444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The aseptic negative pressure isolators market is experiencing robust growth driven by the increasing demand for sterile manufacturing environments, stringent regulatory requirements, and rising adoption of advanced containment solutions in pharmaceutical and biotechnology industries. Aseptic negative pressure isolators are specialized containment systems designed to provide a sterile and controlled environment for the handling of hazardous materials, potent compounds, and sterile products, minimizing the risk of contamination and ensuring product quality and safety.

Meaning

The aseptic negative pressure isolators market comprises manufacturers, suppliers, and end-users involved in the design, production, and utilization of specialized containment systems for aseptic processing applications. Aseptic negative pressure isolators utilize negative pressure differentials to prevent the escape of hazardous contaminants and airborne particles from the containment area, thereby protecting operators, products, and the surrounding environment from potential contamination. These systems play a critical role in pharmaceutical manufacturing, compounding pharmacies, research laboratories, and healthcare facilities where aseptic conditions are essential for sterile processing and handling of sensitive materials.

Executive Summary

The aseptic negative pressure isolators market is witnessing significant growth driven by the increasing emphasis on product quality and safety, growing regulatory scrutiny, and advancements in containment technology. Key factors contributing to market expansion include the adoption of single-use and disposable isolator systems, integration of advanced filtration and sterilization technologies, and expansion of biopharmaceutical manufacturing facilities. However, challenges such as high initial investment costs, regulatory compliance, and complexity of system validation may impact market adoption and growth.

Key Market Insights

The aseptic negative pressure isolators market is characterized by technological innovation, strategic partnerships, and regulatory compliance. Key trends driving market growth include the development of modular and flexible isolator systems, integration of advanced monitoring and control systems, and expansion into emerging markets with high demand for sterile processing solutions. Additionally, the COVID-19 pandemic has underscored the importance of containment systems in infection control and biosafety, driving demand for aseptic isolators in healthcare facilities and research laboratories.

Market Drivers

Several factors are driving the growth of the aseptic negative pressure isolators market. These include the increasing focus on product quality and safety, stringent regulatory requirements for sterile manufacturing, and growing demand for biopharmaceuticals and personalized medicines. Additionally, advancements in containment technology, such as barrier isolation systems, high-efficiency particulate air (HEPA) filtration, and vaporized hydrogen peroxide (VHP) sterilization, are enabling the development of advanced isolator systems with enhanced performance and reliability. Furthermore, the expansion of biopharmaceutical manufacturing facilities, increasing investments in R&D, and rising adoption of personalized medicine approaches are driving demand for aseptic isolators for sterile processing and handling of sensitive materials.

Market Restraints

Despite the promising growth prospects, the aseptic negative pressure isolators market faces several challenges that may hinder its expansion. These include high initial investment costs, long lead times for system installation and validation, and regulatory complexities associated with compliance with current good manufacturing practices (cGMP) and international standards. Additionally, the complexity of system integration with existing manufacturing processes, potential compatibility issues with biopharmaceutical production systems, and the need for specialized training and expertise for system operation and maintenance may impact market adoption and growth.

Market Opportunities

Despite the challenges, the aseptic negative pressure isolators market presents significant opportunities for innovation and growth. Key opportunities include the development of next-generation isolator systems with advanced features, such as real-time monitoring, remote operation, and data analytics capabilities, to enhance system performance and user experience. Additionally, expansion into emerging markets with growing pharmaceutical and biotechnology sectors, adoption of containment solutions in research laboratories and compounding pharmacies, and increasing demand for personalized medicine and biologics production offer new market opportunities for isolator manufacturers and suppliers.

Market Dynamics

The aseptic negative pressure isolators market is characterized by dynamic trends and factors that influence its growth trajectory. Key market dynamics include technological innovation, regulatory compliance, industry consolidation, and changing customer preferences. Additionally, the COVID-19 pandemic has accelerated the adoption of containment solutions in healthcare facilities, research laboratories, and pharmaceutical manufacturing sites, creating new opportunities for aseptic isolators in infection control, biosafety, and sterile processing applications.

Regional Analysis

The aseptic negative pressure isolators market is global in scope, with North America, Europe, Asia Pacific, Latin America, and Middle East & Africa emerging as key regions for market expansion. North America dominates the market, driven by the presence of leading pharmaceutical and biotechnology companies, stringent regulatory requirements, and high investments in R&D. Europe is also a significant market, fueled by increasing government funding for biopharmaceutical research, expansion of biomanufacturing capacity, and growing demand for personalized medicine and biologics. Asia Pacific is expected to witness rapid growth, driven by rising healthcare expenditure, expanding pharmaceutical industry, and increasing adoption of advanced containment solutions in emerging markets.

Competitive Landscape

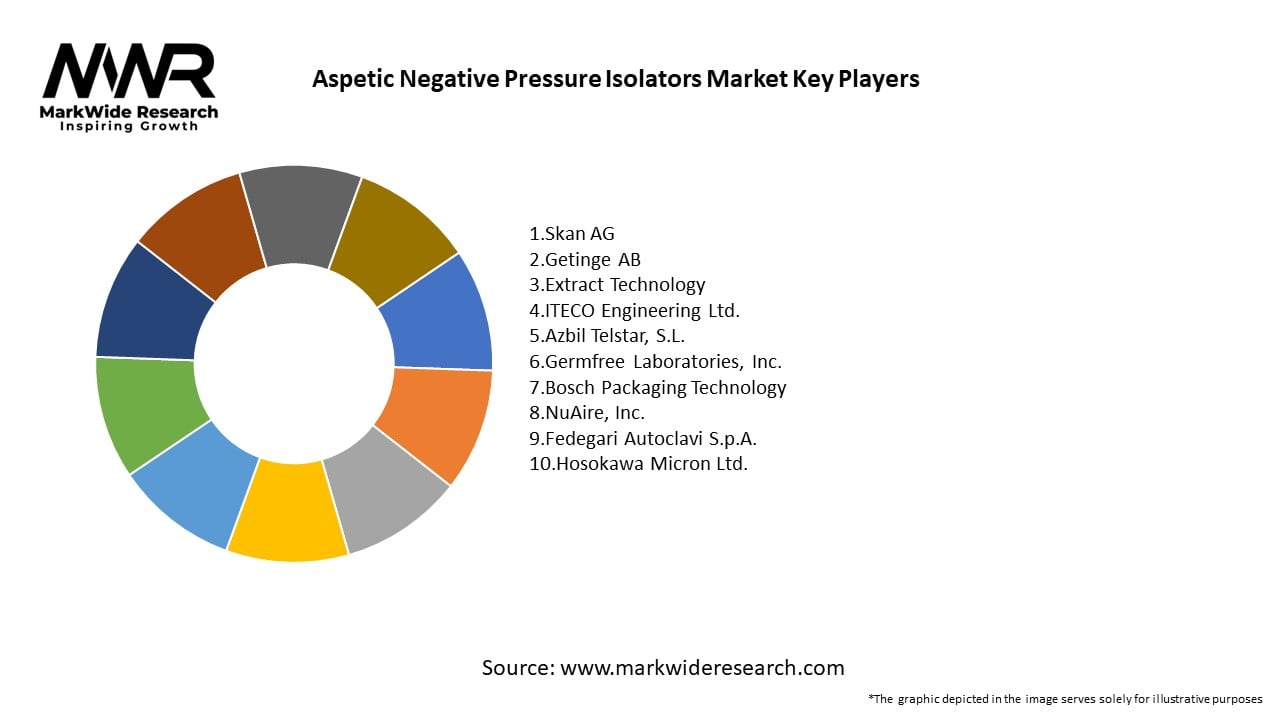

The aseptic negative pressure isolators market is highly competitive, with a diverse mix of global players, regional manufacturers, and specialized suppliers competing for market share. Key players in the market include Getinge AB, Esco Micro Pte. Ltd., Thermo Fisher Scientific Inc., Germfree Laboratories Inc., and Hosokawa Micron Powder Systems, among others. These companies offer a wide range of isolator systems, including glovebox isolators, barrier isolators, and containment isolators, tailored to meet the diverse needs of pharmaceutical manufacturers, research laboratories, and healthcare facilities. Additionally, strategic partnerships, collaborations, and acquisitions are common strategies among isolator manufacturers to expand product portfolios, enhance technical capabilities, and strengthen market presence.

Segmentation

The aseptic negative pressure isolators market can be segmented based on product type, application, end-user, and region. By product type, the market includes glovebox isolators, barrier isolators, containment isolators, and others. By application, isolator systems are used for aseptic processing, sterile compounding, hazardous drug handling, and research and development. By end-user, isolators are utilized by pharmaceutical manufacturers, biotechnology companies, research laboratories, compounding pharmacies, and healthcare facilities. Geographically, the market is segmented into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

The adoption of aseptic negative pressure isolators offers several benefits for industry participants and stakeholders:

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Several key trends are shaping the aseptic negative pressure isolators market:

Covid-19 Impact

The Covid-19 pandemic has underscored the importance of infection control, biosafety, and sterile processing in healthcare facilities, research laboratories, and pharmaceutical manufacturing sites. Aseptic negative pressure isolators have played a critical role in containing infectious pathogens, minimizing the risk of cross-contamination, and ensuring product quality and safety. Additionally, the pandemic has accelerated the adoption of containment solutions in infection control, biosafety, and pandemic preparedness, creating new opportunities for isolator manufacturers and suppliers.

Key Industry Developments

Analyst Suggestions

To capitalize on the opportunities presented by the aseptic negative pressure isolators market, industry participants and stakeholders should:

Future Outlook

The future outlook for the aseptic negative pressure isolators market is positive, with continued growth expected in the coming years. Key drivers of market growth include the increasing emphasis on product quality and safety, growing demand for sterile processing solutions, and rising adoption of advanced containment technology in pharmaceutical and biotechnology industries. Additionally, technological advancements, regulatory compliance, and industry collaboration are expected to drive market differentiation and innovation. However, challenges such as high initial investment costs, regulatory complexities, and competitive pressures may impact market growth and adoption rates.

Conclusion

In conclusion, the aseptic negative pressure isolators market is experiencing robust growth driven by increasing demand for sterile processing solutions, stringent regulatory requirements, and advancements in containment technology. Despite challenges such as high initial investment costs, regulatory compliance, and competitive pressures, the market presents significant opportunities for innovation and growth. By investing in research and development, expanding market presence, and enhancing customer education and support, industry participants and stakeholders can capitalize on the growing demand for aseptic isolators and contribute to advancements in infection control, biosafety, and sterile processing applications.

What is Aspetic Negative Pressure Isolators?

Aspetic Negative Pressure Isolators are specialized containment devices designed to maintain a sterile environment while preventing the escape of contaminants. They are commonly used in healthcare settings, particularly in laboratories and pharmaceutical manufacturing, to protect both the product and the operator from hazardous materials.

What are the key players in the Aspetic Negative Pressure Isolators Market?

Key players in the Aspetic Negative Pressure Isolators Market include companies such as Getinge AB, Thermo Fisher Scientific, and Esco Micro Pte Ltd, which are known for their innovative solutions in sterile containment. These companies focus on enhancing safety and efficiency in laboratory and pharmaceutical applications, among others.

What are the growth factors driving the Aspetic Negative Pressure Isolators Market?

The growth of the Aspetic Negative Pressure Isolators Market is driven by increasing demand for sterile environments in healthcare and pharmaceutical sectors, along with rising awareness of infection control. Additionally, advancements in technology and regulatory requirements for safety standards contribute to market expansion.

What challenges does the Aspetic Negative Pressure Isolators Market face?

The Aspetic Negative Pressure Isolators Market faces challenges such as high initial costs and the need for regular maintenance and calibration. Furthermore, the complexity of regulatory compliance can hinder market growth, as companies must navigate stringent safety and quality standards.

What opportunities exist in the Aspetic Negative Pressure Isolators Market?

Opportunities in the Aspetic Negative Pressure Isolators Market include the development of advanced isolator technologies and the expansion of applications in emerging markets. Additionally, increasing investments in healthcare infrastructure and research facilities present significant growth potential.

What trends are shaping the Aspetic Negative Pressure Isolators Market?

Trends in the Aspetic Negative Pressure Isolators Market include the integration of automation and smart technologies to enhance operational efficiency. There is also a growing emphasis on sustainability and eco-friendly materials in the design of isolators, reflecting broader industry shifts towards environmental responsibility.

Aspetic Negative Pressure Isolators Market

| Segmentation Details | Description |

|---|---|

| Product Type | Single-Use Isolators, Multi-Use Isolators, Portable Isolators, Fixed Isolators |

| Application | Pharmaceutical Manufacturing, Laboratory Research, Hospital Use, Biotech Applications |

| End User | Pharmaceutical Companies, Research Institutions, Hospitals, Contract Manufacturing Organizations |

| Technology | Mechanical Systems, Electronic Systems, Hybrid Systems, Advanced Filtration |

Leading Companies in the Aspetic Negative Pressure Isolators Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at