444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The aviation gas turbine market is witnessing significant growth worldwide. Gas turbines play a vital role in powering aircraft engines, providing thrust and ensuring efficient performance during flight operations. These turbines have become an integral part of the aviation industry due to their high power-to-weight ratio, reliability, and fuel efficiency.

Meaning

An aviation gas turbine is a type of engine that uses combustion of a fuel-air mixture to generate power for aircraft propulsion. It consists of several components, including a compressor, combustion chamber, turbine, and exhaust nozzle. The compressor compresses incoming air, which is then mixed with fuel and ignited in the combustion chamber. The resulting hot gases flow through the turbine, driving it and the compressor. This process creates the necessary thrust to propel the aircraft forward.

Executive Summary

The aviation gas turbine market is experiencing steady growth, driven by the increasing demand for air travel, technological advancements in engine design, and the rising need for fuel-efficient aircraft. The market is highly competitive, with several key players vying for market share by focusing on product innovation, research and development, and strategic collaborations. The market’s future looks promising, as the aviation industry continues to expand, and the need for reliable and efficient engines remains high.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

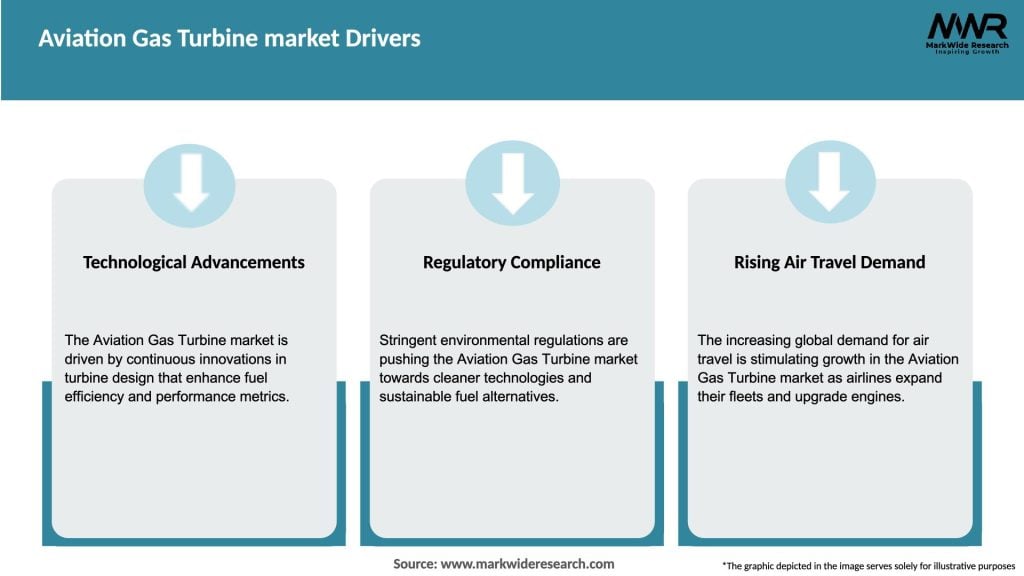

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The aviation gas turbine market is driven by a combination of industry-specific factors and broader market dynamics. The increasing demand for air travel, focus on fuel efficiency, and technological advancements act as primary drivers for market growth. However, factors such as high initial investment and technical complexities pose challenges to market expansion. It is essential for industry participants to navigate these dynamics effectively to capitalize on the market opportunities.

Regional Analysis

The aviation gas turbine market can be analyzed across various regions, including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Each region has its unique characteristics and market dynamics that influence the demand for aviation gas turbines.

Competitive Landscape

Leading Companies in the Aviation Gas Turbine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The aviation gas turbine market can be segmented based on engine type, aircraft type, and end-user.

By engine type:

Turbojet engines are primarily used in military aircraft, while turbofan engines are widely used in commercial aircraft due to their high fuel efficiency. Turboprop engines are commonly used in regional and small aircraft.

By aircraft type:

Commercial aircraft have the highest demand for aviation gas turbines, driven by the growth of the commercial aviation sector. Military aircraft utilize gas turbines for their high thrust and performance requirements. Business jets and helicopters also rely on gas turbines for propulsion.

By end-user:

OEMs are the primary customers for aviation gas turbines, as they integrate the engines into aircraft during the manufacturing process. MRO providers offer maintenance and repair services for gas turbine engines, ensuring their optimal performance throughout their lifecycle. The aftermarket segment includes the sale of spare parts and components for gas turbines.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The aviation industry, including the aviation gas turbine market, has been significantly impacted by the Covid-19 pandemic. The global travel restrictions, lockdowns, and reduced passenger demand resulted in a sharp decline in air travel, leading to decreased aircraft orders and engine installations. Airlines faced financial challenges, resulting in fleet downsizing and deferred maintenance activities.

However, as vaccination rates increase and travel restrictions ease, the industry is gradually recovering. Governments and industry stakeholders are implementing measures to restore passenger confidence and revive air travel. The aviation gas turbine market is expected to rebound as airlines resume operations, renew their fleets, and invest in fuel-efficient engines to optimize costs.

The pandemic has also highlighted the importance of resilient and efficient supply chains in the aviation industry.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future of the aviation gas turbine market looks promising, driven by the growth of the aviation industry and the increasing emphasis on sustainability. The demand for air travel is projected to continue rising, particularly in emerging markets, leading to increased aircraft orders and installations of gas turbines.

Technological advancements will play a crucial role in shaping the market’s future. Engine manufacturers will focus on improving fuel efficiency, reducing emissions, and enhancing engine performance through innovations in materials, design, and digitalization.

Additionally, the industry will witness increased collaboration and partnerships to leverage expertise and resources for faster development and market penetration. Strategic alliances will enable companies to offer integrated solutions and address the evolving needs of airlines and aircraft manufacturers.

Conclusion

The aviation gas turbine market is poised for growth as the aviation industry expands and seeks more efficient and sustainable solutions. The market benefits from increasing air travel demand, technological advancements, and a focus on fuel efficiency and environmental sustainability.

Industry participants should prioritize research and development efforts, strengthen aftermarket services, and embrace collaboration to stay competitive. Adapting to evolving regulations and customer preferences while investing in sustainable technologies will be crucial for long-term success.

What is Aviation Gas Turbine?

Aviation Gas Turbine refers to a type of engine that converts fuel into mechanical energy to power aircraft. These turbines are essential for jet propulsion and are widely used in commercial and military aviation.

What are the key players in the Aviation Gas Turbine market?

Key players in the Aviation Gas Turbine market include General Electric, Rolls-Royce, Pratt & Whitney, and Safran, among others. These companies are known for their innovative technologies and extensive product offerings in the aviation sector.

What are the main drivers of the Aviation Gas Turbine market?

The main drivers of the Aviation Gas Turbine market include the increasing demand for fuel-efficient engines, advancements in turbine technology, and the growth of the aviation industry. Additionally, the rise in air travel and cargo transport contributes to market expansion.

What challenges does the Aviation Gas Turbine market face?

The Aviation Gas Turbine market faces challenges such as stringent environmental regulations, high manufacturing costs, and the need for continuous innovation. These factors can impact the development and adoption of new turbine technologies.

What opportunities exist in the Aviation Gas Turbine market?

Opportunities in the Aviation Gas Turbine market include the development of sustainable aviation fuels, the integration of digital technologies for performance optimization, and the expansion of the market in emerging economies. These trends can lead to new applications and increased efficiency.

What are the current trends in the Aviation Gas Turbine market?

Current trends in the Aviation Gas Turbine market include a focus on reducing emissions, the adoption of hybrid-electric propulsion systems, and advancements in materials used for turbine components. These innovations aim to enhance performance and sustainability in aviation.

Aviation Gas Turbine Market:

| Segmentation | Details |

|---|---|

| Type | Turbojet Engines, Turbofan Engines, Turboprop Engines, Others |

| Application | Commercial Aircraft, Military Aircraft, Business Aircraft, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Aviation Gas Turbine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at