444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

The Argentina container glass market represents a dynamic and evolving segment within the country’s packaging industry, characterized by robust demand across multiple end-use sectors. Container glass manufacturing in Argentina has experienced steady growth, driven by increasing consumption of beverages, pharmaceuticals, and food products that require premium glass packaging solutions. The market demonstrates resilience despite economic fluctuations, with local manufacturers adapting to changing consumer preferences and sustainability requirements.

Market dynamics indicate that Argentina’s container glass sector is experiencing a transformation toward more sustainable and innovative packaging solutions. The industry benefits from abundant raw material availability and established manufacturing infrastructure, positioning Argentina as a significant player in the South American glass packaging landscape. Growth projections suggest the market will expand at a compound annual growth rate of 4.2% over the forecast period, supported by recovering economic conditions and increasing industrial activity.

Regional distribution shows concentration in key industrial provinces, with Buenos Aires, Córdoba, and Santa Fe accounting for approximately 75% of total production capacity. The market structure includes both multinational corporations and domestic players, creating a competitive environment that drives innovation and efficiency improvements. Technological advancements in glass manufacturing processes are enabling producers to meet evolving quality standards while maintaining cost competitiveness in regional markets.

The Argentina container glass market refers to the comprehensive ecosystem encompassing the production, distribution, and consumption of glass containers used for packaging various products including beverages, food items, pharmaceuticals, and cosmetics within Argentina’s domestic and export markets. This market includes manufacturing facilities, supply chain networks, and end-user industries that rely on glass packaging solutions for product protection, preservation, and brand presentation.

Container glass specifically denotes hollow glass products manufactured through molding processes, designed to hold and protect contents while providing visual appeal and functional benefits. The Argentine market encompasses various container types including bottles, jars, vials, and specialty containers, each serving specific industry requirements and consumer preferences. Market participants include glass manufacturers, raw material suppliers, equipment providers, and downstream customers across multiple industrial sectors.

Argentina’s container glass market demonstrates steady growth momentum despite regional economic challenges, supported by strong domestic demand and expanding export opportunities. The market benefits from established manufacturing infrastructure, skilled workforce, and strategic geographic positioning for serving both domestic and regional markets. Key growth drivers include increasing beverage consumption, pharmaceutical industry expansion, and growing preference for sustainable packaging solutions.

Market segmentation reveals that beverage containers represent the largest application segment, accounting for approximately 60% of total demand, followed by food packaging and pharmaceutical applications. The competitive landscape features a mix of international and domestic players, with leading companies investing in capacity expansion and technological upgrades to maintain market position. Sustainability initiatives are becoming increasingly important, with manufacturers implementing recycling programs and developing eco-friendly production processes.

Future prospects indicate continued market expansion driven by urbanization, changing consumer lifestyles, and increasing awareness of glass packaging benefits. The market is expected to benefit from government initiatives supporting industrial development and environmental sustainability. Investment opportunities exist in advanced manufacturing technologies, specialty glass products, and export market development.

Strategic analysis reveals several critical insights shaping the Argentina container glass market landscape:

Economic recovery in Argentina is generating positive momentum for the container glass market, with improving consumer confidence and increased industrial activity driving demand across multiple sectors. The beverage industry’s expansion, particularly in wine and craft beer segments, creates substantial growth opportunities for glass container manufacturers. Premium positioning of glass packaging appeals to quality-conscious consumers, supporting market growth in high-value applications.

Sustainability trends are becoming increasingly influential, with consumers and businesses prioritizing environmentally friendly packaging solutions. Glass containers offer superior recyclability and chemical inertness, making them preferred choices for health-conscious consumers and premium product segments. Government initiatives promoting circular economy principles and waste reduction are creating favorable regulatory environments for glass packaging adoption.

Export opportunities in neighboring countries are expanding, driven by Argentina’s competitive manufacturing costs and established trade relationships. The country’s strategic location provides access to growing South American markets, while free trade agreements facilitate cross-border commerce. Industrial diversification efforts are creating new applications for container glass in pharmaceutical, cosmetic, and specialty chemical sectors.

Technological advancements in glass manufacturing are enabling producers to develop innovative products with enhanced functionality and aesthetic appeal. Advanced molding techniques, surface treatments, and quality control systems are improving product performance while reducing production costs. Consumer preferences for premium packaging experiences are driving demand for specialty glass containers with unique designs and functional features.

Economic volatility in Argentina continues to present challenges for the container glass market, with currency fluctuations and inflation affecting both production costs and consumer purchasing power. Energy costs represent a significant operational expense for glass manufacturers, with natural gas and electricity price variations impacting production economics and competitive positioning.

Competition from alternative packaging materials, particularly plastic and aluminum containers, poses ongoing challenges for glass market share. These alternatives often offer cost advantages and lighter weight benefits, making them attractive for price-sensitive applications and export markets. Transportation costs for glass containers are higher due to weight and fragility considerations, limiting competitiveness in certain market segments.

Raw material quality variations can impact production efficiency and product quality, requiring careful supplier management and quality control processes. Environmental regulations regarding emissions and waste management are increasing compliance costs for manufacturers, particularly smaller operations with limited resources for environmental upgrades.

Skilled labor availability presents challenges in certain regions, with specialized glass manufacturing expertise requiring ongoing training and development investments. Capital intensity of glass manufacturing operations creates barriers to entry for new players and limits flexibility in responding to market changes.

Export market expansion presents significant opportunities for Argentine container glass manufacturers, with growing demand in neighboring countries and established trade relationships facilitating market access. Premium product segments offer higher margins and growth potential, particularly in wine, spirits, and luxury cosmetic applications where glass packaging provides distinct advantages.

Sustainability initiatives create opportunities for manufacturers to differentiate their products through environmental benefits and circular economy participation. Recycling programs and closed-loop systems can reduce raw material costs while appealing to environmentally conscious customers. Lightweight glass technologies can address transportation cost concerns while maintaining glass packaging benefits.

Pharmaceutical industry growth in Argentina and regional markets creates demand for specialized glass containers meeting stringent quality and safety requirements. E-commerce expansion is driving demand for protective packaging solutions, with glass containers offering superior product protection for high-value items.

Innovation opportunities exist in smart packaging technologies, decorative treatments, and functional enhancements that add value for end users. Strategic partnerships with beverage producers, pharmaceutical companies, and cosmetic brands can secure long-term supply agreements and collaborative product development opportunities.

Supply chain dynamics in the Argentina container glass market are characterized by integrated operations and strategic supplier relationships. Raw material sourcing benefits from domestic silica sand deposits and established supplier networks, providing cost advantages and supply security. Manufacturing operations are concentrated in industrial regions with access to transportation infrastructure and skilled labor pools.

Demand patterns show seasonal variations aligned with beverage consumption cycles, with peak demand during summer months and holiday periods. Customer relationships tend to be long-term partnerships with major beverage producers and pharmaceutical companies, providing stability and predictable demand patterns. Pricing dynamics reflect raw material costs, energy prices, and competitive pressures from alternative packaging materials.

Technological evolution is driving efficiency improvements and product innovation throughout the industry. Automation adoption is increasing across manufacturing operations, improving quality consistency and reducing labor costs. Quality management systems are becoming more sophisticated, with real-time monitoring and statistical process control enhancing product reliability.

Regulatory environment influences market dynamics through environmental standards, food safety requirements, and trade policies. Market consolidation trends are creating larger, more efficient operations while maintaining competitive dynamics through regional and specialty players.

Comprehensive market analysis was conducted using multiple research approaches to ensure accuracy and reliability of findings. Primary research included structured interviews with industry executives, manufacturing managers, and key stakeholders across the container glass value chain. Secondary research encompassed analysis of industry reports, government statistics, trade association data, and company financial statements.

Data collection methods included surveys of market participants, facility visits to major manufacturing operations, and analysis of import/export statistics. Market sizing was performed through bottom-up analysis of production capacity, utilization rates, and demand patterns across end-use segments. Competitive analysis examined market share, strategic positioning, and operational capabilities of key players.

Validation processes included cross-referencing multiple data sources, expert consultations, and triangulation of findings through different analytical approaches. Forecasting methodologies incorporated econometric modeling, trend analysis, and scenario planning to project future market developments. Quality assurance measures ensured data accuracy and analytical rigor throughout the research process.

Buenos Aires Province dominates the Argentina container glass market, accounting for approximately 45% of total production capacity and hosting major manufacturing facilities of leading companies. The region benefits from proximity to key markets, port access for exports, and established industrial infrastructure. Greater Buenos Aires area serves as the primary consumption center, driving significant local demand for beverage and food packaging applications.

Córdoba Province represents the second-largest manufacturing region, with approximately 20% of national production capacity concentrated in industrial parks around Córdoba city. The region’s central location provides strategic advantages for serving both domestic and export markets. Manufacturing operations in Córdoba focus on specialty glass products and high-quality containers for premium applications.

Santa Fe Province contributes approximately 15% of total production capacity, with facilities concentrated in the Rosario industrial corridor. The region’s access to river transportation and agricultural markets creates opportunities for food packaging applications. Export activities are significant, with Santa Fe facilities serving regional markets through river and road transportation networks.

Other regions including Mendoza, San Juan, and Tucumán account for the remaining 20% of production capacity, often specializing in specific applications or serving local markets. Mendoza’s wine industry creates substantial demand for wine bottles, supporting specialized glass manufacturing operations. Regional development initiatives are encouraging industrial expansion in secondary markets.

Market structure in Argentina’s container glass industry features a mix of multinational corporations and domestic manufacturers, creating a competitive environment that drives innovation and efficiency improvements. Leading companies have established strong market positions through strategic investments, technological capabilities, and customer relationships.

Competitive strategies include capacity expansion, technological upgrades, and market diversification initiatives. Innovation focus areas encompass lightweight glass technologies, sustainable manufacturing processes, and specialty product development. Strategic partnerships with major customers are common, providing stability and collaborative product development opportunities.

Market positioning varies among competitors, with some focusing on high-volume commodity products while others target premium and specialty segments. Operational excellence initiatives are driving efficiency improvements and cost competitiveness across the industry.

By Product Type:

By End-Use Industry:

By Manufacturing Process:

By Capacity:

Beverage Containers represent the dominant category in Argentina’s container glass market, driven by strong wine industry demand and growing craft beer segment. Wine bottles account for the largest volume within this category, supported by Argentina’s position as a major wine producer and exporter. Premium positioning of glass packaging appeals to quality-conscious consumers and export markets.

Food Packaging applications show steady growth, particularly in gourmet and artisanal food segments where glass containers provide superior product protection and shelf appeal. Preserve jars and specialty food containers benefit from increasing consumer preference for premium packaging. Export opportunities exist for high-quality food packaging solutions in regional markets.

Pharmaceutical Containers represent a high-value, specialized segment with stringent quality requirements and regulatory compliance needs. Growth drivers include expanding pharmaceutical industry and increasing healthcare spending. Technical expertise and quality certifications are essential for success in this segment.

Cosmetic Applications offer premium pricing opportunities and design differentiation potential. Luxury positioning of glass packaging appeals to high-end cosmetic brands seeking distinctive packaging solutions. Innovation opportunities exist in decorative treatments and functional enhancements.

Manufacturers benefit from established market demand, available raw materials, and skilled workforce in Argentina’s container glass industry. Operational advantages include lower labor costs compared to developed markets and access to regional export opportunities. Technology partnerships enable access to advanced manufacturing processes and quality improvement initiatives.

End-users gain access to high-quality glass containers that provide superior product protection, shelf appeal, and sustainability benefits. Local sourcing advantages include reduced transportation costs, shorter lead times, and responsive customer service. Customization capabilities allow for tailored packaging solutions meeting specific requirements.

Investors find opportunities in a stable market with growth potential and established infrastructure. Export market access provides diversification benefits and growth opportunities beyond domestic demand. Sustainability trends create long-term value proposition for glass packaging investments.

Suppliers benefit from integrated supply chains and long-term customer relationships in the container glass industry. Raw material suppliers enjoy stable demand and proximity advantages. Equipment suppliers find opportunities in modernization and capacity expansion projects.

Government stakeholders benefit from industrial employment, export revenues, and sustainable manufacturing practices. Economic development initiatives are supported by container glass industry investments and expansion projects.

Strengths:

Weaknesses:

Opportunities:

Threats:

Sustainability initiatives are reshaping the Argentina container glass market, with manufacturers implementing comprehensive recycling programs and developing eco-friendly production processes. Circular economy principles are driving innovation in glass recycling technologies and closed-loop manufacturing systems. Environmental certifications are becoming increasingly important for market access and customer relationships.

Lightweight glass technologies are gaining adoption as manufacturers seek to reduce transportation costs while maintaining glass packaging benefits. Advanced molding techniques enable production of thinner-walled containers without compromising strength or quality. Material optimization initiatives are reducing raw material consumption and improving production efficiency.

Premium packaging trends are driving demand for specialty glass containers with unique designs, decorative treatments, and functional enhancements. Customization capabilities are becoming competitive advantages as brands seek distinctive packaging solutions. Smart packaging technologies are emerging in high-value applications.

Digital transformation is impacting manufacturing operations through automation, quality monitoring systems, and predictive maintenance technologies. Industry 4.0 concepts are being implemented to improve operational efficiency and product quality. Data analytics applications are optimizing production processes and supply chain management.

Export market development is becoming increasingly important as manufacturers seek growth opportunities beyond domestic demand. Regional integration initiatives are facilitating cross-border trade and market access. Quality standardization efforts are supporting export competitiveness.

Capacity expansion projects are underway at several major manufacturing facilities, with companies investing in modern equipment and increased production capabilities. Technology upgrades include installation of advanced furnaces, automated handling systems, and quality control equipment. Sustainability investments focus on energy efficiency improvements and waste reduction initiatives.

Strategic partnerships between glass manufacturers and major customers are creating collaborative product development opportunities and long-term supply agreements. Innovation collaborations with technology providers are advancing glass manufacturing processes and product capabilities. Research initiatives focus on lightweight glass technologies and specialty applications.

Market consolidation activities include acquisitions and strategic alliances aimed at strengthening market positions and operational capabilities. International expansion efforts are targeting regional markets with growth potential. Vertical integration initiatives are optimizing supply chain efficiency and cost structure.

Regulatory developments include new environmental standards and quality requirements affecting manufacturing operations and product specifications. Trade policy changes are impacting export opportunities and competitive dynamics. Industry standards evolution is driving quality improvements and market harmonization.

Investment announcements from both domestic and international companies indicate continued confidence in Argentina’s container glass market potential. Government support programs are facilitating industrial development and export promotion initiatives.

MarkWide Research recommends that container glass manufacturers in Argentina focus on operational excellence initiatives to improve cost competitiveness and quality consistency. Investment priorities should include energy efficiency improvements, automation technologies, and quality management systems. Market diversification strategies should target high-value applications in pharmaceuticals and cosmetics to reduce dependence on commodity segments.

Export market development represents a critical growth opportunity, requiring strategic partnerships, quality certifications, and logistics optimization. Sustainability initiatives should be prioritized to align with global trends and customer requirements. Innovation investments in lightweight glass technologies and specialty products can create competitive advantages.

Strategic partnerships with major customers should be strengthened through collaborative product development and long-term supply agreements. Supply chain optimization initiatives can improve efficiency and reduce costs. Talent development programs are essential for maintaining technical expertise and operational capabilities.

Risk management strategies should address economic volatility, energy cost fluctuations, and competitive pressures from alternative materials. Financial planning should incorporate currency hedging and flexible cost structures. Market intelligence systems should monitor competitive developments and customer requirements.

Long-term prospects for Argentina’s container glass market remain positive, supported by recovering economic conditions, growing export opportunities, and increasing sustainability awareness. Market expansion is expected to continue at a steady growth rate of 4.2% annually, driven by beverage industry growth and expanding pharmaceutical applications. Investment flows into manufacturing capacity and technology upgrades will support market development.

Technological evolution will continue reshaping the industry through advanced manufacturing processes, quality improvement systems, and sustainability innovations. Automation adoption will accelerate, improving operational efficiency and product consistency. Digital transformation initiatives will optimize supply chain management and customer relationships.

Export market growth will become increasingly important as regional economies recover and trade relationships strengthen. Quality standards harmonization will facilitate market access and competitive positioning. Sustainability requirements will drive continued innovation in recycling technologies and eco-friendly production processes.

Market structure evolution may include further consolidation activities and strategic partnerships aimed at strengthening competitive positions. New market entrants may emerge in specialty segments with differentiated value propositions. Customer relationships will become more strategic and collaborative, focusing on joint value creation.

MWR analysis indicates that successful companies will be those that combine operational excellence with innovation capabilities and market diversification strategies. Investment opportunities will continue emerging in advanced technologies, export market development, and sustainability initiatives throughout the forecast period.

Argentina’s container glass market presents a compelling combination of established infrastructure, growing demand, and strategic opportunities for expansion and innovation. The market demonstrates resilience despite economic challenges, supported by strong fundamentals including raw material availability, skilled workforce, and established customer relationships. Growth prospects remain positive, driven by beverage industry expansion, pharmaceutical sector development, and increasing sustainability awareness.

Key success factors for market participants include operational excellence, technological innovation, and strategic market positioning. Companies that invest in advanced manufacturing capabilities, develop export market presence, and align with sustainability trends will be best positioned for long-term success. Competitive advantages will increasingly depend on quality leadership, customer partnerships, and operational efficiency.

Future market development will be shaped by technological advancement, regulatory evolution, and changing consumer preferences toward sustainable packaging solutions. The Argentina container glass market is well-positioned to capitalize on these trends while maintaining its competitive position in regional and international markets. Strategic investments in capacity, technology, and market development will continue driving industry growth and evolution.

What is Container Glass?

Container glass refers to glass products designed for packaging and storing various goods, including beverages, food, and pharmaceuticals. This type of glass is favored for its durability, recyclability, and ability to preserve the quality of its contents.

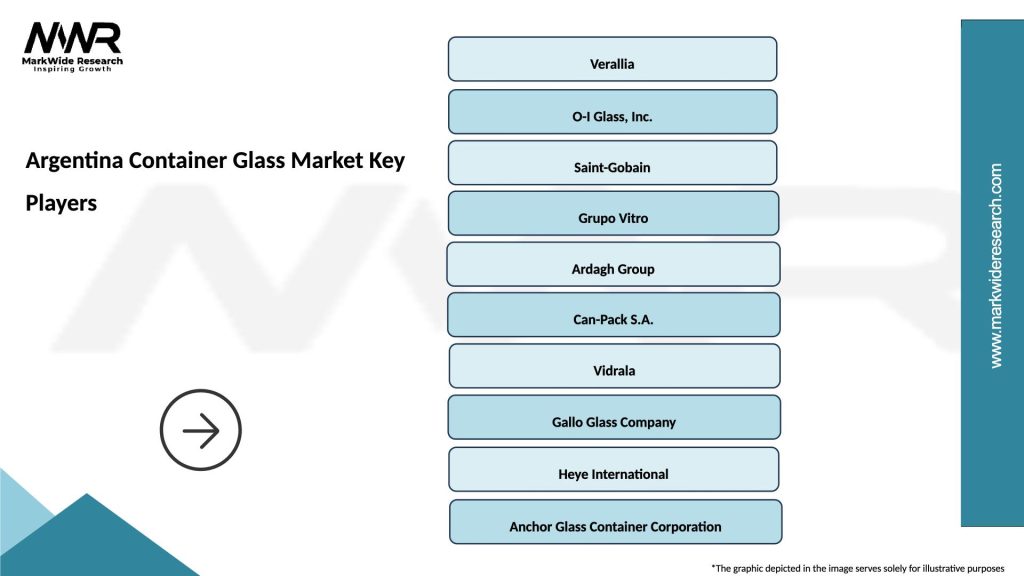

What are the key players in the Argentina Container Glass Market?

Key players in the Argentina Container Glass Market include Verallia, Owens-Illinois, and Saint-Gobain, which are known for their extensive production capabilities and innovative packaging solutions, among others.

What are the growth factors driving the Argentina Container Glass Market?

The Argentina Container Glass Market is driven by increasing consumer demand for sustainable packaging solutions, the growth of the beverage industry, and a rising preference for glass over plastic due to health and environmental concerns.

What challenges does the Argentina Container Glass Market face?

Challenges in the Argentina Container Glass Market include high production costs, competition from alternative packaging materials, and the need for significant energy consumption during manufacturing processes.

What opportunities exist in the Argentina Container Glass Market?

Opportunities in the Argentina Container Glass Market include the expansion of the e-commerce sector, which increases demand for safe and durable packaging, and innovations in glass recycling technologies that enhance sustainability.

What trends are shaping the Argentina Container Glass Market?

Trends in the Argentina Container Glass Market include a shift towards lightweight glass packaging, the introduction of smart packaging solutions, and an increasing focus on eco-friendly production practices.

Argentina Container Glass Market

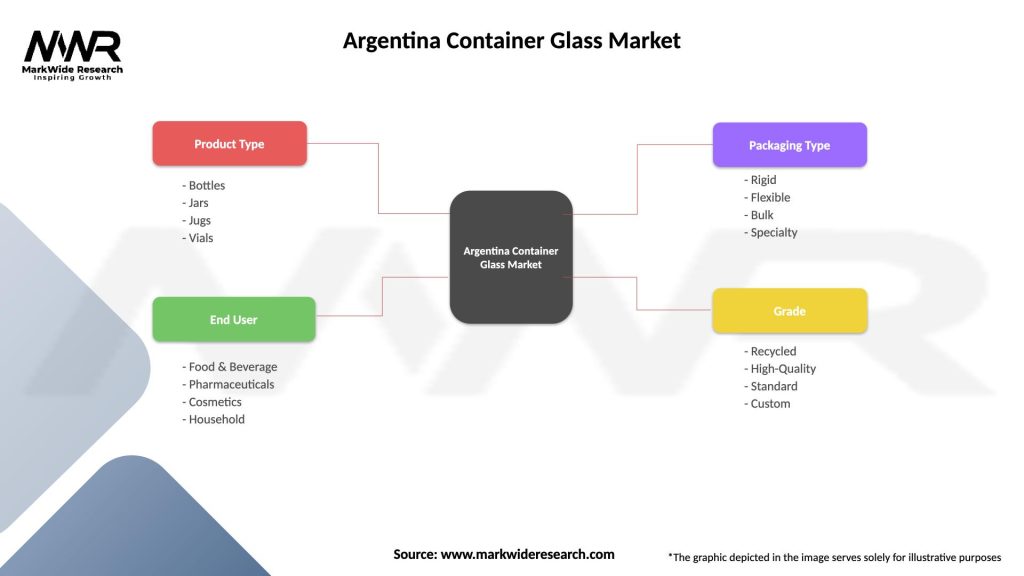

| Segmentation Details | Description |

|---|---|

| Product Type | Bottles, Jars, Jugs, Vials |

| End User | Food & Beverage, Pharmaceuticals, Cosmetics, Household |

| Packaging Type | Rigid, Flexible, Bulk, Specialty |

| Grade | Recycled, High-Quality, Standard, Custom |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Argentina Container Glass Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at