444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

Market Overview

The Asia Pacific Industrial Computed Tomography (CT) market is experiencing significant growth and is expected to expand at a steady pace in the coming years. Industrial CT is a non-destructive testing technique that uses X-ray technology to generate detailed 3D images of the internal structure of objects. It is widely used in various industries such as aerospace, automotive, electronics, and manufacturing for quality control, defect detection, and metrology applications.

Meaning

Industrial computed tomography, commonly known as CT, is a sophisticated imaging technique that uses X-ray technology to create cross-sectional images of objects. It provides a non-destructive way to examine the internal structure of objects and enables precise measurements of their dimensions and densities. In the industrial sector, CT scanning plays a crucial role in ensuring the quality and integrity of products, detecting defects or flaws, and aiding in product development and research.

Executive Summary

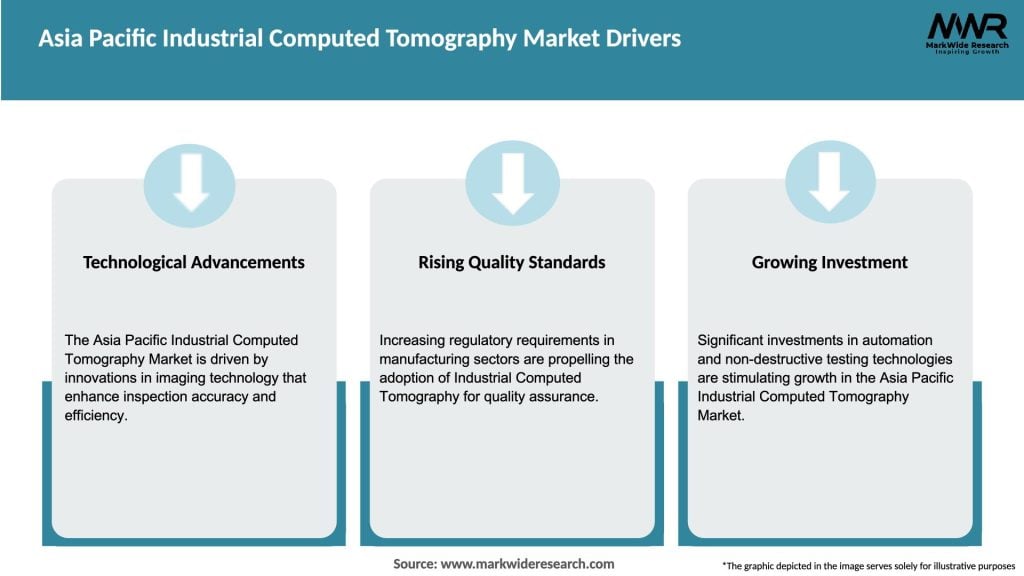

The Asia Pacific Industrial Computed Tomography market is witnessing substantial growth due to the increasing adoption of CT technology across various industries. The market is driven by factors such as the rising demand for advanced inspection techniques, stringent quality control regulations, and the need for accurate measurements in manufacturing processes. The market offers lucrative opportunities for CT equipment manufacturers, software providers, and service providers to cater to the growing demand in the region.

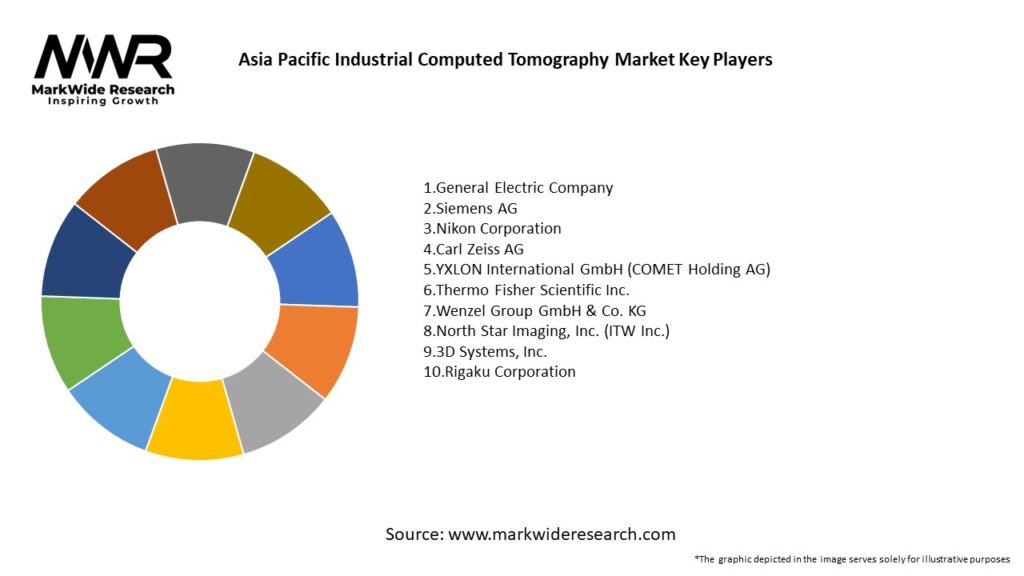

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Asia Pacific Industrial Computed Tomography market is driven by various dynamic factors that influence its growth trajectory. These dynamics include the demand-supply trends, technological advancements, regulatory landscape, competitive landscape, and changing customer preferences. Understanding and adapting to these dynamics is crucial for market players to capitalize on the opportunities and address the challenges in the industry.

Regional Analysis

The Asia Pacific region dominates the industrial CT market, accounting for a significant share in terms of revenue. The region’s strong manufacturing base, technological advancements, and increasing adoption of automation and quality control measures contribute to its leadership position. Within the region, countries such as China, Japan, and South Korea are at the forefront due to their robust industrial sectors and emphasis on research and development activities. Other countries in Southeast Asia, such as India, Singapore, and Malaysia, are also witnessing significant growth potential, driven by their expanding industrial landscape.

Competitive Landscape

Leading Companies in the Asia Pacific Industrial Computed Tomography Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

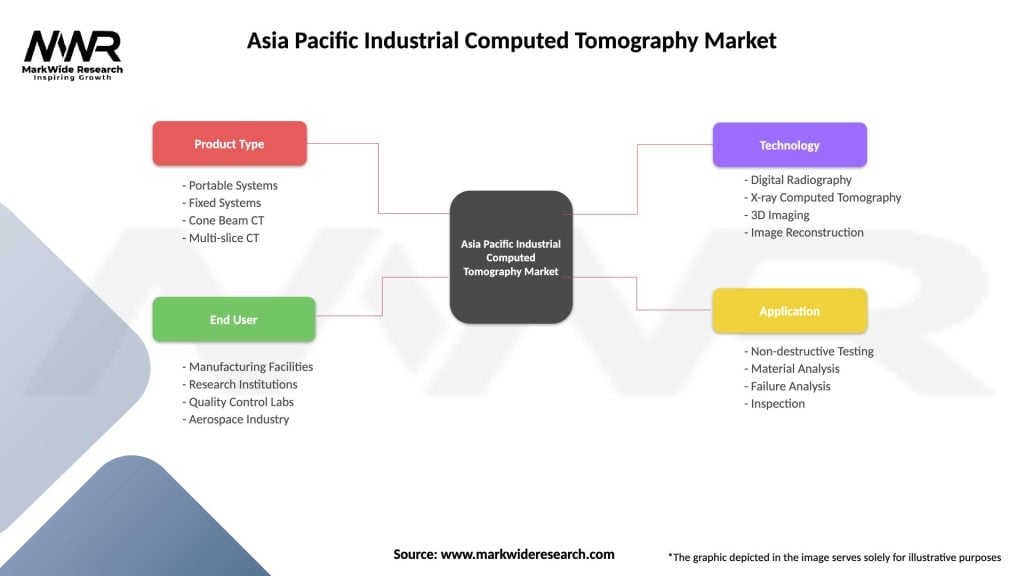

Segmentation

The Asia Pacific Industrial Computed Tomography market can be segmented based on technology, component, application, and end-user industry.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic had a mixed impact on the Asia Pacific Industrial Computed Tomography market. While the market witnessed a temporary slowdown during the initial phase of the pandemic due to disruptions in manufacturing activities and supply chains, it rebounded quickly as industries resumed operations. The pandemic highlighted the importance of quality control, product integrity, and supply chain resilience, driving the adoption of industrial CT for ensuring manufacturing efficiency and mitigating risks.

Key Industry Developments

Analyst Suggestions

Future Outlook

The Asia Pacific Industrial Computed Tomography market is poised for steady growth in the coming years. The market will be driven by increasing industrialization, the demand for advanced inspection techniques, and the focus on quality control and safety regulations across industries. Technological advancements, such as higher-resolution systems and AI integration, will further enhance the capabilities and adoption of industrial CT. Emerging economies, investments in research and development, and the expansion of key industries will present lucrative opportunities for market players.

Conclusion

The Asia Pacific Industrial Computed Tomography market is experiencing robust growth, driven by the need for advanced inspection techniques and quality control measures. The market offers significant opportunities for CT equipment manufacturers, software providers, and service providers to cater to the growing demand across industries. However, challenges such as high costs, lack of skilled professionals, and limited awareness need to be addressed. By focusing on innovation, partnerships, and cost optimization, market players can capitalize on the market’s potential and contribute to the advancement of industrial CT technology in the region.

What is Industrial Computed Tomography?

Industrial Computed Tomography refers to a non-destructive testing technique that uses X-ray or gamma-ray imaging to create detailed three-dimensional images of an object’s internal structure. This technology is widely used in various industries for quality control, failure analysis, and research and development.

What are the key players in the Asia Pacific Industrial Computed Tomography Market?

Key players in the Asia Pacific Industrial Computed Tomography Market include companies such as GE Measurement & Control Solutions, Nikon Metrology, and Zeiss, among others. These companies are known for their advanced imaging technologies and solutions tailored for industrial applications.

What are the growth factors driving the Asia Pacific Industrial Computed Tomography Market?

The growth of the Asia Pacific Industrial Computed Tomography Market is driven by increasing demand for non-destructive testing in manufacturing, advancements in imaging technology, and the rising need for quality assurance in various sectors such as aerospace, automotive, and electronics.

What challenges does the Asia Pacific Industrial Computed Tomography Market face?

Challenges in the Asia Pacific Industrial Computed Tomography Market include high initial investment costs, the need for skilled personnel to operate the equipment, and regulatory compliance issues related to radiation safety and environmental concerns.

What opportunities exist in the Asia Pacific Industrial Computed Tomography Market?

Opportunities in the Asia Pacific Industrial Computed Tomography Market include the growing adoption of automation in manufacturing processes, the expansion of the automotive and aerospace industries, and the increasing focus on research and development activities that require advanced imaging techniques.

What trends are shaping the Asia Pacific Industrial Computed Tomography Market?

Trends shaping the Asia Pacific Industrial Computed Tomography Market include the integration of artificial intelligence for enhanced image analysis, the development of portable and compact CT systems, and the increasing use of CT in additive manufacturing processes.

Asia Pacific Industrial Computed Tomography Market

| Segmentation Details | Description |

|---|---|

| Product Type | Portable Systems, Fixed Systems, Cone Beam CT, Multi-slice CT |

| End User | Manufacturing Facilities, Research Institutions, Quality Control Labs, Aerospace Industry |

| Technology | Digital Radiography, X-ray Computed Tomography, 3D Imaging, Image Reconstruction |

| Application | Non-destructive Testing, Material Analysis, Failure Analysis, Inspection |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Asia Pacific Industrial Computed Tomography Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at