444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

The automotive aluminum extrusion market is a growing industry that involves the manufacturing process of aluminum profiles or shapes with a uniform cross-section through the use of a die. These extrusions are commonly used in the automotive industry for their lightweight and high-strength properties, making them an ideal choice for various components such as body parts, chassis, and engine components. The use of aluminum extrusions helps automakers to achieve better fuel efficiency and reduce emissions, in line with stricter environmental regulations.

According to a report by MarketsandMarkets, the global automotive aluminum extrusion market is expected to reach USD 10.62 billion by 2025, growing at a CAGR of 8.5% from 2020 to 2025. The market is highly competitive, with several players offering a wide range of extrusion products and services. The Asia Pacific region is expected to dominate the market, driven by the growing automotive industry in countries such as China and India.

Meaning

Aluminum extrusion is a process of manufacturing profiles or shapes of aluminum alloys by forcing heated billets through a die. These extrusions are used in the automotive industry for various applications such as body parts, chassis, and engine components due to their lightweight and high-strength properties. Aluminum extrusions are also highly versatile and can be customized to fit specific design requirements, making them a popular choice for automotive manufacturers.

Executive Summary

The global automotive aluminum extrusion market is expected to grow significantly in the coming years, driven by the increasing demand for lightweight materials, the adoption of electric vehicles, and the shift towards sustainable manufacturing processes. The market is highly competitive, with several players offering a wide range of extrusion products and services. The Asia Pacific region is expected to dominate the market, driven by the growing automotive industry in countries such as China and India.

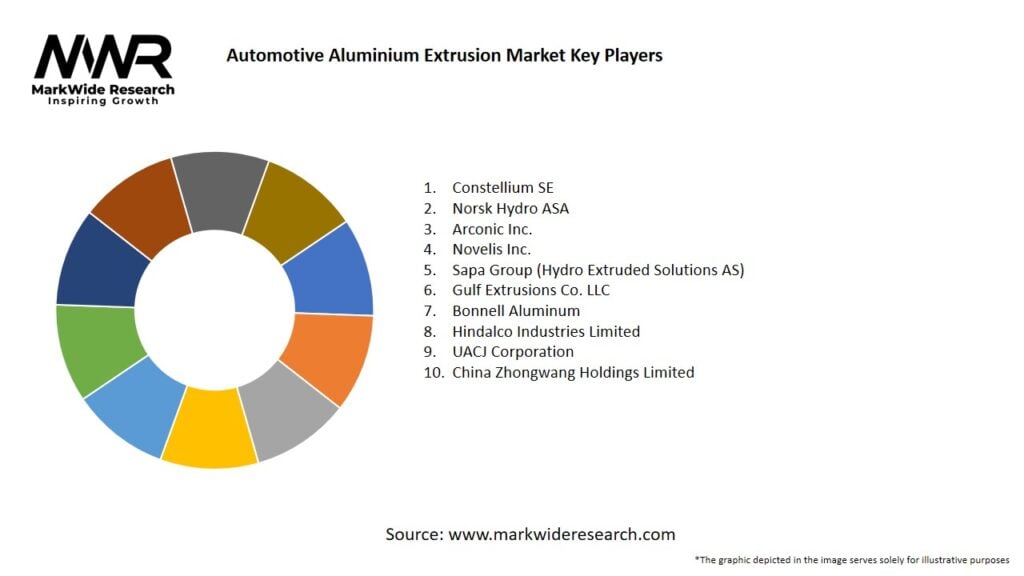

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

The following are some of the key market insights of the global automotive aluminum extrusion market:

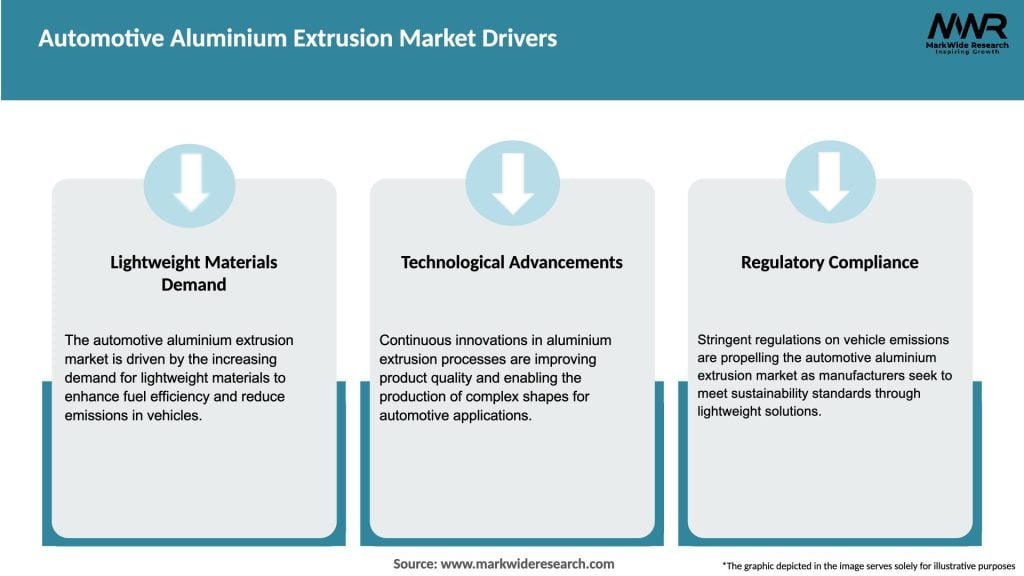

Market Drivers

One of the key drivers of the automotive aluminum extrusion market is the rising demand for lightweight materials in the automotive industry. Lightweight materials such as aluminum help to reduce the weight of vehicles, which in turn improves fuel efficiency and reduces emissions. The use of aluminum extrusions in automotive components such as body parts, chassis, and engine components has become increasingly popular due to their lightweight and high-strength properties.

The increasing adoption of electric vehicles is also driving the demand for aluminum extrusions in the automotive industry. Electric vehicles require lightweight materials to maximize their range, and aluminum extrusions are a popular choice due to their lightweight and high-strength properties. As the adoption of electric vehicles continues to grow, the demand for aluminum extrusions is expected to increase.

Another driver of the automotive aluminum extrusion market is the shift towards sustainable manufacturing processes. The automotive industry is increasingly focused on reducing its environmental footprint, and the use of sustainable materials and processes is a key part of this effort. Aluminum extrusions are a sustainable choice, as they are 100% recyclable and can be used to create lightweight components that help to reduce emissions.

Market Restraints

One of the key restraints of the automotive aluminum extrusion market is the high cost of aluminum extrusions compared to other materials. The cost of aluminum extrusions can be higher than that of other materials such as steel or plastic, which can be a limiting factor for some manufacturers. However, the benefits of using aluminum extrusions such as improved fuel efficiency and reduced emissions can offset the higher cost in the long run.

Another restraint of the automotive aluminum extrusion market is the volatility of aluminum prices. The price of aluminum can be affected by various factors such as supply and demand, geopolitical tensions, and fluctuations in currency exchange rates. This can make it challenging for manufacturers to forecast their costs accurately and can result in unexpected price increases, affecting their profitability.

Market Opportunities

The growing demand for electric vehicles presents a significant opportunity for the automotive aluminum extrusion market. As electric vehicles require lightweight materials to maximize their range, the demand for aluminum extrusions is expected to increase significantly. In addition, the increasing adoption of electric vehicles is driving the development of new and innovative components that can further benefit from the properties of aluminum extrusions.

The increasing focus on sustainability in the automotive industry is another opportunity for the aluminum extrusion market. The use of sustainable materials and processes is becoming a key consideration for automotive manufacturers, and aluminum extrusions are a sustainable choice due to their recyclability and ability to reduce emissions. This presents an opportunity for aluminum extrusion manufacturers to differentiate themselves by offering sustainable solutions that meet the needs of the market.

Market Dynamics

The global automotive aluminum extrusion market is a dynamic and evolving industry that is driven by various factors such as market trends, technological advancements, and regulatory changes. The market is highly competitive, with several players offering a wide range of extrusion products and services. The following are some of the key dynamics of the market:

Technological advancements are driving innovation in the automotive aluminum extrusion market, leading to the development of new and improved products that offer better performance and cost-effectiveness. For example, the use of simulation software and 3D printing technology is enabling manufacturers to create complex extrusions with improved accuracy and precision.

Regulatory changes are also driving the automotive aluminum extrusion market, with stricter environmental regulations and safety standards requiring manufacturers to develop lightweight and sustainable components. For example, the Corporate Average Fuel Economy (CAFE) standards in the United States require automakers to improve the fuel efficiency of their vehicles, which is driving the demand for lightweight materials such as aluminum extrusions.

Regional Analysis

The global automotive aluminum extrusion market is segmented into North America, Europe, Asia Pacific, and Rest of the World. The Asia Pacific region is expected to dominate the market, driven by the growing automotive industry in countries such as China and India. The increasing demand for lightweight materials and the adoption of electric vehicles in the region are also driving the growth of the market. North America and Europe are also significant markets for automotive aluminum extrusions, driven by the strict regulatory environment and the increasing focus on sustainability in these regions.

Competitive Landscape

Leading Companies in the Automotive Aluminium Extrusion Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

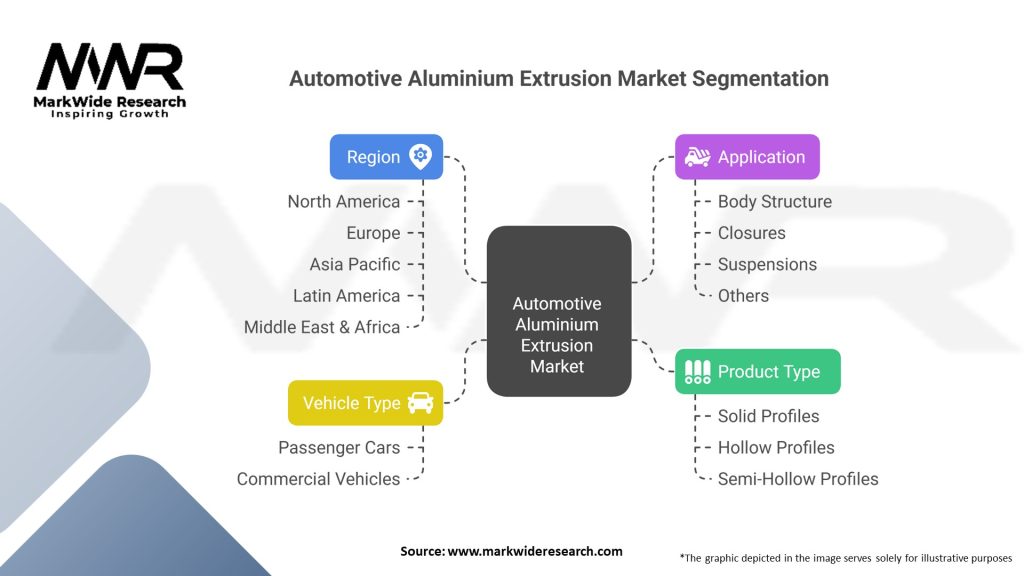

Segmentation

The global automotive aluminum extrusion market is segmented based on product type, application, and region. By product type, the market is segmented into standard and custom extrusions. Standard extrusions are pre-designed shapes that are commonly used in the automotive industry, while custom extrusions are designed to meet specific customer requirements. By application, the market is segmented into body parts, chassis, engine components, and others.

Category-wise Insights

The standard extrusions segment is expected to dominate the market, driven by the widespread use of pre-designed shapes in the automotive industry. However, the custom extrusions segment is expected to grow at a faster rate, driven by the increasing demand for customized components that meet specific design requirements.

The body parts segment is expected to dominate the market, driven by the high demand for lightweight and durable components in the automotive industry. However, the engine components segment is expected to grow at a faster rate, driven by the increasing adoption of electric vehicles that require lightweight components to maximize their range.

Key Benefits for Industry Participants and Stakeholders

The following are some of the key benefits of the automotive aluminum extrusion market for industry participants and stakeholders:

The use of aluminum extrusions in automotive components helps to reduce the weight of vehicles, which in turn improves fuel efficiency and reduces emissions.

Aluminum extrusions can be customized to fit specific design requirements, enabling manufacturers to create unique and innovative components that meet the needs of their customers.

Aluminum extrusions are a sustainable choice, as they are 100% recyclable and can be used to create lightweight components that help to reduce emissions.

SWOT Analysis

The following is a SWOT analysis of the automotive aluminum extrusion market:

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

The following are some of the key trends in the automotive aluminum extrusion market:

The increasing demand for lightweight and sustainable components is driving the development of new and innovative components that can benefit from the properties of aluminum extrusions. For example, automakers are exploring the use of aluminum extrusions in new applications such as battery enclosures for electric vehicles.

Manufacturers in the automotive aluminum extrusion market are increasingly partnering and collaborating with each other to develop new products and solutions. For example, Hydro Extrusions and Light Metals Coloring have partnered to develop a new technology for coloring aluminum extrusions, which can improve the durability and aesthetic appeal of automotive components.

Covid-19 Impact

The Covid-19 pandemic has had a significant impact on the global automotive industry, including the automotive aluminum extrusion market. The pandemic has led to disruptions in the supply chain, reduced demand for vehicles, and lower production levels. However, the market is expected to recover in the coming years, driven by the increasing demand for lightweight materials, the adoption of electric vehicles, and the shift towards sustainable manufacturing processes.

Key Industry Developments

The following are some of the key industry developments in the automotive aluminum extrusion market:

Hydro Extrusions has signed a multi-year agreement to supply extruded aluminum to BMW for various automotive components. The agreement highlights the growing demand for lightweight materials in the automotive industry and the role of aluminum extrusions in meeting this demand.

Norsk Hydro ASA has completed the acquisition of Sapa AS, a leading supplier of aluminum extrusions and rolled products. The acquisition strengthens Norsk Hydro’s position in the automotive aluminum extrusion market and enhances its ability to provide customized solutions to its customers.

Analyst Suggestions

According to analysts, the global automotive aluminum extrusion market is expected to grow significantly in the coming years, driven by the increasing demand for lightweight materials and the adoption of electric vehicles. To capitalize on these trends, manufacturers in the market should focus on the following:

Manufacturers should focus on developing new and innovative products that meet the evolving needs of the market. This can include customized solutions that are tailored to specific customer requirements and the development of new applications for aluminum extrusions.

Manufacturers should focus on sustainability in their manufacturing processes, as this is becoming an increasingly important consideration for automotive manufacturers. This can include the use of renewable energy sources, reducing waste and emissions, and using sustainable materials.

Future Outlook

The future outlook for the global automotive aluminum extrusion market is positive, driven by the increasing demand for lightweight materials, the adoption of electric vehicles, and the shift towards sustainable manufacturing processes. The market is expected to grow significantly in the coming years, with the Asia Pacific region dominating the market. Manufacturers in the market should focus on product innovation and sustainable manufacturing processes to capitalize on these trends and stay ahead of the competition.

Conclusion

The global automotive aluminum extrusion market is a growing industry that offers a wide range of extrusion products and services to automotive manufacturers. The market is driven by the increasing demand for lightweight materials, the adoption of electric vehicles, and the shift towards sustainable manufacturing processes. The market is highly competitive, with several players offering a wide range of products and services. The future outlook for the market is positive, with manufacturers focusing on product innovation and sustainable manufacturing processes to stay ahead of the competition and meet the evolving needs of the market.

What is Automotive Aluminium Extrusion?

Automotive Aluminium Extrusion refers to the process of shaping aluminium into specific profiles and components used in the automotive industry, such as frames, panels, and structural parts. This method is favored for its lightweight properties and strength, contributing to fuel efficiency and performance in vehicles.

What are the key players in the Automotive Aluminium Extrusion Market?

Key players in the Automotive Aluminium Extrusion Market include companies like Hydro Aluminium, Constellium, and Novelis, which specialize in producing aluminium products for automotive applications. These companies focus on innovation and sustainability to meet the growing demand for lightweight materials in vehicles, among others.

What are the main drivers of the Automotive Aluminium Extrusion Market?

The main drivers of the Automotive Aluminium Extrusion Market include the increasing demand for lightweight vehicles to enhance fuel efficiency and reduce emissions. Additionally, the growing trend towards electric vehicles and the need for improved safety features are propelling the market forward.

What challenges does the Automotive Aluminium Extrusion Market face?

Challenges in the Automotive Aluminium Extrusion Market include the high cost of aluminium compared to traditional materials and the complexities involved in the extrusion process. Additionally, fluctuations in raw material prices can impact production costs and profitability.

What opportunities exist in the Automotive Aluminium Extrusion Market?

Opportunities in the Automotive Aluminium Extrusion Market are driven by advancements in manufacturing technologies and the increasing adoption of aluminium in electric and hybrid vehicles. Furthermore, the push for sustainable practices in automotive production presents avenues for growth.

What trends are shaping the Automotive Aluminium Extrusion Market?

Trends shaping the Automotive Aluminium Extrusion Market include the integration of smart manufacturing techniques and the development of new aluminium alloys that enhance performance. Additionally, there is a growing focus on recycling and sustainability within the industry.

Automotive Aluminium Extrusion Market:

| Segmentation | Details |

|---|---|

| Product Type | Solid Profiles, Hollow Profiles, Semi-Hollow Profiles |

| Application | Body Structure, Closures, Suspensions, Others |

| Vehicle Type | Passenger Cars, Commercial Vehicles |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Automotive Aluminium Extrusion Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at