444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The automotive tie rod assembly market is an integral part of the global automotive industry. It plays a crucial role in ensuring the safety and performance of vehicles by connecting the steering mechanism to the wheels. Tie rod assemblies are essential components that enable precise steering control and help maintain stability during vehicle operation.

Meaning

An automotive tie rod assembly is a mechanical linkage that connects the steering system to the wheels. It consists of inner and outer tie rods, along with other components such as tie rod ends and adjusting sleeves. The primary function of a tie rod assembly is to transmit steering input from the driver to the wheels, allowing the vehicle to change direction smoothly.

Executive Summary

The automotive tie rod assembly market has witnessed steady growth in recent years. Factors such as increasing vehicle production, growing demand for advanced steering systems, and rising awareness about vehicle safety have contributed to the market’s expansion. Manufacturers in this industry are focusing on product innovation and technological advancements to meet the evolving demands of customers and comply with stringent safety regulations.

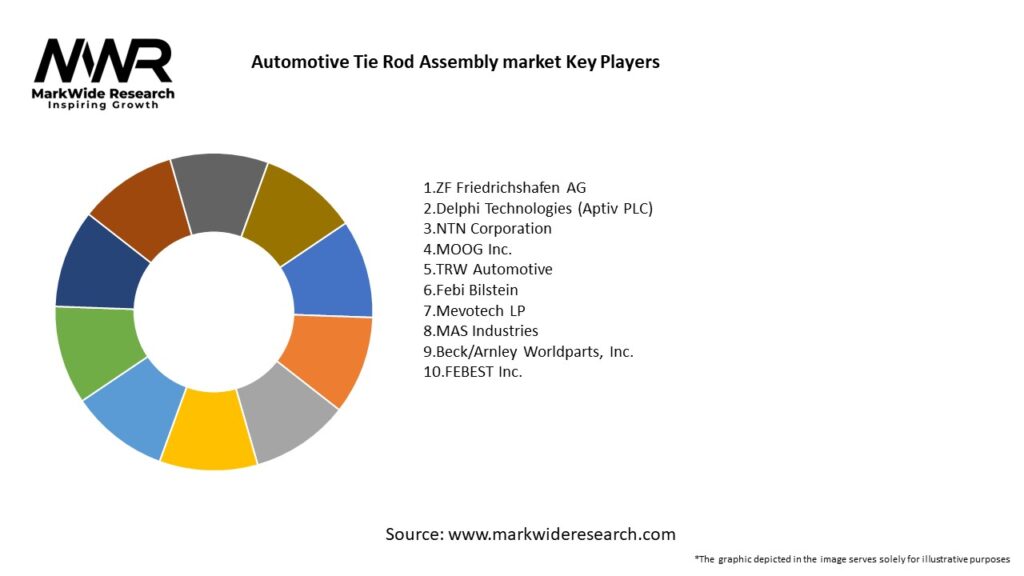

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The automotive tie rod assembly market is influenced by various dynamic factors, including market drivers, restraints, opportunities, and industry trends. Understanding these dynamics is crucial for stakeholders to make informed decisions and formulate effective strategies.

The market drivers, such as increasing vehicle sales, stringent safety regulations, and technological advancements, propel the growth of the tie rod assembly market. On the other hand, restraints like volatility in raw material prices, intense competition, and potential disruption from electric vehicles pose challenges to market players.

However, the market also presents several opportunities, including emerging markets, lightweight materials, rising demand for electric vehicles, and the aftermarket segment. By capitalizing on these opportunities, manufacturers can expand their market presence and achieve sustainable growth.

Monitoring market dynamics and staying abreast of industry trends is essential for manufacturers and stakeholders in the automotive tie rod assembly market to adapt to changing market conditions and gain a competitive advantage.

Regional Analysis

The automotive tie rod assembly market exhibits a global presence, with significant regional variations in terms of market size, growth rate, and key players. The market can be segmented into regions such as North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa.

North America and Europe have well-established automotive industries with a strong focus on vehicle safety standards. The presence of prominent automobile manufacturers and stringent safety regulations in these regions drives the demand for high-quality tie rod assemblies.

Asia Pacific, particularly China and India, is experiencing rapid growth in the automotive sector. The increasing vehicle production, expanding middle-class population, and rising disposable income contribute to the demand for tie rod assemblies in this region.

Latin America and the Middle East and Africa also present growth opportunities, fueled by infrastructure development, increasing vehicle sales, and a rising emphasis on vehicle safety.

It is crucial for market participants to analyze regional trends, consumer preferences, and regulatory frameworks to tailor their strategies and effectively cater to the specific requirements of each region.

Competitive Landscape

Leading Companies in the Automotive Tie Rod Assembly Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The automotive tie rod assembly market can be segmented based on various factors, including component type, vehicle type, sales channel, and region.

Based on component type, the market can be divided into inner tie rods, outer tie rods, tie rod ends, adjusting sleeves, and others. Each component plays a specific role in the tie rod assembly system and contributes to the overall performance and safety of the vehicle.

Vehicle type segmentation includes passenger cars, light commercial vehicles, and heavy commercial vehicles. Different vehicle types have varying requirements for tie rod assemblies based on factors such as weight, size, and steering mechanism.

The sales channel segment encompasses OEM (Original Equipment Manufacturer) and aftermarket. OEM tie rod assemblies are directly supplied to vehicle manufacturers for installation during the production process. Aftermarket tie rod assemblies are sold as replacement parts and are available through authorized dealers, independent retailers, and e-commerce platforms.

Geographically, the market can be segmented into North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Each region has its own market dynamics, including vehicle production, consumer preferences, safety regulations, and aftermarket demand.

Segmentation allows manufacturers and stakeholders to analyze specific market segments, identify growth opportunities, and tailor their strategies accordingly to maximize their market presence and profitability.

Category-wise Insights

Category-wise insights provide a deeper understanding of each component’s role and requirements in the tie rod assembly system. Manufacturers can focus on developing innovative solutions for each category to meet customer expectations, enhance performance, and ensure safety.

Key Benefits for Industry Participants and Stakeholders

Key benefits for industry participants and stakeholders

In the automotive tie rod assembly market include market growth opportunities, meeting safety standards, technological advancements, aftermarket potential, and collaborative partnerships.

SWOT Analysis

A SWOT (Strengths, Weaknesses, Opportunities, Threats) analysis provides a comprehensive assessment of the automotive tie rod assembly market’s internal and external factors that influence its competitiveness and growth potential.

Strengths:

Weaknesses:

Opportunities:

Threats:

A SWOT analysis enables industry participants and stakeholders to identify their strengths and weaknesses, capitalize on opportunities, and mitigate potential threats. It helps in developing strategies that leverage strengths, address weaknesses, seize opportunities, and navigate the competitive landscape effectively.

Market Key Trends

Understanding and adapting to these key trends is vital for industry participants and stakeholders to stay ahead in the evolving automotive tie rod assembly market. By aligning their strategies with these trends, manufacturers can position themselves as industry leaders and capture emerging opportunities.

Covid-19 Impact

The Covid-19 pandemic had a significant impact on the global automotive industry, including the tie rod assembly market. The pandemic led to a decline in vehicle production and sales, supply chain disruptions, and temporary shutdowns of manufacturing facilities. As a result, the demand for tie rod assemblies experienced a significant contraction during the initial stages of the pandemic.

However, as the automotive industry gradually recovered, the tie rod assembly market witnessed a rebound. The resumption of vehicle production, government stimulus packages, and pent-up demand contributed to the market’s recovery. Moreover, the growing focus on vehicle safety and the replacement of aging tie rod assemblies in existing vehicles drove market demand.

The pandemic also accelerated certain trends in the automotive industry, such as the adoption of electric vehicles and the shift towards online sales channels. These trends indirectly influenced the tie rod assembly market and shaped future market dynamics.

While the pandemic posed challenges, it also presented opportunities for industry participants to adapt and innovate. Manufacturers implemented strict health and safety measures, optimized production processes, and explored digital solutions to maintain business continuity and meet customer demands.

As the situation evolves, continuous monitoring of the Covid-19 impact and flexibility in adapting to changing market conditions will be crucial for industry participants to navigate the challenges and seize emerging opportunities.

Key Industry Developments

These key industry developments reflect the dynamic nature of the automotive tie rod assembly market. By embracing these trends, manufacturers can stay ahead of the competition, meet customer expectations, and contribute to the advancement of the automotive industry as a whole.

Analyst Suggestions

Based on the analysis of the automotive tie rod assembly market, several suggestions can be made for industry participants and stakeholders:

By following these analyst suggestions, industry participants and stakeholders in the automotive tie rod assembly market can navigate the evolving landscape, capitalize on emerging opportunities, and achieve sustainable growth and success.

Future Outlook

The future outlook for the automotive tie rod assembly market is expected to be positive, driven by several factors that will shape the industry landscape.

Conclusion

The automotive tie rod assembly market plays a crucial role in ensuring safe and reliable steering control in vehicles. As the global automotive industry continues to grow, the demand for tie rod assemblies is expected to rise. Factors such as increasing vehicle production, technological advancements, and a focus on vehicle safety drive the growth of this market.

However, the market also faces challenges, including raw material price fluctuations, intense competition, and potential disruption from electric vehicles. To overcome these challenges, industry participants should implement effective cost management strategies, differentiate themselves through product quality and customization, and stay abreast of industry trends and technological advancements.

In conclusion, the automotive tie rod assembly market presents both opportunities and challenges. By embracing innovation, customer-centric approaches, and strategic collaborations, industry participants can navigate the evolving landscape, meet market demands, and contribute to the advancement of the automotive industry as a whole.

What is Automotive Tie Rod Assembly?

Automotive Tie Rod Assembly is a crucial component in a vehicle’s steering system, connecting the steering gear to the wheel assembly. It plays a vital role in ensuring proper alignment and handling of the vehicle.

Who are the key players in the Automotive Tie Rod Assembly market?

Key players in the Automotive Tie Rod Assembly market include companies like TRW Automotive, Moog, and ACDelco, which are known for their high-quality steering components and systems, among others.

What are the growth factors driving the Automotive Tie Rod Assembly market?

The growth of the Automotive Tie Rod Assembly market is driven by the increasing demand for vehicle safety and performance, advancements in automotive technology, and the rising production of vehicles globally.

What challenges does the Automotive Tie Rod Assembly market face?

The Automotive Tie Rod Assembly market faces challenges such as fluctuating raw material prices, stringent regulations regarding vehicle safety, and the growing trend of electric vehicles which may alter traditional steering systems.

What opportunities exist in the Automotive Tie Rod Assembly market?

Opportunities in the Automotive Tie Rod Assembly market include the development of lightweight materials for improved fuel efficiency, the integration of smart technologies in steering systems, and the expansion of electric and hybrid vehicle markets.

What trends are shaping the Automotive Tie Rod Assembly market?

Trends in the Automotive Tie Rod Assembly market include the increasing adoption of advanced driver-assistance systems (ADAS), the shift towards electric vehicles, and innovations in manufacturing processes aimed at enhancing durability and performance.

Automotive Tie Rod Assembly market

| Segmentation Details | Description |

|---|---|

| Product Type | Standard Tie Rod, Adjustable Tie Rod, Heavy-Duty Tie Rod, Performance Tie Rod |

| Material | Steel, Aluminum, Carbon Fiber, Composite |

| End User | OEMs, Aftermarket Providers, Vehicle Assemblers, Tier-1 Suppliers |

| Application | Passenger Vehicles, Commercial Vehicles, Off-Road Vehicles, Racing Vehicles |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Automotive Tie Rod Assembly Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at