444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

Market Overview

The Asia-Pacific laser interferometer market is witnessing significant growth, driven by factors such as increasing adoption of precision measurement technologies, rising demand for high-precision components in manufacturing, and advancements in laser technology. Laser interferometers play a crucial role in various industries, including manufacturing, electronics, aerospace, and automotive, by providing accurate and precise measurements for quality control, alignment, and calibration purposes. As industries in the Asia-Pacific region continue to emphasize precision and quality, the demand for laser interferometers is expected to grow.

Meaning

Laser interferometers are precision measurement devices that use laser light to measure distances with high accuracy. They work on the principle of interference, where two or more beams of light interfere with each other to create a pattern of light and dark fringes. By measuring the phase difference between these fringes, laser interferometers can determine distances with sub-micron accuracy. Laser interferometers are used in various applications, including metrology, semiconductor manufacturing, optical testing, and scientific research.

Executive Summary

The Asia-Pacific laser interferometer market is experiencing robust growth, driven by the increasing demand for high-precision measurement solutions in industries such as manufacturing, electronics, and healthcare. Laser interferometers offer unparalleled accuracy and reliability, making them essential tools for ensuring product quality, improving process efficiency, and meeting regulatory standards. As industries in the region continue to embrace digitalization and automation, the demand for laser interferometers is expected to increase further.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Asia-Pacific laser interferometer market is dynamic, driven by factors such as technological advancements, changing customer preferences, regulatory changes, and competitive pressures. These dynamics shape the market landscape and require laser interferometer manufacturers to innovate and adapt to stay competitive.

Regional Analysis

Competitive Landscape

Leading Companies in the Asia-Pacific Laser Interferometer Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The Asia-Pacific laser interferometer market can be segmented based on type, application, and end-user. Types of laser interferometers include homodyne interferometers, heterodyne interferometers, and common-path interferometers. Applications include metrology, semiconductor manufacturing, optical testing, and scientific research. End-users include manufacturing, electronics, aerospace, automotive, and healthcare industries.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has had a mixed impact on the Asia-Pacific laser interferometer market. While the initial phase of the pandemic led to disruptions in supply chains and manufacturing operations, the market quickly rebounded as industries resumed operations and focused on recovering from the crisis. The pandemic has also highlighted the importance of laser interferometers in industries such as healthcare, where precise measurements are critical for diagnostics and treatment.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future outlook for the Asia-Pacific laser interferometer market is positive, with continued growth expected driven by factors such as increasing demand for high-precision measurement solutions, technological advancements, and the adoption of Industry 4.0 technologies. However, challenges such as cost, complexity, and competition need to be addressed to unlock the full potential of the market.

Conclusion

The Asia-Pacific laser interferometer market is experiencing robust growth, driven by the increasing demand for high-precision measurement solutions in industries such as manufacturing, electronics, and healthcare. Laser interferometers offer unparalleled accuracy and reliability, making them essential tools for ensuring product quality, improving process efficiency, and meeting regulatory standards. As industries in the region continue to embrace digitalization and automation, the demand for laser interferometers is expected to increase further. By investing in technology, focusing on customer needs, and fostering collaborations, laser interferometer manufacturers can capitalize on the opportunities offered by the Asia-Pacific market and drive growth in the region.

What is Laser Interferometer?

Laser Interferometer is a precision measurement instrument that uses the interference of light waves to measure small distances, displacements, or changes in refractive index. It is widely used in fields such as metrology, optics, and engineering applications.

What are the key players in the Asia-Pacific Laser Interferometer Market?

Key players in the Asia-Pacific Laser Interferometer Market include Renishaw, Zeiss, and Keysight Technologies, which are known for their advanced measurement solutions and technologies in various industrial applications, among others.

What are the growth factors driving the Asia-Pacific Laser Interferometer Market?

The growth of the Asia-Pacific Laser Interferometer Market is driven by increasing demand for precision measurement in industries such as aerospace, automotive, and electronics. Additionally, advancements in laser technology and the rising need for quality control are significant contributors.

What challenges does the Asia-Pacific Laser Interferometer Market face?

Challenges in the Asia-Pacific Laser Interferometer Market include high initial costs of equipment and the need for skilled personnel to operate these sophisticated instruments. Furthermore, competition from alternative measurement technologies can also pose a challenge.

What opportunities exist in the Asia-Pacific Laser Interferometer Market?

Opportunities in the Asia-Pacific Laser Interferometer Market include the growing adoption of automation in manufacturing processes and the increasing use of laser interferometers in research and development. Emerging markets also present potential for expansion.

What trends are shaping the Asia-Pacific Laser Interferometer Market?

Trends in the Asia-Pacific Laser Interferometer Market include the integration of artificial intelligence for enhanced measurement accuracy and the development of compact, portable interferometers for field applications. Additionally, there is a growing focus on sustainability in manufacturing processes.

Asia-Pacific Laser Interferometer Market

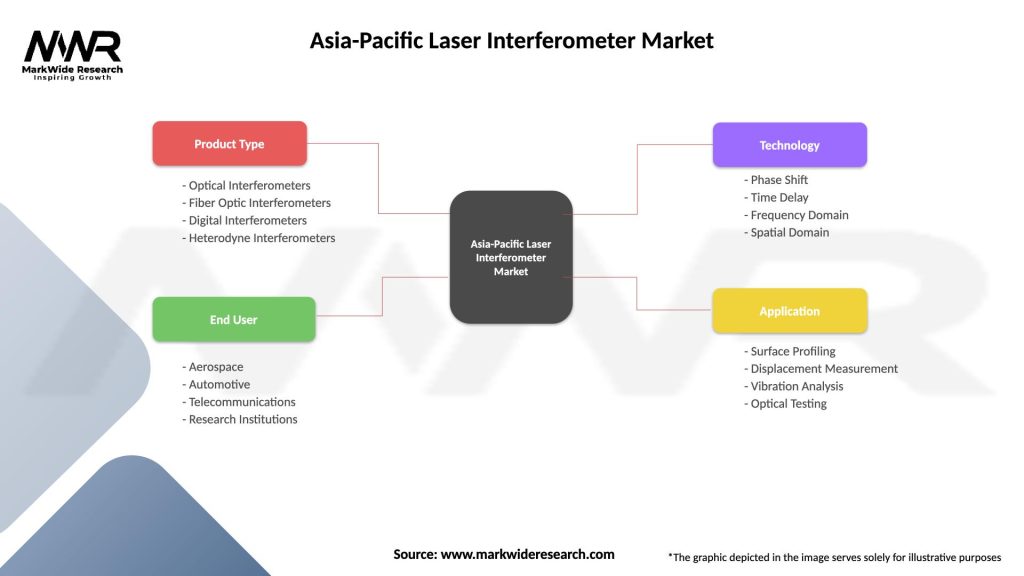

| Segmentation Details | Description |

|---|---|

| Product Type | Optical Interferometers, Fiber Optic Interferometers, Digital Interferometers, Heterodyne Interferometers |

| End User | Aerospace, Automotive, Telecommunications, Research Institutions |

| Technology | Phase Shift, Time Delay, Frequency Domain, Spatial Domain |

| Application | Surface Profiling, Displacement Measurement, Vibration Analysis, Optical Testing |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Asia-Pacific Laser Interferometer Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at