Market Overview

The Asia-Pacific Semiconductor Metrology and Inspection Market is a critical segment within the semiconductor industry, encompassing a range of technologies and solutions aimed at ensuring the quality and reliability of semiconductor manufacturing processes. Metrology and inspection tools play a crucial role in detecting defects, measuring critical dimensions, and verifying process parameters during semiconductor fabrication, contributing to the production of high-performance electronic devices. With the rapid growth of the semiconductor market in the Asia-Pacific region, driven by increasing demand for consumer electronics, automotive electronics, and IoT devices, the need for advanced metrology and inspection solutions is on the rise.

Meaning

The Asia-Pacific Semiconductor Metrology and Inspection Market refer to the sector focused on providing advanced tools and technologies for measuring, analyzing, and inspecting semiconductor devices during the manufacturing process. Semiconductor metrology involves the measurement and characterization of critical dimensions, material properties, and device features to ensure compliance with design specifications and performance requirements. Semiconductor inspection, on the other hand, involves the detection and classification of defects and anomalies in semiconductor wafers, chips, and packaging, ensuring product quality and reliability.

Executive Summary

The Asia-Pacific Semiconductor Metrology and Inspection Market have experienced significant growth in recent years, driven by factors such as the increasing complexity of semiconductor devices, shrinking feature sizes, and the growing demand for high-performance electronic products. This market offers lucrative opportunities for metrology and inspection equipment manufacturers, semiconductor fabs, and semiconductor equipment suppliers to capitalize on the rising demand for advanced process control solutions. However, challenges such as technological complexity, cost constraints, and market competition necessitate strategic planning and innovation to maintain a competitive edge.

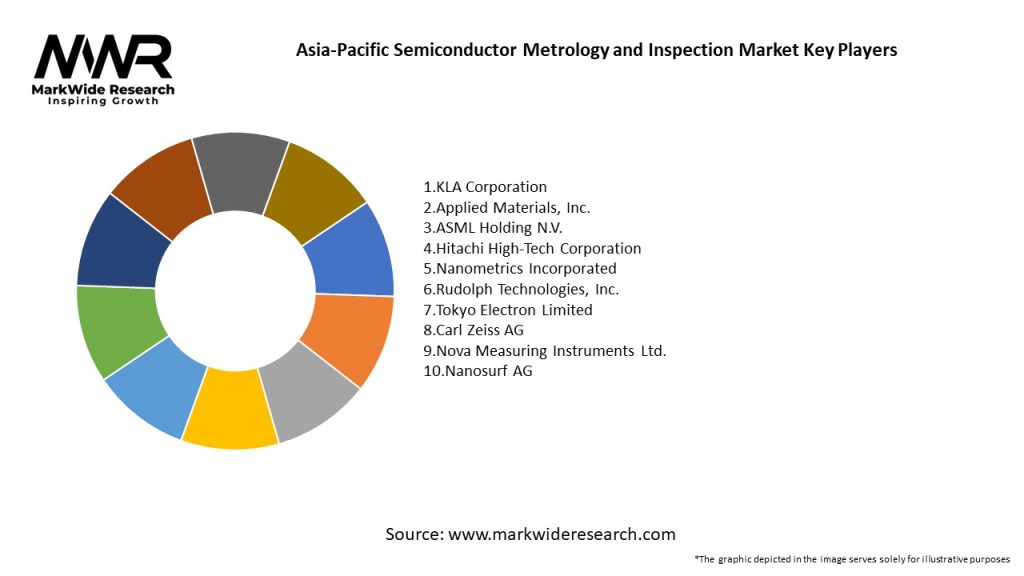

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

- Increasing Semiconductor Complexity: The continuous advancement of semiconductor technology has led to the development of increasingly complex devices with shrinking feature sizes and tighter tolerances, driving demand for advanced metrology and inspection solutions.

- Growing Demand for Process Control: Semiconductor manufacturers are increasingly relying on metrology and inspection tools to ensure process uniformity, defect detection, and yield improvement, enhancing product quality and reliability.

- Adoption of Advanced Materials and Packaging Technologies: The adoption of advanced materials and packaging technologies, such as 3D integration and wafer-level packaging, presents new challenges for metrology and inspection, spurring innovation and investment in next-generation solutions.

- Focus on Yield Enhancement and Cost Reduction: Semiconductor fabs are under pressure to improve yield and reduce manufacturing costs, driving demand for metrology and inspection solutions that enable process optimization, defect reduction, and yield enhancement.

Market Drivers

- Increasing Demand for Consumer Electronics: The growing adoption of smartphones, tablets, laptops, and other consumer electronics devices in the Asia-Pacific region is driving demand for advanced semiconductor devices, fueling the need for metrology and inspection solutions to ensure product quality and reliability.

- Expansion of Automotive Electronics Market: The automotive industry’s transition towards electric vehicles, autonomous driving technologies, and connected car solutions is driving demand for semiconductor devices with higher performance and reliability requirements, driving the adoption of advanced metrology and inspection tools.

- Growth of IoT and AI Applications: The proliferation of Internet of Things (IoT) devices, artificial intelligence (AI) applications, and edge computing solutions is driving demand for semiconductor devices with increased functionality and performance, driving the need for advanced metrology and inspection solutions to ensure product quality and reliability.

- Government Initiatives and Investments: Government initiatives and investments aimed at promoting semiconductor manufacturing, research, and development in countries like China, South Korea, Taiwan, and Singapore are driving growth in the Asia-Pacific Semiconductor Metrology and Inspection Market, creating opportunities for industry players to expand their presence and market share in the region.

Market Restraints

- Technological Complexity: The increasing complexity of semiconductor devices, materials, and processes poses challenges for metrology and inspection equipment manufacturers in developing and commercializing advanced solutions that meet the evolving needs of semiconductor fabs.

- Cost Constraints: The high cost of metrology and inspection equipment, combined with the pressure to reduce manufacturing costs and improve profitability, presents challenges for semiconductor fabs in investing in new equipment and technology upgrades.

- Market Competition: The Asia-Pacific Semiconductor Metrology and Inspection Market is highly competitive, with numerous players vying for market share, intensifying competition and price pressures for metrology and inspection equipment manufacturers and suppliers.

- Technological Obsolescence: Rapid technological advancements and innovation in semiconductor manufacturing processes and equipment can lead to technological obsolescence, requiring continuous investment in research and development to stay ahead of the competition and meet customer demands.

Market Opportunities

- Advancements in Metrology and Inspection Technologies: Opportunities exist for metrology and inspection equipment manufacturers to develop and commercialize advanced solutions, such as optical metrology, X-ray inspection, and electron microscopy, to meet the evolving needs of semiconductor fabs for process control and defect detection.

- Adoption of Industry 4.0 and Smart Manufacturing: The adoption of Industry 4.0 principles and smart manufacturing technologies, such as automation, data analytics, and artificial intelligence, presents opportunities for metrology and inspection equipment manufacturers to integrate their solutions into semiconductor fabs’ digital transformation initiatives.

- Collaboration and Partnerships: Collaborating with semiconductor fabs, research institutions, and industry stakeholders can foster innovation and knowledge sharing, enabling companies to develop cutting-edge metrology and inspection solutions that address specific customer needs and market demands.

- Market Expansion and Diversification: Expanding into emerging markets and diversifying product portfolios to address new applications and industry segments, such as advanced packaging, MEMS, and compound semiconductors, presents opportunities for metrology and inspection equipment manufacturers to achieve growth and market differentiation.

Market Dynamics

The Asia-Pacific Semiconductor Metrology and Inspection Market operate in a dynamic environment shaped by factors such as technological advancements, market trends, regulatory developments, and competitive forces. Understanding these dynamics is essential for industry participants to identify opportunities, mitigate risks, and make informed business decisions.

Regional Analysis:

- China: As a major semiconductor manufacturing hub, China drives significant demand for metrology and inspection solutions. The country’s investments in semiconductor technology and manufacturing capacity contribute to market growth.

- Japan: Japan’s strong semiconductor industry and technological advancements in metrology and inspection drive demand for precision tools and defect detection solutions.

- South Korea: South Korea’s semiconductor industry, characterized by leading companies and technological innovation, boosts the demand for advanced metrology and inspection technologies.

- Taiwan: Taiwan’s prominence in semiconductor manufacturing and research and development activities fuels the demand for high-precision metrology and inspection solutions.

Competitive Landscape:

Leading Companies in Asia-Pacific Semiconductor Metrology and Inspection Market:

- KLA Corporation

- Applied Materials, Inc.

- ASML Holding N.V.

- Hitachi High-Tech Corporation

- Nanometrics Incorporated

- Rudolph Technologies, Inc.

- Tokyo Electron Limited

- Carl Zeiss AG

- Nova Measuring Instruments Ltd.

- Nanosurf AG

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation: The semiconductor metrology and inspection market can be segmented based on:

- Type of Equipment: Includes optical metrology, X-ray inspection, electron microscopy, and others.

- Application: Segmented into wafer inspection, die and packaging inspection, and others.

- End-User Industry: Semiconductor manufacturing, electronics, automotive, and others.

- Geography: North America, Europe, Asia-Pacific, Latin America, Middle East & Africa.

Category-wise Insights:

- Wafer Inspection: Essential for ensuring the quality and performance of semiconductor wafers, leading to high demand for advanced inspection tools.

- Die and Packaging Inspection: Focuses on detecting defects in semiconductor dies and packaging, critical for maintaining product reliability and yield.

- Optical Metrology: Widely used for precision measurements in semiconductor manufacturing, driving demand for advanced optical metrology tools.

- X-ray Inspection: Provides non-destructive analysis of semiconductor devices, essential for detecting hidden defects and ensuring product quality.

Key Benefits for Industry Participants and Stakeholders:

- Improved Yield: Advanced metrology and inspection technologies help in identifying and minimizing defects, leading to improved manufacturing yield and reduced costs.

- Enhanced Product Quality: Ensuring high-quality standards through precise measurement and defect detection contributes to better performance and reliability of semiconductor devices.

- Market Leadership: Investing in cutting-edge technologies and innovations can provide a competitive edge and establish market leadership in the semiconductor industry.

- Regulatory Compliance: Meeting industry standards and regulatory requirements through advanced metrology and inspection solutions ensures compliance and reduces risks.

SWOT Analysis:

- Strengths:

- Advanced technology and precision

- High demand due to expanding semiconductor applications

- Strong presence of key market players in Asia-Pacific

- Weaknesses:

- High equipment costs

- Rapid technological changes leading to obsolescence

- Complexity of advanced semiconductor devices

- Opportunities:

- Integration of AI and ML for enhanced capabilities

- Expansion into emerging markets

- Strategic partnerships and collaborations

- Threats:

- Regulatory challenges and compliance issues

- Intense competition among key players

- Economic fluctuations impacting semiconductor industry investments

Market Key Trends:

- Technological Integration: Increasing integration of AI and ML in metrology and inspection to improve defect detection and measurement accuracy.

- Growth in Semiconductor Applications: Rising demand for semiconductor devices in various industries driving the need for advanced metrology solutions.

- Advancements in Metrology Tools: Continuous innovation and development of new metrology tools to meet the evolving needs of semiconductor manufacturing.

- Focus on Quality and Yield Improvement: Emphasis on improving semiconductor manufacturing quality and yield through advanced inspection technologies.

Covid-19 Impact:

- Supply Chain Disruptions: The pandemic caused disruptions in the semiconductor supply chain, impacting the availability of metrology and inspection equipment.

- Increased Demand for Electronics: The surge in demand for electronics during the pandemic, driven by remote work and online activities, boosted the need for semiconductor production and quality control.

- Operational Challenges: Semiconductor manufacturers faced operational challenges due to lockdowns and restrictions, affecting the demand and distribution of metrology and inspection tools.

Key Industry Developments:

- Technological Innovations: Advancements in metrology and inspection technologies, including the development of high-resolution imaging and advanced analytical tools.

- Regulatory Changes: Evolving regulations and standards impacting semiconductor manufacturing and quality control, driving the need for compliance solutions.

- Market Expansion: Expansion of semiconductor manufacturing capabilities in Asia-Pacific, leading to increased demand for metrology and inspection solutions.

- Strategic Partnerships: Collaborations between technology providers and semiconductor manufacturers to develop innovative solutions and enhance market reach.

Analyst Suggestions:

- Invest in R&D: Companies should invest in research and development to stay ahead of technological advancements and meet the evolving needs of semiconductor manufacturing.

- Focus on Emerging Markets: Target emerging markets with growing semiconductor manufacturing capabilities to expand market presence and capitalize on new opportunities.

- Leverage Technological Innovations: Integrate AI, ML, and other emerging technologies into metrology and inspection solutions to enhance performance and differentiation.

- Enhance Strategic Partnerships: Form strategic partnerships with semiconductor manufacturers and technology providers to foster innovation and expand market reach.

Future Outlook: The Asia-Pacific semiconductor metrology and inspection market is expected to continue its growth trajectory, driven by advancements in semiconductor technology, increasing demand for high-quality devices, and the expansion of manufacturing capabilities in the region. Companies that focus on innovation, strategic partnerships, and market expansion will be well-positioned to capitalize on future opportunities and drive sustained growth.

Conclusion: The Asia-Pacific semiconductor metrology and inspection market is a critical segment of the semiconductor industry, driven by technological advancements, growing demand for semiconductor devices, and regional manufacturing growth. By addressing market drivers, restraints, and opportunities, and adapting to evolving industry trends, stakeholders can navigate the competitive landscape and achieve success in this dynamic market.

![]()