444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

The Asia-Pacific LFP battery pack market represents one of the most dynamic and rapidly expanding segments within the global energy storage ecosystem. Lithium Iron Phosphate (LFP) battery packs have emerged as a cornerstone technology driving the region’s transition toward sustainable energy solutions, particularly in electric vehicles, renewable energy storage, and industrial applications. The market demonstrates exceptional growth momentum, with regional adoption rates reaching 42% annually across key application sectors.

Regional dynamics indicate that Asia-Pacific has become the epicenter of LFP battery pack innovation and manufacturing, with countries like China, Japan, South Korea, and India leading technological advancement and production capacity expansion. The market benefits from robust government support, favorable regulatory frameworks, and increasing consumer awareness regarding environmental sustainability. Manufacturing capabilities in the region account for approximately 68% of global LFP battery pack production, establishing Asia-Pacific as the dominant force in this critical technology sector.

Market characteristics reveal strong demand across multiple verticals, including automotive electrification, grid-scale energy storage, residential solar systems, and industrial backup power applications. The region’s commitment to carbon neutrality goals and renewable energy targets has accelerated LFP battery pack adoption, with government incentives supporting market penetration rates exceeding 35% in key metropolitan areas.

The Asia-Pacific LFP battery pack market refers to the comprehensive ecosystem encompassing the development, manufacturing, distribution, and deployment of lithium iron phosphate battery systems across the Asia-Pacific region. LFP battery packs utilize lithium iron phosphate as the cathode material, offering superior safety characteristics, extended cycle life, and enhanced thermal stability compared to other lithium-ion battery chemistries.

Market scope includes complete battery pack systems integrating LFP cells, battery management systems, thermal management components, and protective housing designed for various applications. These systems serve critical roles in electric vehicle powertrains, renewable energy storage installations, telecommunications infrastructure, and industrial equipment. Regional market definition encompasses all countries within the Asia-Pacific geographic boundary, including major economies such as China, Japan, India, South Korea, Australia, and Southeast Asian nations.

Technology characteristics distinguish LFP battery packs through their inherent safety features, including resistance to thermal runaway, stable chemical composition, and minimal risk of fire or explosion. The market represents the convergence of advanced materials science, sophisticated manufacturing processes, and innovative system integration capabilities that enable reliable, long-lasting energy storage solutions for diverse applications across the Asia-Pacific region.

Market leadership in the Asia-Pacific LFP battery pack sector reflects the region’s strategic position as both the largest producer and consumer of advanced energy storage technologies. The market demonstrates exceptional resilience and growth potential, driven by accelerating electric vehicle adoption, expanding renewable energy installations, and increasing demand for reliable backup power systems. Regional advantages include established supply chains, advanced manufacturing infrastructure, and supportive government policies promoting clean energy transition.

Key growth drivers encompass multiple factors, including declining battery costs, improving energy density, enhanced safety profiles, and expanding application opportunities. The market benefits from technological innovations that have increased LFP battery pack efficiency by approximately 28% over recent years, while simultaneously reducing manufacturing costs and improving performance characteristics. Investment flows into the sector have intensified, with both domestic and international companies establishing significant production capacity throughout the region.

Competitive dynamics reveal a landscape dominated by established Asian manufacturers who have developed comprehensive capabilities spanning raw material processing, cell production, pack assembly, and system integration. The market structure supports both large-scale industrial applications and emerging consumer segments, with product diversification enabling companies to address varied customer requirements across different industries and applications.

Strategic insights reveal several critical factors shaping the Asia-Pacific LFP battery pack market landscape:

Market intelligence indicates that these insights collectively contribute to a robust foundation for sustained growth and market expansion across diverse application segments and geographic markets within the Asia-Pacific region.

Electric vehicle proliferation serves as the primary catalyst driving Asia-Pacific LFP battery pack market expansion. Regional governments have implemented comprehensive electrification strategies, including purchase incentives, charging infrastructure development, and emission regulations that favor electric vehicle adoption. Consumer acceptance of electric vehicles has accelerated significantly, with LFP battery packs offering the optimal balance of safety, performance, and cost-effectiveness for mass-market applications.

Renewable energy integration represents another fundamental market driver, as countries throughout the region pursue ambitious clean energy targets. LFP battery packs provide essential grid stabilization capabilities, enabling higher renewable energy penetration while maintaining power quality and reliability. Utility-scale projects increasingly specify LFP technology due to its superior cycle life and safety characteristics, supporting long-term energy storage investments.

Cost reduction trends have made LFP battery packs increasingly competitive across multiple applications. Manufacturing scale economies, improved production processes, and raw material cost optimization have collectively reduced system costs while maintaining performance standards. Technology advancement continues to enhance energy density and charging capabilities, expanding the addressable market for LFP battery pack solutions.

Industrial applications are driving additional demand growth, particularly in telecommunications, data centers, and manufacturing facilities requiring reliable backup power systems. LFP battery packs offer superior safety profiles and longer service life compared to traditional lead-acid alternatives, supporting the transition to more advanced energy storage technologies across industrial sectors.

Energy density limitations represent a significant constraint for certain LFP battery pack applications, particularly in scenarios requiring maximum energy storage within minimal space and weight constraints. While LFP technology offers excellent safety and cycle life characteristics, energy density remains lower than some alternative lithium-ion chemistries, potentially limiting adoption in space-constrained applications such as premium electric vehicles or portable electronics.

Raw material supply chain vulnerabilities pose ongoing challenges for market participants, particularly regarding lithium and iron phosphate availability and pricing stability. Supply chain disruptions can impact production schedules and cost structures, requiring companies to develop diversified sourcing strategies and maintain strategic inventory levels to ensure operational continuity.

Competition from alternative technologies creates market pressure, as other battery chemistries continue advancing in performance and cost-effectiveness. Technological evolution in competing battery technologies may challenge LFP market share in specific applications, requiring continuous innovation and improvement to maintain competitive positioning.

Regulatory complexity across different Asia-Pacific markets can complicate market entry and expansion strategies. Varying safety standards, certification requirements, and import regulations create compliance challenges for manufacturers seeking to operate across multiple regional markets, potentially increasing operational costs and market entry barriers.

Emerging applications present substantial growth opportunities for Asia-Pacific LFP battery pack manufacturers, particularly in sectors such as marine propulsion, aviation, and specialized industrial equipment. These applications value LFP technology’s safety characteristics and reliability, creating premium market segments with favorable pricing dynamics and limited competition from alternative technologies.

Grid modernization initiatives across the region offer significant market expansion potential, as utilities invest in smart grid infrastructure and distributed energy resources. LFP battery packs provide essential capabilities for grid stabilization, peak shaving, and renewable energy integration, supporting utility-scale deployment opportunities with long-term contract structures.

Export market development represents a major opportunity for regional manufacturers to leverage their cost advantages and technical capabilities in global markets. International expansion can provide access to premium markets while diversifying revenue sources and reducing dependence on domestic demand fluctuations.

Technology partnerships with automotive manufacturers, renewable energy developers, and system integrators can accelerate market penetration while sharing development costs and risks. Strategic alliances enable companies to access new markets, technologies, and customer segments while building sustainable competitive advantages through collaborative innovation.

Supply and demand dynamics in the Asia-Pacific LFP battery pack market reflect the complex interplay between rapidly growing demand across multiple sectors and expanding production capacity throughout the region. Demand growth consistently outpaces supply expansion, creating favorable pricing conditions for manufacturers while encouraging continued investment in production capacity and technological advancement.

Competitive intensity varies significantly across different market segments, with commodity applications experiencing price pressure while specialized and high-performance applications maintain premium pricing structures. Market consolidation trends are emerging as smaller players seek partnerships or acquisition opportunities with larger, more established manufacturers possessing greater resources and market access.

Innovation cycles drive continuous market evolution, with manufacturers investing heavily in research and development to improve energy density, reduce costs, and enhance safety characteristics. Technology roadmaps indicate ongoing improvements in LFP battery pack performance, with efficiency gains of approximately 15% expected over the next development cycle.

Regulatory evolution continues shaping market dynamics, with governments implementing increasingly stringent safety standards and environmental regulations that favor LFP technology’s inherent advantages. Policy support for domestic manufacturing and clean energy adoption creates favorable market conditions while encouraging long-term investment in regional production capabilities.

Comprehensive market analysis employs multiple research methodologies to ensure accurate and reliable insights into the Asia-Pacific LFP battery pack market. Primary research includes extensive interviews with industry executives, technology experts, and key stakeholders across the value chain, providing firsthand insights into market trends, challenges, and opportunities.

Secondary research encompasses detailed analysis of industry reports, company financial statements, patent filings, and regulatory documents to establish comprehensive market understanding. Data validation processes ensure information accuracy through cross-referencing multiple sources and expert verification of key findings and market projections.

Quantitative analysis utilizes statistical modeling and forecasting techniques to project market trends and identify growth patterns across different segments and geographic regions. Market sizing methodologies incorporate bottom-up and top-down approaches to ensure comprehensive coverage of all relevant market segments and applications.

Qualitative assessment provides context and interpretation for quantitative findings, incorporating expert opinions and industry insights to explain market dynamics and competitive positioning. Research validation includes peer review processes and expert consultation to ensure findings accuracy and reliability for strategic decision-making purposes.

China dominates the Asia-Pacific LFP battery pack market, accounting for approximately 58% of regional production capacity and serving as the global manufacturing hub for LFP technology. Chinese manufacturers benefit from integrated supply chains, government support, and massive domestic demand from electric vehicle and energy storage applications. The market demonstrates exceptional scale economies and cost competitiveness that influence global pricing dynamics.

Japan maintains a strong position in high-performance and specialized LFP battery pack applications, leveraging advanced manufacturing capabilities and stringent quality standards. Japanese companies focus on premium market segments requiring superior reliability and performance characteristics, particularly in automotive and industrial applications where safety and longevity are paramount considerations.

South Korea has emerged as a significant player in LFP battery pack manufacturing, with major conglomerates investing heavily in production capacity and technology development. Korean manufacturers pursue strategies combining cost competitiveness with technological innovation, targeting both domestic and export markets across multiple application segments.

India represents a rapidly growing market for LFP battery pack consumption, driven by government initiatives promoting electric vehicle adoption and renewable energy deployment. Market development in India focuses on building domestic manufacturing capabilities while addressing growing demand from transportation and energy storage applications, with local production accounting for approximately 23% of domestic consumption.

Market leadership in the Asia-Pacific LFP battery pack sector is characterized by a combination of established technology companies and emerging specialists focused on specific application segments. Competitive positioning reflects companies’ abilities to balance cost competitiveness with technological advancement and quality assurance.

Competitive strategies emphasize vertical integration, technological innovation, and strategic partnerships to maintain market position while addressing evolving customer requirements across diverse application segments.

By Application:

By Capacity:

By End-user:

Automotive segment represents the largest and fastest-growing category within the Asia-Pacific LFP battery pack market, driven by accelerating electric vehicle adoption and supportive government policies. OEM partnerships have become increasingly strategic, with battery manufacturers working closely with automotive companies to develop customized solutions optimized for specific vehicle platforms and performance requirements.

Energy storage applications demonstrate strong growth momentum, particularly in utility-scale installations supporting renewable energy integration and grid stabilization. Project scale continues expanding, with individual installations reaching multi-gigawatt-hour capacities that require sophisticated battery management systems and thermal control technologies.

Industrial applications offer stable demand patterns and premium pricing opportunities, as companies prioritize reliability and safety over cost considerations. Mission-critical applications in telecommunications and data centers drive demand for high-quality LFP battery packs with extended service life and minimal maintenance requirements.

Consumer electronics represent an emerging opportunity for LFP battery pack manufacturers, as safety concerns and environmental awareness drive adoption in portable devices and power tools. Market penetration in this segment remains limited but shows potential for significant growth as technology improvements address size and weight constraints.

Manufacturers benefit from expanding market opportunities across multiple application segments, enabling revenue diversification and reduced dependence on any single market vertical. Production scale economies support improved cost structures and competitive positioning, while technological leadership creates opportunities for premium pricing in specialized applications.

Automotive companies gain access to safer, more reliable battery technology that addresses consumer concerns about electric vehicle safety while providing competitive total cost of ownership. LFP battery packs enable automotive manufacturers to offer vehicles with extended warranties and reduced maintenance requirements, supporting customer satisfaction and brand reputation.

Utility companies benefit from LFP battery pack technology’s superior cycle life and safety characteristics, enabling long-term energy storage investments with predictable performance and maintenance costs. Grid applications leverage LFP technology’s stability and reliability to support renewable energy integration while maintaining power quality standards.

End consumers receive improved safety, reliability, and value from LFP battery pack applications, whether in electric vehicles, home energy storage systems, or consumer electronics. Technology advantages translate into reduced ownership costs, enhanced safety, and improved environmental sustainability compared to alternative battery technologies.

Strengths:

Weaknesses:

Opportunities:

Threats:

Technology convergence represents a significant trend shaping the Asia-Pacific LFP battery pack market, with manufacturers integrating advanced battery management systems, artificial intelligence, and IoT connectivity to enhance performance and monitoring capabilities. Smart battery packs provide real-time performance data and predictive maintenance capabilities that improve system reliability and operational efficiency.

Sustainability focus drives increasing emphasis on battery recycling and circular economy principles throughout the LFP battery pack lifecycle. Recycling initiatives are becoming integral to manufacturer strategies, with companies developing closed-loop systems that recover valuable materials and reduce environmental impact while supporting cost competitiveness.

Customization trends reflect growing demand for application-specific battery pack solutions optimized for particular use cases and performance requirements. Modular designs enable flexible configuration options while maintaining manufacturing efficiency and cost-effectiveness across diverse application segments.

Integration strategies are expanding beyond traditional battery pack manufacturing to encompass complete energy storage systems and turnkey solutions. Value chain expansion enables companies to capture additional value while providing customers with comprehensive solutions that simplify procurement and installation processes.

Manufacturing capacity expansion continues accelerating throughout the Asia-Pacific region, with major players announcing significant investments in new production facilities and technology upgrades. Capacity additions reflect strong demand growth expectations and companies’ strategies to maintain market leadership through scale advantages and technological advancement.

Strategic partnerships between battery manufacturers and automotive companies are deepening, with joint ventures and long-term supply agreements becoming increasingly common. Collaboration initiatives enable shared investment in research and development while ensuring supply chain security for critical applications.

Technology breakthroughs in LFP battery pack design and manufacturing processes continue improving performance characteristics while reducing costs. Innovation focus areas include energy density improvements, fast-charging capabilities, and enhanced thermal management systems that expand application opportunities.

Regulatory developments across the region are establishing clearer standards for battery safety, performance, and environmental impact. Standardization efforts support market development by providing consistent requirements while encouraging technological innovation and quality improvement initiatives.

MarkWide Research recommends that industry participants focus on developing differentiated value propositions that leverage LFP technology’s inherent safety and reliability advantages. Strategic positioning should emphasize applications where these characteristics provide compelling benefits over alternative technologies, particularly in safety-critical and long-duration applications.

Investment priorities should balance capacity expansion with technological advancement, ensuring companies maintain competitive positioning while building scale advantages. Research and development investments in energy density improvements and cost reduction initiatives will be critical for long-term market success and competitive differentiation.

Partnership strategies should focus on building strong relationships with key customers and technology partners to ensure market access and shared development costs. Vertical integration opportunities may provide competitive advantages, particularly in raw material sourcing and specialized component manufacturing.

Market expansion strategies should consider both geographic diversification and application segment development to reduce market concentration risks while capturing growth opportunities. Export market development can leverage regional cost advantages while providing access to premium market segments with favorable pricing dynamics.

Long-term growth prospects for the Asia-Pacific LFP battery pack market remain exceptionally positive, supported by fundamental trends toward electrification, renewable energy adoption, and energy storage deployment. Market evolution is expected to continue favoring LFP technology’s safety and reliability advantages, particularly as applications expand into more demanding and safety-critical environments.

Technology advancement will likely address current limitations in energy density and temperature performance, expanding the addressable market while maintaining LFP technology’s core advantages. Innovation trajectories suggest continued improvements in performance characteristics, with energy density gains of approximately 25% anticipated over the next five years through materials science breakthroughs and manufacturing process optimization.

Market structure evolution may see increased consolidation as companies seek scale advantages and technological capabilities required for global competition. Competitive dynamics will likely favor companies with strong technological capabilities, integrated supply chains, and diversified market presence across multiple application segments and geographic regions.

MWR analysis indicates that regulatory support for clean energy technologies and carbon reduction initiatives will continue providing favorable market conditions for LFP battery pack adoption. Policy frameworks supporting domestic manufacturing and technology development are expected to strengthen regional competitive advantages while encouraging continued investment in production capacity and innovation capabilities.

The Asia-Pacific LFP battery pack market represents a dynamic and rapidly evolving sector positioned at the forefront of the global energy transition. Regional advantages in manufacturing capabilities, supply chain integration, and government support have established Asia-Pacific as the dominant force in LFP battery pack production and innovation, with market leadership extending across multiple application segments and technology categories.

Growth fundamentals remain exceptionally strong, driven by accelerating electric vehicle adoption, expanding renewable energy deployment, and increasing demand for reliable energy storage solutions across industrial and commercial applications. Technology advantages inherent in LFP chemistry, particularly superior safety characteristics and extended cycle life, position this technology favorably for long-term market expansion and application diversification.

Competitive positioning within the market reflects the complex interplay between scale advantages, technological innovation, and strategic partnerships that enable companies to address diverse customer requirements while maintaining cost competitiveness. Market evolution continues favoring participants with integrated capabilities spanning research and development, manufacturing excellence, and comprehensive customer support across multiple market segments.

Future success in the Asia-Pacific LFP battery pack market will depend on companies’ abilities to balance continued cost reduction with technological advancement while building strategic partnerships that ensure market access and shared development risks. The market’s trajectory toward sustained growth and technological leadership positions it as a critical component of the region’s clean energy future and global competitiveness in advanced battery technologies.

What is LFP Battery Pack?

LFP Battery Pack refers to lithium iron phosphate battery packs, which are known for their safety, thermal stability, and long cycle life. These battery packs are widely used in electric vehicles, renewable energy storage, and various industrial applications.

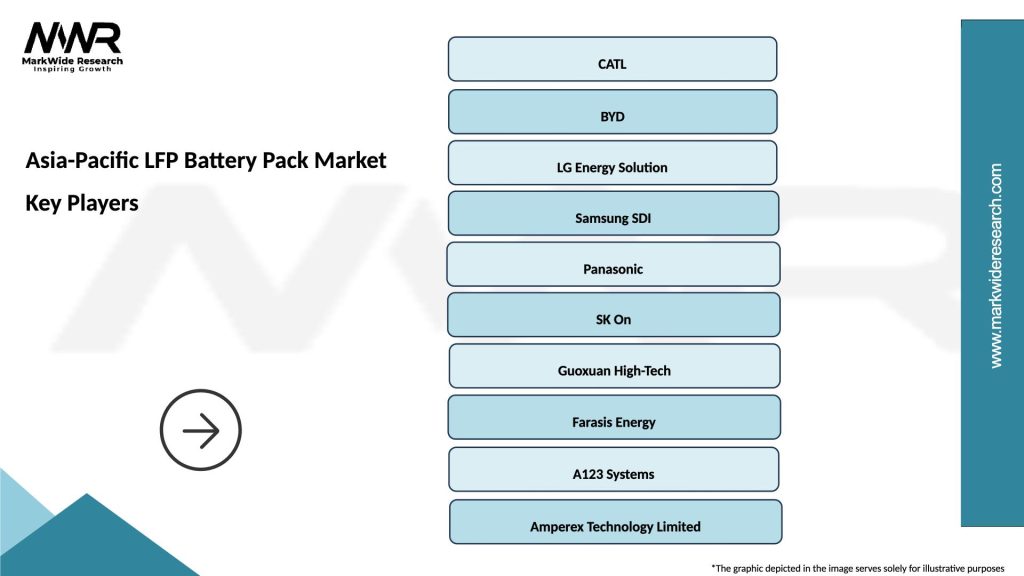

What are the key companies in the Asia-Pacific LFP Battery Pack Market?

Key companies in the Asia-Pacific LFP Battery Pack Market include CATL, BYD, and A123 Systems, which are leading manufacturers in the battery technology sector. These companies focus on innovation and expanding their production capacities to meet growing demand, among others.

What are the main drivers of the Asia-Pacific LFP Battery Pack Market?

The main drivers of the Asia-Pacific LFP Battery Pack Market include the increasing demand for electric vehicles, the growth of renewable energy storage solutions, and advancements in battery technology. These factors contribute to a rising interest in sustainable energy solutions.

What challenges does the Asia-Pacific LFP Battery Pack Market face?

Challenges in the Asia-Pacific LFP Battery Pack Market include competition from other battery technologies, supply chain disruptions, and the need for significant investment in manufacturing infrastructure. These factors can hinder market growth and innovation.

What opportunities exist in the Asia-Pacific LFP Battery Pack Market?

Opportunities in the Asia-Pacific LFP Battery Pack Market include the expansion of electric vehicle infrastructure, increasing government support for clean energy initiatives, and the potential for new applications in grid storage and consumer electronics. These trends can drive market growth.

What trends are shaping the Asia-Pacific LFP Battery Pack Market?

Trends shaping the Asia-Pacific LFP Battery Pack Market include the shift towards sustainable energy solutions, advancements in battery recycling technologies, and the integration of smart technologies in battery management systems. These trends are influencing consumer preferences and industry standards.

Asia-Pacific LFP Battery Pack Market

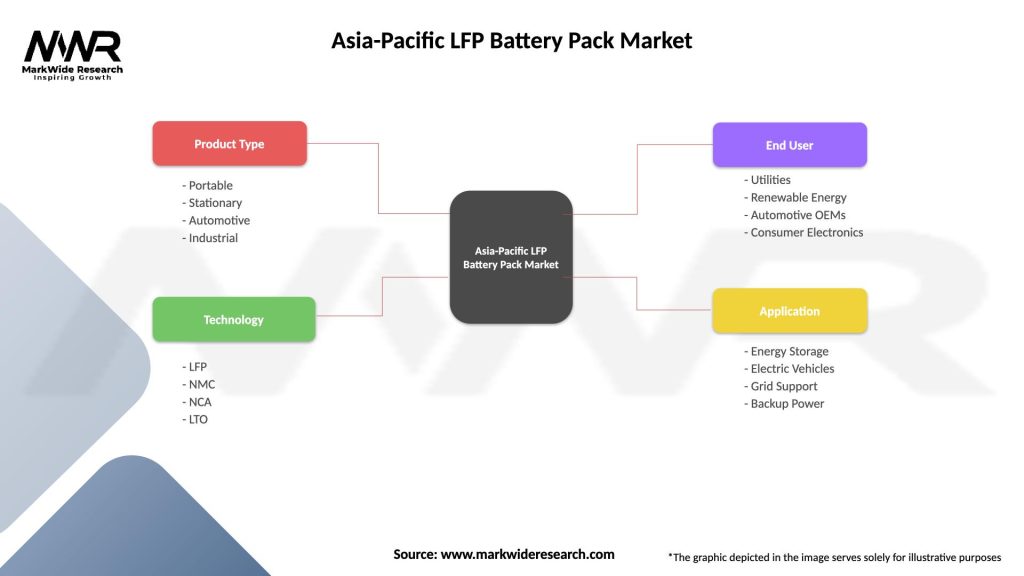

| Segmentation Details | Description |

|---|---|

| Product Type | Portable, Stationary, Automotive, Industrial |

| Technology | LFP, NMC, NCA, LTO |

| End User | Utilities, Renewable Energy, Automotive OEMs, Consumer Electronics |

| Application | Energy Storage, Electric Vehicles, Grid Support, Backup Power |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Asia-Pacific LFP Battery Pack Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at