444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

Augmented Reality (AR) and Virtual Reality (VR) have emerged as disruptive technologies with the potential to transform the manufacturing industry. These immersive technologies offer innovative solutions that enhance productivity, efficiency, and safety in manufacturing processes. By overlaying virtual elements onto the real world or creating entirely virtual environments, AR and VR enable manufacturers to visualize and interact with digital information in real-time. This market overview provides valuable insights into the current state and future prospects of the Augmented Reality and Virtual Reality in Manufacturing market.

Meaning

Augmented Reality refers to the technology that overlays digital information, such as 3D models, animations, or data, onto the real world. It enhances the user’s perception and interaction with the physical environment. On the other hand, Virtual Reality creates a completely immersive experience by transporting users into a simulated environment, often through the use of head-mounted displays and motion tracking. Both AR and VR technologies offer unique capabilities and have found numerous applications across various industries, including manufacturing.

Executive Summary

The Augmented Reality and Virtual Reality in Manufacturing market is witnessing significant growth due to the increasing demand for advanced visualization tools and the need to improve operational efficiency in manufacturing processes. The integration of AR and VR technologies enables manufacturers to streamline workflows, reduce errors, and enhance collaboration among teams. Additionally, these technologies facilitate the training of employees, remote assistance, and maintenance of complex machinery, leading to increased productivity and cost savings.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Augmented Reality and Virtual Reality in Manufacturing market is driven by a combination of factors, including technological advancements, increasing demand for remote collaboration tools, improved training and education capabilities, and a focus on design visualization and quality control. However, the market faces challenges related to high initial investments, technological limitations, integration complexities, security concerns, and the lack of standardization. Despite these challenges, the market offers significant opportunities for Industry 4.0 integration, training and simulation, maintenance and repair, supply chain optimization, and customization.

Regional Analysis

The adoption of AR and VR technologies in the manufacturing sector varies across regions. North America and Europe have been early adopters, driven by strong technological capabilities, advanced manufacturing industries, and a focus on innovation. The Asia-Pacific region is witnessing rapid growth due to the presence of manufacturing powerhouses like China, Japan, and South Korea. These countries are investing in AR and VR technologies to enhance their manufacturing capabilities and gain a competitive edge. Emerging economies in Latin America and the Middle East are also expected to witness increased adoption as awareness and infrastructure improve.

Competitive Landscape

Leading Companies in the Augmented Reality and Virtual Reality In Manufacturing Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

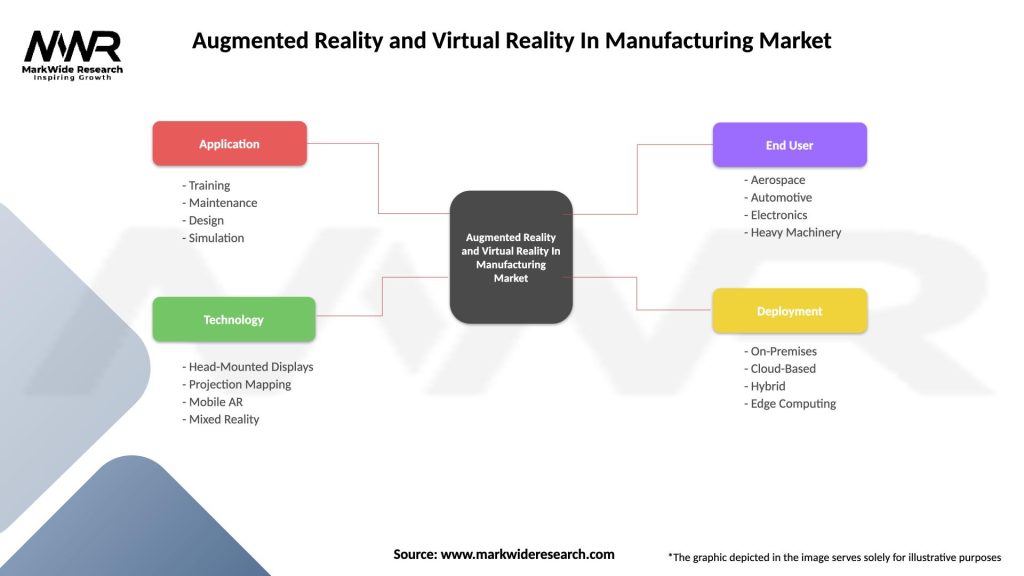

Segmentation

The Augmented Reality and Virtual Reality in Manufacturing market can be segmented based on technology, component, application, and geography. By technology, the market can be categorized into AR and VR. Components include hardware (headsets, displays, sensors, etc.), software, and services. Applications of AR and VR in manufacturing encompass design and prototyping, assembly and maintenance, quality control, training and simulation, and others. Geographically, the market can be divided into North America, Europe, Asia-Pacific, Latin America, and the Middle East and Africa.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic has had a significant impact on the Augmented Reality and Virtual Reality in Manufacturing market. As manufacturers faced disruptions in operations, travel restrictions, and social distancing requirements, the need for remote collaboration and virtual training became more critical than ever. AR and VR technologies provided effective solutions for virtual meetings, remote assistance, and training simulations, enabling manufacturers to maintain business continuity and minimize the impact of the pandemic. The crisis has accelerated the adoption of AR and VR technologies in manufacturing and highlighted their potential in addressing future challenges.

Key Industry Developments

Analyst Suggestions

Future Outlook

The Augmented Reality and Virtual Reality in Manufacturing market is poised for significant growth in the coming years. The integration of AR and VR technologies with Industry 4.0 solutions, increasing demand for remote collaboration tools, and the need for enhanced training and visualization capabilities will be key drivers for market expansion. As technological advancements continue to address limitations and reduce costs, smaller manufacturers are also expected to adopt these technologies. The market will witness increased competition, collaborations, and acquisitions as players strive to innovate and establish their presence in the evolving landscape.

Conclusion

Augmented Reality and Virtual Reality technologies are transforming the manufacturing industry by enhancing productivity, safety, and collaboration. Manufacturers are leveraging these immersive technologies to optimize design and prototyping, streamline assembly and maintenance processes, improve quality control, and enhance training and simulation experiences. Despite challenges related to initial investments, technological limitations, integration complexities, and security concerns, the market offers significant opportunities for Industry 4.0 integration, training and simulation, maintenance and repair, supply chain optimization, and customization. As the market continues to evolve, manufacturers should embrace these technologies and leverage them to gain a competitive advantage in the dynamic manufacturing landscape.

What are Augmented Reality and Virtual Reality in manufacturing?

Augmented Reality (AR) and Virtual Reality (VR) in manufacturing refer to technologies that enhance or create immersive environments for various applications, such as training, design visualization, and maintenance. These technologies enable manufacturers to improve efficiency, reduce errors, and enhance worker safety.

What companies are leading the Augmented Reality and Virtual Reality in manufacturing market?

Leading companies in the Augmented Reality and Virtual Reality in manufacturing market include PTC, Siemens, and Dassault Systèmes, which provide innovative solutions for design and operational efficiency, among others.

What are the key drivers of growth in the Augmented Reality and Virtual Reality in manufacturing market?

Key drivers of growth in the Augmented Reality and Virtual Reality in manufacturing market include the increasing demand for automation, the need for enhanced training solutions, and the growing focus on improving operational efficiency and safety in production processes.

What challenges does the Augmented Reality and Virtual Reality in manufacturing market face?

Challenges in the Augmented Reality and Virtual Reality in manufacturing market include high implementation costs, the need for skilled personnel to operate these technologies, and potential resistance to change from traditional manufacturing practices.

What opportunities exist in the Augmented Reality and Virtual Reality in manufacturing market?

Opportunities in the Augmented Reality and Virtual Reality in manufacturing market include the potential for remote collaboration, advancements in hardware and software technologies, and the ability to create customized solutions for specific manufacturing needs.

What trends are shaping the Augmented Reality and Virtual Reality in manufacturing market?

Trends shaping the Augmented Reality and Virtual Reality in manufacturing market include the integration of AI and machine learning for enhanced data analysis, the rise of cloud-based solutions for easier access, and the increasing use of AR and VR for remote assistance and maintenance.

Augmented Reality and Virtual Reality In Manufacturing Market

| Segmentation Details | Description |

|---|---|

| Application | Training, Maintenance, Design, Simulation |

| Technology | Head-Mounted Displays, Projection Mapping, Mobile AR, Mixed Reality |

| End User | Aerospace, Automotive, Electronics, Heavy Machinery |

| Deployment | On-Premises, Cloud-Based, Hybrid, Edge Computing |

Leading Companies in the Augmented Reality and Virtual Reality In Manufacturing Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at