444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

Market Overview

The Asia Pacific Automotive AHSS (Advanced High-Strength Steel) market is witnessing significant growth and is expected to expand at a steady pace in the coming years. AHSS refers to a type of steel that exhibits excellent strength and high formability, making it an ideal material for the automotive industry. This market overview provides valuable insights into the key drivers, restraints, opportunities, market dynamics, regional analysis, competitive landscape, segmentation, and category-wise insights of the Asia Pacific Automotive AHSS market.

Meaning

Advanced High-Strength Steel (AHSS) is a specialized type of steel that offers exceptional strength and durability while maintaining a lightweight structure. It is characterized by its high tensile strength, improved formability, and enhanced crash performance. AHSS is extensively used in the automotive industry to manufacture vehicle components such as chassis, body panels, and structural reinforcements. Its superior properties make it an ideal choice for meeting the stringent safety standards and fuel efficiency requirements of modern automobiles.

Executive Summary

The Asia Pacific Automotive AHSS market is witnessing substantial growth due to the rising demand for lightweight vehicles, stringent regulations related to fuel efficiency and emissions, and the need for improved safety in automobiles. The market is driven by the increasing adoption of AHSS in the production of electric vehicles, as well as the growing emphasis on vehicle lightweighting to enhance fuel efficiency. However, challenges such as high production costs and the availability of alternative lightweight materials may hinder market growth. Nonetheless, the market presents significant opportunities for AHSS manufacturers, especially in emerging economies with a growing automotive sector.

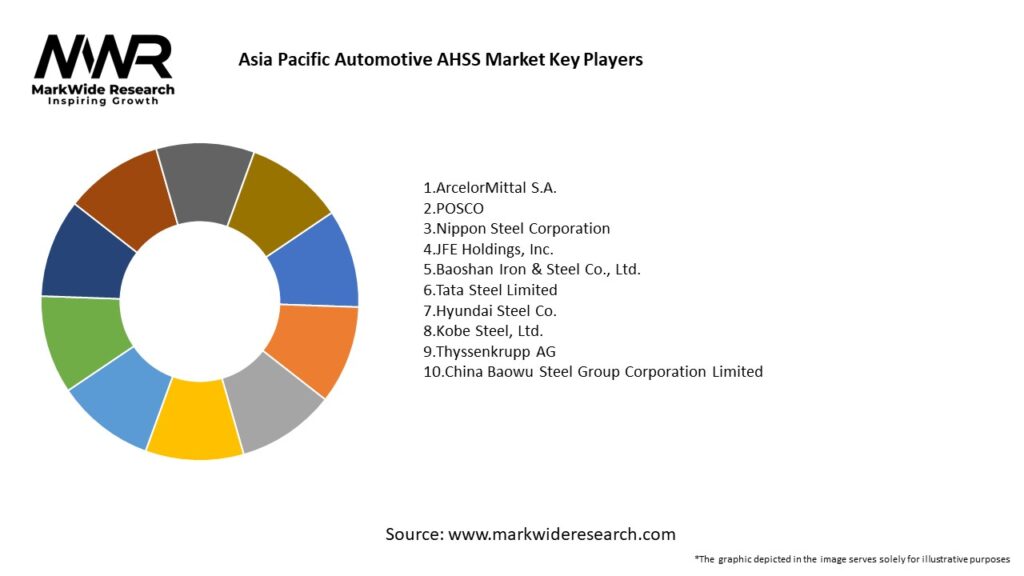

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Asia Pacific Automotive AHSS market is characterized by intense competition, technological advancements, and a dynamic regulatory landscape. The market dynamics are influenced by factors such as changing consumer preferences, government policies, advancements in manufacturing processes, and the emergence of new market players. Continuous research and development efforts, along with strategic collaborations, are crucial for AHSS manufacturers to stay competitive and meet the evolving demands of the automotive industry.

Regional Analysis

The Asia Pacific Automotive AHSS market is geographically segmented into several key regions, including China, Japan, South Korea, India, and Southeast Asian countries. China dominates the market due to its large automotive production capacity and government initiatives to promote electric vehicles. Japan and South Korea are also significant contributors to the market, driven by their advanced automotive industries and focus on lightweight vehicle production. India and Southeast Asian countries are experiencing rapid growth in the automotive sector, presenting lucrative opportunities for AHSS manufacturers in the region.

Competitive Landscape

Leading Companies in Asia Pacific Automotive AHSS Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The Asia Pacific Automotive AHSS market can be segmented based on product type, vehicle type, and application.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The Asia Pacific Automotive AHSS market was not immune to the impact of the COVID-19 pandemic. The automotive industry witnessed a significant decline in sales and production during the initial phase of the pandemic due to lockdown measures and supply chain disruptions. However, as economies started to recover and restrictions were lifted, the automotive sector rebounded, driving the demand for AHSS. The pandemic highlighted the importance of vehicle safety and fuel efficiency, creating opportunities for AHSS manufacturers to cater to these requirements.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future outlook for the Asia Pacific Automotive AHSS market remains positive. The market is expected to witness steady growth, driven by factors such as the increasing demand for lightweight vehicles, the growth of electric vehicles, and the focus on safety and sustainability. Ongoing research and development efforts, along with technological advancements, will further enhance the properties and performance of AHSS. Continued collaboration between AHSS manufacturers and automakers, as well as the expansion of production capacities, will contribute to market growth in the coming years.

Conclusion

The Asia Pacific Automotive AHSS market presents significant opportunities for manufacturers, suppliers, and stakeholders in the automotive industry. The market is driven by the demand for lightweight vehicles, stringent regulations, the growth of electric vehicles, and the need for enhanced safety. While challenges such as high production costs and the availability of alternative lightweight materials exist, the market continues to grow due to ongoing advancements in AHSS grades, strategic collaborations, and the expanding automotive industries in emerging economies. The future outlook for the Asia Pacific Automotive AHSS market is promising, with a focus on customization, sustainability, and technological innovation expected to drive market growth.

What is Automotive AHSS?

Automotive AHSS refers to advanced high-strength steel used in the automotive industry to enhance vehicle safety and performance. It is characterized by its superior strength-to-weight ratio, making it ideal for various automotive applications such as body structures and crash components.

What are the key players in the Asia Pacific Automotive AHSS Market?

Key players in the Asia Pacific Automotive AHSS Market include companies like ArcelorMittal, Tata Steel, and POSCO, which are known for their innovative steel solutions and extensive product offerings in the automotive sector, among others.

What are the growth factors driving the Asia Pacific Automotive AHSS Market?

The Asia Pacific Automotive AHSS Market is driven by increasing demand for lightweight vehicles, stringent safety regulations, and the need for improved fuel efficiency. Additionally, advancements in manufacturing technologies are facilitating the adoption of AHSS in automotive applications.

What challenges does the Asia Pacific Automotive AHSS Market face?

Challenges in the Asia Pacific Automotive AHSS Market include the high cost of production and the complexity of manufacturing processes. Furthermore, competition from alternative materials such as aluminum and composites poses a significant challenge to market growth.

What opportunities exist in the Asia Pacific Automotive AHSS Market?

Opportunities in the Asia Pacific Automotive AHSS Market include the growing trend towards electric vehicles, which require lightweight materials for better efficiency. Additionally, increasing investments in automotive research and development are expected to drive innovation in AHSS applications.

What trends are shaping the Asia Pacific Automotive AHSS Market?

Trends in the Asia Pacific Automotive AHSS Market include the rising adoption of advanced manufacturing techniques such as hot stamping and the integration of smart materials. These innovations are enhancing the performance and safety of vehicles while reducing overall weight.

Asia Pacific Automotive AHSS Market

| Segmentation Details | Description |

|---|---|

| Vehicle Type | SUV, Sedan, Hatchback, Coupe |

| Material Grade | High Strength, Ultra High Strength, Advanced High Strength, Low Alloy |

| Manufacturing Stage | Stamping, Welding, Assembly, Coating |

| End User | OEMs, Tier-1 Suppliers, Aftermarket Providers, Vehicle Assemblers |

Leading Companies in Asia Pacific Automotive AHSS Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at