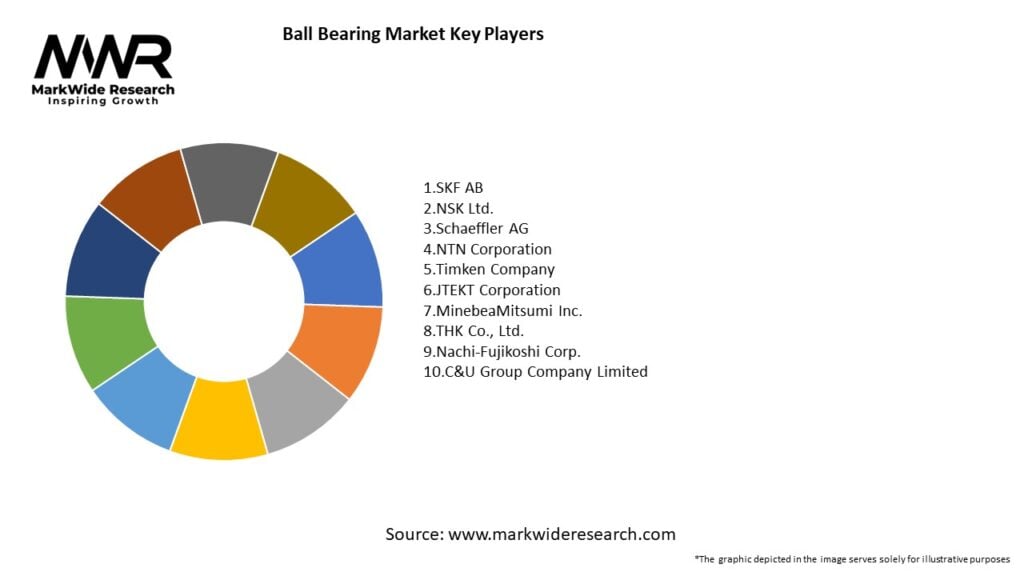

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

- Growing industrialization and automation: The increasing adoption of automation across industries has boosted the demand for efficient machinery, driving the ball bearing market.

- Technological advancements: Manufacturers are investing in research and development activities to introduce advanced ball bearing designs with enhanced load capacities and durability.

- Rising automotive production: The automotive industry is a major consumer of ball bearings, with the growing production of vehicles contributing to market growth.

- Increasing demand for renewable energy: The renewable energy sector, including wind turbines and solar panels, requires reliable ball bearings to ensure optimal performance and longevity of equipment.

- Emerging economies: Rapid industrialization and infrastructural development in emerging economies, particularly in Asia Pacific, are fueling the demand for ball bearings.

Market Drivers

-

Automation & Robotics Adoption: Industrial automation in manufacturing and assembly lines increases demand for precision bearings.

-

Growth in Automotive Production: Rising vehicle output worldwide drives requirements for high-performance wheel and engine bearings.

-

Energy Sector Investments: Wind turbines and electric motors rely on specialized ball bearings for efficient, low-friction operation.

-

Miniaturization Trends: Electronics and medical devices require miniature bearings with high load capacity in compact designs.

-

Material Innovations: Introduction of ceramic and hybrid bearings offers superior wear resistance and temperature tolerance.

Market Restraints

-

Economic Cyclicality: Slowdowns in automotive and industrial sectors directly impact bearing demand and pricing levels.

-

Commodity Steel Price Fluctuations: Volatility in steel and alloy costs affects bearing production expenses and final prices.

-

Counterfeit & Low-Quality Imports: Influx of substandard bearings undermines market trust and can cause equipment failures.

-

High Capital Equipment Requirements: Modern bearing manufacturing demands precision machinery and clean-room environments, elevating entry barriers.

-

Maintenance & Replacement Costs: Frequent bearing replacements in heavy-load applications may deter end-users seeking longer service intervals.

Market Opportunities

- Aerospace industry growth: The expanding aerospace sector presents significant opportunities for ball bearing manufacturers as these components are crucial for aircraft and spacecraft.

- Increasing demand for high-speed bearings: Various industries, such as robotics, medical devices, and machine tools, require high-speed bearings for efficient operations.

- Growing aftermarket sales: The replacement and maintenance of ball bearings in existing machinery create a substantial aftermarket, offering additional revenue opportunities.

Market Dynamics

The ball bearing market operates in a dynamic landscape influenced by various factors. The market dynamics include:

- Technological advancements

- Changing customer preferences and requirements

- Competitive landscape and market consolidation

- Economic and industrial growth

- Environmental regulations and sustainability initiatives

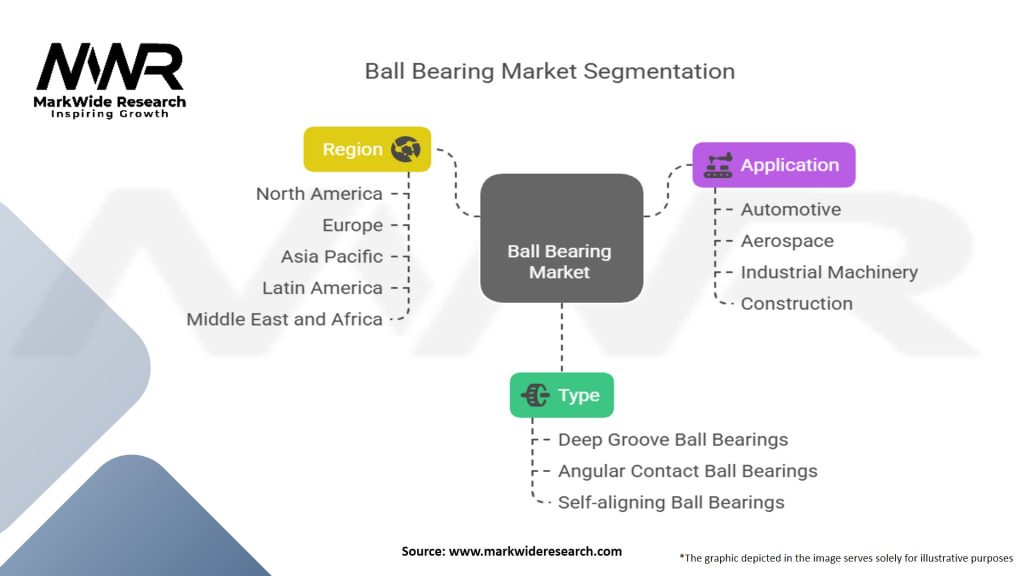

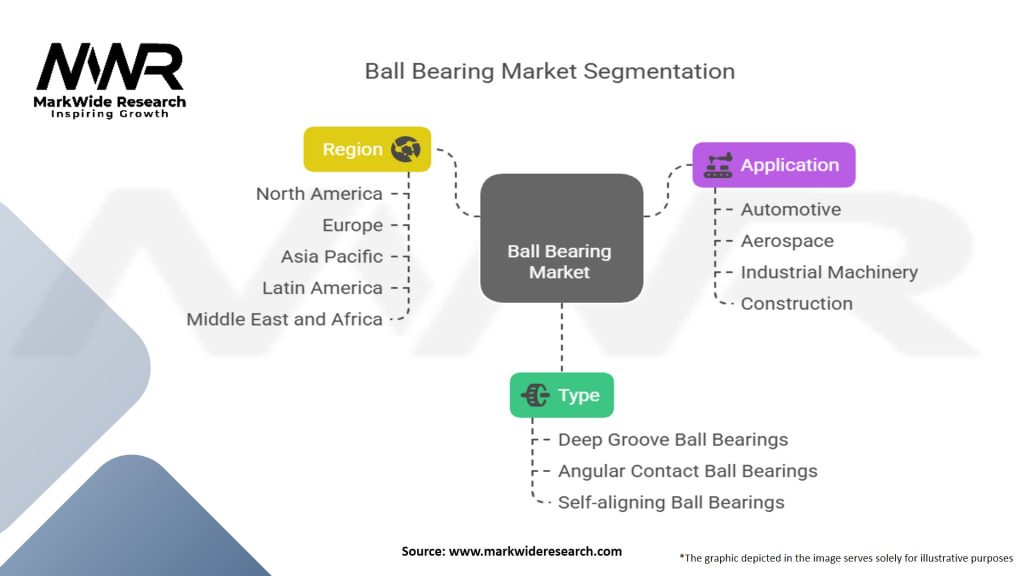

Regional Analysis

The ball bearing market exhibits a global presence, with key regions including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Asia Pacific dominates the market due to its extensive industrialization and manufacturing activities. The region’s growing automotive, machinery, and construction sectors drive the demand for ball bearings. North America and Europe also hold significant market shares, supported by the presence of major automotive and aerospace industries.

Competitive Landscape

Leading Companies in the Ball Bearing Market:

- SKF AB

- NSK Ltd.

- Schaeffler AG

- NTN Corporation

- Timken Company

- JTEKT Corporation

- MinebeaMitsumi Inc.

- THK Co., Ltd.

- Nachi-Fujikoshi Corp.

- C&U Group Company Limited

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The ball bearing market can be segmented based on type, application, and end-use industry.

By Type:

- Deep Groove Ball Bearings

- Self-Aligning Ball Bearings

- Angular Contact Ball Bearings

- Thrust Ball Bearings

- Others

By Application:

- Automotive

- Aerospace

- Industrial Machinery

- Construction

- Power Generation

- Others

By End-Use Industry:

- Automotive

- Aerospace

- Machinery Manufacturing

- Energy

- Construction

- Others

Category-wise Insights

- Deep Groove Ball Bearings: These are the most widely used ball bearings due to their versatility and cost-effectiveness. They find applications in various industries, including automotive, machinery manufacturing, and appliances.

- Self-Aligning Ball Bearings: Designed to accommodate misalignment, self-aligning ball bearings are commonly used in applications with high radial loads and moderate axial loads, such as textile machinery and conveyors.

- Angular Contact Ball Bearings: These bearings are suitable for applications requiring high precision and high-speed rotation, including machine tools, robotics, and medical equipment.

- Thrust Ball Bearings: Primarily used to support axial loads, thrust ball bearings are commonly found in automotive transmissions, marine applications, and heavy machinery.

- Others: This category includes specialty ball bearings designed for specific applications, such as high-temperature environments, extreme load conditions, and corrosive environments.

Key Benefits for Industry Participants and Stakeholders

- Enhanced machinery performance and efficiency

- Reduction in friction and wear

- Increased durability and reliability

- Cost savings through improved productivity and reduced maintenance

- Access to a growing market with expanding industrial sectors

SWOT Analysis

- Strengths: Technological expertise, extensive product portfolio, strong distribution networks

- Weaknesses: Price volatility of raw materials, counterfeiting issues

- Opportunities: Growing aerospace industry, increasing demand for high-speed bearings, aftermarket sales potential

- Threats: Intense competition, economic fluctuations, stringent environmental regulations

Market Key Trends

- Adoption of advanced materials: Manufacturers are exploring the use of advanced materials, such as ceramic and composite, to improve the performance and longevity of ball bearings.

- Integration of sensor technology: IoT-enabled ball bearings with built-in sensors are gaining traction, allowing real-time monitoring of equipment health and predictive maintenance.

- Focus on sustainability: Market players are increasingly emphasizing sustainability by developing eco-friendly and energy-efficient ball bearing solutions.

- Integration of Industry 4.0 technologies: Ball bearing manufacturers are incorporating Industry 4.0 technologies like automation, AI, and data analytics to optimize production processes and improve product quality.

Covid-19 Impact

The COVID-19 pandemic had a significant impact on the ball bearing market. The global lockdowns and disruptions in industrial activities led to a temporary decline in demand. However, as industries resumed operations and supply chains stabilized, the market gradually recovered. The pandemic highlighted the importance of resilient and reliable supply chains, driving the demand for high-quality ball bearings to ensure uninterrupted operations.

Key Industry Developments

- Strategic partnerships: Market players are entering into strategic partnerships to expand their product portfolios, strengthen market presence, and cater to diverse customer requirements.

- Technological advancements: Companies are investing in research and development to introduce innovative ball bearing solutions with improved performance and durability.

- Geographic expansion: Leading players are expanding their global footprint through mergers, acquisitions, and the establishment of manufacturing facilities in emerging markets.

Analyst Suggestions

- Focus on R&D: Continued investment in research and development will enable manufacturers to introduce innovative ball bearing designs that meet evolving customer needs.

- Embrace digital transformation: Leveraging digital technologies and data analytics can enhance operational efficiency, product quality, and customer service.

- Strengthen supply chain resilience: The COVID-19 pandemic highlighted the importance of robust supply chains. Manufacturers should assess and enhance their supply chain resilience to mitigate future disruptions.

Future Outlook

The ball bearing market is expected to witness steady growth in the coming years. Factors such as increasing industrialization, automation, and the demand for efficient machinery will drive market expansion. Technological advancements, including the integration of sensors and IoT capabilities, will further enhance the performance and functionality of ball bearings. Moreover, the growing emphasis on sustainability and energy efficiency will present new opportunities for market players.

Conclusion

The ball bearing market plays a crucial role in various industries, enabling smooth rotational motion and reducing friction. The market is driven by factors such as industrialization, automation, and the demand for reliable machinery. Technological advancements, increasing automotive production, and the rise of renewable energy contribute to market growth. Despite challenges such as intense competition and counterfeit products, the market presents opportunities in aerospace, high-speed applications, and aftermarket sales. With continued innovation and strategic initiatives, the ball bearing market is poised for a promising future, catering to the evolving needs of industries worldwide.