444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The automotive metal stamping market refers to the manufacturing process that transforms flat metal sheets into different shapes and sizes using a press or stamping machine. This process is widely used in the automotive industry to create various automotive parts, including chassis, engine components, body panels, and others. The market for automotive metal stamping is witnessing significant growth due to the growing demand for lightweight and fuel-efficient vehicles, as well as the increasing adoption of electric vehicles worldwide.

Meaning

Automotive metal stamping is a manufacturing process that involves pressing a flat metal sheet into a particular shape or size using a stamping machine. This process is used to create different automotive parts that are used in the manufacturing of vehicles. The process involves several steps, including blanking, piercing, forming, and drawing, to create the desired shape of the metal part.

Executive Summary

The automotive metal stamping market is witnessing significant growth due to the growing demand for lightweight and fuel-efficient vehicles, increasing adoption of electric vehicles worldwide, and the rise in the production of passenger and commercial vehicles. The market is segmented by stamping type, material type, application type, and region. The Asia Pacific region is the largest market for automotive metal stamping due to the presence of several automotive manufacturers in the region. The key players operating in the market include Gestamp, Magna International, Martinrea International, Tower International, and others.

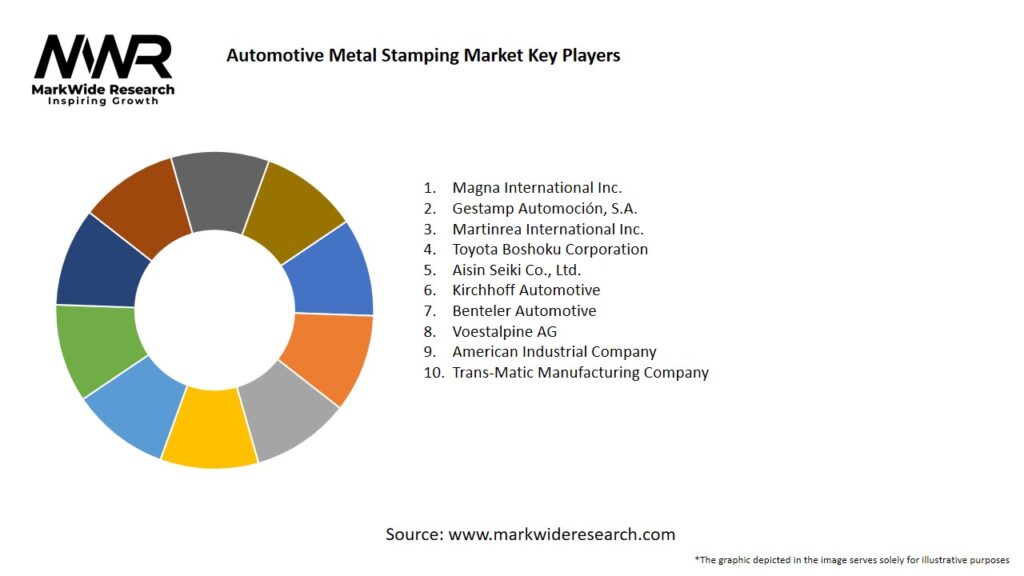

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

The global automotive metal stamping market is expected to grow at a CAGR of around 4.5% during the forecast period (2021-2026). The market is driven by various factors, including:

However, the market growth is hindered by several factors, including:

Market Drivers

Growing Demand for Lightweight and Fuel-Efficient Vehicles

The growing demand for lightweight and fuel-efficient vehicles is driving the market for automotive metal stamping. The use of lightweight materials in the manufacturing of vehicles is becoming increasingly popular due to the benefits they offer, including reduced fuel consumption, lower emissions, and improved handling and performance. The use of lightweight materials also allows for more interior space and better safety performance.

Increasing Adoption of Electric Vehicles Worldwide

The increasing adoption of electric vehicles worldwide is driving the market for automotive metal stamping. The demand for electric vehicles is increasing due to their environmental benefits, including lower emissions and reduced dependence on fossil fuels. Electric vehicles require lightweight materials in their construction to improve their range and performance. This is expected to drive the demand for automotive metal stamping in the manufacturing of electric vehicle components.

Rise in the Production of Passenger and Commercial Vehicles

The Rise in the Production of Passenger and Commercial Vehicles is driving the market for automotive metal stamping. The automotive industry is witnessing significant growth due to the increasing demand for vehicles worldwide. This is expected to drive the demand for automotive metal stamping in the manufacturing of various automotive components, including body panels, chassis, and engine components.

Advancements in Stamping Technology

Advancements in stamping technology are driving the market for automotive metal stamping. The development of new stamping techniques and processes is improving the efficiency and productivity of the stamping process. This is expected to drive the demand for automotive metal stamping in the manufacturing of automotive components.

Focus on Reducing Vehicle Weight and Improving Fuel Efficiency

The focus on reducing vehicle weight and improving fuel efficiency is driving the market for automotive metal stamping. The use of lightweight materials in the manufacturing of vehicles is becoming increasingly popular due to the benefits they offer, including improved fuel economy, reduced emissions, and better handling and performance. Automotive metal stamping is an essential process in the manufacturing of lightweight vehicle components, such as body panels, doors, hoods, and trunk lids.

Market Restraints

Volatility in Raw Material Prices

The volatility in raw material prices is a major restraint for the automotive metal stamping market. The prices of raw materials, such as steel, aluminum, and copper, are subject to fluctuations due to various factors, including supply and demand, political instability, and natural disasters. This makes it difficult for manufacturers to predict their production costs accurately, leading to increased prices of automotive components.

High Tooling and Equipment Costs

The high tooling and equipment costs are a significant restraint for the automotive metal stamping market. The stamping process requires specialized equipment and tooling, which can be expensive to acquire and maintain. This increases the production costs for manufacturers, leading to higher prices of automotive components.

Stringent Government Regulations Regarding Emission Control

Stringent government regulations regarding emission control are a significant restraint for the automotive metal stamping market. Governments worldwide are implementing regulations to reduce emissions from vehicles to address environmental concerns. These regulations require manufacturers to use lightweight materials in the manufacturing of vehicles, which drives the demand for automotive metal stamping. However, these regulations also increase the production costs for manufacturers, leading to higher prices of automotive components.

Market Opportunities

Growing Demand for Electric Vehicles

The growing demand for electric vehicles is a significant opportunity for the automotive metal stamping market. The production of electric vehicles requires lightweight materials in their construction to improve their range and performance. This is expected to drive the demand for automotive metal stamping in the manufacturing of electric vehicle components, including battery casings, structural components, and other parts.

Increasing Use of Advanced High-Strength Steel (AHSS)

The increasing use of Advanced High-Strength Steel (AHSS) is an opportunity for the automotive metal stamping market. AHSS is a type of steel that has a high strength-to-weight ratio, making it an ideal material for lightweight vehicle components. The use of AHSS in the manufacturing of automotive components is increasing due to its excellent crash performance and low cost. This is expected to drive the demand for automotive metal stamping in the manufacturing of AHSS components.

Rise in the Production of Commercial Vehicles

The rise in the production of commercial vehicles is an opportunity for the automotive metal stamping market. The demand for commercial vehicles is increasing due to the growth of the e-commerce industry and the need for efficient transportation. This is expected to drive the demand for automotive metal stamping in the manufacturing of various commercial vehicle components, including chassis and body panels.

Market Dynamics

The automotive metal stamping market is highly competitive, with several players operating in the market. The key players in the market are focusing on expanding their product portfolio, improving their manufacturing processes, and investing in research and development to gain a competitive edge in the market. The market is also witnessing significant consolidation, with several mergers and acquisitions taking place.

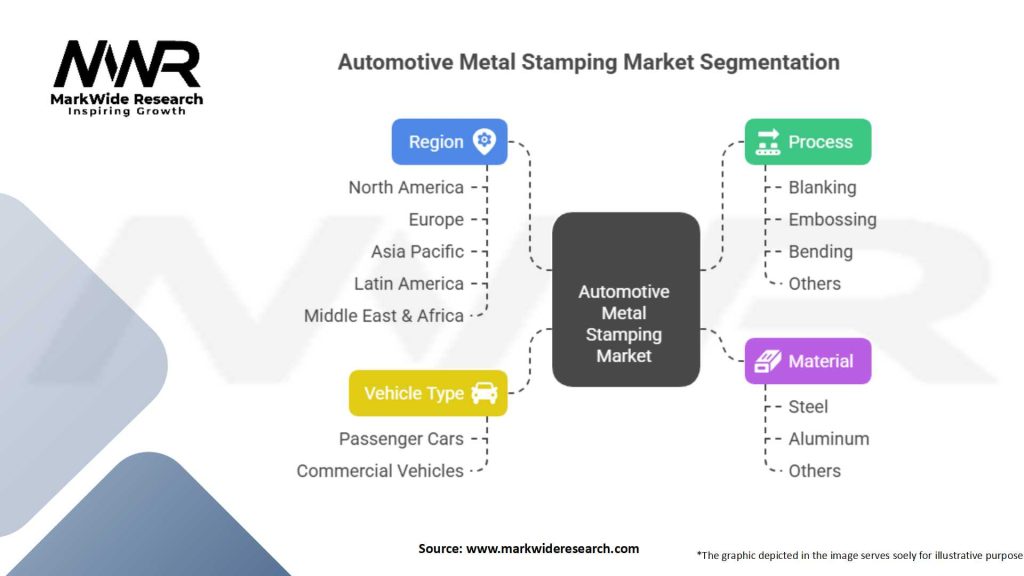

The market is segmented by stamping type, material type, application type, and region. The stamping type segment is further divided into blanking, piercing, forming, and drawing. The material type segment is divided into steel, aluminum, and others. The application type segment is divided into body panels, engine components, chassis, and others. The region segment is divided into North America, Europe, Asia Pacific, and Rest of the World.

Regional Analysis

The Asia Pacific region is the largest market for automotive metal stamping, accounting for a significant share of the market. The region’s growth is driven by the presence of several automotive manufacturers in the region, including Toyota, Honda, Nissan, Hyundai, and others. The increasing demand for electric vehicles and lightweight materials in the region is also driving the demand for automotive metal stamping.

North America and Europe are also significant markets for automotive metal stamping, with the presence of several key players in the region. The rising demand for fuel-efficient vehicles and the increasing adoption of electric vehicles in these regions are expected to drive the demand for automotive metal stamping.

The Rest of the World region is witnessing significant growth in the automotive industry, with several automotive manufacturers setting up manufacturing facilities in the region. The rising demand for vehicles in this region is expected to drive the demand for automotive metal stamping.

Competitive Landscape

Leading Companies in the Automotive Metal Stamping Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The automotive metal stamping market is segmented by stamping type, material type, application type, and region.

By Stamping Type:

By Material Type:

By Application Type:

By Region:

Category-wise Insights

By Stamping Type:

By Material Type:

By Application Type:

Key Benefits for Industry Participants and Stakeholders

The automotive metal stamping market offers several benefits to industry participants and stakeholders, including:

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Some key trends in the automotive metal stamping market include:

Covid-19 Impact

The Covid-19 pandemic had a significant impact on the automotive industry, leading to a decline in vehicle sales and production worldwide. The automotive metal stamping market was also affected by the pandemic, with several manufacturers temporarily shutting down their manufacturing facilities to comply with government regulations and protect their employees’ safety.

However, the market is expected to recover as the automotive industry recovers from the pandemic’s impact. The increasing demand for lightweight and fuel-efficient vehicles and the growing adoption of electric vehicles are expected to drive the demand for automotive metal stamping in the coming years.

Key Industry Developments

Some key industry developments in the automotive metal stamping market include:

Analyst Suggestions

Industry analysts suggest that automotive metal stamping manufacturers should focus on:

Future Outlook

The automotive metal stamping market is expected to grow at a CAGR of around 4.5% during the forecast period (2021-2026). The market is driven by the growing demand for lightweight and fuel-efficient vehicles, increasing adoption of electric vehicles worldwide, and the rise in the production of passenger and commercial vehicles.

The Asia Pacific region is expected to continue to be the largest market for automotive metal stamping due to the presence of several automotive manufacturers in the region. The increasing demand for electric vehicles and lightweight materials in the region is also expected to drive the demand for automotive metal stamping.

The market is also expected to witness significant consolidation, with several mergers and acquisitions taking place in the coming years. The key players operating in the market are expected to focus on expanding their product portfolio, improving their manufacturing processes, and investing in research and development to gain a competitive edge in the market.

Conclusion

The automotive metal stamping market is witnessing significant growth due to the growing demand for lightweight and fuel-efficient vehicles, increasing adoption of electric vehicles worldwide, and the rise in the production of passenger and commercial vehicles. The market is highly competitive, with several players operating in the market. The Asia Pacific region is the largest market for automotive metal stamping due to the presence of several automotive manufacturers in the region.

The market is expected to grow in the coming years, driven by the increasing demand for electric vehicles and lightweight materials in the automotive industry. Industry participants and stakeholders can benefit from the market’s growth by investing in research and development, expanding their product portfolio, and adopting advanced technologies to improve manufacturing efficiency and reduce production costs.

Automotive Metal Stamping Market:

| Segmentation | Details |

|---|---|

| Process | Blanking, Embossing, Bending, Others |

| Material | Steel, Aluminum, Others |

| Vehicle Type | Passenger Cars, Commercial Vehicles |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Automotive Metal Stamping Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at