444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview

The Austria prefabricated housing market has witnessed significant growth in recent years. Prefabricated housing, also known as modular housing or off-site construction, refers to the process of manufacturing building components or entire structures in a factory and then assembling them on-site. This method offers several advantages, including cost-effectiveness, reduced construction time, improved quality control, and sustainability.

Meaning

Prefabricated housing involves the production of various building components, such as walls, roofs, floors, and modules, in a controlled factory environment. These components are manufactured using advanced machinery and techniques, ensuring precise dimensions and high-quality standards. Once produced, the prefabricated elements are transported to the construction site, where they are assembled to create the final structure. This construction method offers numerous benefits over traditional on-site construction, making it an attractive option for homebuyers and builders.

Executive Summary

The Austria prefabricated housing market has experienced steady growth in recent years, driven by factors such as rapid urbanization, population growth, and the need for affordable housing solutions. The market is characterized by the presence of both domestic and international players, offering a wide range of prefabricated housing solutions to cater to diverse customer preferences. Key market participants include manufacturers, contractors, architects, and real estate developers. The market is expected to continue its upward trajectory in the coming years, driven by technological advancements, favorable government policies, and increasing environmental consciousness.

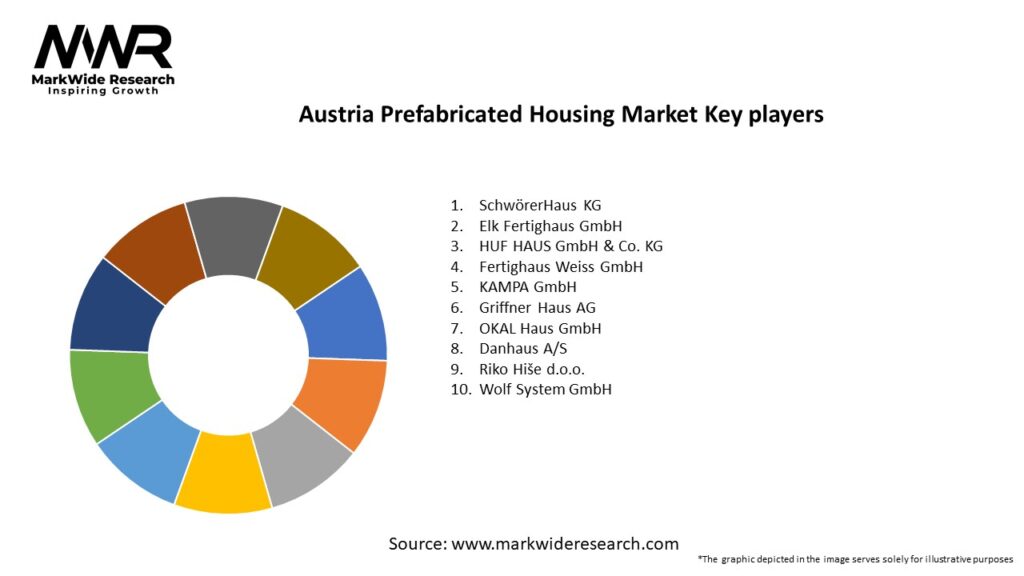

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Austria prefabricated housing market is driven by a combination of factors, including the demand for affordable housing, technological advancements, government initiatives, and the need for sustainable construction practices. These dynamics have contributed to the growth and evolution of the market, shaping its current landscape and future prospects.

Regional Analysis

The Austria prefabricated housing market exhibits regional variations, with different areas experiencing varying levels of market penetration and demand. Urban centers, such as Vienna, Graz, and Linz, have witnessed significant growth due to population density and urbanization. These regions offer a higher concentration of infrastructure and attract a larger customer base, creating ample opportunities for prefabricated housing providers.

Competitive Landscape

Leading Companies in the Austria Prefabricated Housing Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

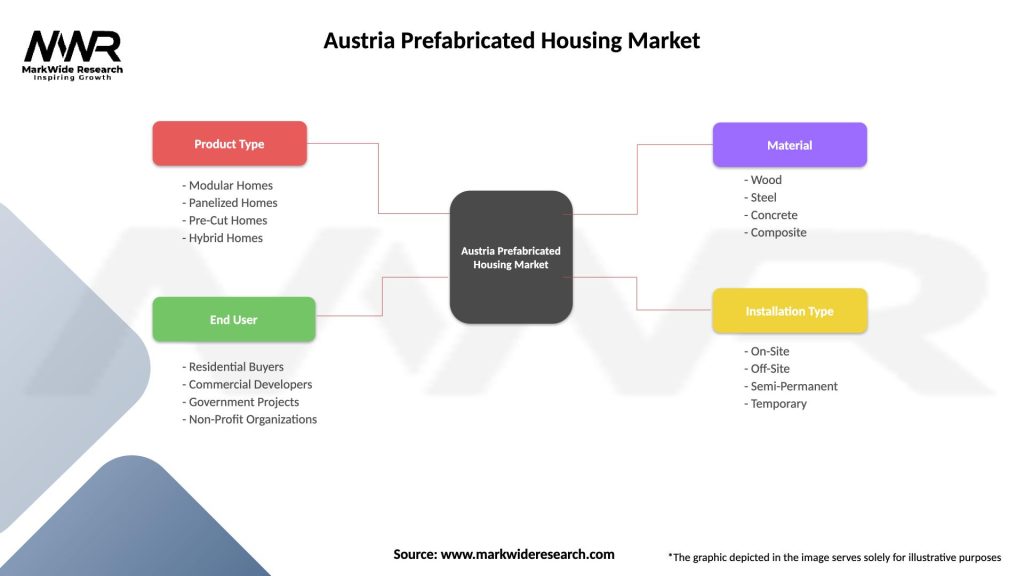

Segmentation

The Austria prefabricated housing market can be segmented based on various factors, including product type, end-user, and application. The primary product types in the market include modular homes, panelized homes, pre-cut homes, and manufactured homes. The end-users of prefabricated housing can be categorized into residential, commercial, and industrial sectors. The application of prefabricated housing includes single-family homes, multi-family homes, offices, retail spaces, and educational institutions.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

The Austria prefabricated housing market offers several key benefits for industry participants and stakeholders:

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has had both positive and negative effects on the Austria prefabricated housing market. While the construction industry as a whole faced challenges due to temporary shutdowns and supply chain disruptions, the prefabricated housing sector proved more resilient due to its off-site manufacturing approach. Prefabrication allowed for continued production even during lockdowns, ensuring the availability of housing units. Additionally, the pandemic highlighted the need for sustainable and affordable housing solutions, further driving the demand for prefabricated housing.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future of the Austria prefabricated housing market looks promising, driven by factors such as the demand for affordable housing, sustainable construction practices, and technological advancements. The industry is expected to witness continued growth as more customers recognize the benefits of prefabricated housing, and governments promote sustainable and affordable housing solutions. Collaboration, innovation, and a focus on customization and sustainability will be key drivers in shaping the future of the market.

Conclusion

The Austria prefabricated housing market has experienced significant growth due to its cost-effectiveness, time efficiency, improved quality control, and sustainability features. The market is driven by factors such as rapid urbanization, favorable government initiatives, technological advancements, and increased awareness among consumers. While there are challenges to overcome, such as perception issues and infrastructure requirements, the market offers numerous opportunities for industry participants. The future outlook for the prefabricated housing market in Austria is optimistic, with continued growth expected through collaboration, innovation, and a focus on sustainability.

What is Prefabricated Housing?

Prefabricated housing refers to structures that are manufactured off-site in advance, typically in sections or modules, and then transported to the construction site for assembly. This method is known for its efficiency and cost-effectiveness in the housing sector.

What are the key players in the Austria Prefabricated Housing Market?

Key players in the Austria Prefabricated Housing Market include companies like KAMPA, EHL AG, and Züblin, which specialize in modular construction and sustainable building practices. These companies are known for their innovative designs and commitment to quality, among others.

What are the growth factors driving the Austria Prefabricated Housing Market?

The growth of the Austria Prefabricated Housing Market is driven by factors such as the increasing demand for affordable housing, the need for faster construction methods, and a growing emphasis on sustainability in building practices. Additionally, advancements in technology are enhancing the efficiency of prefabricated construction.

What challenges does the Austria Prefabricated Housing Market face?

Challenges in the Austria Prefabricated Housing Market include regulatory hurdles, potential resistance from traditional construction sectors, and the need for skilled labor in assembly processes. These factors can impact the speed and efficiency of project completion.

What opportunities exist in the Austria Prefabricated Housing Market?

Opportunities in the Austria Prefabricated Housing Market include the potential for expanding into eco-friendly housing solutions and the integration of smart home technologies. As urbanization continues, there is also a growing market for affordable housing solutions.

What trends are shaping the Austria Prefabricated Housing Market?

Trends in the Austria Prefabricated Housing Market include a shift towards sustainable materials, increased customization options for consumers, and the adoption of modular designs that allow for flexibility in living spaces. These trends reflect changing consumer preferences and environmental considerations.

Austria Prefabricated Housing Market

| Segmentation Details | Description |

|---|---|

| Product Type | Modular Homes, Panelized Homes, Pre-Cut Homes, Hybrid Homes |

| End User | Residential Buyers, Commercial Developers, Government Projects, Non-Profit Organizations |

| Material | Wood, Steel, Concrete, Composite |

| Installation Type | On-Site, Off-Site, Semi-Permanent, Temporary |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Austria Prefabricated Housing Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at